Nitriding method and device

A technology of nitriding treatment and temperature detection device, which is used in ion implantation plating, coating, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

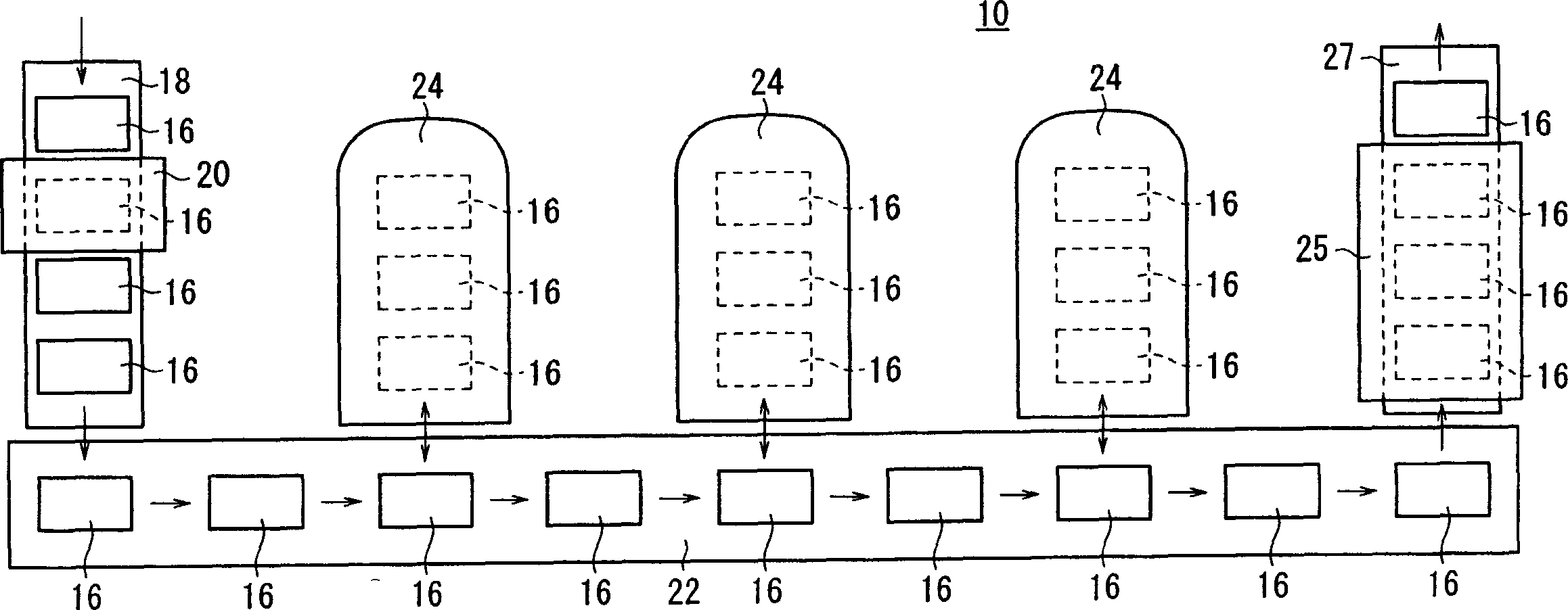

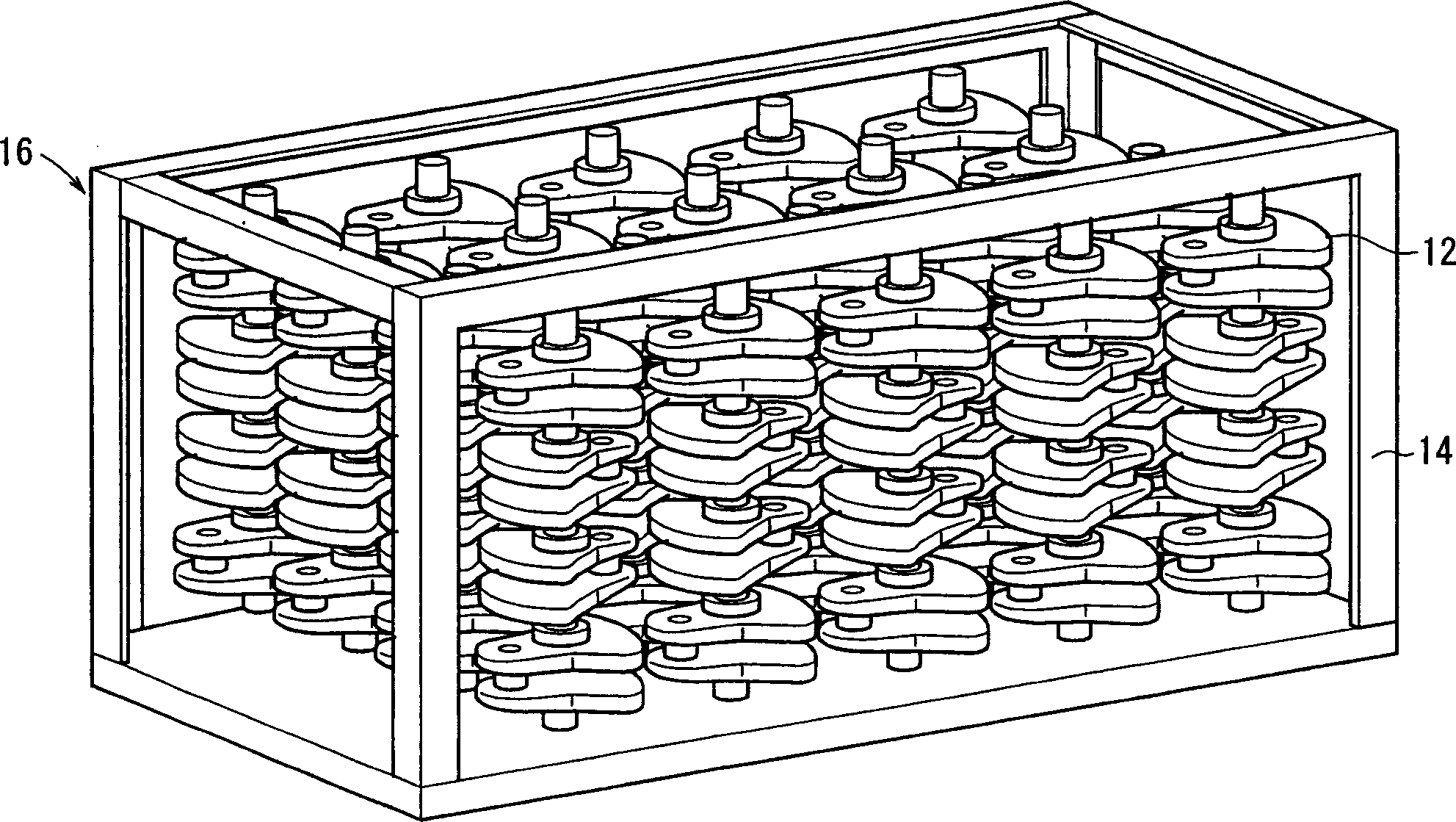

[0022] figure 1 A schematic arrangement of a nitriding treatment system 10 including a nitriding treatment device according to an embodiment of the present invention is shown. Such as figure 2 As shown, a plurality of crankshafts 12 as workpieces are fed to the nitriding treatment system 10 in the form of a hopper 16 in which the plurality of crankshafts 12 are positioned with a clamp 14 .

[0023] The nitriding treatment system 10 includes a washing machine 20 which, for example, removes dust and oil adhering to the crankshaft 12 conveyed by a conveyor 18 from which the washed crankshaft 12 is received to clean them. Conveyor 22 that transfers to each workbench, transverse type heat treatment furnace 24 that is installed on a plurality of workbenches along conveyor 22, and cooling box 25 that cools through the connection Crankshaft 12 conveyed by conveyor 27 to the terminal end of conveyor 22 .

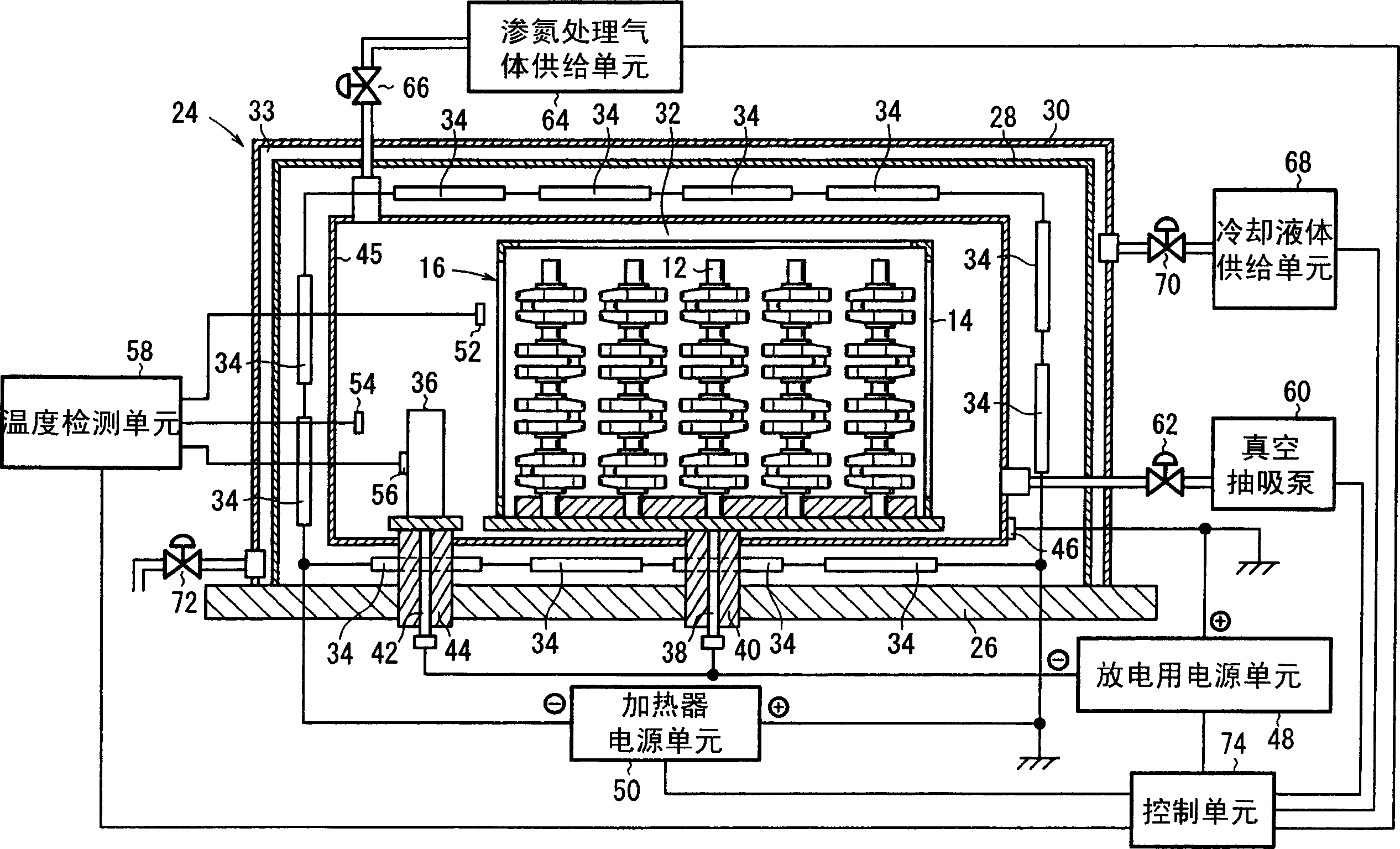

[0024] FIG. 13 shows the arrangement of the transverse type heat treatment f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com