Automatic transporter with high-temperature water channel for sterilization

A technology of automatic conveying device and water tank, applied in packaging sterilization, conveyor objects, transportation and packaging, etc., can solve the problems of high labor intensity, low production efficiency, harsh production environment, etc., to reduce labor intensity and improve product quality. and yield, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

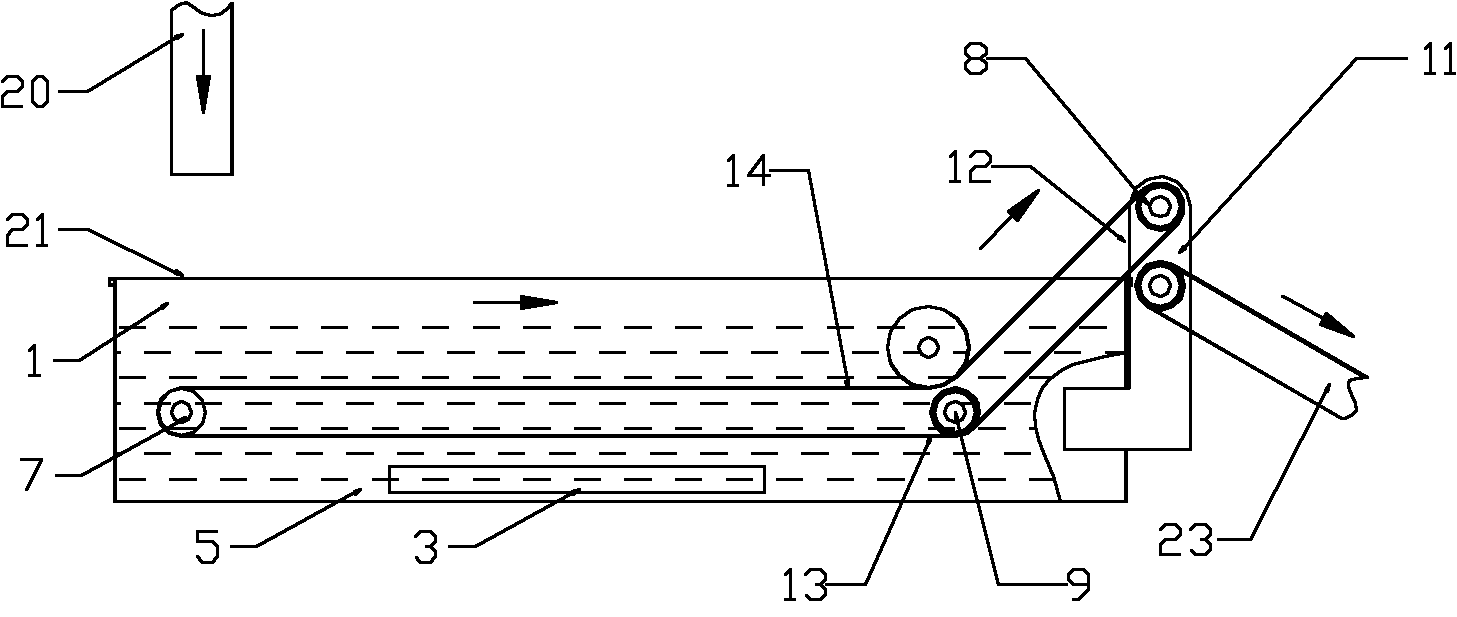

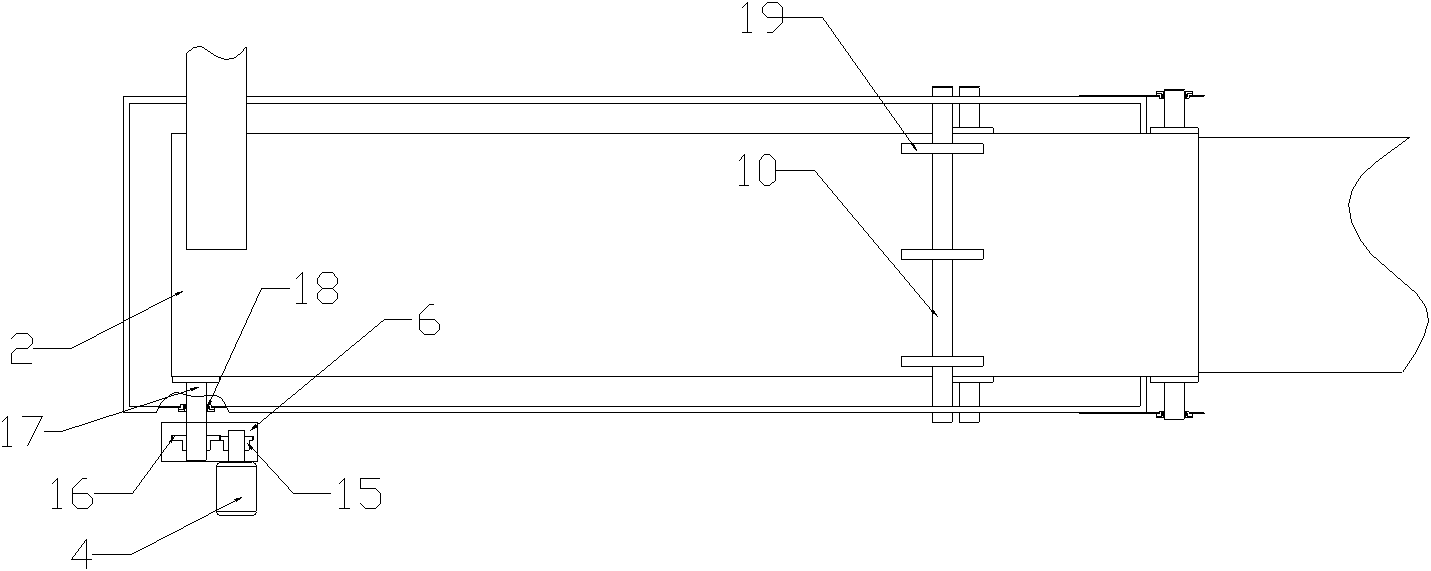

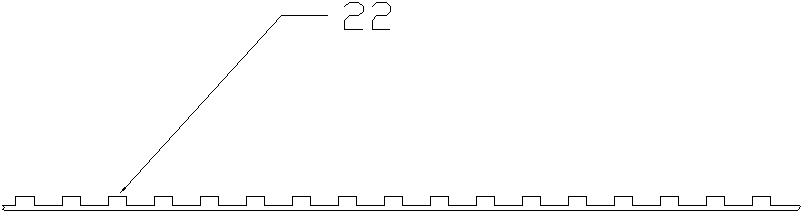

[0012] Such as figure 1 , figure 2 As shown, the present embodiment provides an automatic conveying device for sterilization of a high-temperature water tank, which includes a water tank 1, a transmission conveyor belt 2, a heater 3 and a motor 4, and the heater 3 is arranged at the inner bottom 5 of the water tank 1 Above, the water tank 1 is provided with a transmission main shaft 7, a driven shaft 8, a steering shaft 9, a pressing shaft 10 and a fixed bracket 11, and a motor 4 and a transmission system 6 are provided on the outer surface 15 of the water tank 1, and the transmission main shaft 7 passes through The transmission system 6 is connected with the motor 4 . In order to make the packaged product automatically leave the water surface after high-temperature sterilization in the water tank and enter the next process, the transmission conveyor belt needs to have a process of bending upwards. The driven shaft 8 is arranged on the upper end 12 of the water tank 1 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com