Induction electric kettle

An electric kettle and induction technology, applied in the field of induction electric kettle, can solve the problems of no water level control system, water overflowing into the kettle, unbalanced heating, etc., so as to shorten the boiling time, reduce the cooling time, and shorten the heating time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

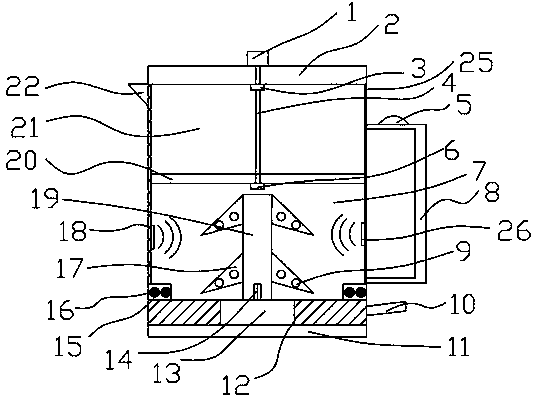

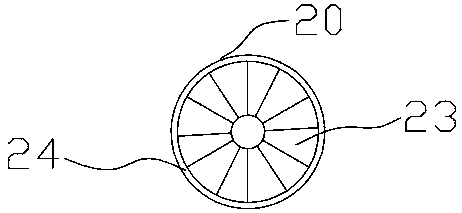

[0021] Such as Figure 1-4 As shown, the induction electric kettle includes a casing 25, the upper end of the casing 25 is provided with a cover 2, the cover 2 is movably connected to the motor 1, the output end of the motor 1 is connected to the rotating shaft 4, and the lower end of the rotating shaft 4 is located in the partition 20, and the partition 20 The shell 25 is divided into an upper chamber 21 and a lower chamber 7, and insulation cotton 18 is provided between the upper and lower chambers and the shell 25, a heating rod 19 is provided in the lower chamber 7, and a base 11 is provided at the bottom of the shell 25. The partition divides the electric kettle into upper and lower chambers to separate the water in the kettle. At the same time, the heat exchange rate of the hot water is used to heat the hot water. The insulation cotton can improve the thermal insulation of the whole kettle and reduce the The device is simple in structure, easy to operate, short in heatin...

Embodiment 2

[0030] Such as Figure 1-4 As shown, the working principle of the induction electric kettle is as follows: first fill half of the water into the lower chamber 7 and separate it with a partition 20, then add water to the upper chamber 21, cover the top cover 2 after filling, and turn on the heating switch 10. The heating rod 19 starts to generate heat to heat the water in the lower chamber 7. After the water in the lower chamber 7 boils, the second sensor 6 sends a signal to the motor 1, and the motor 1 drives the rotating shaft 4 to rotate, and the partition 20 is opened. The upper movable partition 23, the water in the upper chamber 21 is mixed with the water in the lower chamber 7, and the water is heated by the heat exchange rate of the hot water until the whole pot of water is boiled. After boiling, the heating switch 10 jumps off and stops heating.

[0031] The conventional technologies in the above embodiments are known to those skilled in the art, so they will not be d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com