Continuous secondary sterilization machine

A secondary sterilization and sterilization device technology, applied in food science, sanitary equipment for toilets, food preservation, etc., can solve the problems of unfavorable maintenance of physical indicators of the object to be sterilized, re-pollution, steam leakage, etc., and achieve the removal of a large number of artificial Effects of heavy work, product quality assurance, and negative impact reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

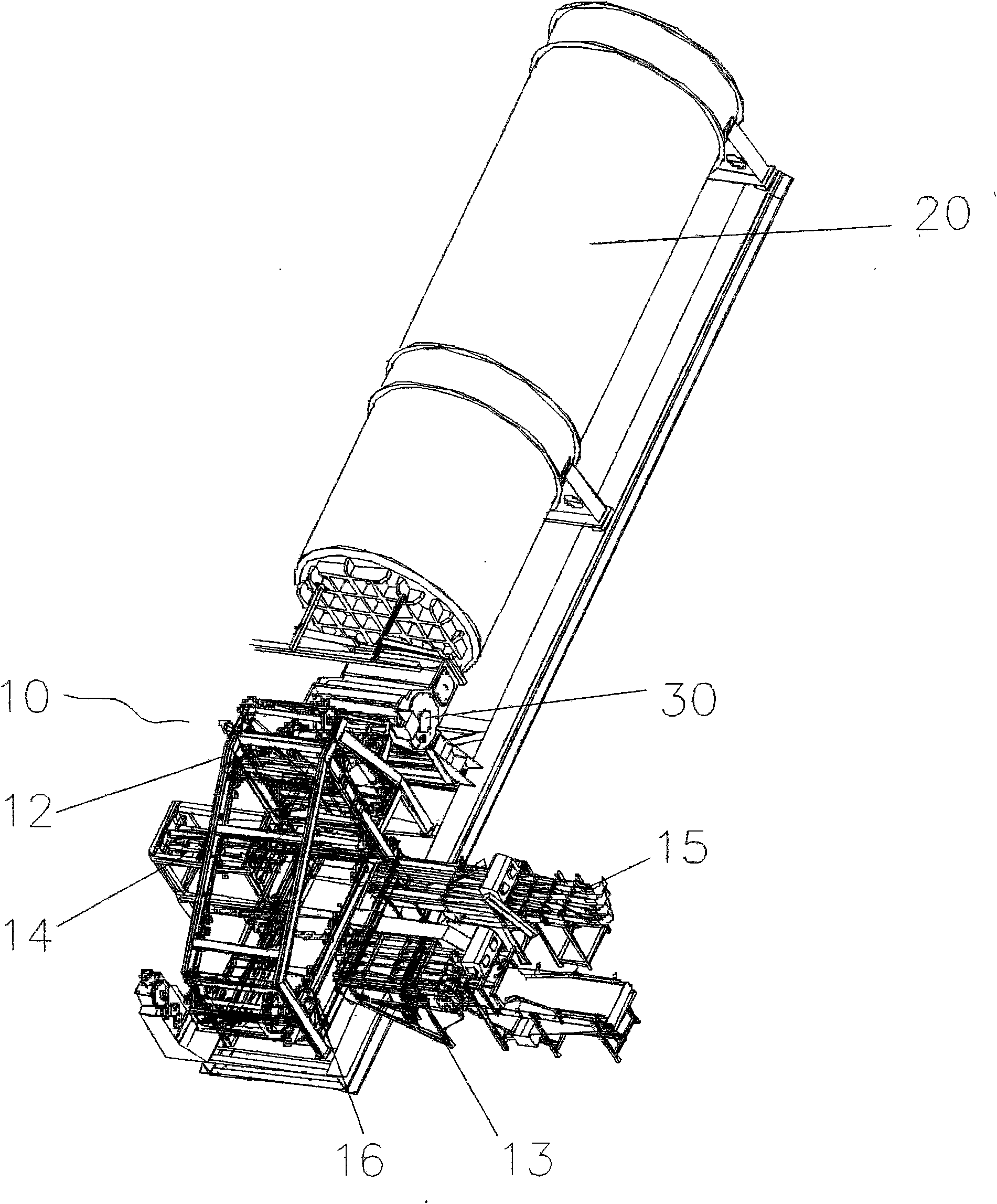

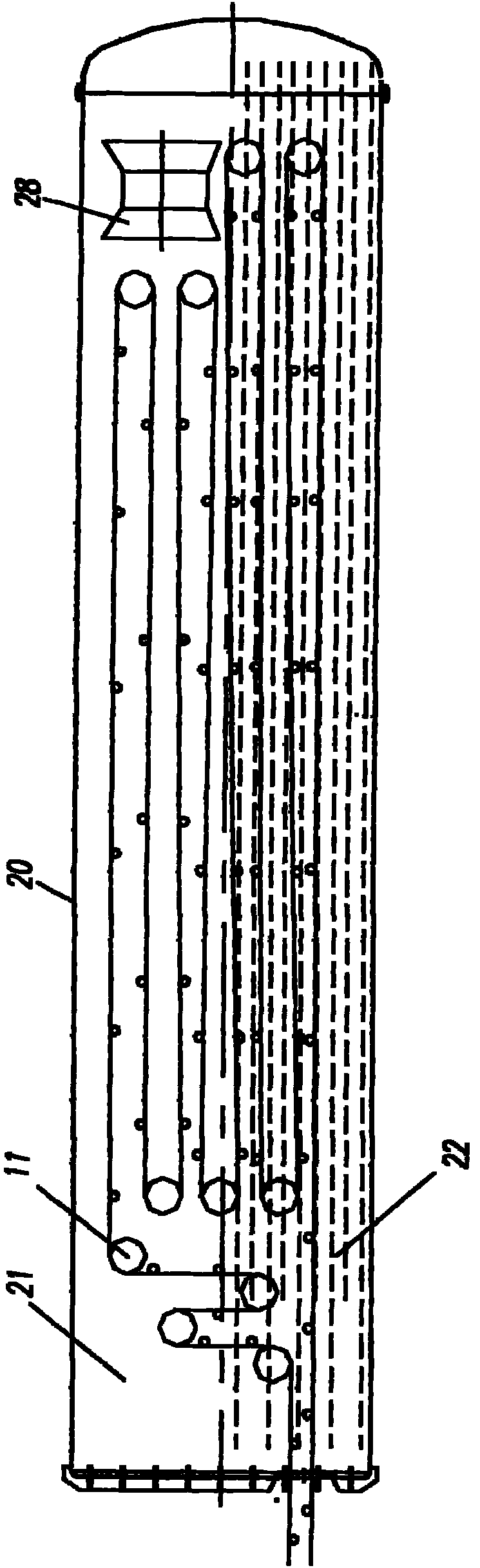

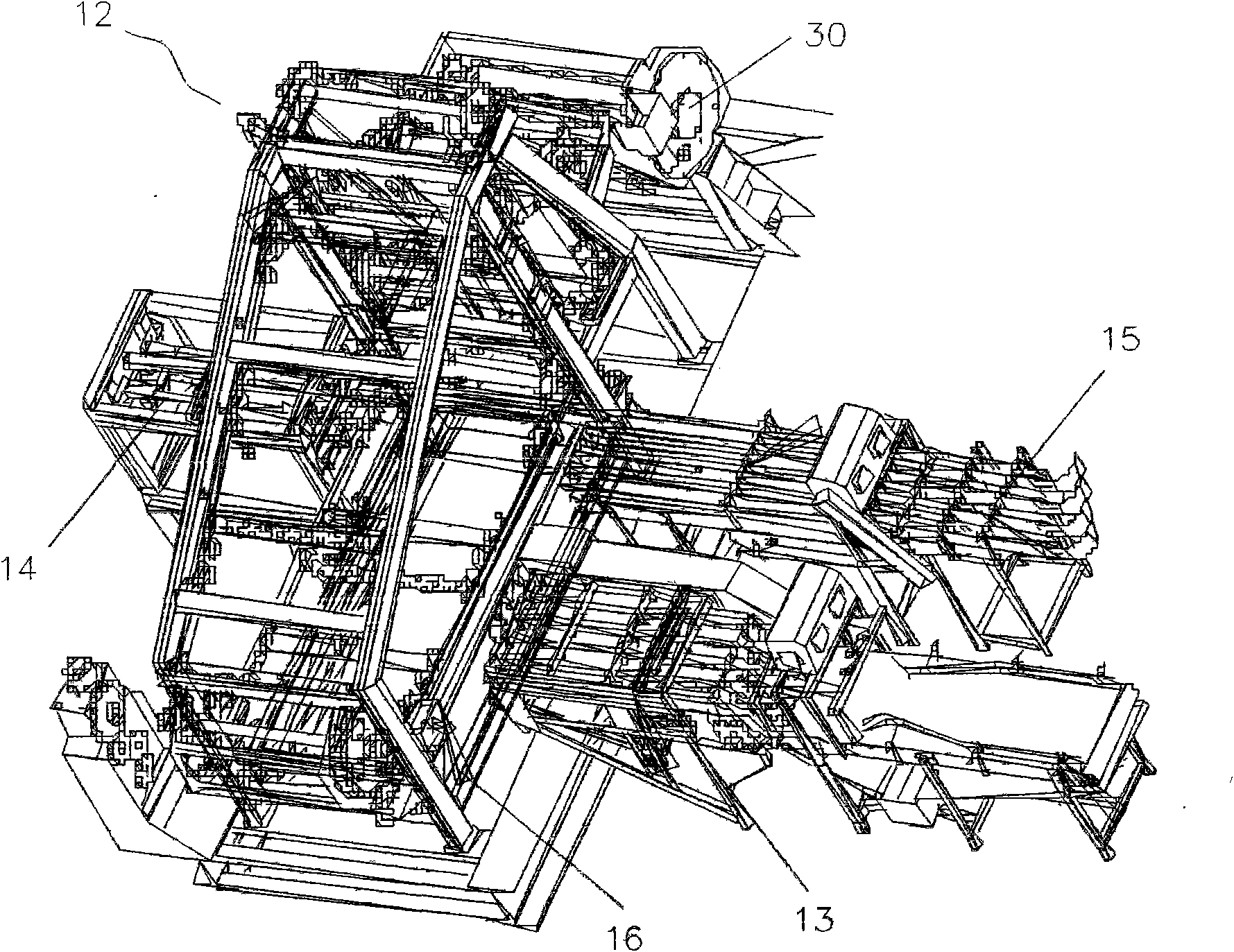

[0027] Such as figure 1 , figure 2 , image 3 As shown, a specific embodiment of the continuous secondary sterilizing machine of the present invention mainly includes a conveying device 10 and a sterilizing device 20 for transporting objects to be sterilized.

[0028] The conveying device 10 is used for arranging and arranging the objects to be sterilized transferred from the previous working step into a combination according to the production capacity requirement of the sterilizing device 20 and then conveying them into the sterilizing device 20 .

[0029] In the conveying device 10 , the part located inside the sterilizing device 20 and performing continuous conveying is the inner conveying mechanism 11 . The part located outside the sterilizing device 20 and carrying out gap-stop conveying is the outer conveying mechanism 12 . The inner conveying mechanism 11 and the outer conveying mechanism 12 are respectively driven by two sets of main drives for continuous conveying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com