Liquid food machine and method for making liquid food

A liquid food machine and machine head technology, applied in the field of liquid food machines, can solve problems such as difficult cleaning, unstable work, waste of resources, etc., and achieve the effects of controlling heating time, simple and reasonable structure, and complete color and fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

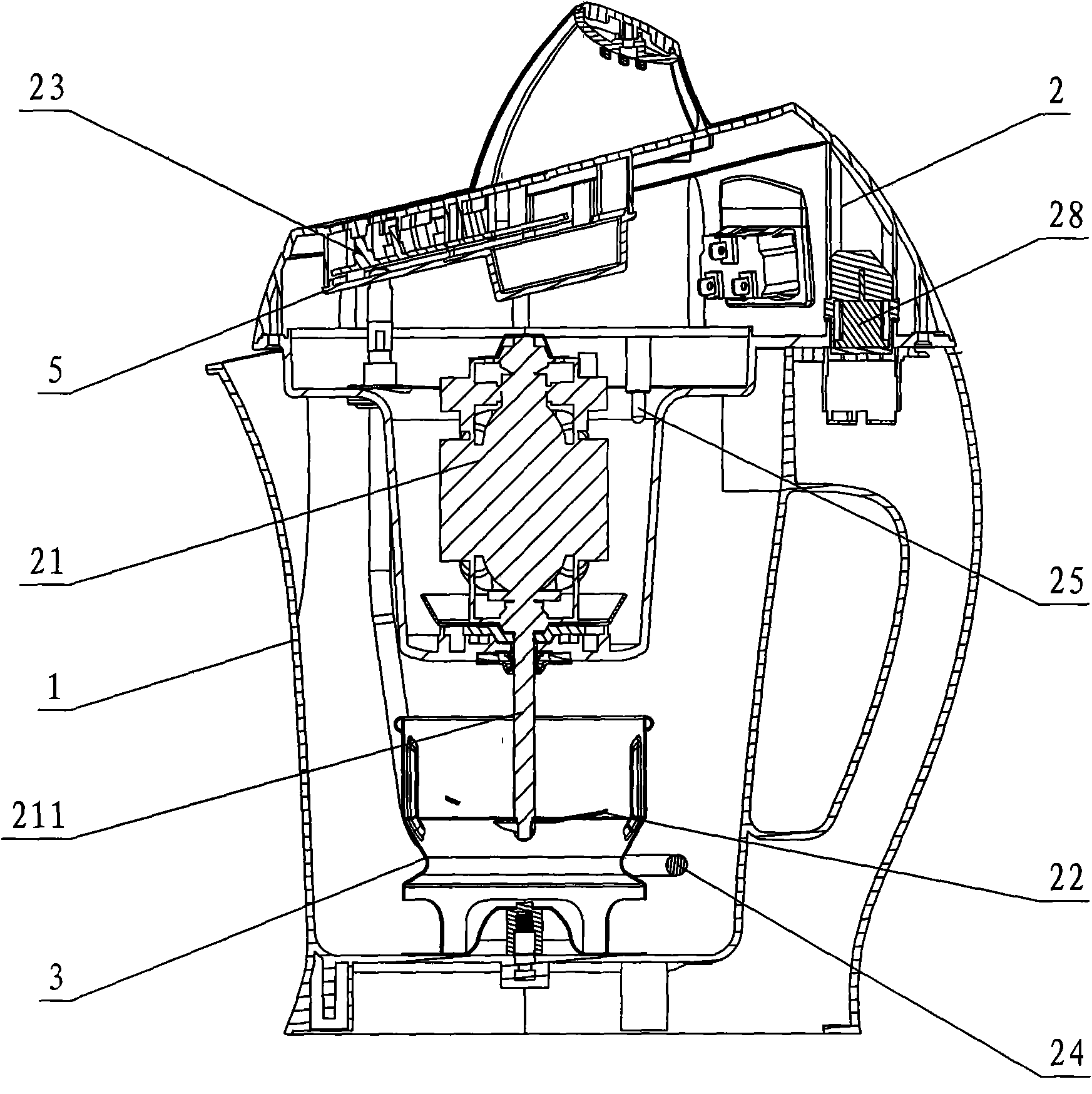

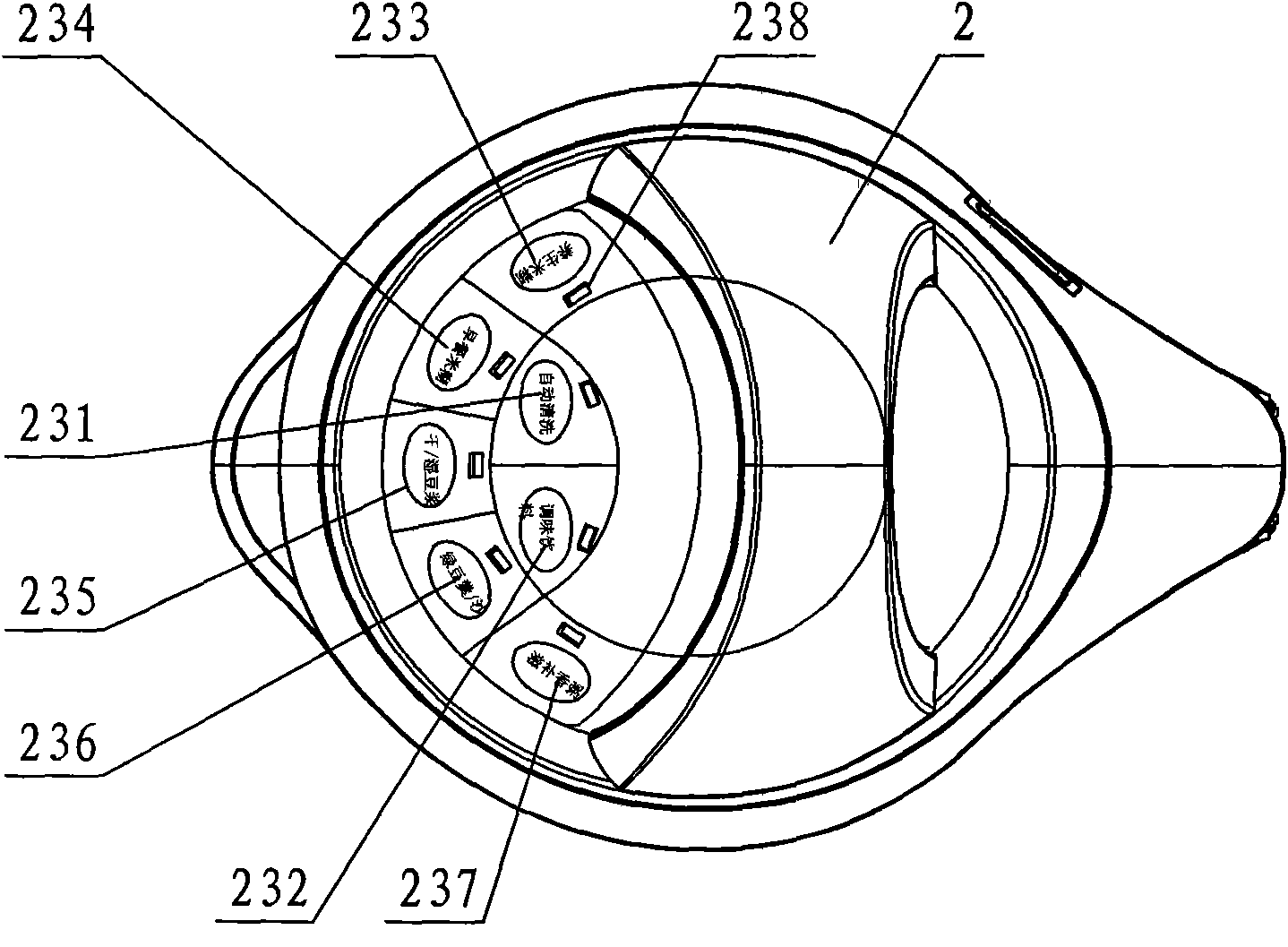

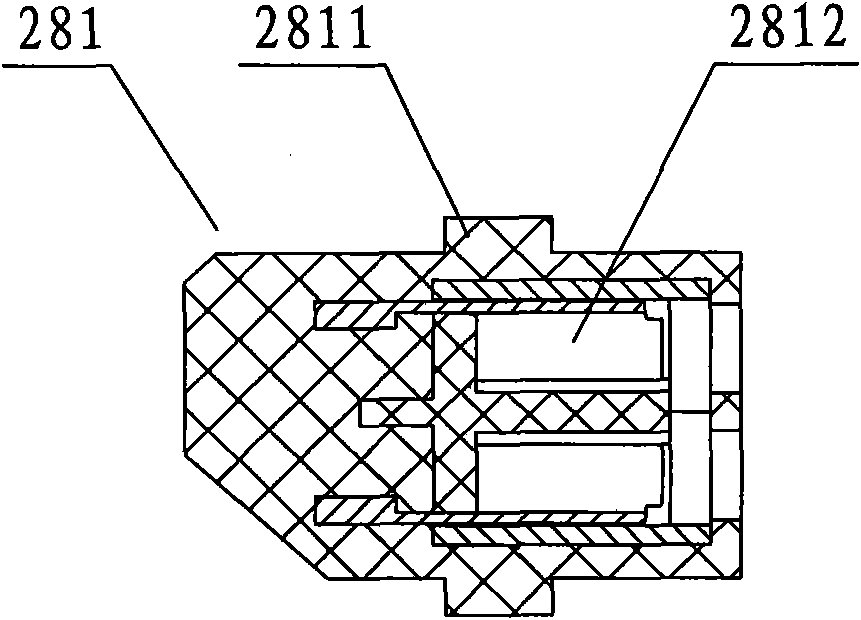

[0034] see Figure 1-Figure 8 , this liquid food machine, comprises the machine head loam cake 2 that is arranged on barrel body 1 top, and machine head loam cake is provided with motor 21, and motor output shaft 211 extends to barrel body, and fixes blade 22 at the end of output shaft; On the machine head The cover is provided with a control switch 23, and the lower end surface is provided with an anti-dry electrode, an anti-overflow electrode 25 and an electric heating tube 24 extending to the bottom of the barrel; the motor, the control switch and the electric heating tube are all connected to the control board 5, and the control board Control, the control board is located in the upper cover of the machine head.

[0035] The control board 5 is provided with a chip 6 with seven control functions including automatic cleaning, making seasoning / beverage, making healthy rice porridge, making breakfast rice porridge, making dry / wet soybean milk, making mung bean soup / sand and mak...

no. 2 example

[0069] see Figure 15 , the whipping cup 13 is cylindrical, connected with the bottom surface of the upper cover 2 of the machine head, the upper cylindrical surface is provided with a discharge window 131, the middle part is provided with a waist, the bottom is open, and the bottom surface of the barrel body 1' corresponds to the center of the whipping cup. The second protrusion 11' is separated from it by a certain distance, and the distance allows the workpiece to be processed to enter. Several vertical damping ribs 132 are also provided on the upper inner wall of the whipping cup 13 . Other unmentioned parts are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com