Method for preparing bismuth oxide-based electrolyte material Bi<1-x>A<x>O<1.5-delta> by utilizing microwave combustion-supporting method

A bi1-xaxo1.5-, electrolyte material technology is applied in the field of preparation of bismuth oxide-based electrolyte materials, which can solve the problems of difficulty in ensuring the uniformity of powder components, difficulty in mixing raw materials uniformly, and long production cycle, and avoid high-temperature calcination. Process, heating speed, energy-saving and high-efficiency effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

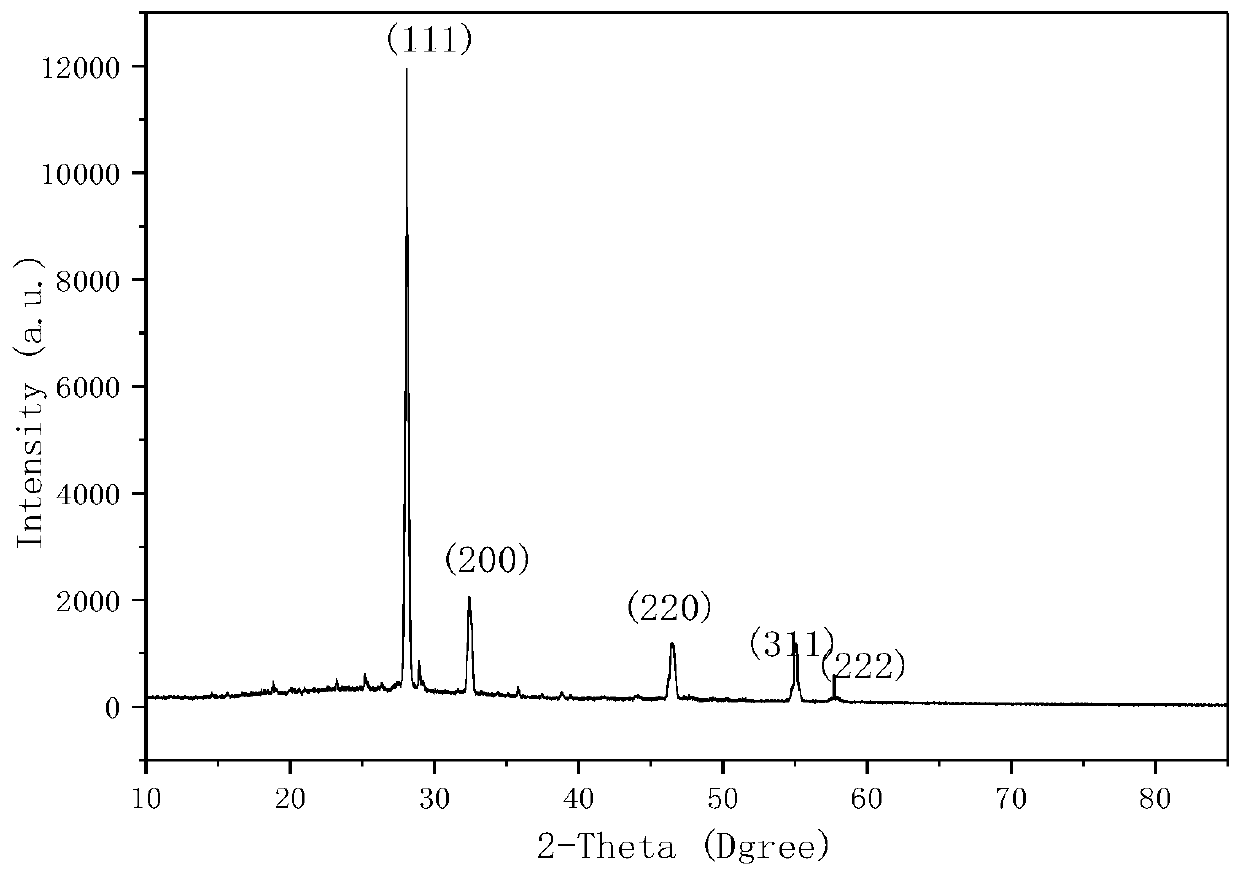

[0026] According to Bi 0.8 T m 0.2 o 1.5 Stoichiometric ratio weighs 8.62g of bismuth nitrate Bi(NO 3 ) 3 ·5H 2 O, 2.06g of thulium nitrate Tm (NO 3 ) 3 ·5H 2 O, dissolved in 25mL of deionized water, stirred into a mixed solution and added 6.43g of citric acid C 6 h 8 o 7 , heated and stirred at 80°C to form a sol with a mass concentration of 20%; the sol was sprayed by a sprayer to form a nanoscale precursor; the precursor was heated and burned in a microwave oven to obtain Bi 0.8 T m 0.2 o 1.5 Nano powder. The obtained powder is dry-pressed, and the formed disc is sintered into porcelain at 800° C. for 10 hours. Bi 0.8 T m 0.2 o 1.5 The conductivity at 800°C is 0.131 S / cm.

[0027] figure 1 It is the XRD spectrum of the product obtained in Example 1 and the corresponding diffraction characteristic peaks, it can be seen that all have generated pure phase Bi 0.8 T m 0.2 o 1.5 . figure 2 It is the FE-SEM picture of the product obtained in Example 1. It ca...

Embodiment 2

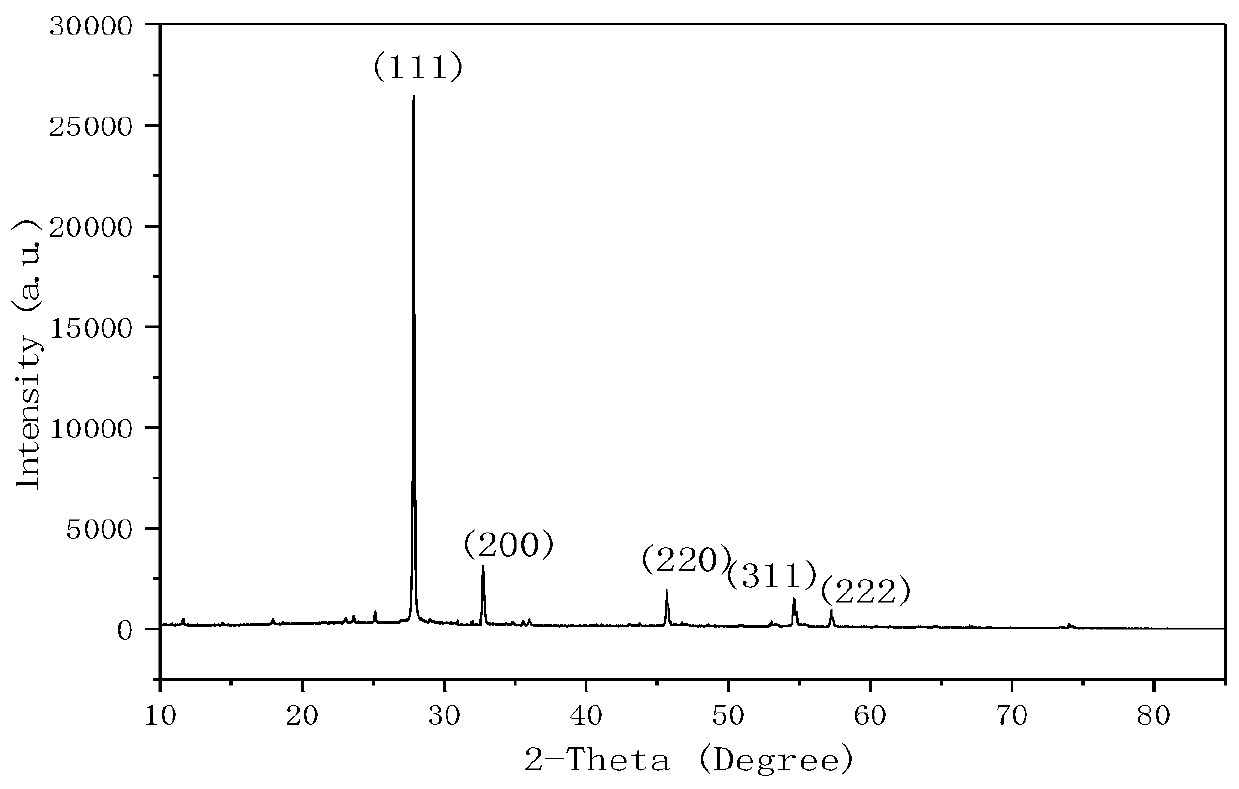

[0029] According to Bi 0.75 Y 0.25 o 1.5 Stoichiometric ratio weighs 8.96g of bismuth nitrate Bi(NO 3 ) 3 ·5H 2 O, 2.36g of yttrium nitrate Y (NO 3 ) 3 ·6H 2 O, dissolved in 10mL of deionized water, stirred into a mixed solution and added 3.7g of glycine C 2 h 5 NO 2 , heated and stirred at 75°C to form a sol with a mass concentration of 30%; the sol was sprayed by a sprayer to form a nanoscale precursor; the precursor was heated and burned in a microwave oven to obtain Bi 0.75 Y 0.25 o 1.5 Nano powder. The obtained powder is dry-pressed and molded, and the molded disc is then kept at 900° C. for 8 hours and sintered into porcelain. Bi 0.75 Y 0.25 o 1.5 The conductivity at 800°C is 0.083 S / cm.

[0030] image 3 It is the XRD spectrum of the product obtained in Example 2 and the corresponding diffraction characteristic peaks, it can be seen that all have generated pure phase Bi 0.75 Y 0.25 o 1.5 . Figure 4 It is the FE-SEM picture of the product obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com