Radiator of energy-saving and high-efficiency electric wall-mounted furnace and production process thereof

A production process and radiator technology, applied in the field of radiators and their production processes, can solve the problems of inability to reduce energy consumption, high temperature burning of relays, short service life, etc., so as to reduce the time for boiling water, prolong the service life, reduce The effect of electricity consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment, the present invention is described in further detail:

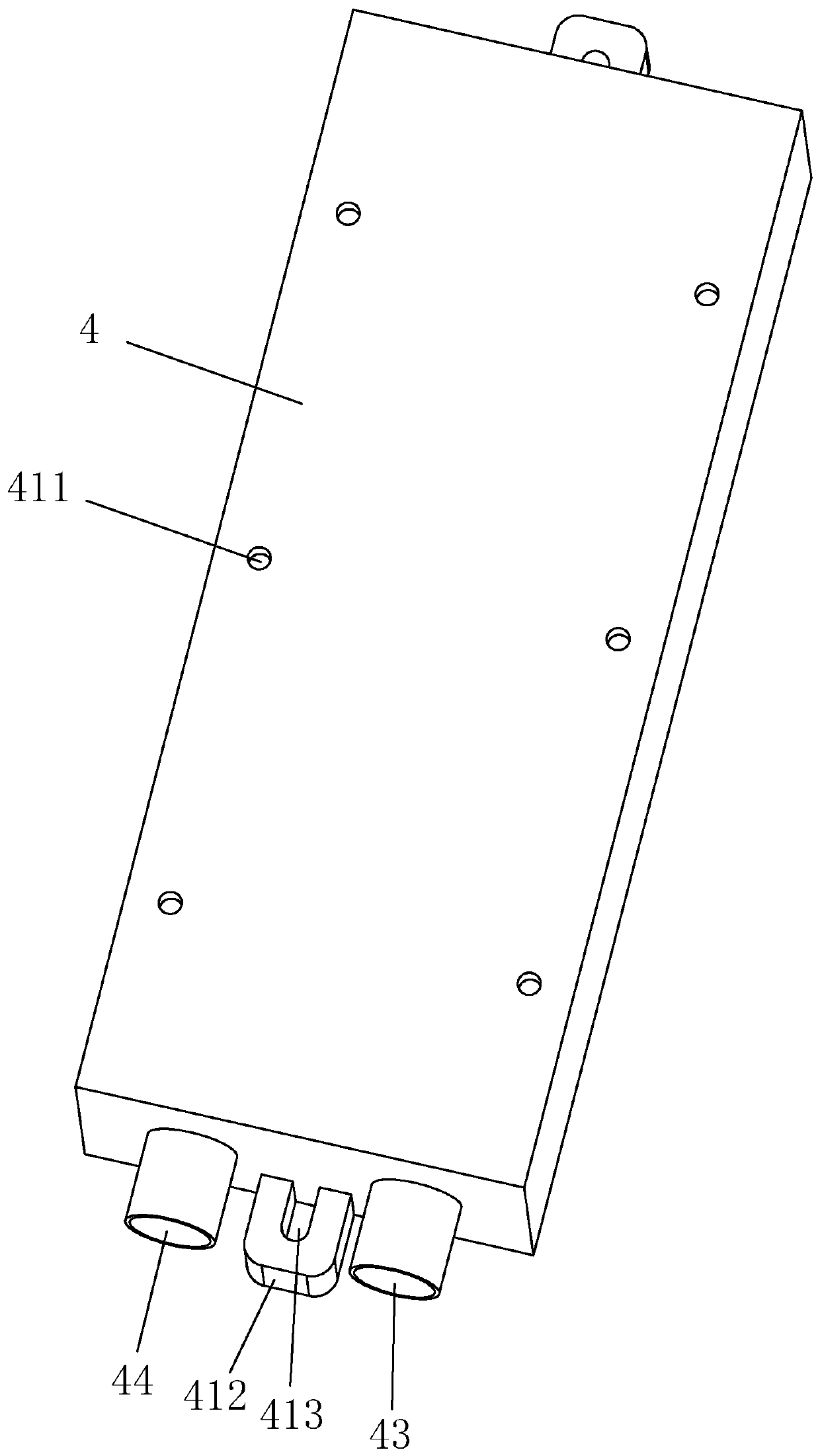

[0026] as attached figure 1 As shown, a radiator of an energy-saving and high-efficiency electric wall-hung boiler, the radiator 4 includes a metal body 41 for fixedly installing the relay 3 and a water pipe 42 arranged in the metal body 41, the metal body 41 is made of aluminum, Water pipe 42 adopts stainless steel water pipe. The metal body 41 is coated on the water pipe 42 to facilitate temperature transfer; one end of the water pipe 42 extends out of the metal body 41 to form the second water inlet 43 of the radiator 4, and the other end extends out of the metal body 41. The second water outlet 44 of the radiator 4 is formed outside the metal body 41 .

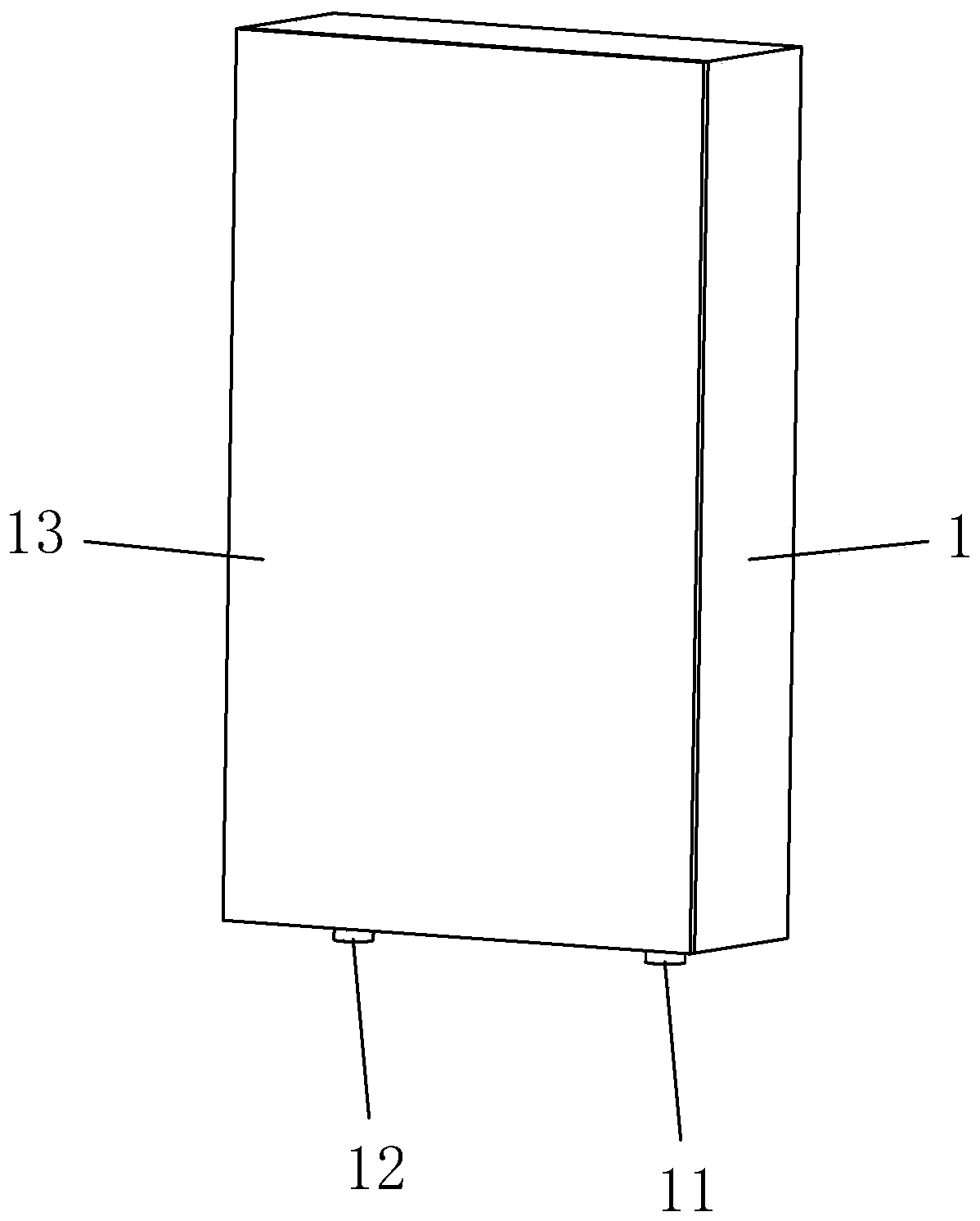

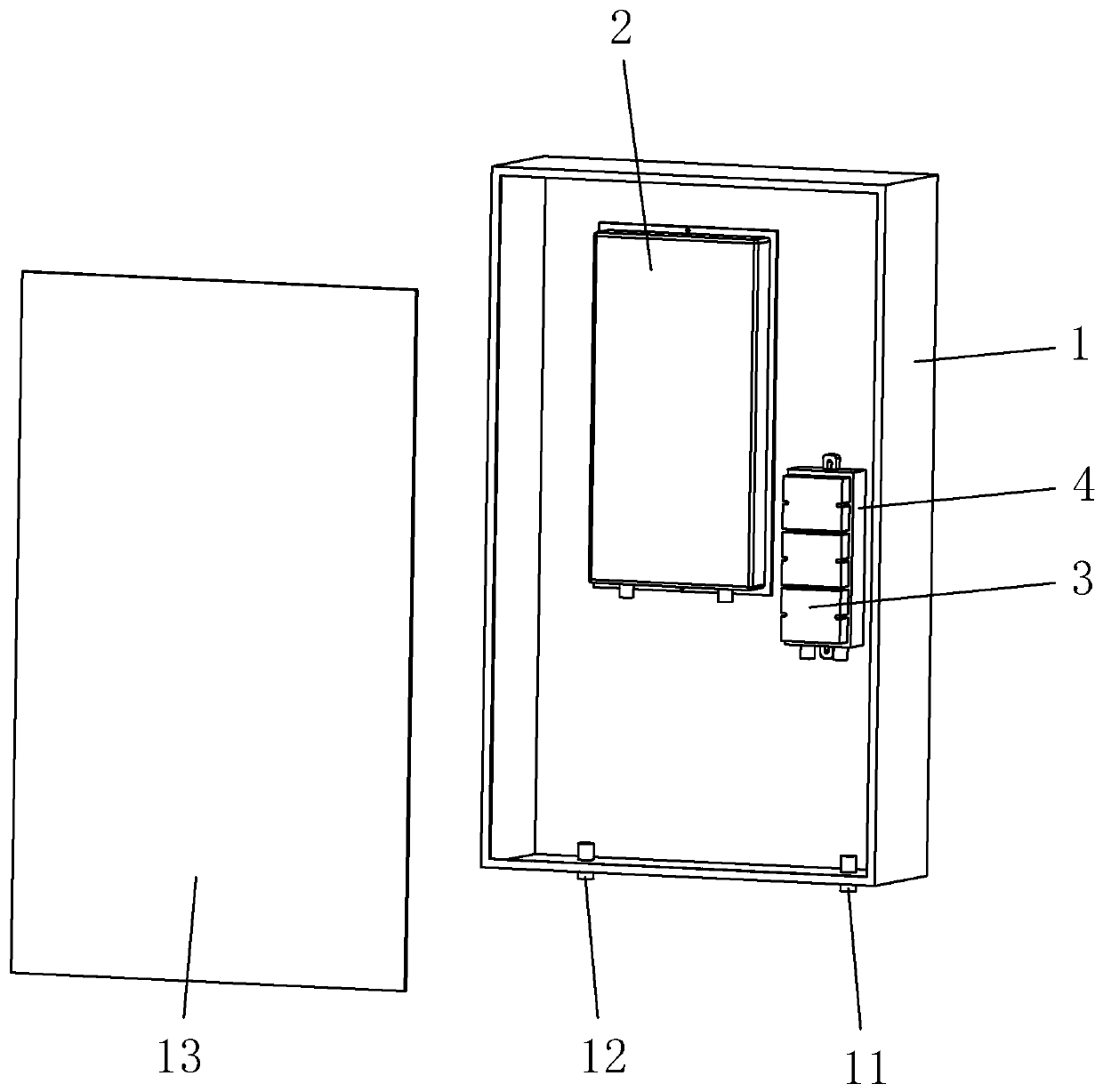

[0027] as attached Figure 2-4 As shown, the radiator can be used in the relay heat dissipation mounting seat of the electric wall-hung boiler in the prior art. The energy-saving and hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com