Flash evaporation system for wheat juice

A flash evaporation and wort technology, applied in the field of evaporation system, can solve the problems of insufficient time for the cracking of dimethyl sulfide precursor, insufficient separation of free dimethyl sulfide, and the decrease of solidifiable nitrogen content, etc., to achieve Reduce the original heat energy consumption, be beneficial to environmental protection, and shorten the effect of boiling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

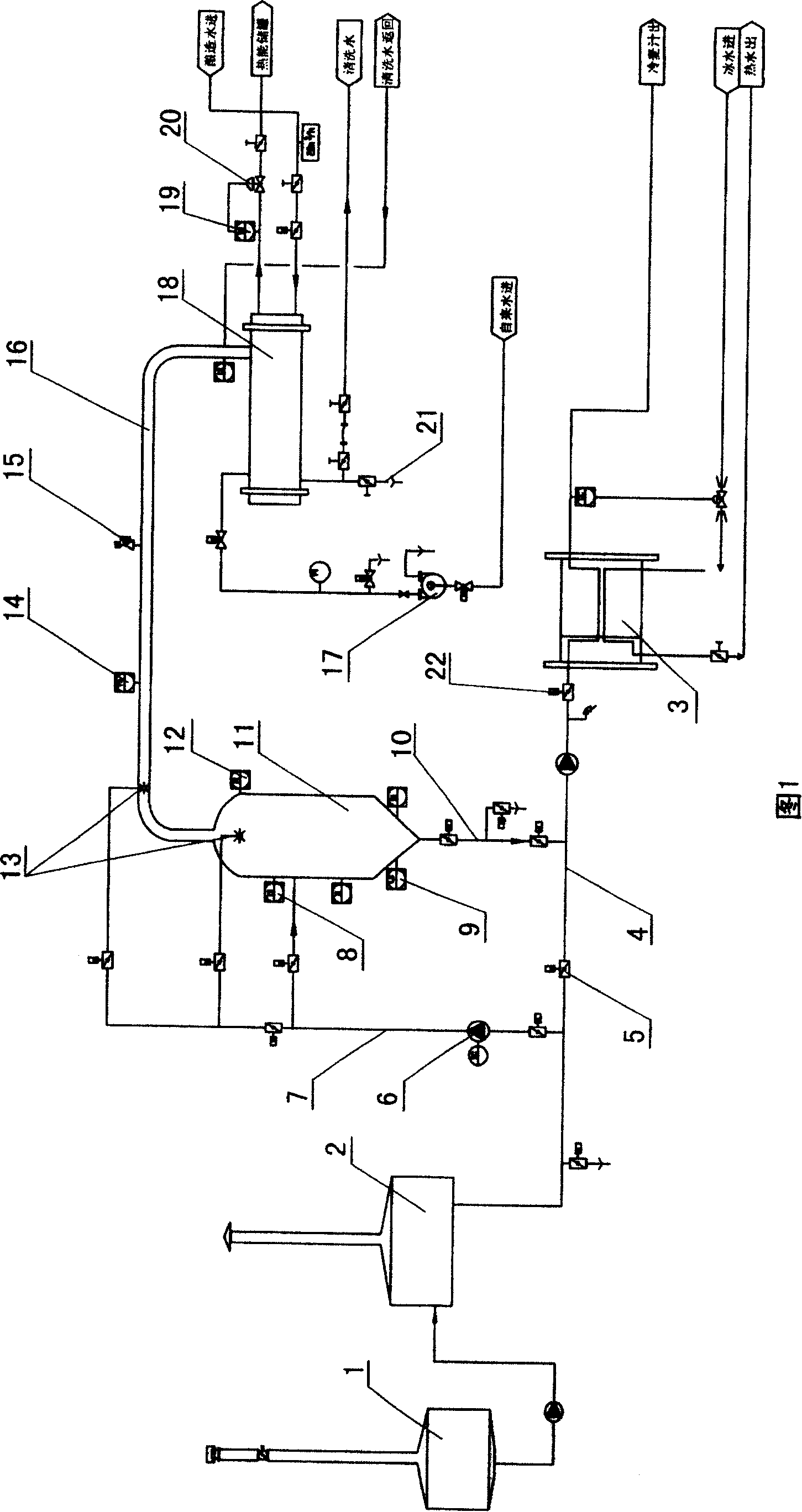

[0010] As shown in Figure 1, the wort flash evaporation system includes a boiling pot 1, a whirling sedimentation tank 2, a flash chamber 11 and a cooler 3, wherein the bottom of the flash chamber 11 is provided with a discharge port, and its upper part is respectively provided with There is a feed port and an exhaust port. When installing and connecting, the discharge port of boiling pot 1 is connected with the feed port of above-mentioned whirlpool sedimentation tank 2 through pipeline, and the discharge port of whirlpool sedimentation tank 2 is connected with the feed inlet of above-mentioned flash chamber 11 through feed pipe 7. The discharge port of the flash chamber is connected to the liquid material inlet of the cooler 3 through the discharge pipe 10, and the exhaust port of the flash chamber is connected to the vacuum pump 17 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com