Processing technology for improved drill stems

A processing technology and an improved technology, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of easy deformation and cracking, limited diameter of drill pipe, insufficient strength, etc., to control the heating time and the increase of impurities, Upsetting head quality assurance, effect of jacking force increase

Inactive Publication Date: 2014-10-01

CHENGDU GAOPU PETROLEUM ENG TECH

View PDF4 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although the traditional drill pipe processing technology is simple, the quality is difficult to guarantee

Coal-fired heating was used in the past, and the cost was low, but the heating time was difficult to control, and the heating temperature could not be controlled, and the impurities increased during the heating process, which most directly affected the post-upsetting treatment of the drill pipe, especially the increase of impurities. It is prone to deformation and cracking during the heading process

In order to ensure sufficient strength at the threads processed at both ends of the drill pipe, thickening methods are often used in production to increase the size of the cross-section. Originally, a self-made three-roller pipe heading machine was used to thicken the head of the drill bit because the strength was not enough. , the quality of the heading head cannot be controlled, sometimes there will be uneven wall thickness and eccentricity, and the diameter of the drill pipe is greatly restricted, and the diameter of the drill pipe is greatly restricted

And the alloy knife was used to turn the thread on the lathe, the pitch error exceeded plus or minus 0.1, and the surface finish could not meet the requirements

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

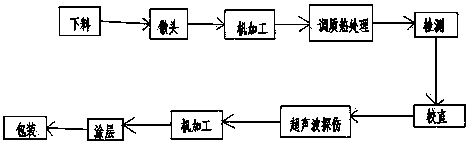

[0026] like figure 1 Shown, the present invention comprises the steps:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a processing technology for improved drill stems. The processing technology comprises the following steps of: cutting out tubes which are identical in length from a seamless steel tube; upsetting heads, including thickening upsetting heads at two ends of the tubes produced in the step A; machining, including rough machining the two ends of the tubes; quenching and tempering; detecting, including performing mechanical property detection on the drill stem which has been subjected to quenching and tempering; straightening; detecting flaws ultrasonically; secondary machining, including cutting an external thread and an internal thread respectively at two ends of the drill stem by a petroleum pipeline threading tool, and measuring taper, thread pitches, screw tightness and thread angles of the threads by a petroleum pipeline measuring instrument; coating; packaging. By adopting the processing technology, the cut threads are small in thread pitch and the surfaces of the threads meets requirements on smooth finish; the processing technology can effectively control heating time and increase of impurities, increases applicability and greatly improves productivity..

Description

technical field [0001] The invention relates to the field of petroleum mechanical equipment processing, in particular to the processing technology of an improved drill pipe. Background technique [0002] Drill pipe is one of the most important materials in drilling equipment, and the quality of drill pipe directly depends on the processing technology of drill pipe. Although the traditional drill pipe processing technology is simple, it is difficult to guarantee the quality. Coal-fired heating was used in the past, and the cost was low, but the heating time was difficult to control, and the heating temperature could not be controlled, and the impurities increased during the heating process, which most directly affected the post-upsetting treatment of the drill pipe, especially the increase of impurities. It is prone to deformation and cracking during the heading process. In order to ensure sufficient strength at the threads processed at both ends of the drill pipe, thickeni...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23P15/00E21B17/00

CPCB23P15/00E21B17/00

Inventor 周斌

Owner CHENGDU GAOPU PETROLEUM ENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com