Internal circulation boiling pot

A boiling pot and internal circulation technology, applied in the direction of beer brewing, etc., can solve the problems of wort overheating, large steam consumption, long heating time, etc., achieve the effect of strengthening thermosiphon, reducing steam consumption, and reducing boiling intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

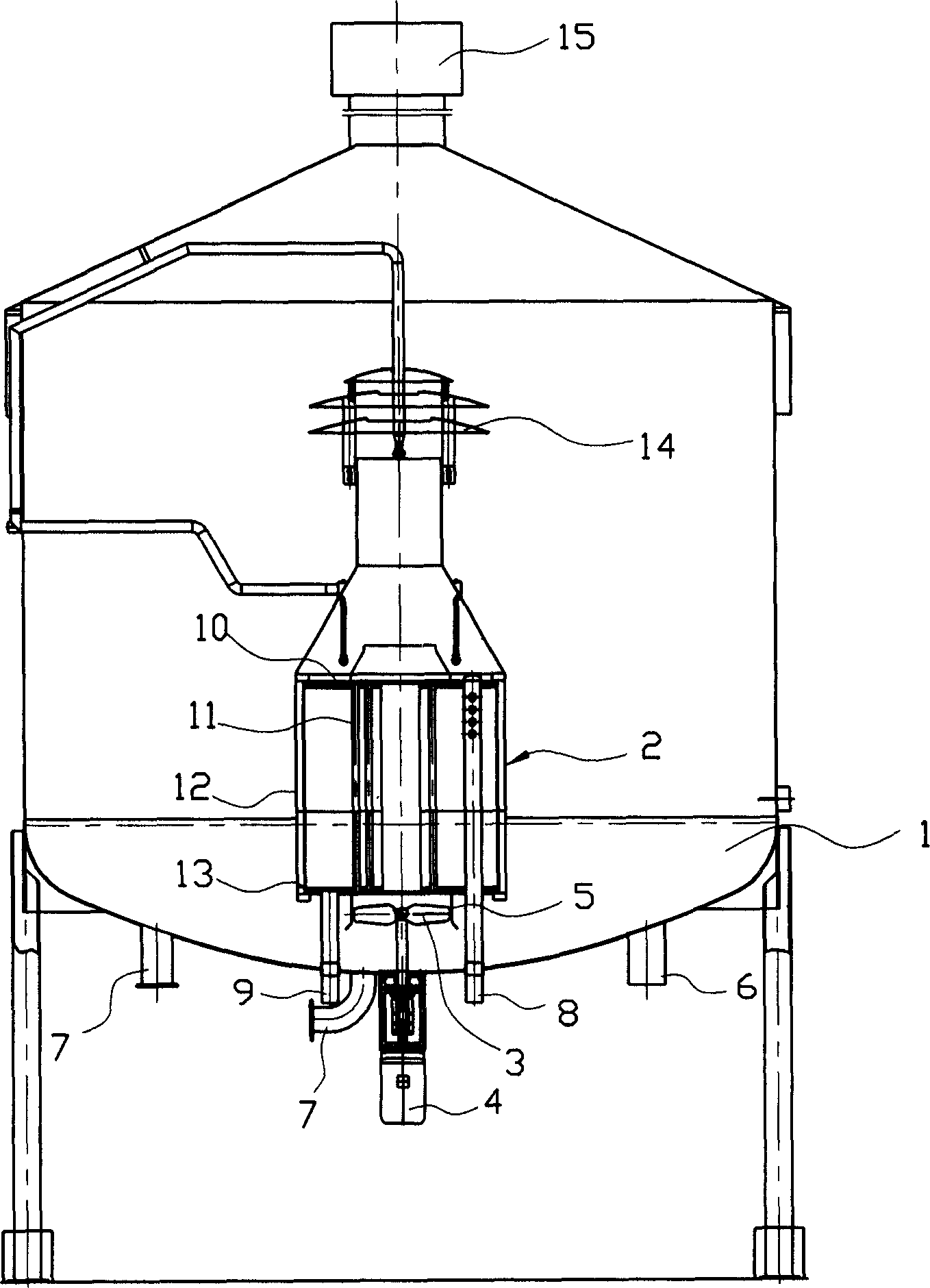

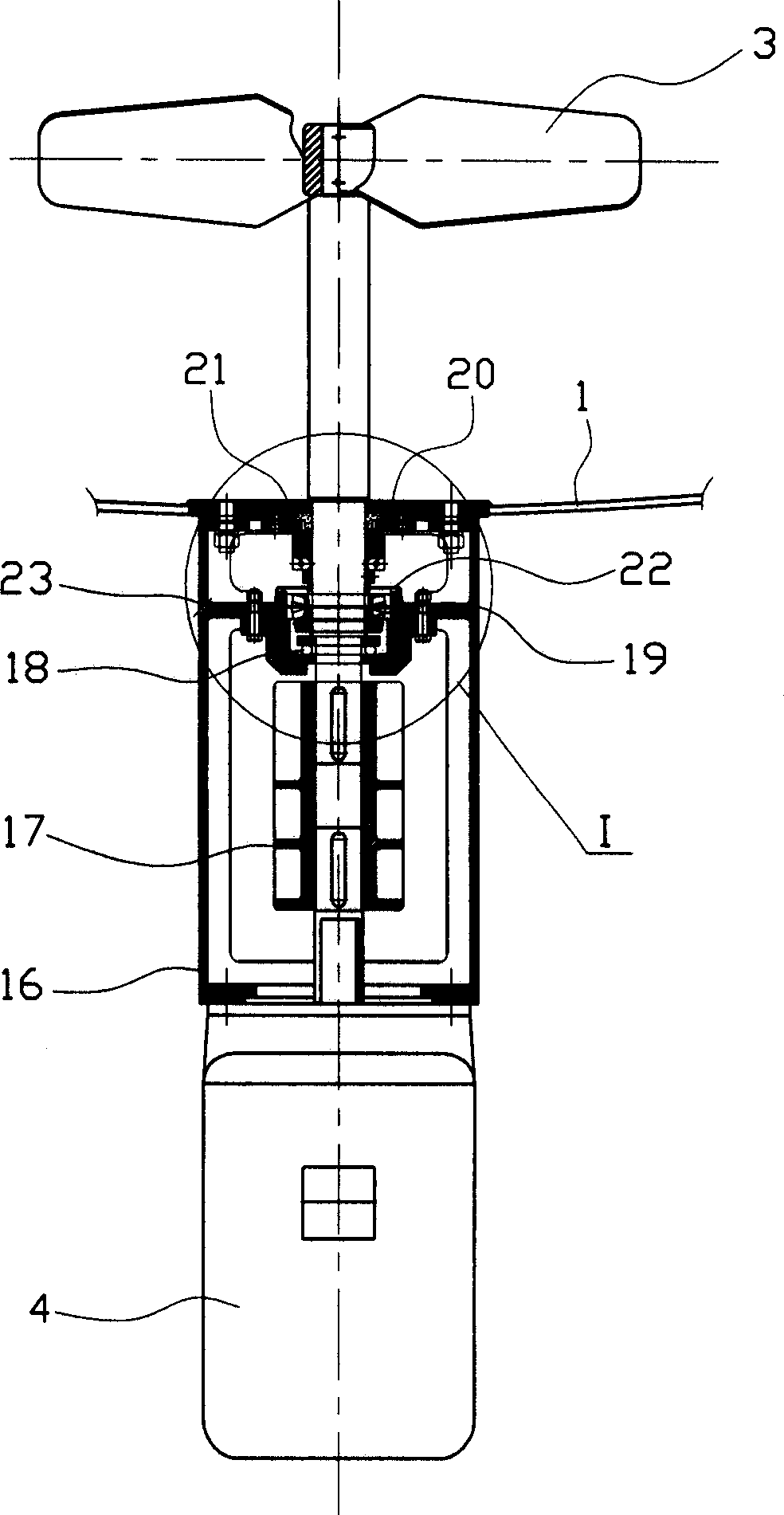

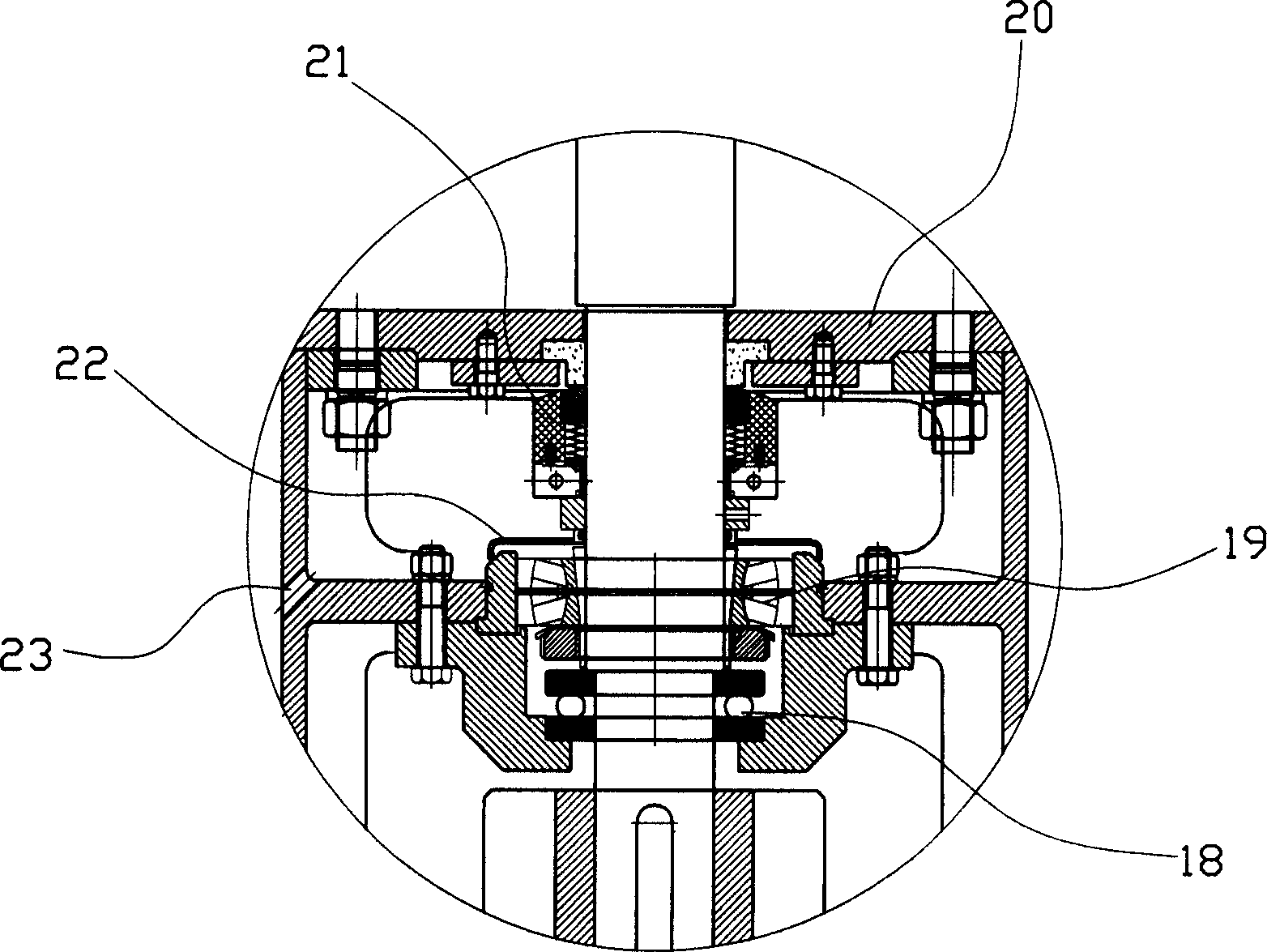

[0015] Such as figure 1 As shown, the boiling pot includes a pot body 1, a shell-and-tube heat exchanger 2 placed in the pot body, a distribution cover 14 and a spiral impeller 3, wherein the bottom of the pot body is provided with a wort inlet 6 and a wort outlet 7, The top of the pot body is provided with an exhaust pipe 15 . The shell-and-tube heat exchanger 2 further includes a shell 12 with a steam inlet 8 and a condensed water outlet 9 and a plurality of heat exchange tubes 11 located in the shell. The steam inlet and condensed water outlet extend out of the pot body through the pipes. In addition, each heat exchange tube 11 is supported between the upper tube sheet 10 and the lower tube sheet 13 of the casing, and both ends are fixedly connected to the upper and lower tube sheets of the casing to receive wort. And distribution cover 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com