Patents

Literature

38results about How to "No scale" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

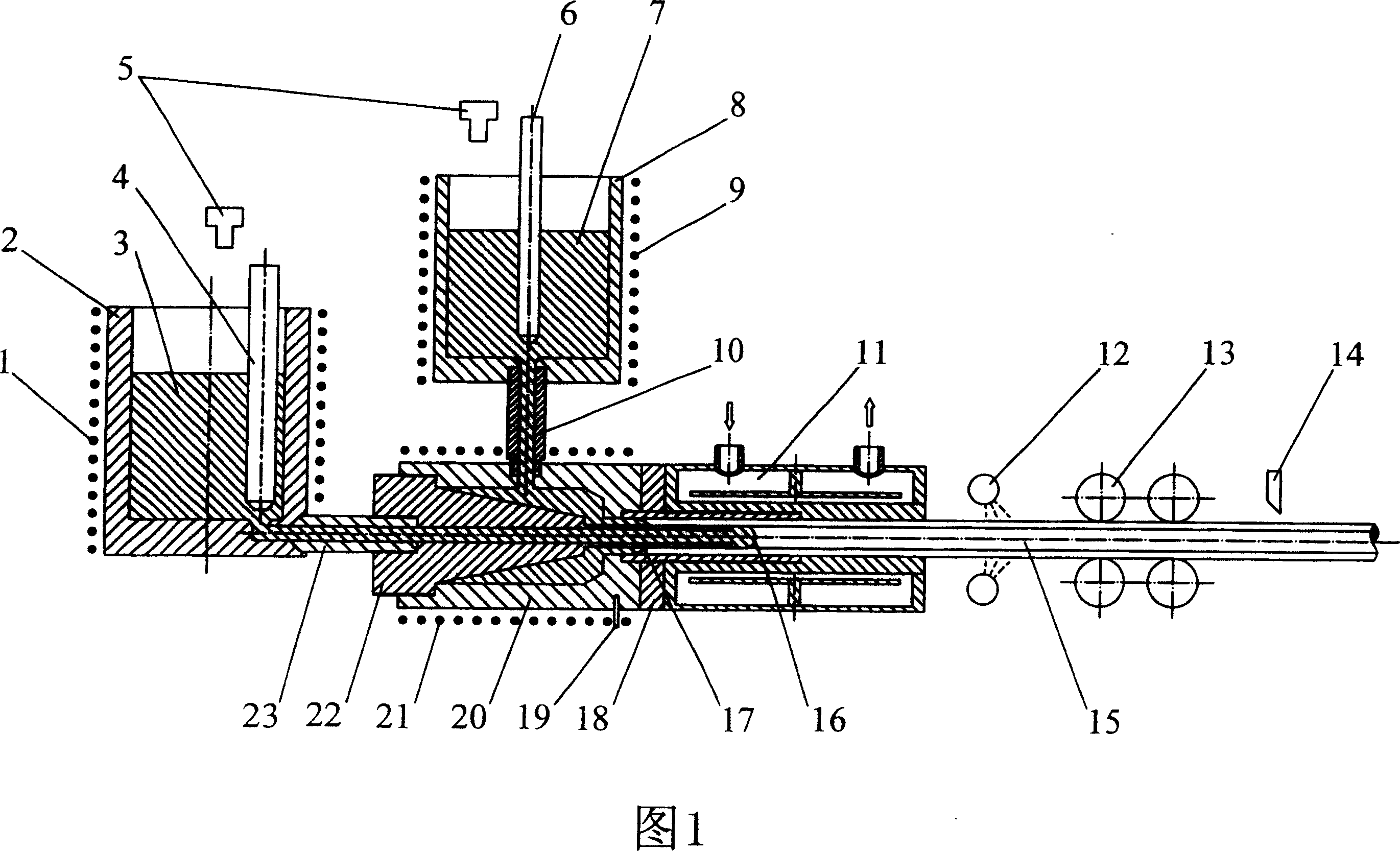

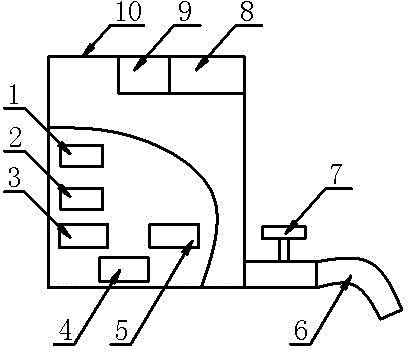

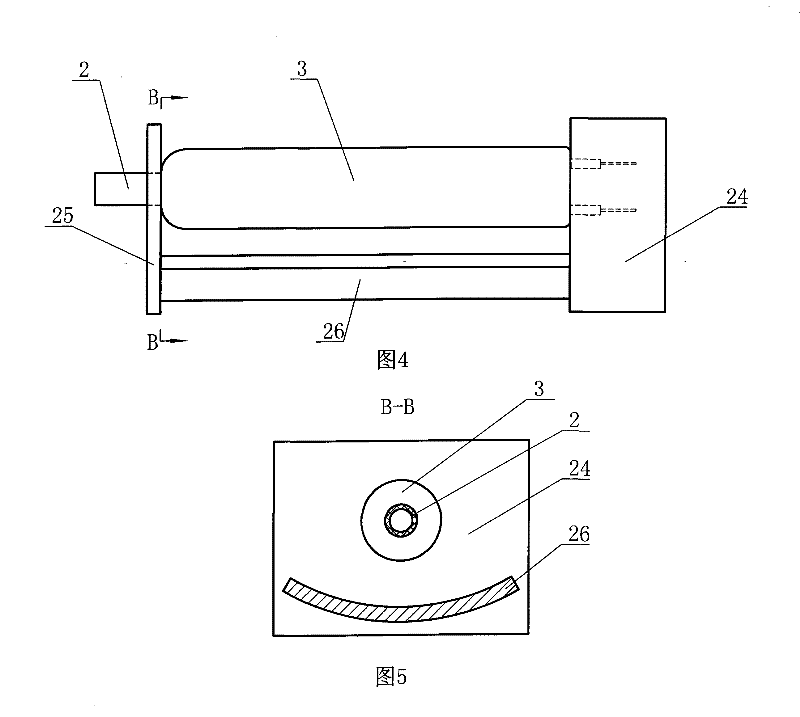

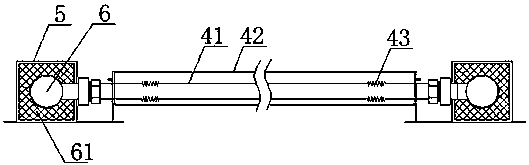

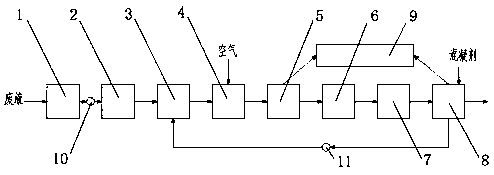

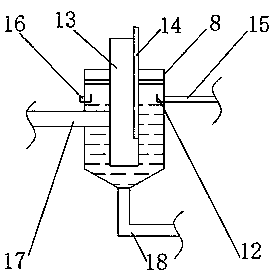

Coating material horizontal continuous casting direct recombination forming apparatus and technology

ActiveCN1927504AAchieve energy saving and consumption reductionContinuous pullHeating elementCrucible

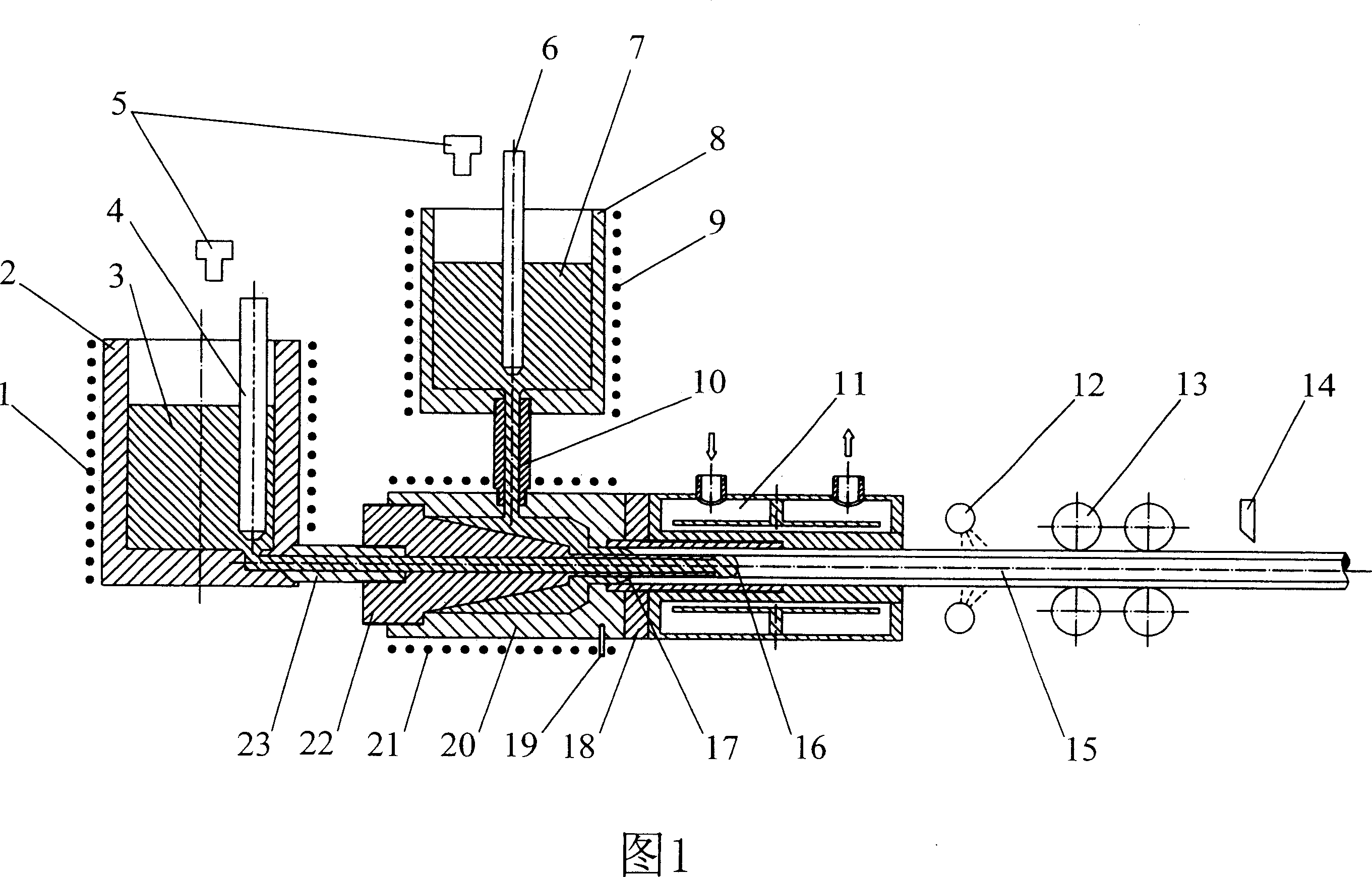

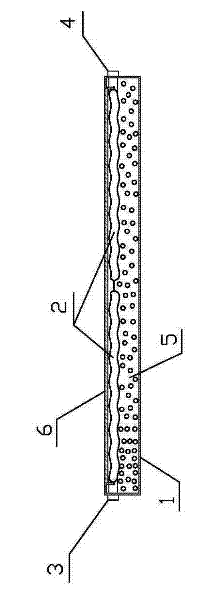

The invention relates to a package material horizontal casting shaping device. Wherein, it comprises core metal temperature-control pot, package metal temperature-control pot, core metal liquid irrigate tube, package metal crystallizer, drawing device, temperature tester, heating element and secondary cooler; and the producing method comprises the temperature of package metal is kept by the package metal temperature-control pot, passing through the package metal thermal-insulated chamber, irrigates into the casting mould formed by crystallizer and irrigate tube to be solidified into package metal tube; the core metal is solidified in the solidified package metal tube, with he package metal tube to form composite cast ingot; the cast ingot via second cooler is cooled and drawn by the drawing device, to be cut by cutter at certain length. The invention has simple process and lower cost, while the interface between package metal and core metal has non oxidization and non pollution.

Owner:UNIV OF SCI & TECH BEIJING

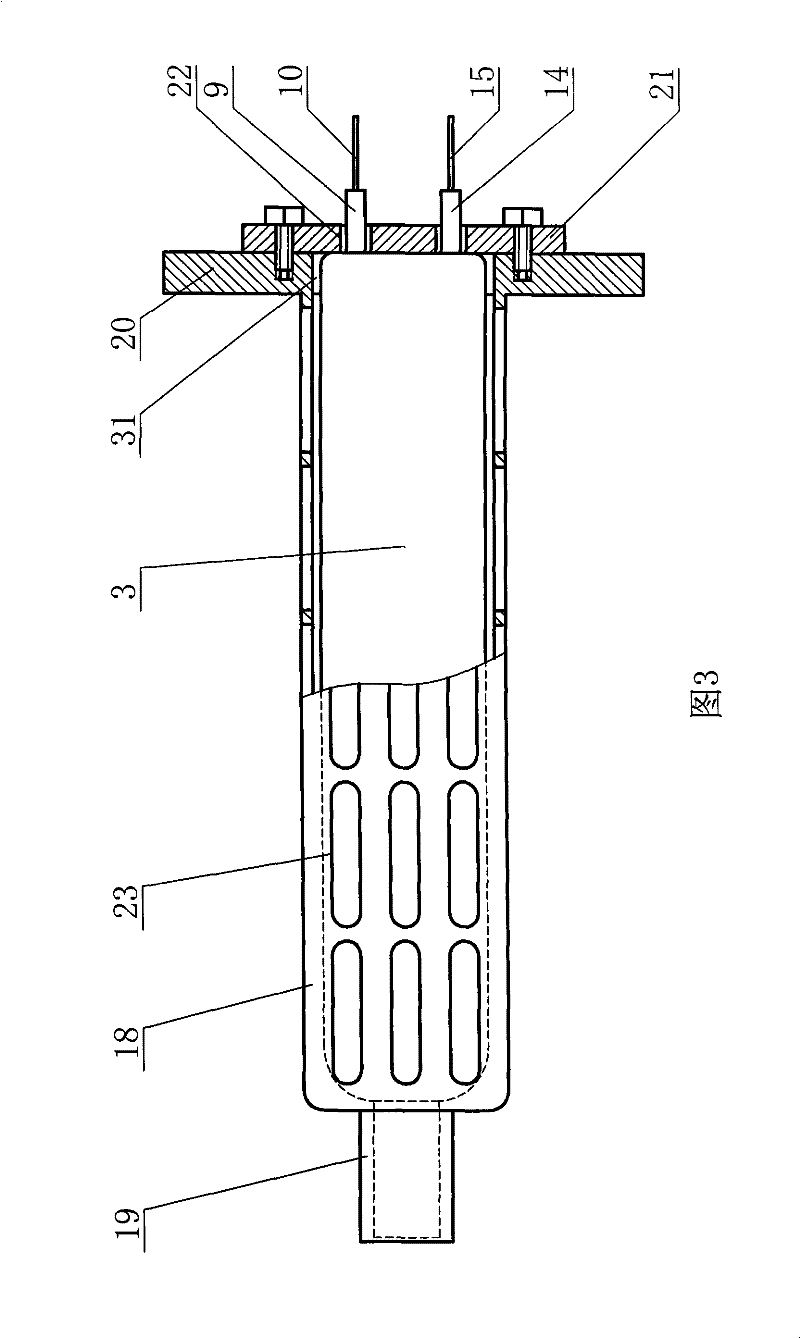

Infrared radiation ceramic heater

InactiveCN101505554AHeating up fastReduce consumptionImmersion heating arrangementsHeating element shapesFiberCarbon fibers

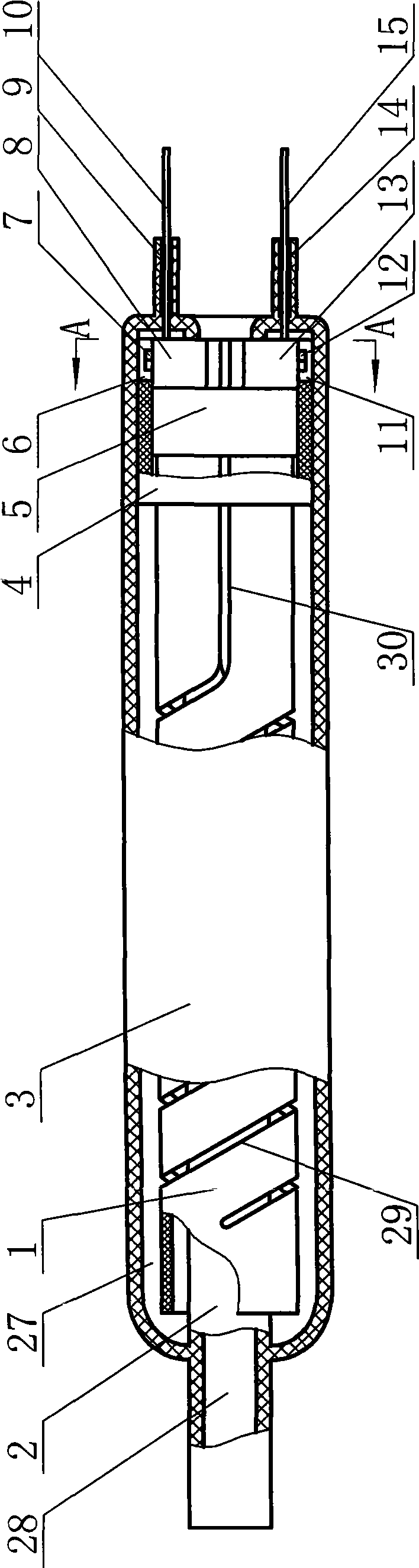

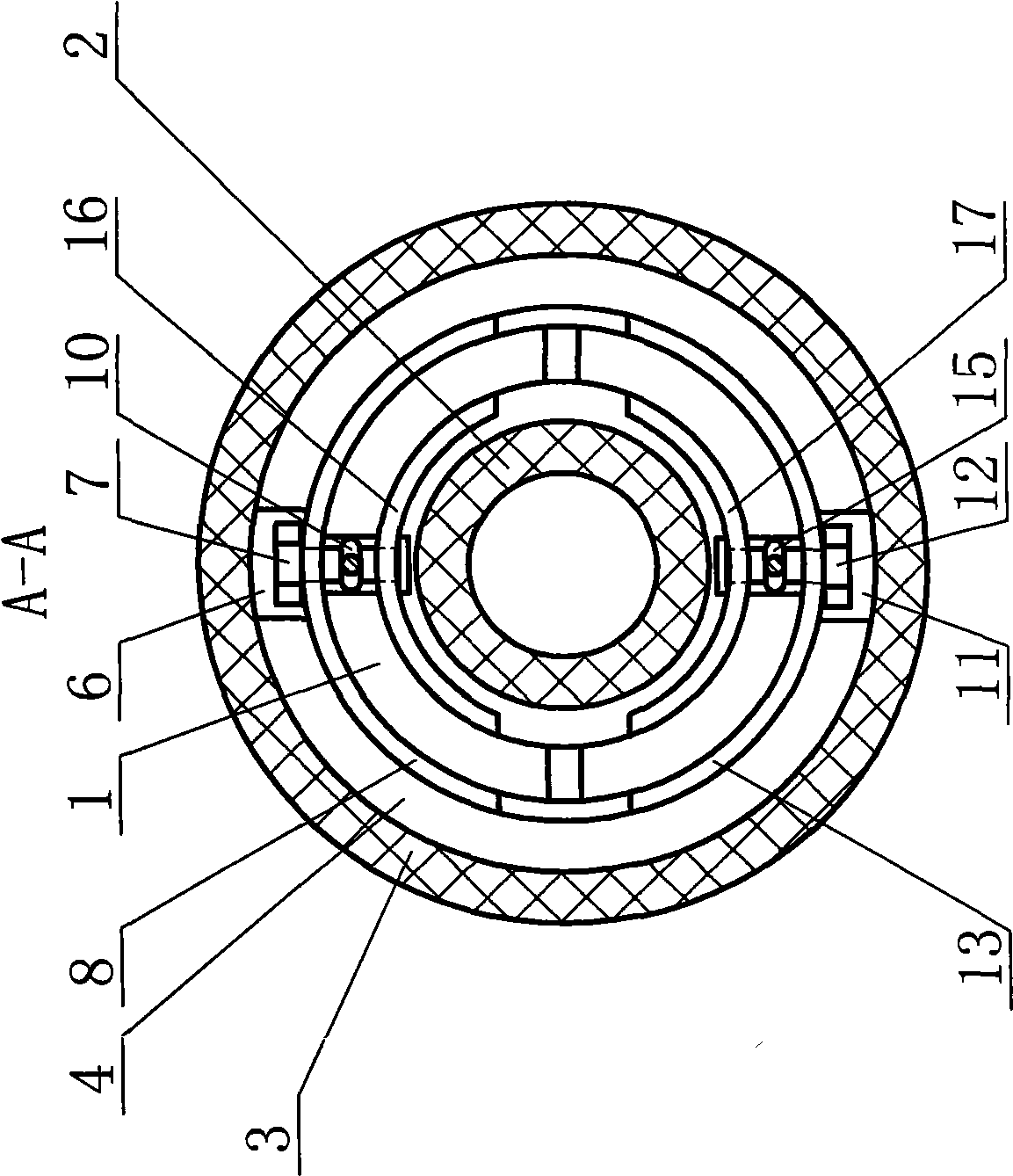

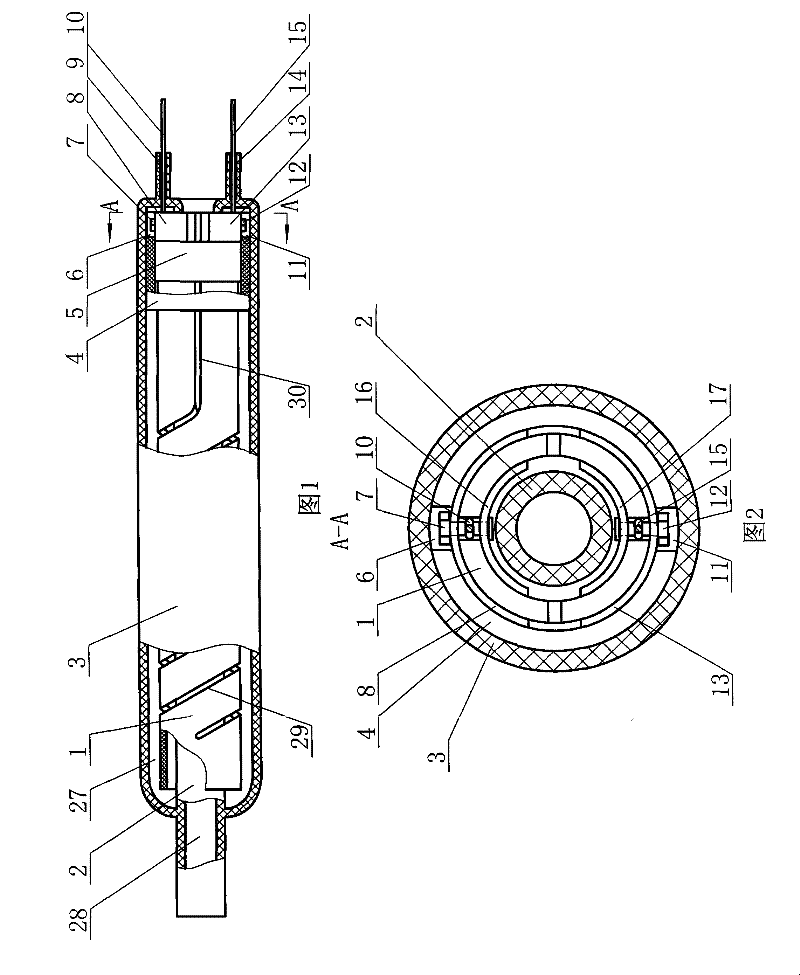

The invention discloses an infrared radiation ceramic heater, which comprises a quartz outer tube and a quartz inner tube, wherein two ends of the quartz outer tube and two ends of the quartz inner tube are connected in a melted and closed mode respectively; a cavity is arranged between the inner wall of the quartz outer tube and the outer wall of the quartz inner tube and provided with a silicon carbon rod inside; the diameter of a through hole in the middle of the quartz inner tube is more than or equal to the length of the quartz outer tube; electrodes are arranged at the ends of the silicon carbon rod; and a silicon dioxide pad is arranged on the outer wall or the inner wall of the ends of the silicon carbon rod. The infrared radiation ceramic heater is mainly used for medium heating of heaters, can also be used for heating in industrial production, and is particularly applicable to heaters adopting water circulation. The product can directly heat water to make the water temperature rise rapidly, water absorbs heat through the quartz outer tube and the quartz inner tube, the heat efficiency is high, because the infrared radiation rate is larger than 97 percent, the energy consumption is low, and compared with the prior silicon fiber wire heating and electrothermal tube heating, the heating mode saves energy by 38 to 45 percent. The infrared radiation ceramic heater has the advantages of long service life along with thoroughly overcoming the defect of easy failures of electric heating and carbon fiber heating.

Owner:周存文

Titanium alloy surface processing process

The invention discloses a titanium alloy surface processing process which comprises steps of (1) sand blasting; (2), chemical processing; (3), rough polish; (4), burr removal; (5), fine polish; (6), finishing polish; (7), corona processing; (8), acid pickling processing; (9), drying by boiling and oil smearing. Titanium alloy processed through the process is smooth and bright in surface, uniform in color and free of color change, oxide skin and the like; and in addition, antioxygenation and creep performance of the titanium alloy processed through the process can also be greatly improved, and a surface microstructure is effectively refined.

Owner:当涂县宏宇金属炉料有限责任公司

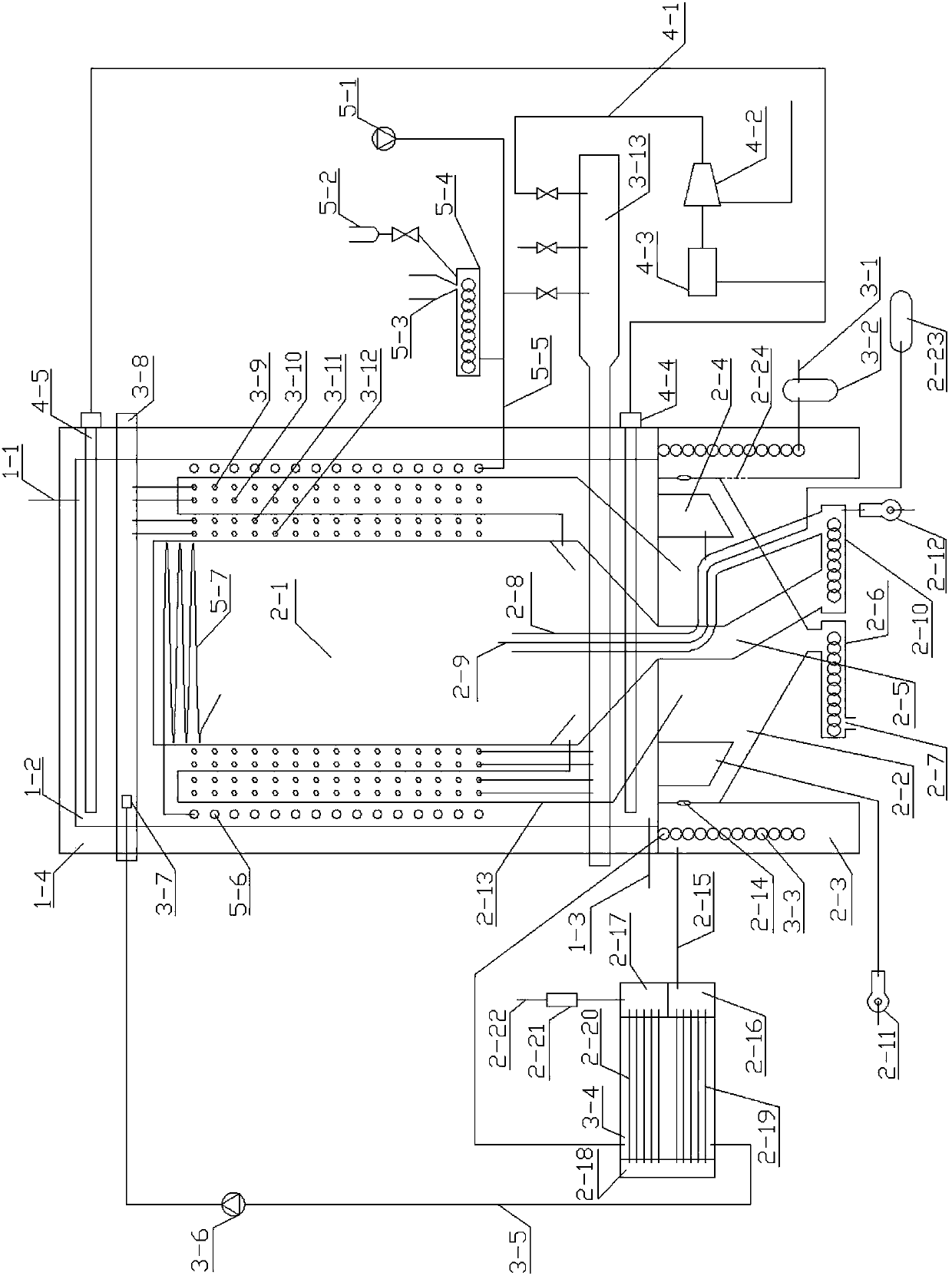

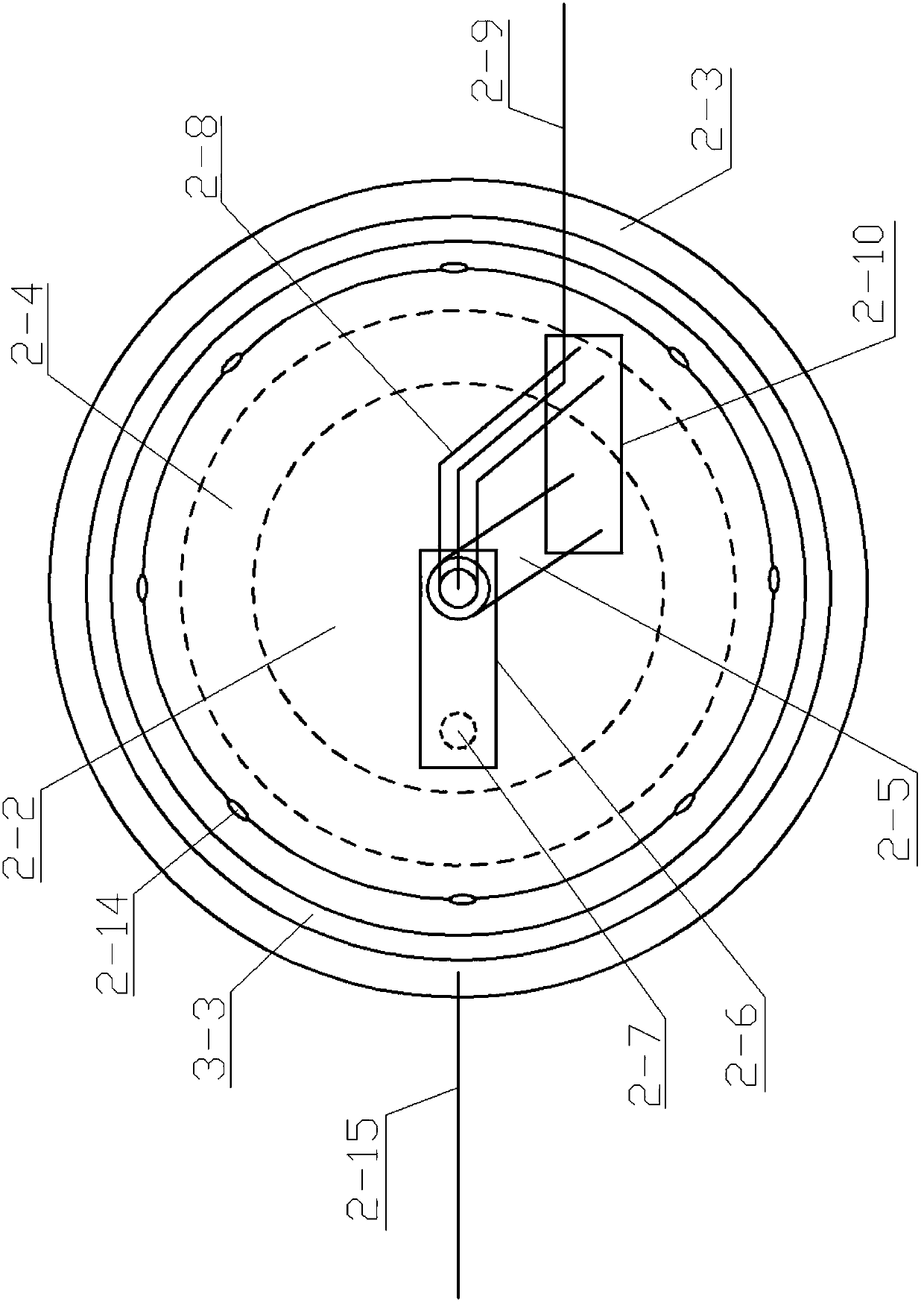

Fuel gas, fuel oil and fused salt integrated steam boiler

InactiveCN105910094APromote expansionProduced quicklySuperheating controlFluidized bed combustionEngineeringFuel oil

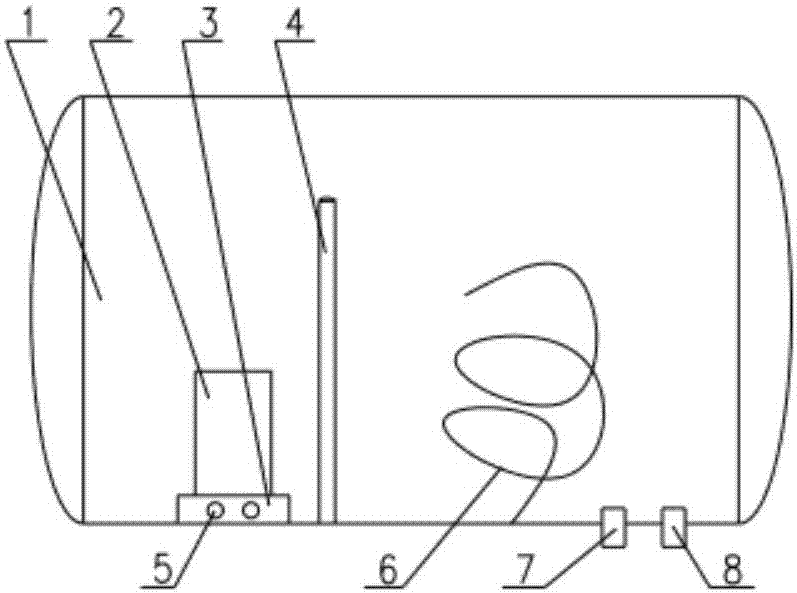

The invention discloses a fuel gas, fuel oil and fused salt integrated steam boiler. The fuel gas, fuel oil and fused salt integrated steam boiler is mainly composed of a first fused salt groove, a second fused salt groove, an insulating layer, a combustion cavity, a combustor, an air preheating recoverer, a chimney, a waste heat recycling water tank, a high-pressure plunger pump, a steam pipe coil, a steam header, a steam generator body and a high-pressure spraying device. The fuel gas, fuel oil and fused salt integrated steam boiler has the advantages that firstly, steam mist jetting is adopted for water feed, the heat exchange area is increased, and the heat efficiency is improved; secondly, the temperature and the pressure of the steam can be adjusted, incrustation is avoided, the service life of the boiler is prolonged, boiler waste water is avoided, and a large number of water resources are saved; and thirdly, waste heat is recycled and utilized completely.

Owner:赖正平 +1

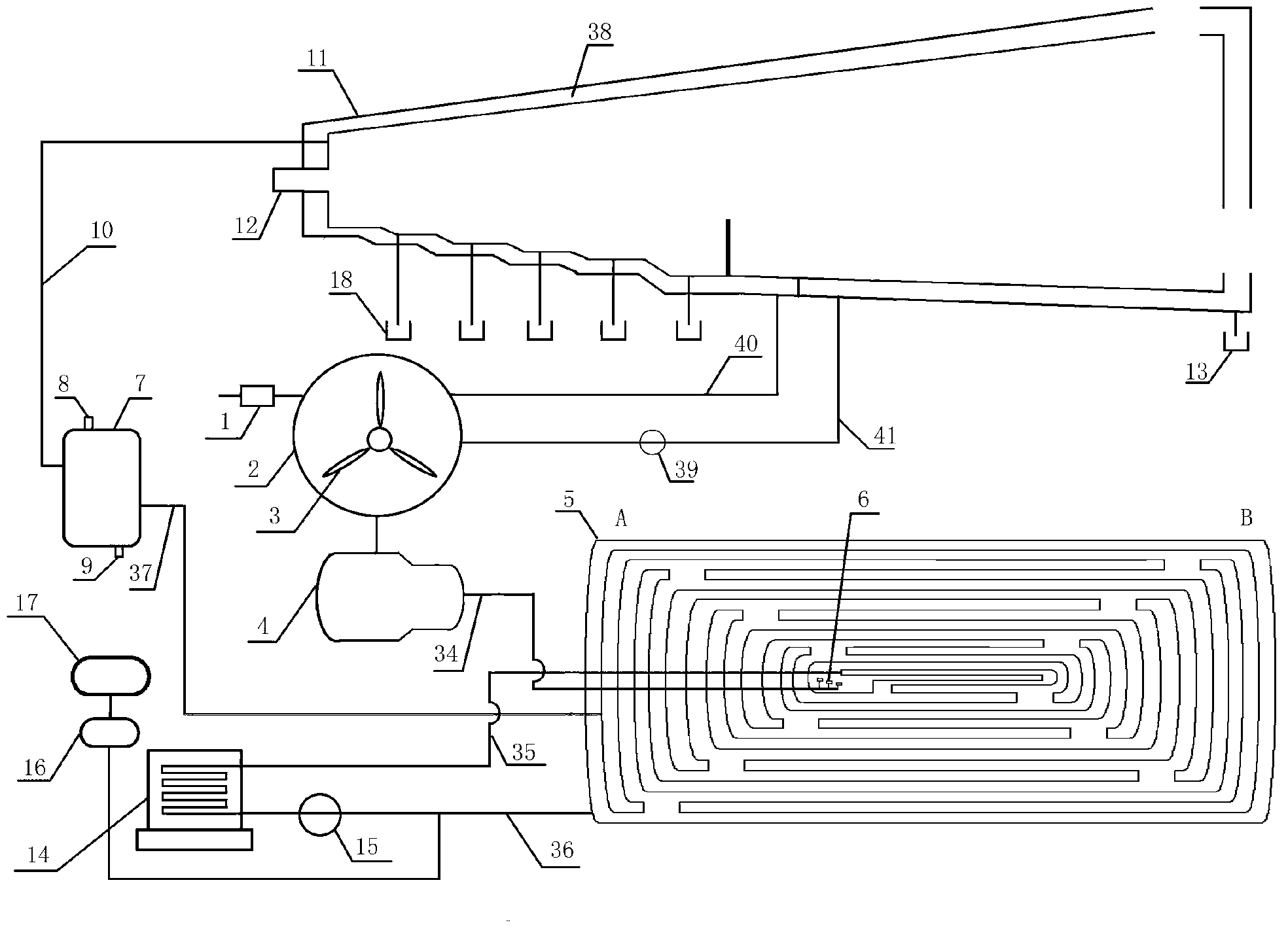

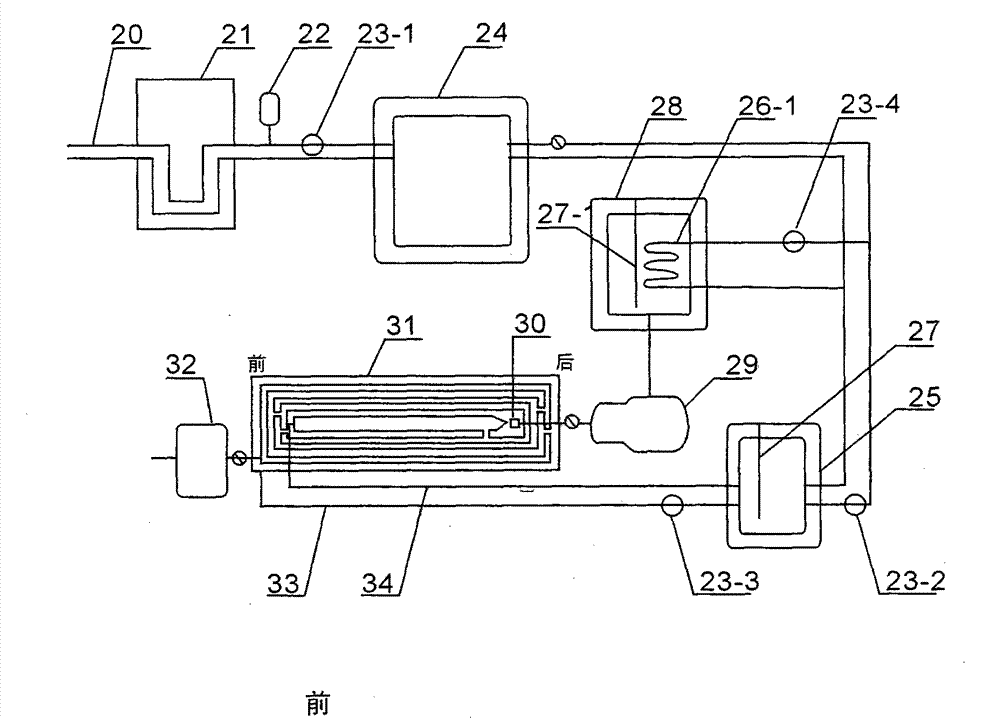

Capillary tube air conditioning system

InactiveCN105972725AMeet the needs of indoor environmentSolve the comfortSolar heating energySolar heat devicesEngineeringAir conditioning

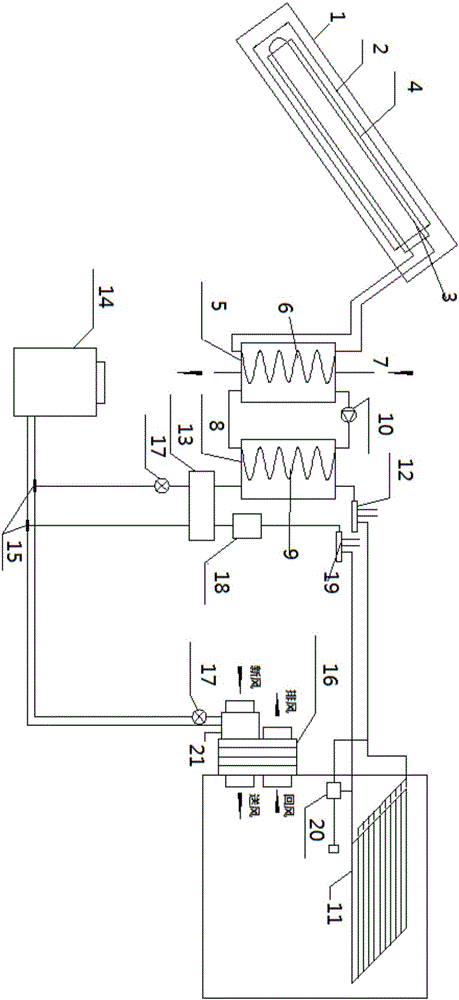

The invention discloses a capillary tube air conditioning system. The capillary tube air conditioning system comprises an evacuated tubular heat collector, a domestic hot water tank, a tail end circulating water tank, an air cooled heat pump main machine, a plate heat exchanger, a heat-pipe type fresh air processing unit and a capillary tube network. An air source heat pump is used as a main cold and heat source, solar energy is used as an auxiliary heat source, the air conditioning system mode of capillary tube radiation cold and heat supply is adopted by the tail end, and the system has wide application range and can be applied to residential buildings and public buildings.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

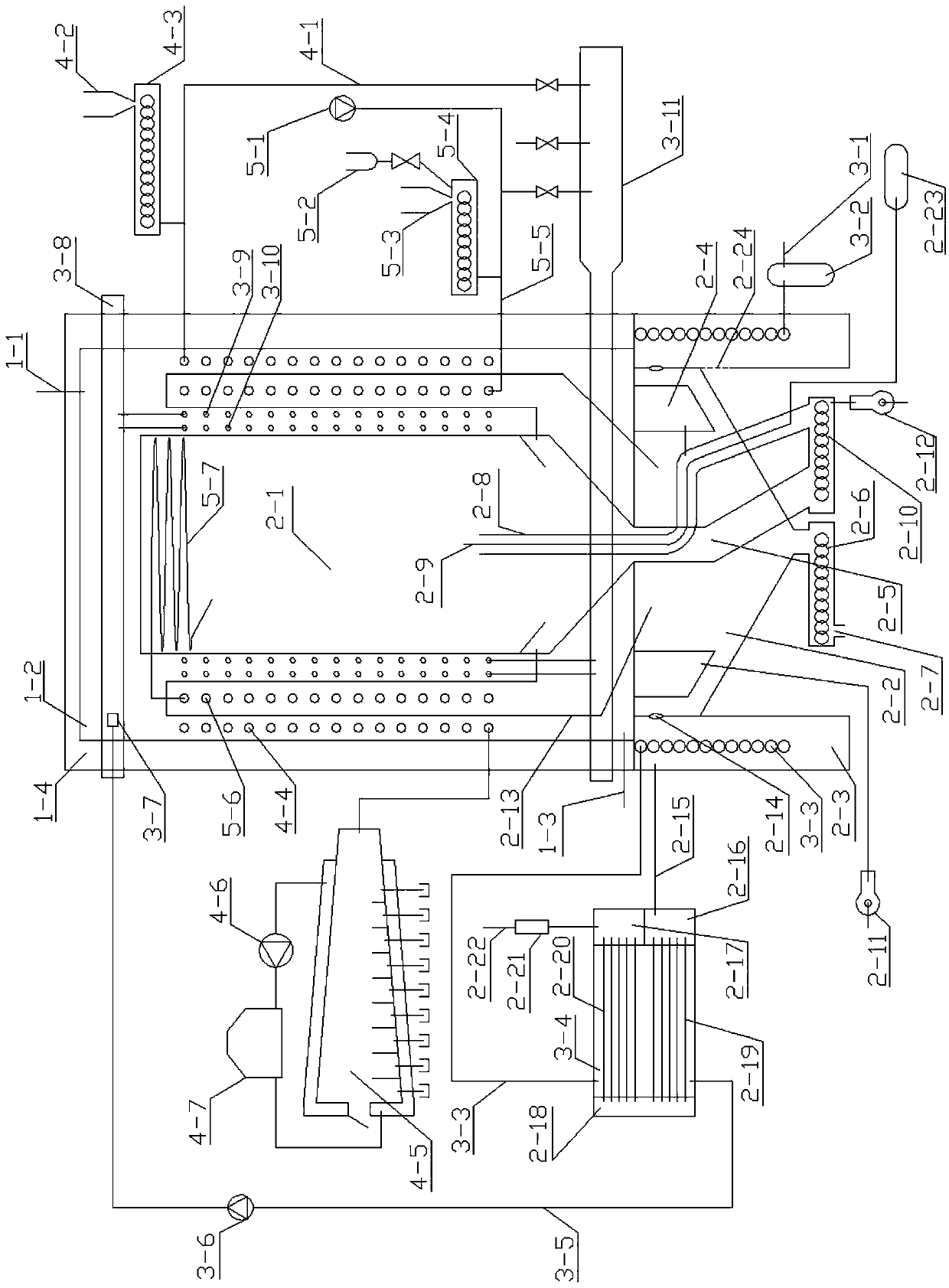

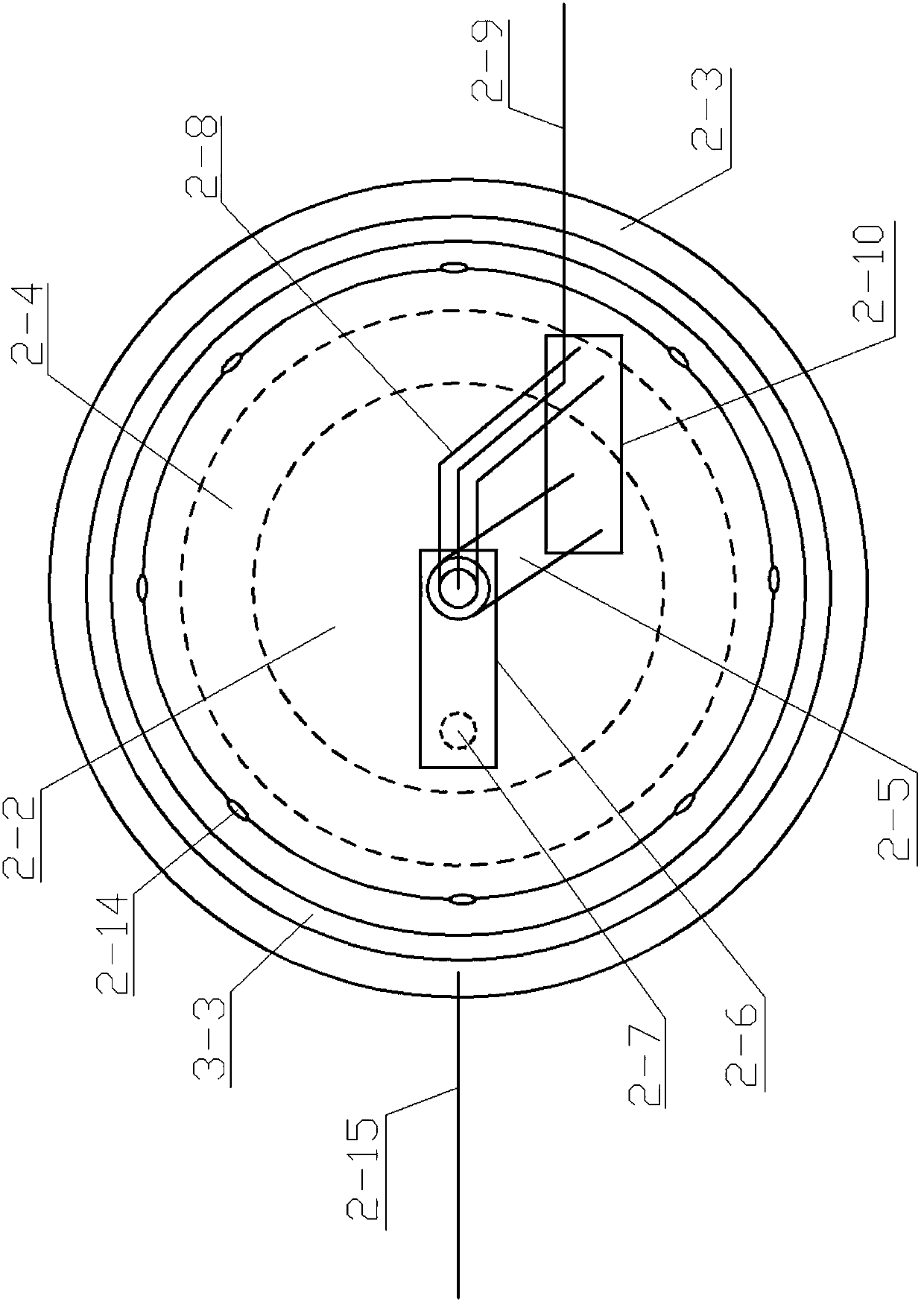

Electronic injection flash boiler for supercritical pyrolysis gas

InactiveCN107940426AIncrease the heat exchange areaHigh thermal efficiencyEnergy inputSpecial form destructive distillationInsulation layerCooling tower

The invention discloses an electronic injection flash boiler for supercritical pyrolysis gas. The electronic injection flash boiler for the supercritical pyrolysis gas is composed of a fused salt adding pipe, a fused salt groove, a fused salt discharge pipe, a heat-insulation layer, a combustion cavity, a smoke pipe, a smoke cavity, a combustor, a waste heat recovery water tank, a water outlet pipe, a high-pressure plunger pump, a high-pressure spraying device, a steam generator, a steam coiled pipe, a steam groove, a steam distribution cylinder, a smoke discharge pipe, a water inlet pipe, a first smoke groove, a second smoke groove, a third smoke groove, an air pipe, a water groove, a steam turbine, a power generator, a first electric heater, a second electric heater, a solid material conveyer, a liquid material conveyer, a steam collision substance decomposition coiled pipe, a vertical separation tower, a horizontal decomposition chamber, a circulation water pump and a cooling tower.The invention provides a substance thermal decomposition and separation device which is simple in structure, efficient and energy-saving, high in heat conversion efficiency, large in heat exchange area, complete in substance classification, adequate in decomposition, clear in separation, high in collection speed, convenient to operate, capable of realizing waste heat utilization, and free from emission.

Owner:广东欣鑫华能环保科技有限公司

Supercritical flashed and pyrolyzed gas material condensation and reduction device

InactiveCN107619687AIncrease the heat exchange areaHigh thermal efficiencyEnergy inputGas purification by non-gaseous materials condensationAir preheaterCooling tower

The invention discloses a supercritical flashed and pyrolyzed gas material condensation and reduction device. The device mainly comprises a molten salt tank, an insulating layer, a combustion chamber,an ash discharging funnel, an annular afterheat recycling tank, a dedusting air preheater, a fluidized combustion tube, a gas conveying pipe, a fuel conveyor, a primary blower, a secondary blower, athree-return stroke heat exchange flue pipe, a first flue gas tank, a second flue gas tank, a third flue gas tank, a first heat exchange flue pipe, a second heat exchange flue pipe, a soft water treater, a preheated water coil, a water tank, a high-pressure plunger pump, a high-pressure spraying device, a steam generator, a first steam coil, a second steam coil, a sub-cylinder, a material conveyer, a material pyrolyzing coil, a decomposing chamber, a cooling tower, a coal slurry tank, a flashing and pyrolyzing gas coil, an overheating tube and the like. The device has the advantages as follows: 1, superheated steam is instantly produced, and the heat efficiency is extremely high; 2, the steam temperature and the steam pressure can be adjusted; 3, coal reacts with the steam to produce watergas, combustion is efficient and clean, and pollution is free; and 4, multi-stage afterheat recycling is achieved, and the smoke exhaust temperature is low.

Owner:广东欣鑫华能环保科技有限公司

Multipurpose spray explosion-type high-pressure temperature-adjustment vapor decomposition drying steam generator

ActiveCN102794030AReduce manufacturing costShort processEnergy industryLiquid separationEnvironmental resistanceExpansion tank

The invention discloses a multipurpose spray explosion-type high-pressure temperature-adjustment vapor decomposition drying steam generator. The multipurpose spray explosion-type high-pressure temperature-adjustment vapor decomposition drying steam generator comprises a liquid feeding filter, a liquid raw material tank, a high-pressure plunger pump, a steam generator, a high pressure spraying device, a primary separation tank, a connection pipe, a high-pressure plunger pump outlet pipe, a heat-conduction oil inlet pipe, a heat-conduction oil outlet pipe, a steam layer outlet pipe, a concentrated dried vapor decomposition chamber, a constant temperature furnace, a circulating pump, a high-position expansion tank, a low-position oil storage tank, a stepwise-decomposed material distillation reduction chamber, a cooling inlet pipe, a cooling outlet pipe and a circulating pump. The multipurpose spray explosion-type high-pressure temperature-adjustment vapor decomposition drying steam generator has the advantages that 1, thermal conversion efficiency is more than 99%; a production cost is greatly reduced; a process flow is shortened; high-pressure and high-temperature steam is produced; and high-pressure and high-temperature disinfection is realized; and 2, defects of the traditional boiler are overcome; concentrated water and water scale in the multipurpose spray explosion-type high-pressure temperature-adjustment vapor decomposition drying steam generator are not produced; sewage is not discharged; environmental benefits are obtained; and costs of manual treatment on water scale and sewage disposal are reduced.

Owner:河北正能锅炉设备有限公司

Supercritical steam colliding substance thermal decomposition boiling range condensation reduction sorting device

InactiveCN107741002AIncrease the heat exchange areaHigh thermal efficiencyCombustion processIndirect carbon-dioxide mitigationCooling towerDecomposition

The invention discloses a supercritical steam colliding substance thermal decomposition boiling range condensation reduction sorting device. The device is composed of a molten salt adding pipe, a molten salt groove, a molten salt discharge pipe, a heat preservation layer, a combustion cavity, a flue gas pipe, a flue gas cavity, a combustion machine, a waste heat recovery water tank, a water outletpipe, a high-pressure plunger pump, a high-pressure spraying device, a steam generator, a steam coil pipe, a steam groove, a steam header, a smoke exhaust pipe, a water inlet pipe, a first flue gas groove, a second flue gas groove, a third flue gas groove, an air pipe, a water groove, a steam turbine, a generator, a first electric heater, a second electric heater, a solid material conveyor, a liquid material conveyor, a steam colliding substance thermal decomposition coil pipe, a vertical separation tower, a horizontal decomposition chamber, a circulating water pump and a cooling tower. The device has the advantages that structure is simple, efficient and energy-saving, heat conversion efficiency is high, heat exchange areas are full, material classification is complete, decomposition issufficient, sorting is clear, the collection speed is high, operation is convenient, waste heat is utilized, and no emission is generated.

Owner:广西汽能壹号节能技术有限公司

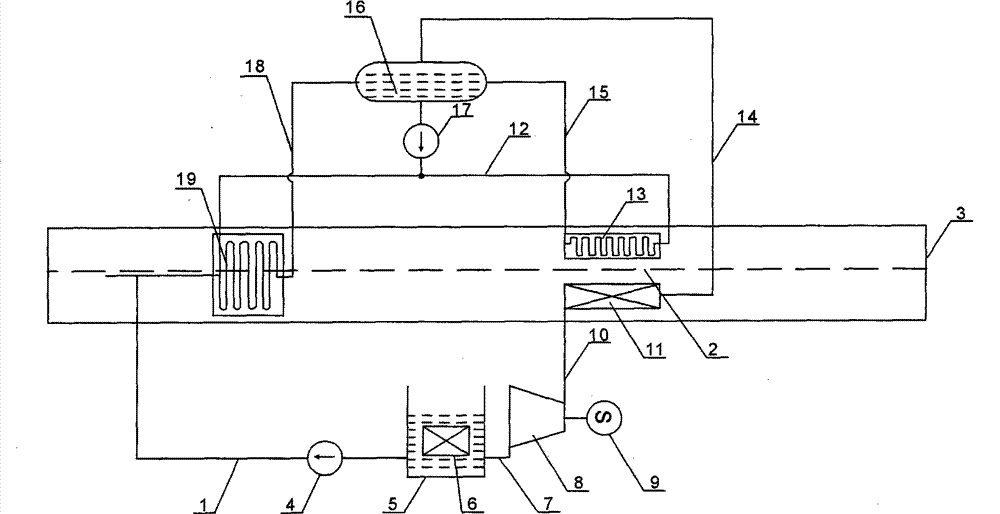

Coating material horizontal continuous casting direct recombination forming apparatus and technology

ActiveCN100377814CAchieve energy saving and consumption reductionContinuous pullTemperature controlCrucible

The invention relates to a package material horizontal casting shaping device. Wherein, it comprises core metal temperature-control pot, package metal temperature-control pot, core metal liquid irrigate tube, package metal crystallizer, drawing device, temperature tester, heating element and secondary cooler; and the producing method comprises the temperature of package metal is kept by the package metal temperature-control pot, passing through the package metal thermal-insulated chamber, irrigates into the casting mould formed by crystallizer and irrigate tube to be solidified into package metal tube; the core metal is solidified in the solidified package metal tube, with he package metal tube to form composite cast ingot; the cast ingot via second cooler is cooled and drawn by the drawing device, to be cut by cutter at certain length. The invention has simple process and lower cost, while the interface between package metal and core metal has non oxidization and non pollution.

Owner:UNIV OF SCI & TECH BEIJING

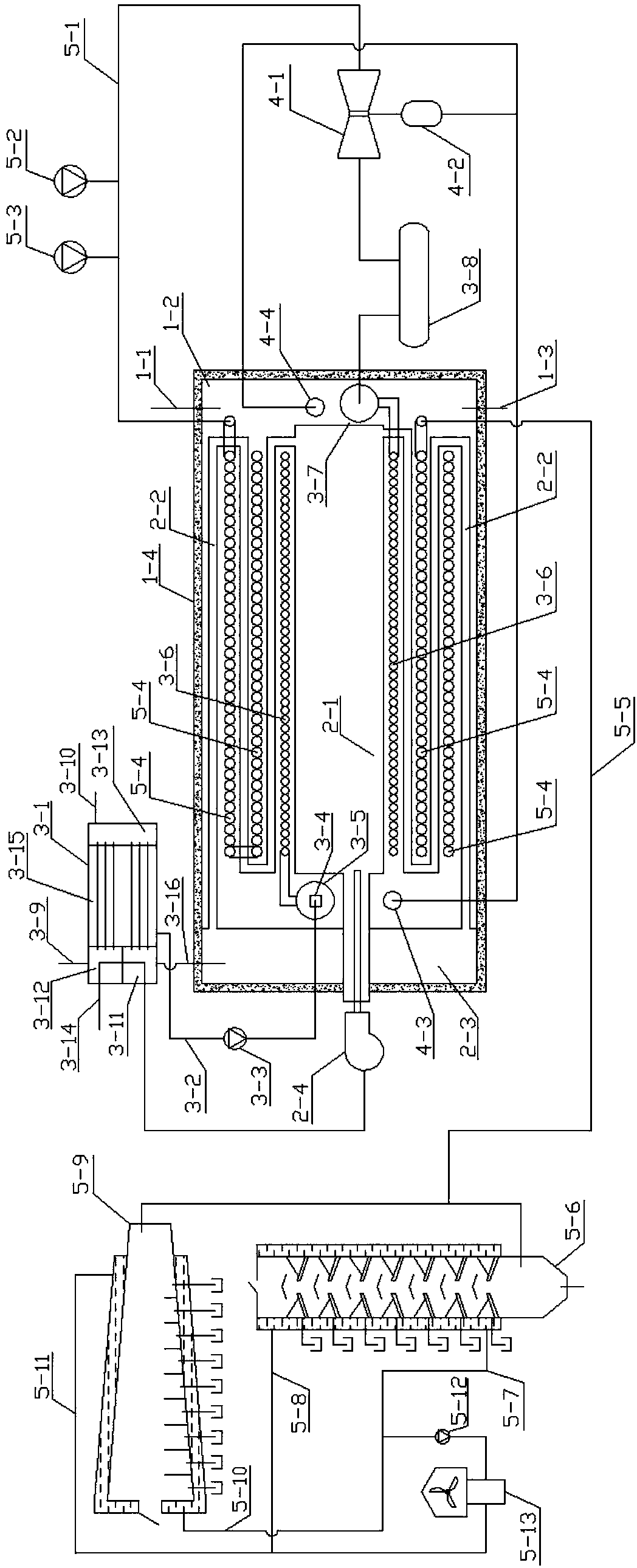

Device for matter heat separation of solid fuel and fused salt integrated boiler

InactiveCN105841139AIncrease the heat exchange areaHigh thermal efficiencySuperheating controlFluidized bed combustionCooling towerCyclonic separation

The invention discloses a device for matter heat separation of a solid fuel and fused salt integrated boiler. The device is mainly composed of an expansion groove, fused salt grooves, fused salt guide pipes, an insulating layer, a burning cavity, an air preheating recoverer, an air blower, another air blower, a centrifugal fan, circulation burning pipes, a waste heat recovery water tank, a combustion air cavity, a fuel preheating coil pipe, a high pressure plunger pump, a steam coil pipe, a steam header, a steam generator main body, a high pressure spraying device, a desulfurization and denitrification device, a dedusting lime water pool, a spraying head, a circulation water pump, an induced draft fan, a chimney, a solid matter conveyor, a liquid matter conveyor, a matter decomposing coil pipe, a cyclone separation tower, a decomposing reduction chamber and a cooling tower. The device has the beneficial effects that fused salt of a fused salt constant temperature system is directly heated in a hearth, and the steam pipe temperature and the heat decomposing pipe temperature are controlled by heat of the fused salt; jet fog enters a steam pipe to obtain steam; and materials enter a heat decomposing pipe to conduct matter decomposing. The device further has the beneficial effects that a steam decomposing and separating technology is adopted for replacing an existing decomposing and separating technology, and the problems of complex technological processes, equipment and the like are solved.

Owner:赖正平 +1

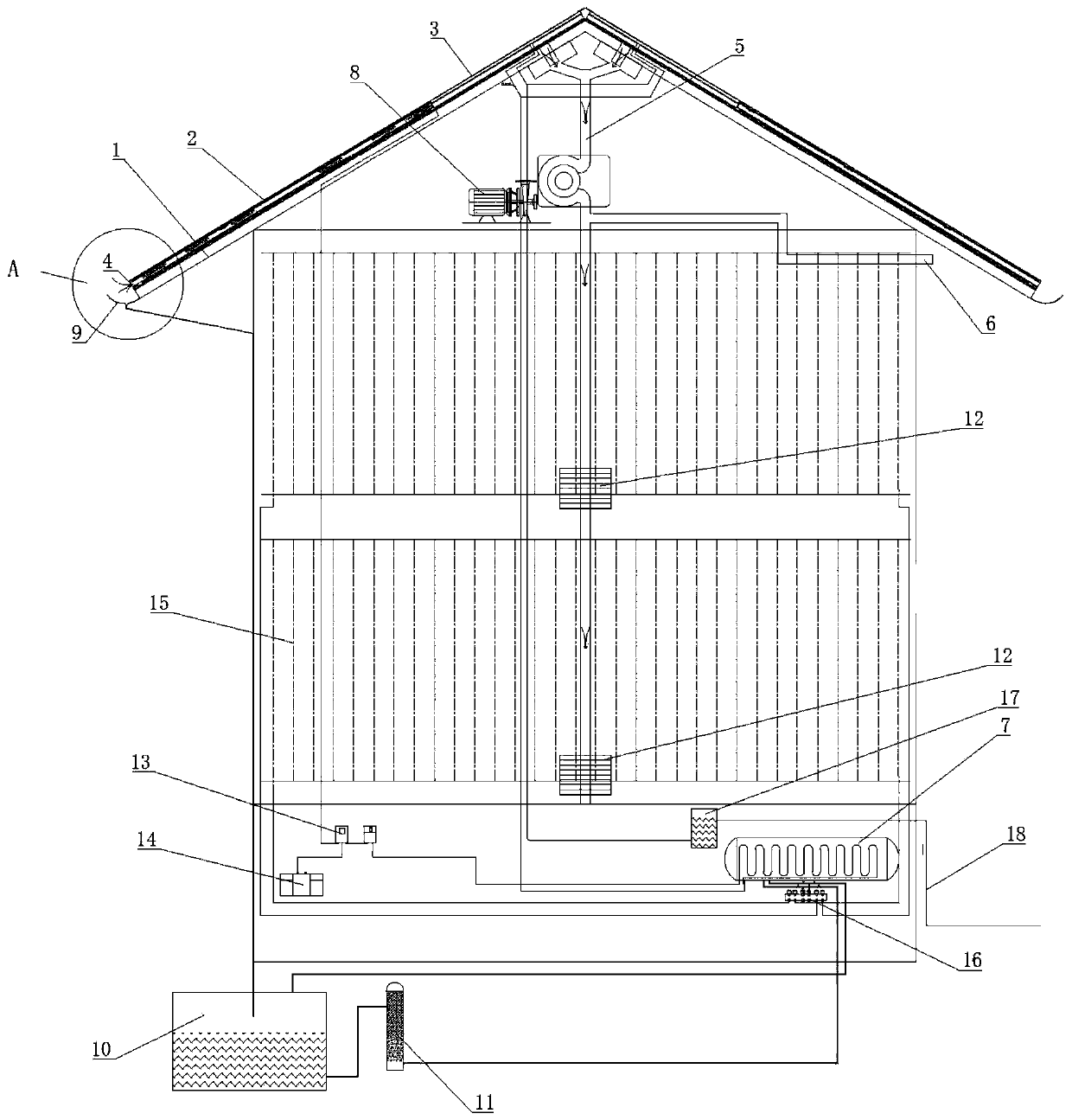

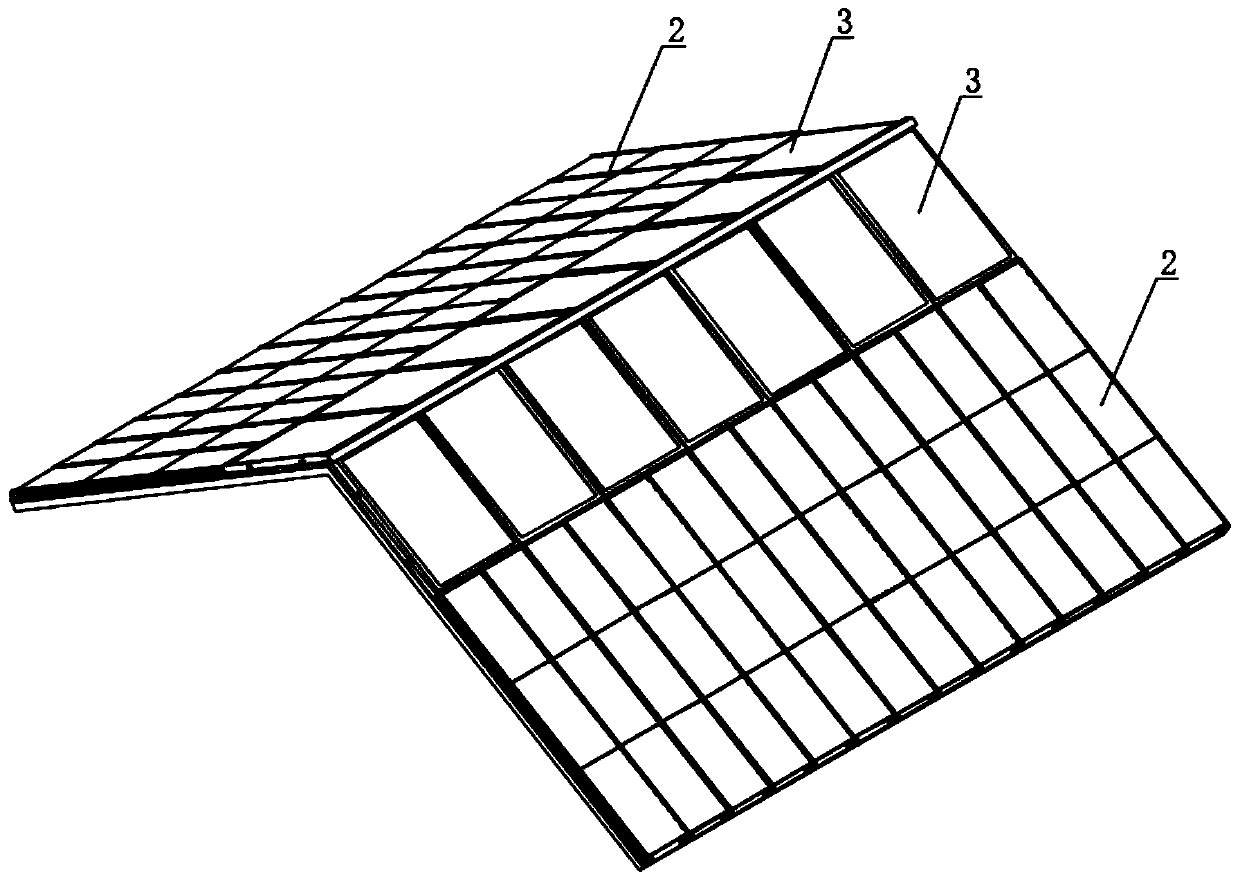

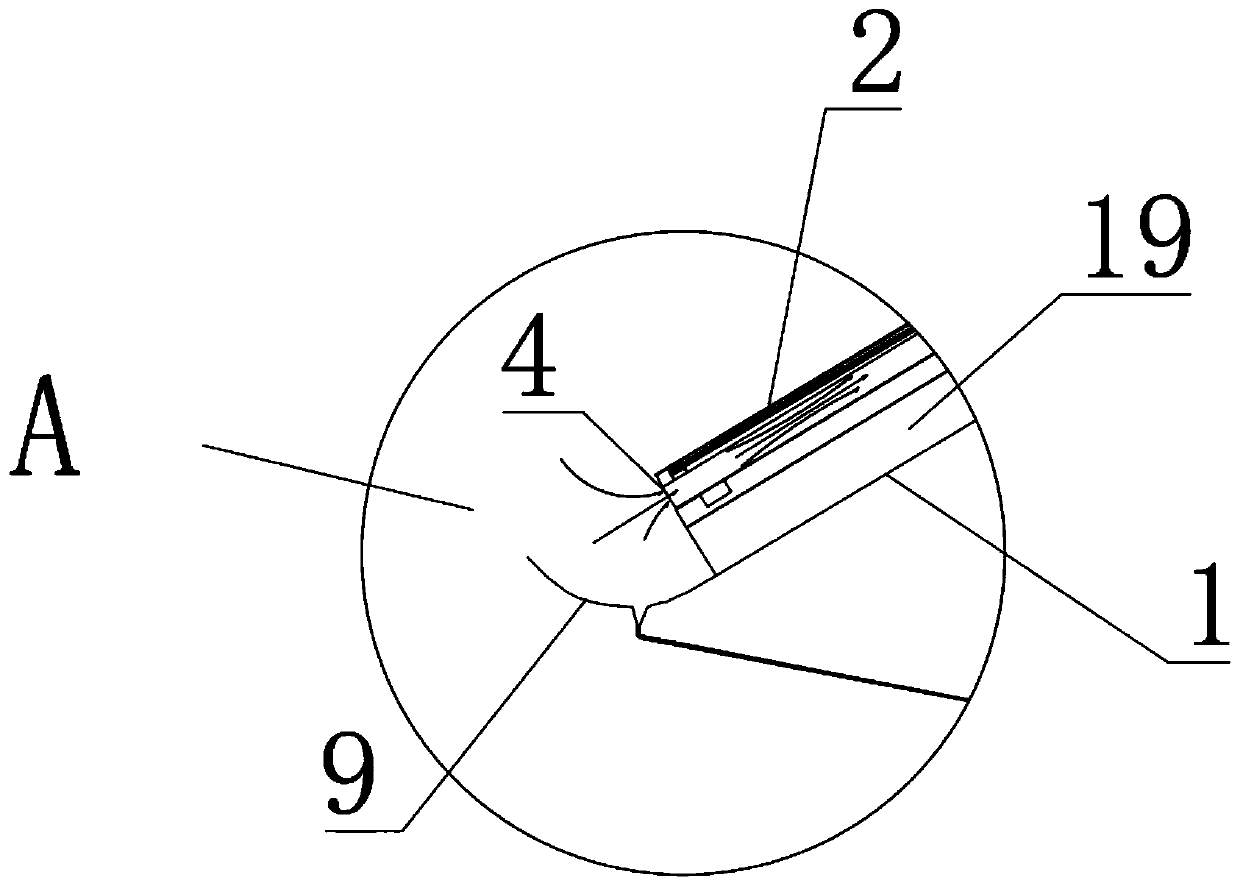

Environmental-friendly house based on photovoltaic effect

InactiveCN110905234AImprove power generation efficiencyLittle influence of temperatureSolar heating energyRoof covering ventilationsEngineeringAtmospheric sciences

The invention provides an environmental-friendly house based on the photovoltaic effect. The environmental-friendly house based on the photovoltaic effect utilizes a photovoltaic system, energy-savingand environmental-friendly effects are achieved, the load of the building on the environment is reduced, the living space with safety, health and good comfort is provided, and a near-natural feel iscreated for an occupant. The environmental-friendly house based on the photovoltaic effect comprises a solar power generation plate and a solar heat absorbing plate which are obliquely arranged on a roof through mounting supports. The solar heat absorbing plate is located on the upper side of the solar power generation plate. A gap is reserved between the solar power generation plate and the solarheat absorbing plate. An air inlet is formed between the end, close to the eave, of the solar power generation plate and the roof. The solar heat absorbing plate comprises a frame and a heat absorbing assembly arranged on the frame. A cavity is formed between the heat absorbing assembly and the frame. An air guide opening is formed in the portion, facing the air inlet, of the frame. An air outletis formed in the frame. An air guide pipe is connected to the air outlet. The air guide pipe can guide air from the air outlet into a room or out of the room through an air exhaust opening.

Owner:SUZHOU CROWNHOMES TIMBER STRUCTURE TECH CO LTD

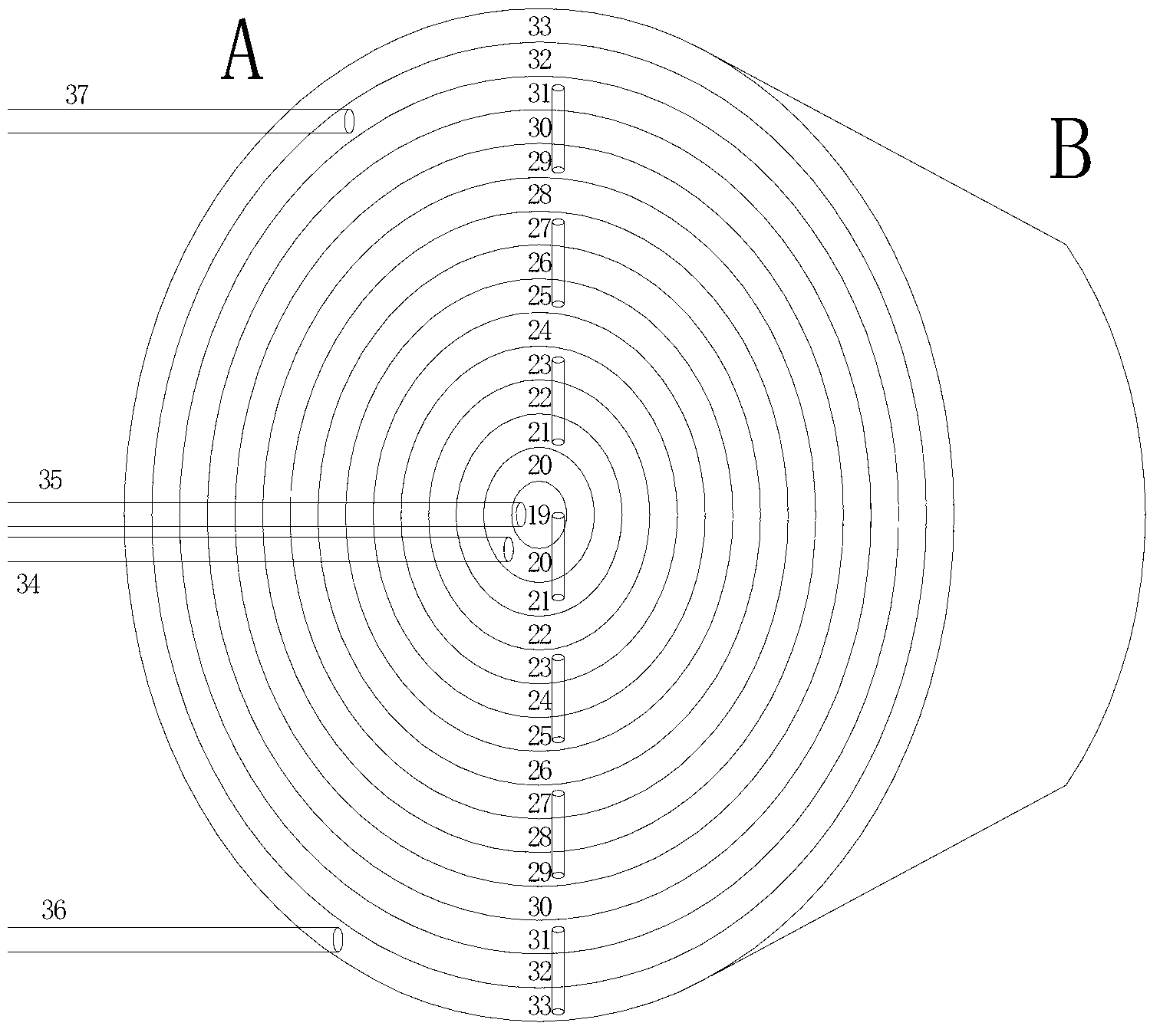

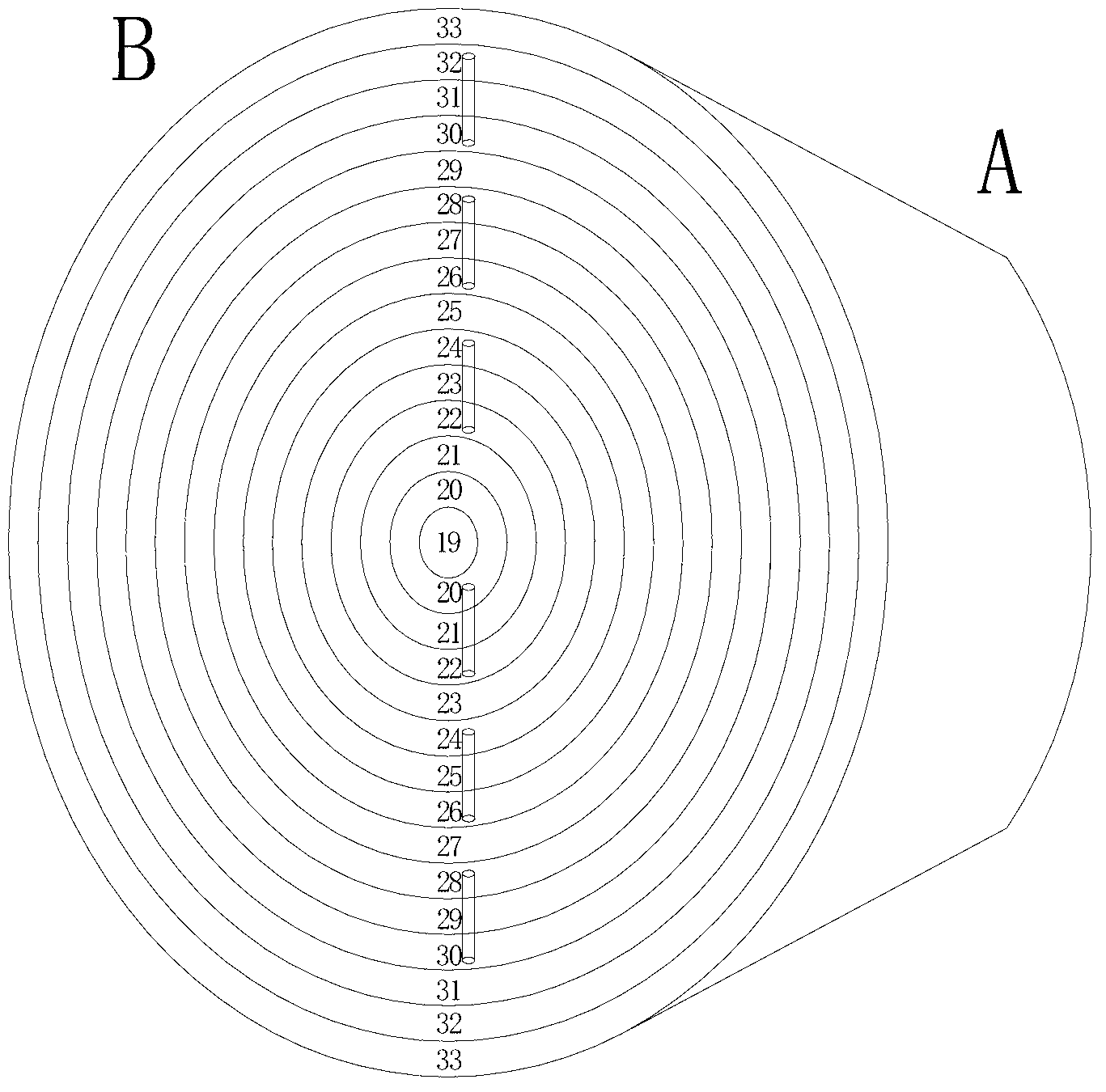

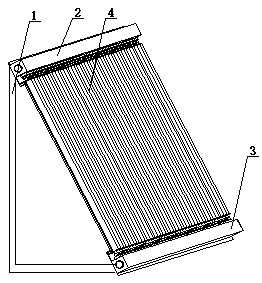

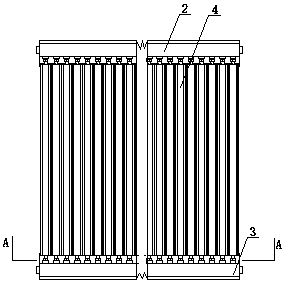

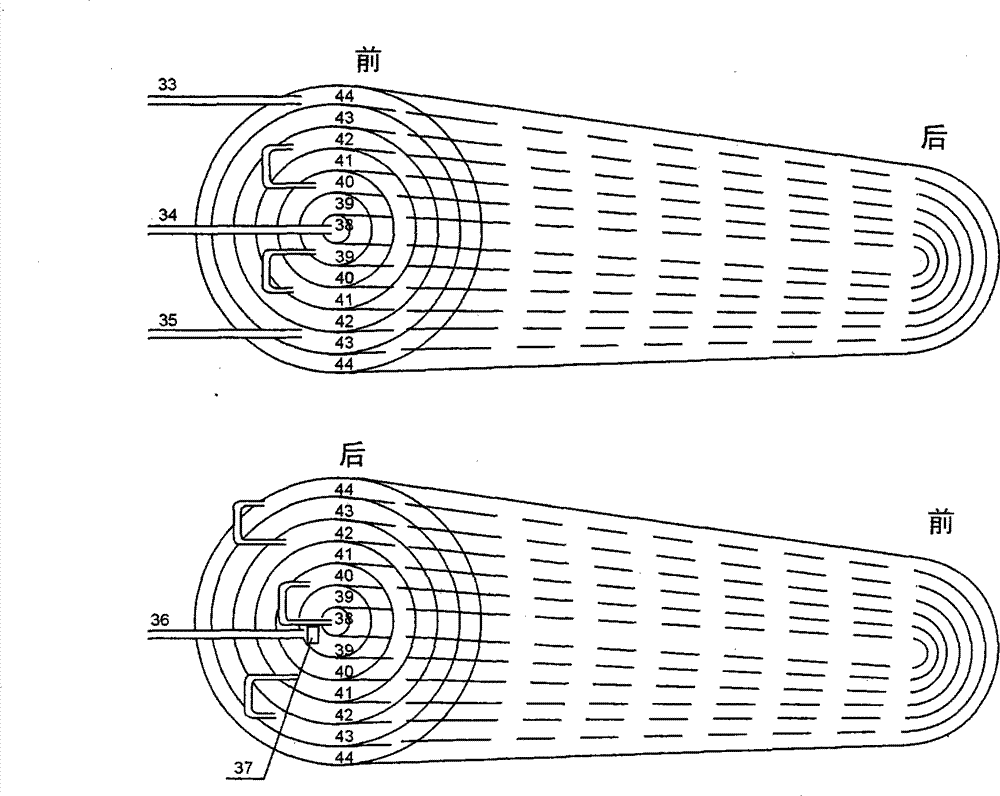

Solar water heater

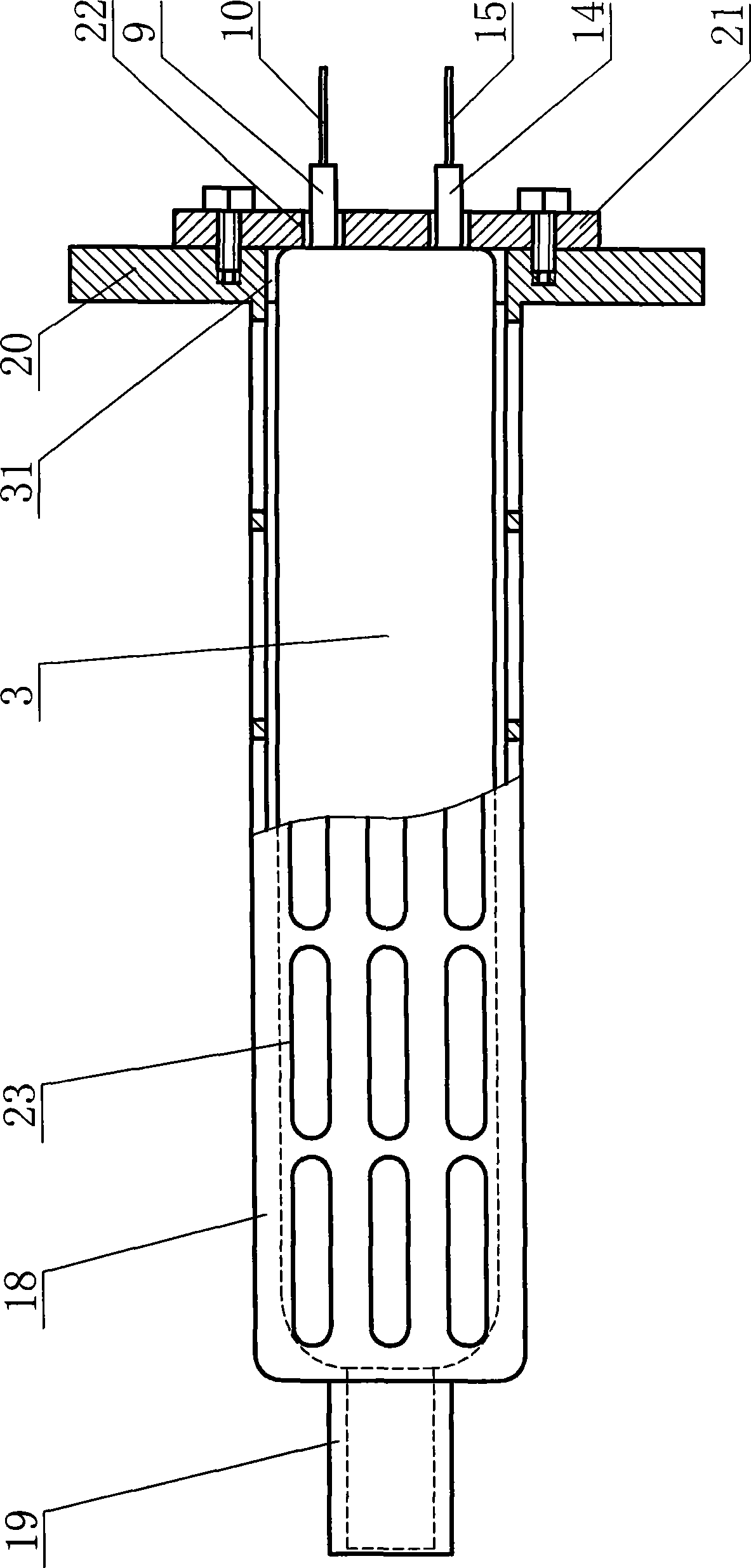

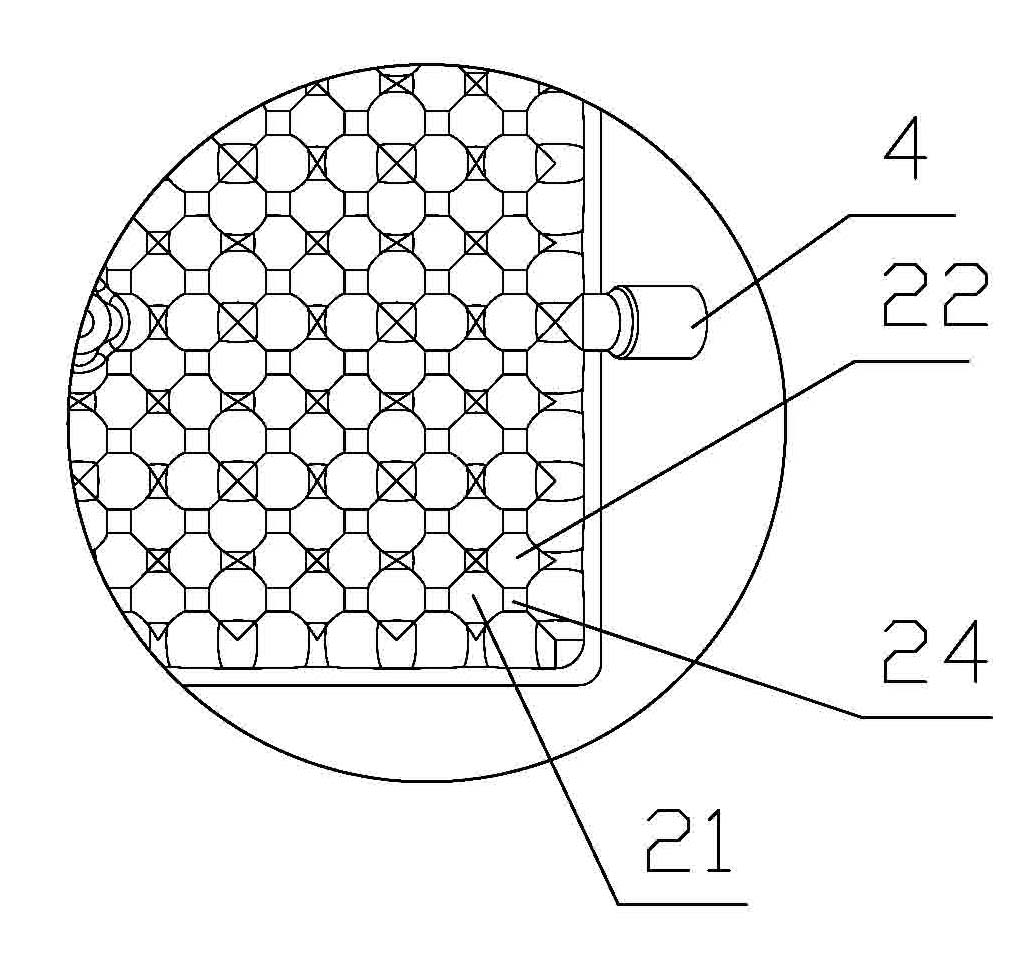

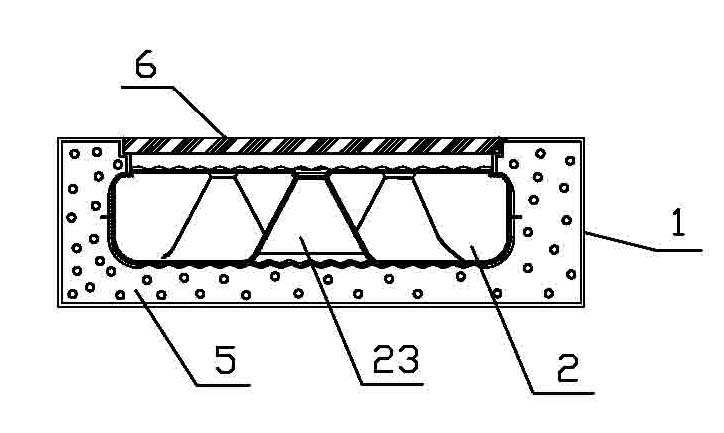

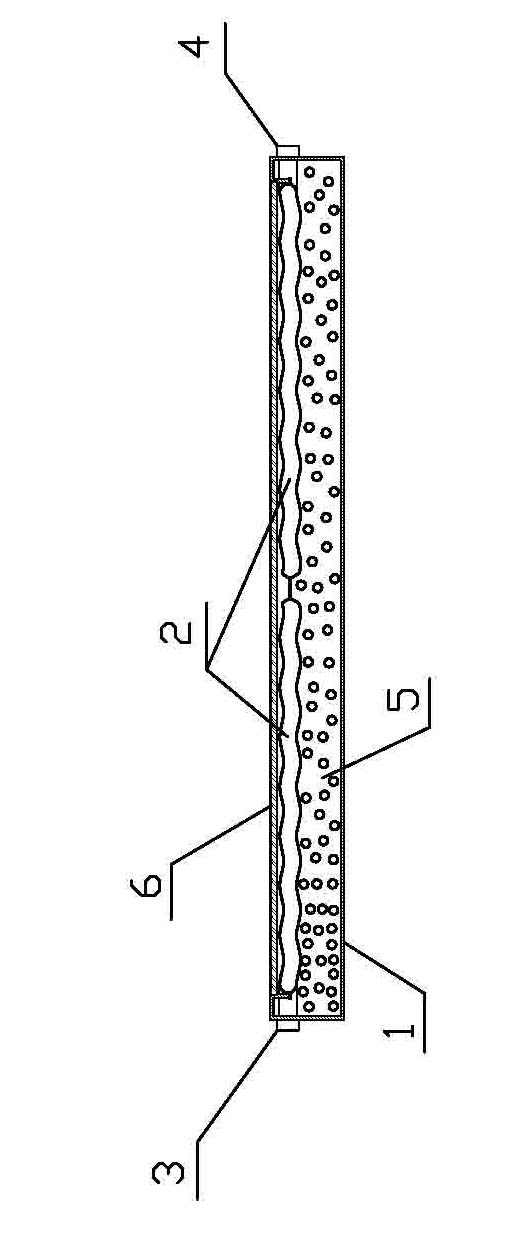

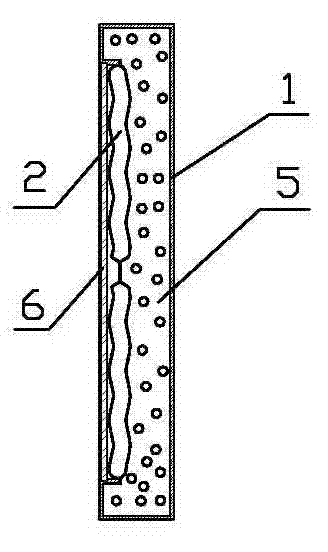

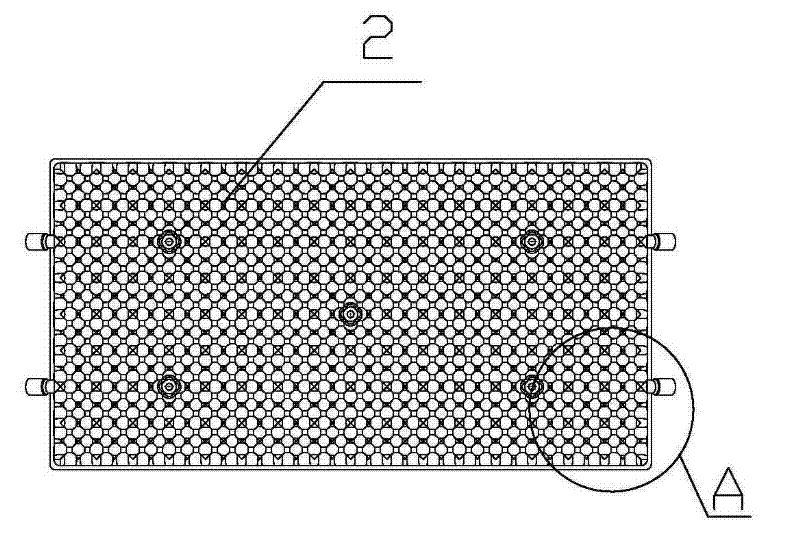

InactiveCN101907360ANo scaleSmall footprintSolar heating energyCollector element reinforcementPlastic materialsSolar water

The invention relates to a plastic inner liner of a water heater, comprising a liner body provided with a cold water inlet and a hot water outlet. The invention is characterized in that the liner body comprises a plurality of parallel horizontal pipes and a plurality of parallel longitudinal pipes; and the horizontal pipes and the longitudinal pipes are positioned on the same plane and are connected with each other by interpenetration. The plastic inner liner of the water heater adopts pipe network type plate structure, has strong pressure bearing capacity, secure structure and good water mobility, can be manufactured by plastic materials, does not produce scale, resists corrosion, occupies less space and is convenient to design and install.

Owner:王涵琳 +1

Supercritical cogeneration device

InactiveCN108506050AIncrease the heat exchange areaHigh thermal efficiencyCombustion technology mitigationSteam superheatersCooling towerCombustion chamber

The invention discloses a supercritical cogeneration device. The supercritical cogeneration device mainly comprises a fused salt tank, a combustion chamber, a smoke tank, an air preheating box, an ashconveyer, a burner, a waste heat recovery water tank, a high-pressure plunger pump, a high-pressure spraying device, a steam generator, a steam coil pipe, a steam collection box, a steam manifold, asteam turbine, an electric generator, an electric heater, a steam collision device, a water gas coil pipe, a matter thermal decomposition coil pipe, a cyclone separating column, a condensation reduction bed, a conveyer, a fan, a cooling tower and the like. The supercritical cogeneration device has the advantages that overheat steam is generated instantly, and the heat efficiency is very high; thetemperature and pressure of steam are adjustable; waste heat recovery is carried out in a multistage manner, and the exhaust gas temperature is low; no scale is formed, no sewage is drained out, and no exhaust gas is emitted; according to the matter thermal decomposition function, high efficiency and energy saving are achieved, and decomposition is complete; water gas is generated at the top speedcontinuously; and one machine is used in multiple ways, and cogeneration and industrial technology integration are achieved.

Owner:广西汽能壹号节能技术有限公司

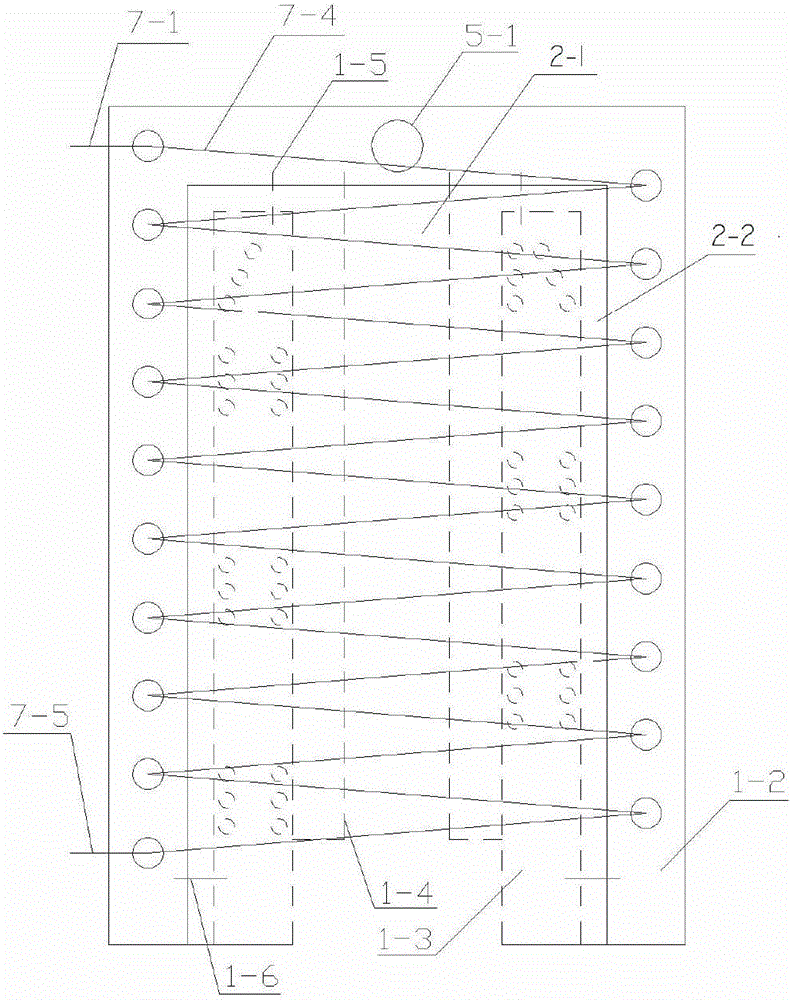

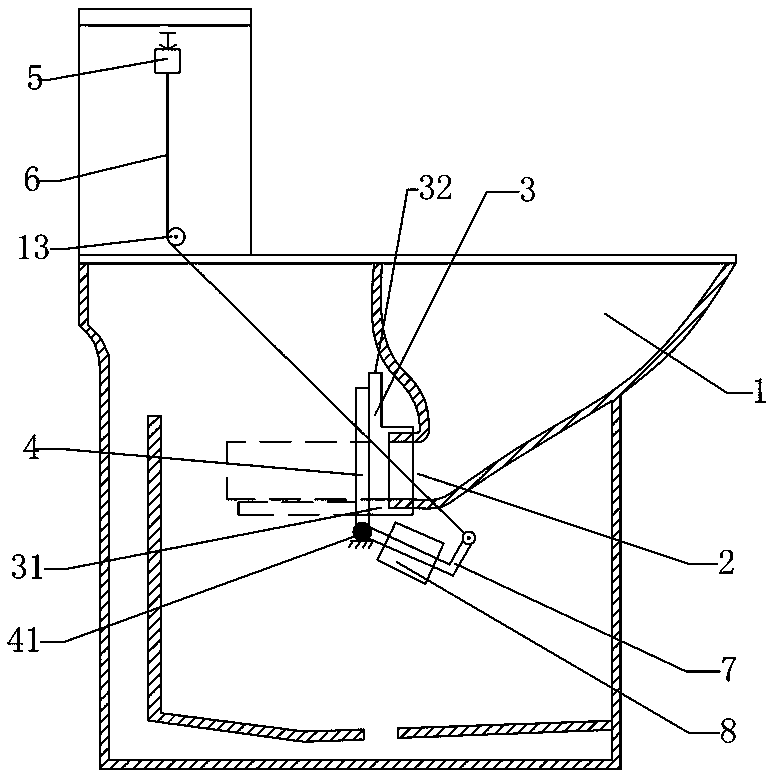

Water-scale-free electric water heater

InactiveCN106871454AHigh activityStrong potential energyFluid heatersWater/sewage treatment by magnetic/electric fieldsEngineeringChina clay

The invention belongs to electric water heaters, and discloses a water-scale-free electric water heater. According to defects in the prior art, due to long-time use, water scales are generated on the inner wall of an electric water heater, an electric heating pipe and the inner wall of a water outlet pipe, power consumption is increased, and the service life of the electric water heater is short. According to the water-scale-free electric water heater, a water treatment plate support (3) is arranged in an electric water heater box body (1), and a water treatment plate (2) is fixed to the water treatment plate support (3) through bolts (5); and the water treatment plate (2) is prepared from, by weight, 8 parts of stone needles, 10 parts of magnets, 5 parts of tourmaline, 70-73 parts of china clay and 4-7 parts of wood bits, raw materials are crushed, mixed and added with a proper amount of water to be stirred and made into a cuboid, the cuboid is placed into an electric furnace to be roasted for 24 h at the temperature being 1000 DEG C and is taken out and cooled to normal temperature, and the water treatment plate is mounted on the water treatment plate support (3). The water-scale-free electric water heater has the beneficial effects that after long-time use, no water scale is generated on the electric water heater box body, an electric heating pipe and a water outlet pipe; power consumption is reduced; and the service life of the electric water heater is prolonged.

Owner:刘华文

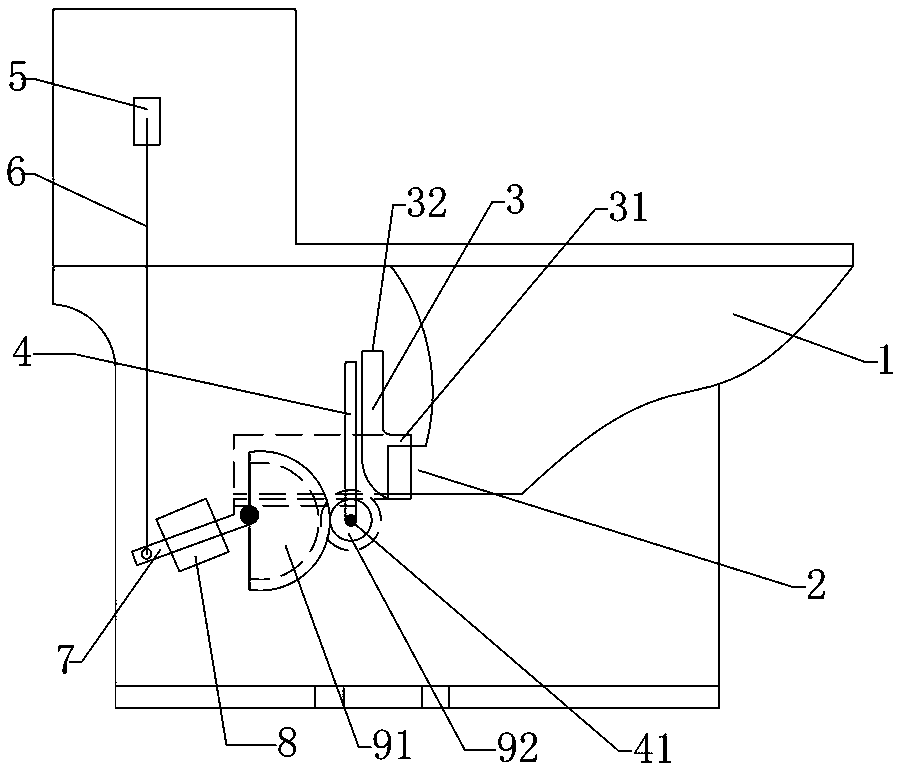

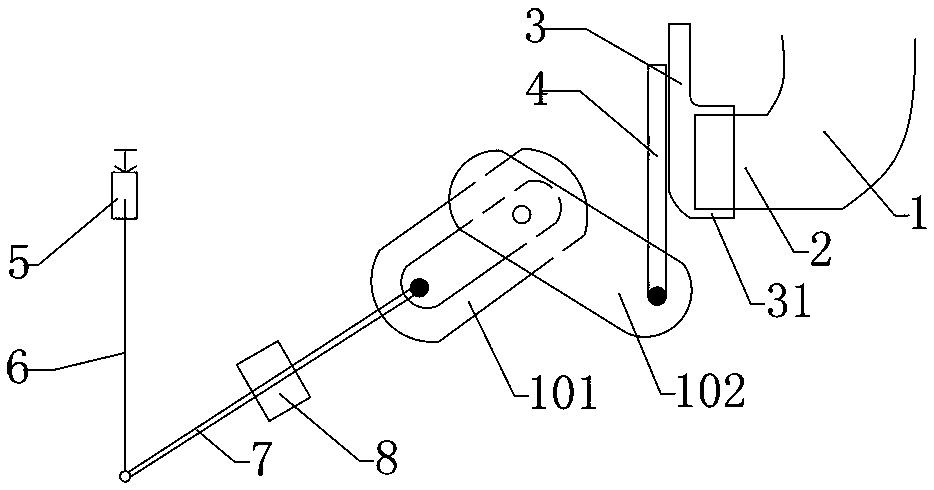

Direct-drain-type water-saving toilet with up-down-displaced sewage draining exit

The invention provides a direct-drain-type water-saving toilet with an up-down-displaced sewage draining exit. The toilet comprises a toilet body, an outer guide tube is arranged at a discharging partin the bottom of the toilet body, a flexible casing is in sleeving connection with the water outlet end of the outer guide tube, and the sewage draining exit is formed in the free end of the flexiblecasing; a turning plate which can control turning-on and turning-off of the flexible casing is arranged on the toilet body, a turning plate control mechanism is further arranged on the toilet body, and the turning plate control mechanism is used for controlling the overturning action of the turning plate. When the sewage draining exit of the flexible casing is higher than the water outlet end, acertain height of water can be stored in the toilet body, and the problem of dirty pool of a waterless toilet during use is solved; when the sewage draining exit is lower than or as as high as the water outlet end, flushing water is directly discharged, no incrustation is generated, the water use amount is little, and flushing is clean. According to the direct-drain-type water-saving toilet with the up-down-displaced sewage draining exit, the flexible casing is always in a deformed state, incrustation and a urine alkali layer cannot be generated on the inner wall of the flexible casing, the problem of pipe blockage is solved, and the toilet is long is service life.

Owner:石家庄多朋商贸有限公司

Device for thermal separation of solid fuel and molten salt integrated boiler

InactiveCN105841139BIncrease the heat exchange areaHigh thermal efficiencyFluidized bed combustionSuperheating controlCooling towerCyclonic separation

The invention discloses a device for matter heat separation of a solid fuel and fused salt integrated boiler. The device is mainly composed of an expansion groove, fused salt grooves, fused salt guide pipes, an insulating layer, a burning cavity, an air preheating recoverer, an air blower, another air blower, a centrifugal fan, circulation burning pipes, a waste heat recovery water tank, a combustion air cavity, a fuel preheating coil pipe, a high pressure plunger pump, a steam coil pipe, a steam header, a steam generator main body, a high pressure spraying device, a desulfurization and denitrification device, a dedusting lime water pool, a spraying head, a circulation water pump, an induced draft fan, a chimney, a solid matter conveyor, a liquid matter conveyor, a matter decomposing coil pipe, a cyclone separation tower, a decomposing reduction chamber and a cooling tower. The device has the beneficial effects that fused salt of a fused salt constant temperature system is directly heated in a hearth, and the steam pipe temperature and the heat decomposing pipe temperature are controlled by heat of the fused salt; jet fog enters a steam pipe to obtain steam; and materials enter a heat decomposing pipe to conduct matter decomposing. The device further has the beneficial effects that a steam decomposing and separating technology is adopted for replacing an existing decomposing and separating technology, and the problems of complex technological processes, equipment and the like are solved.

Owner:赖正平 +1

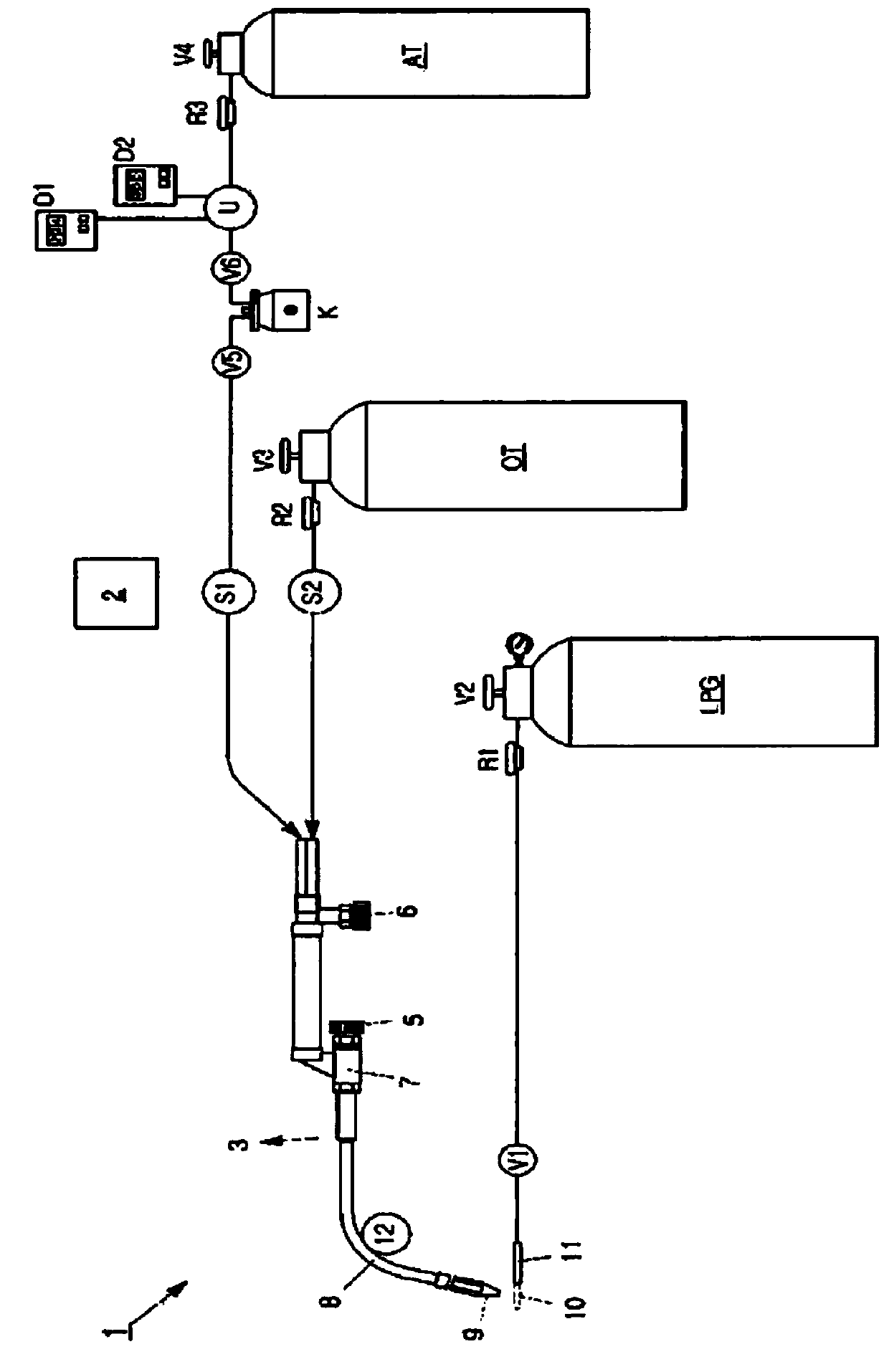

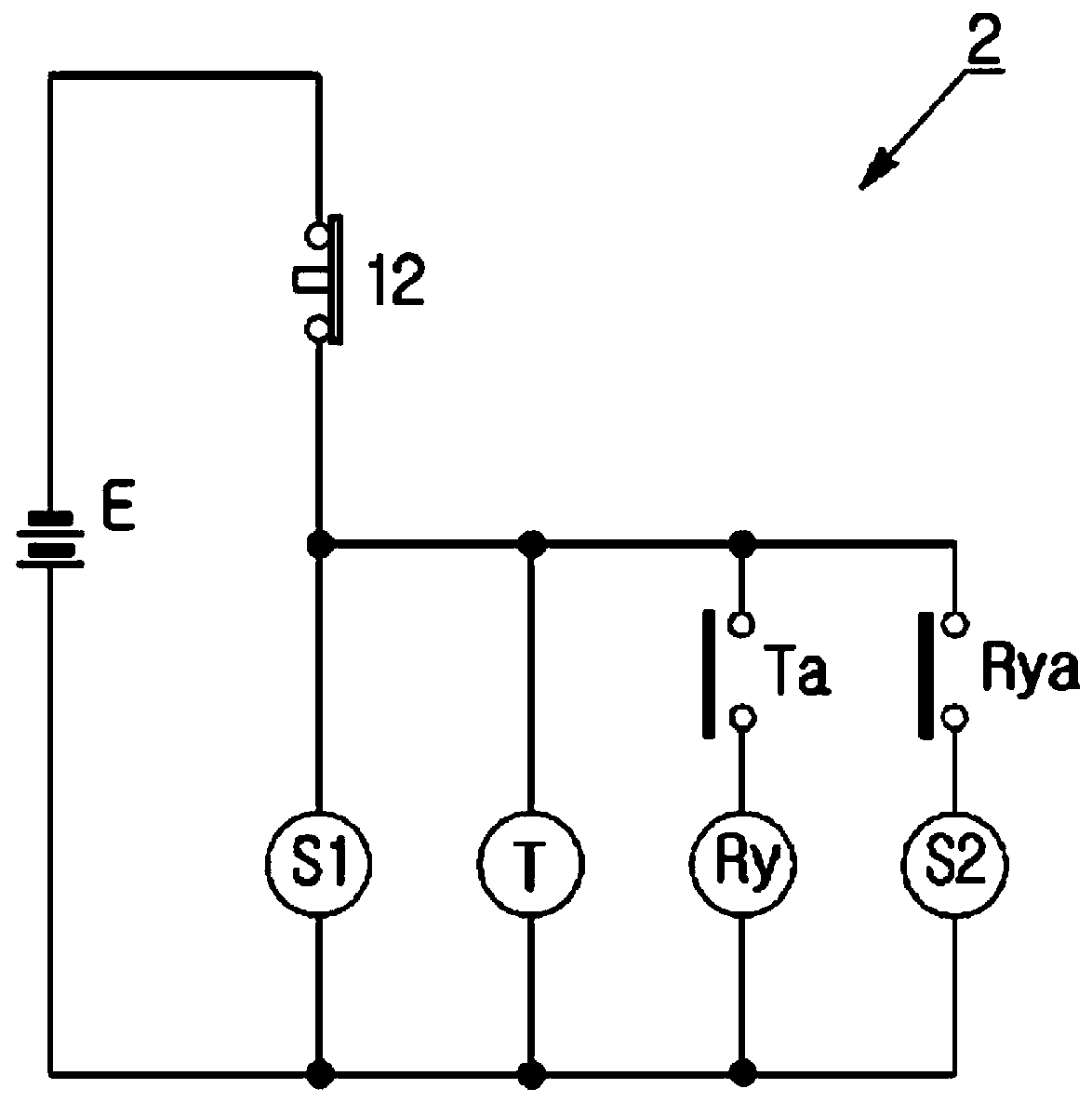

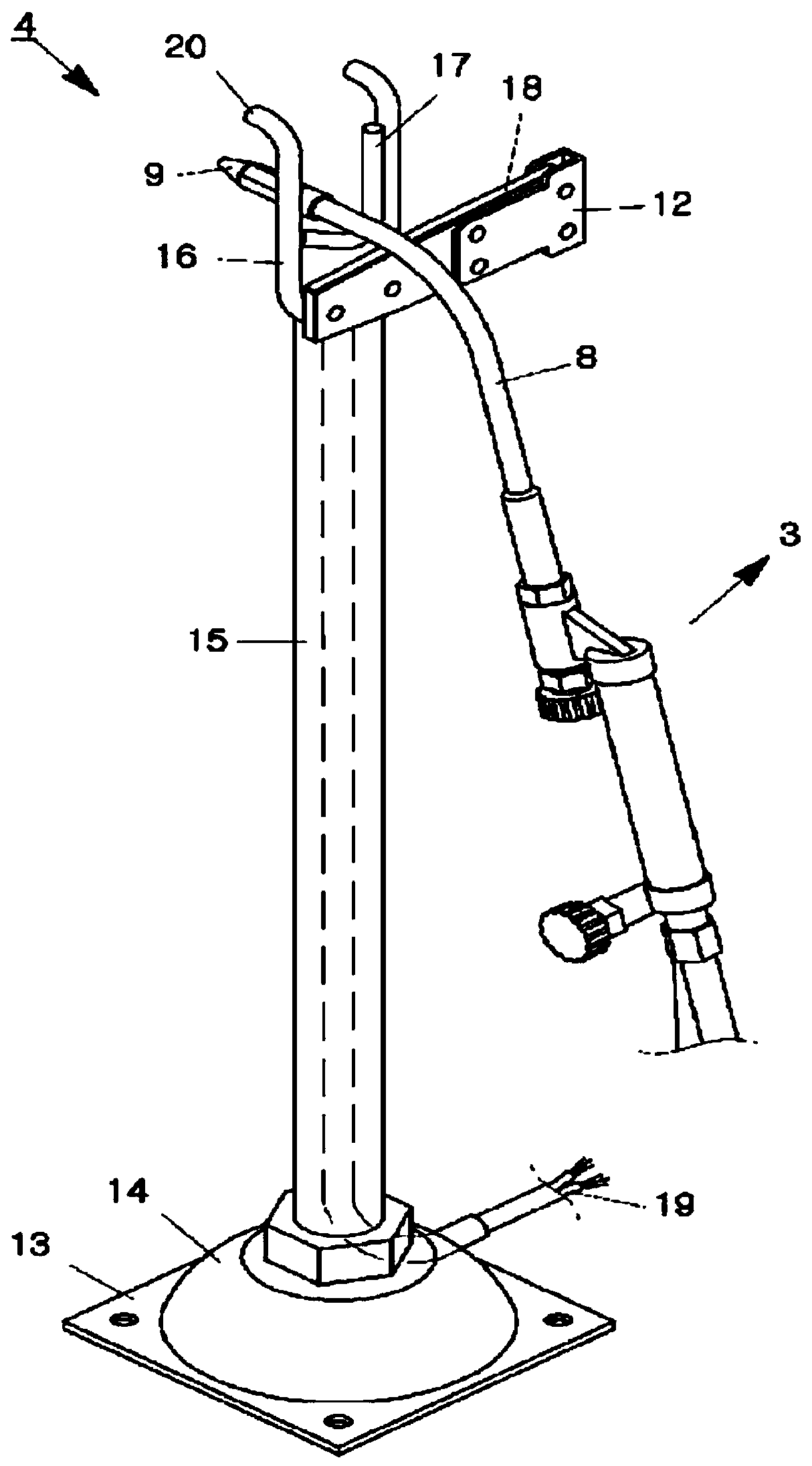

Fuel saving gas welding apparatus

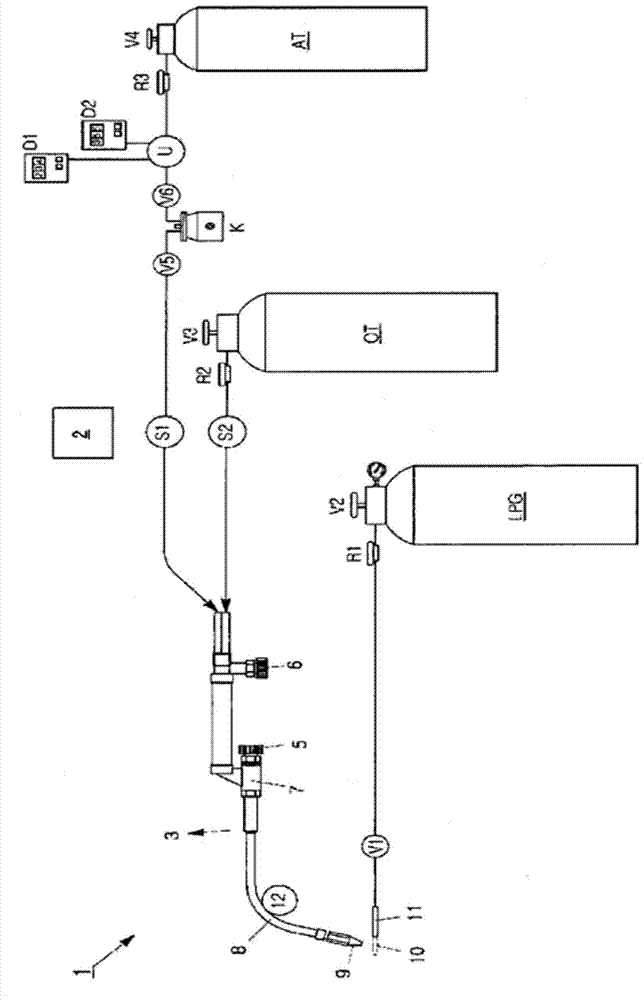

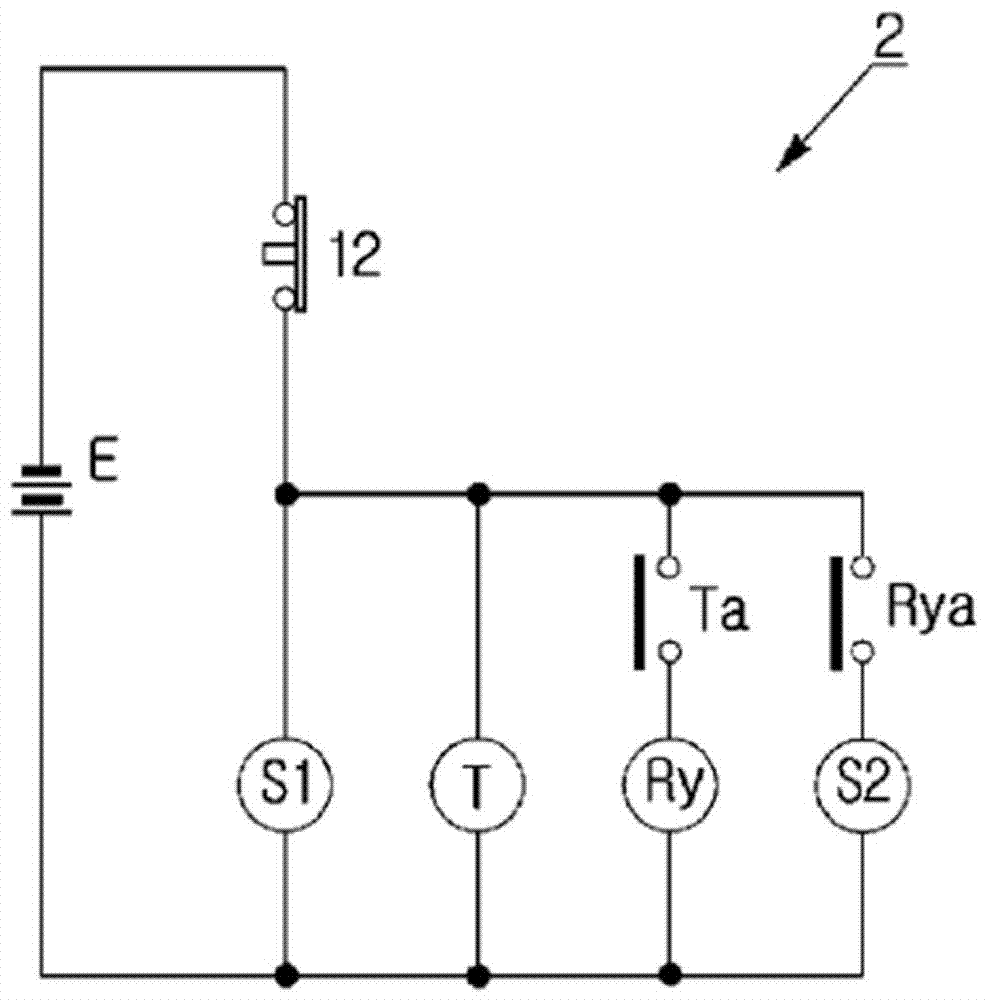

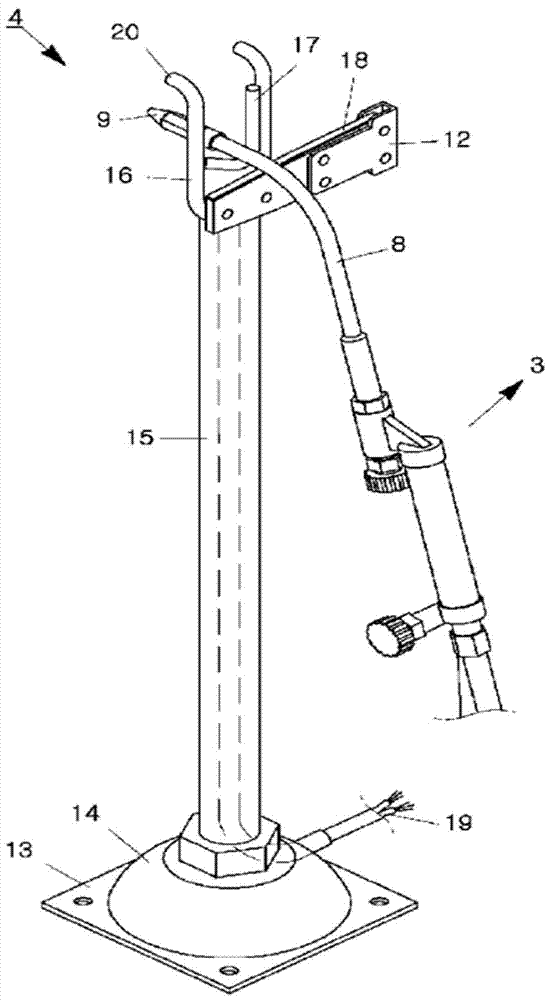

InactiveCN107249799APrevent gas backflow and backfireSave gasWelding/cutting auxillary devicesAuxillary welding devicesOxygen supplyTimer

The present invention relates to a fuel saving gas welding apparatus that comprises: an oxygen gas supply unit that supplies an oxygen gas to a welding torch (3); a fuel gas supply unit that supplies a fuel gas to the welding torch (3); an ignition gas supply unit that supplies flame required for the ignition of the welding torch (3); and a control means (2) that discharges the fuel gas with a delay of 0.2 to 1 second after the oxygen gas to prevent reverse flow and flash back, wherein the fuel gas (e.g., acetylene gas) is supplied with a delay of 0.2 to 1 second after the oxygen gas by using a delay timer (T), a relay (Ry), a switch (12), and solenoid valves (S1) (S2), which makes it possible to prevent reverse flow and flash back in the welding torch (3), to significantly reduce the fuel gas by 30% or more, and to enhance the productivity by 30% or more.

Owner:李昌熙

Quantum sterile water dispenser

InactiveCN104545451AImprove flexibilityPromote absorptionBeverage vesselsOzone generatorActivated carbon

The invention discloses a quantum sterile water dispenser. The quantum sterile water dispenser is characterized in that one end of a quantum water activator is connected with a water inlet; the other end of the quantum water activator is connected with an ozone generator; a heater is arranged at the bottom of the quantum sterile water dispenser; one end of the heater is connected with a water tank; the water tank is connected with the ozone generator; the other end of the heater is connected with activated carbon; the activated carbon is connected with a water valve through a water pipeline; a water wheel head is arranged at the other end of the water valve; a main controller and an audio frequency sensing module are arranged on the top part of a shell of the quantum sterile water dispenser; one end of the main controller is connected with the audio frequency sensing module. Due to the fact that the quantum water activator is arranged at the water inlet of the quantum sterile water dispenser provided by the invention, and the quantum water activator can change water with macromolecules into the water with micromolecules, the tenderness of the water is increased, scales are not generated in the whole device, and the water is easily absorbed by a human body.

Owner:TIANJIN WEIKANG MEDICAL APPLIANCE

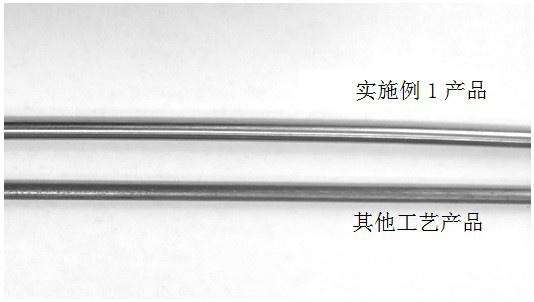

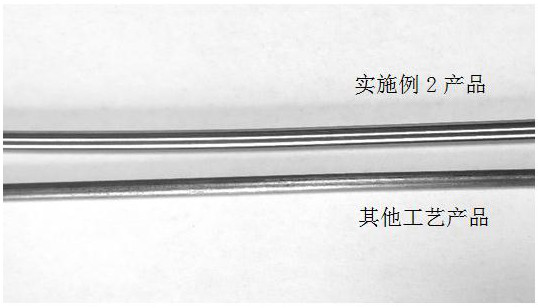

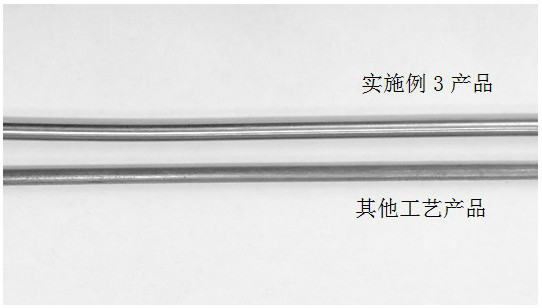

Production method of invar steel wire with high surface quality

PendingCN114130849AGuarantee metallurgical qualityAvoid heavy scaleTemperature control deviceBelt grinding machinesWater coolingMill scale

The invention discloses a production method of a high-surface-quality invar steel wire. The production method comprises the working procedures of vacuum melting, electroslag remelting, forging blank forming, rolling, cold drawing and aging heat treatment. The rolling procedure comprises the steps of high-temperature blooming, high-temperature temperature compensation and spinning water cooling; in the high-temperature temperature compensation step, the temperature is compensated to 1100-1200 DEG C, and the temperature compensation time is 0.5-2 hours; a cold-drawing process: performing peeling and double-abrasive-belt polishing treatment before drawing to the last but one pass or when drawing to D > d + 0.8 mm, and then continuing drawing; wherein D is the diameter of mm of the wire in the drawing process, and d is the diameter of mm of the finished wire; and in the aging heat treatment process, a protective atmosphere is adopted for annealing treatment. The method is suitable for producing invar steel wires with the diameter of 3.0-6.5 mm, the produced wires are bright in surface, free of oxide skin, scratches and drawing powder residues and good in mechanical property, the tensile strength of the wires is larger than or equal to 1100 MPa, and the percentage elongation after fracture at the gauge length of 250 mm is larger than or equal to 5%.

Owner:HEBEI IRON AND STEEL +3

Solar water heater

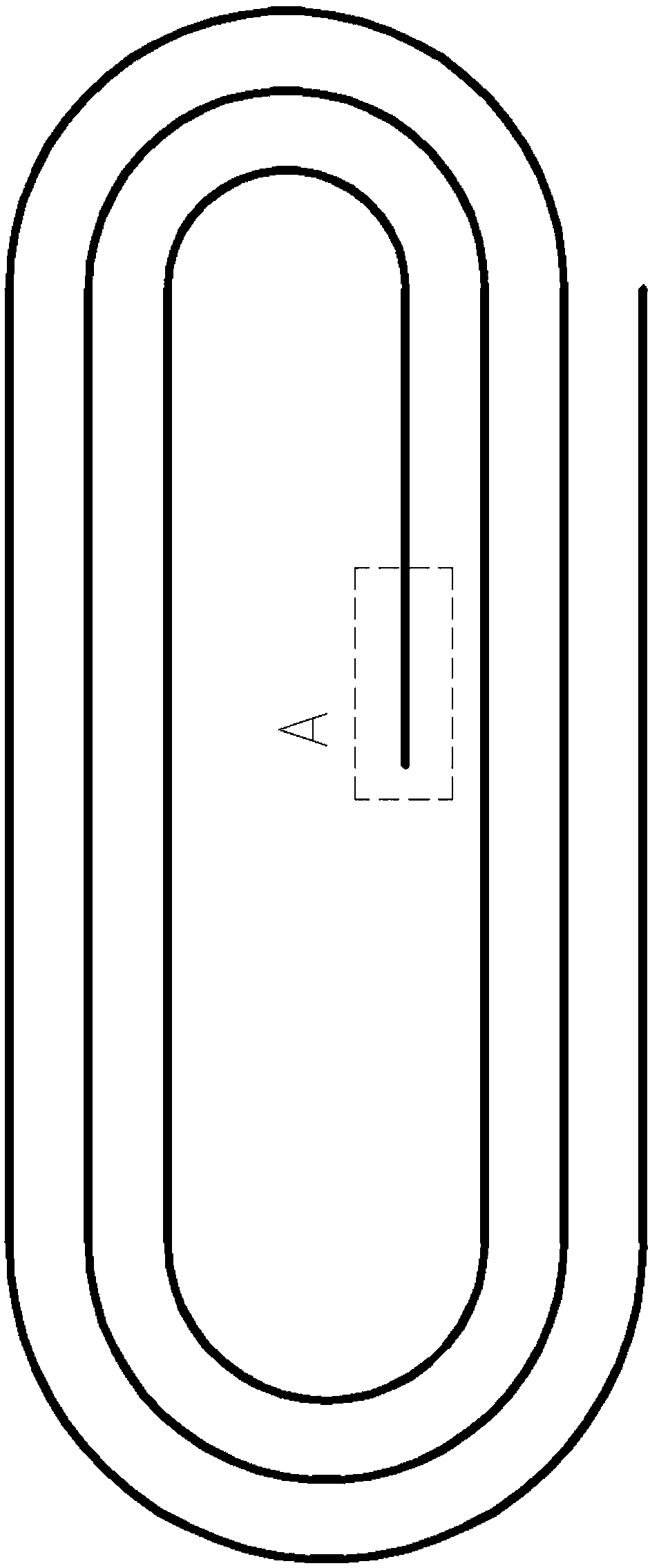

InactiveCN101907360BNo scaleSmall footprintSolar heating energyCollector element reinforcementPlastic materialsSolar water

The invention relates to a plastic inner liner of a water heater, comprising a liner body provided with a cold water inlet and a hot water outlet. The invention is characterized in that the liner body comprises a plurality of parallel horizontal pipes and a plurality of parallel longitudinal pipes; and the horizontal pipes and the longitudinal pipes are positioned on the same plane and are connected with each other by interpenetration. The plastic inner liner of the water heater adopts pipe network type plate structure, has strong pressure bearing capacity, secure structure and good water mobility, can be manufactured by plastic materials, does not produce scale, resists corrosion, occupies less space and is convenient to design and install.

Owner:王涵琳 +1

Infrared Radiant Ceramic Heater

InactiveCN101505554BHeating up fastReduce consumptionImmersion heating arrangementsHeating element shapesYarnFiber

The invention discloses an infrared radiation ceramic heater, which comprises a quartz outer tube and a quartz inner tube. A silicon carbide rod is installed in the cavity, and the diameter of the through hole set in the middle of the quartz inner tube is equal to and greater than or equal to the length of the quartz outer tube. Silicon pad. The invention is mainly used for medium heating of heaters, and can also be used for heating in industrial production, especially for heaters using water circulation. The product of the invention can directly heat the water, so that the temperature of the water rises quickly. The water absorbs heat through the quartz outer tube and the quartz inner tube, and the thermal efficiency is high. Because the infrared radiation rate is greater than 97%, the energy consumption is low, which is better than that of the existing carbon fiber filament heating. , Electric heating tube heating energy saving 38-45%. Another great advantage of the present invention is that the service life is long, and the shortcoming that electric heating and carbon fiber heating are prone to failures is completely avoided.

Owner:周存文

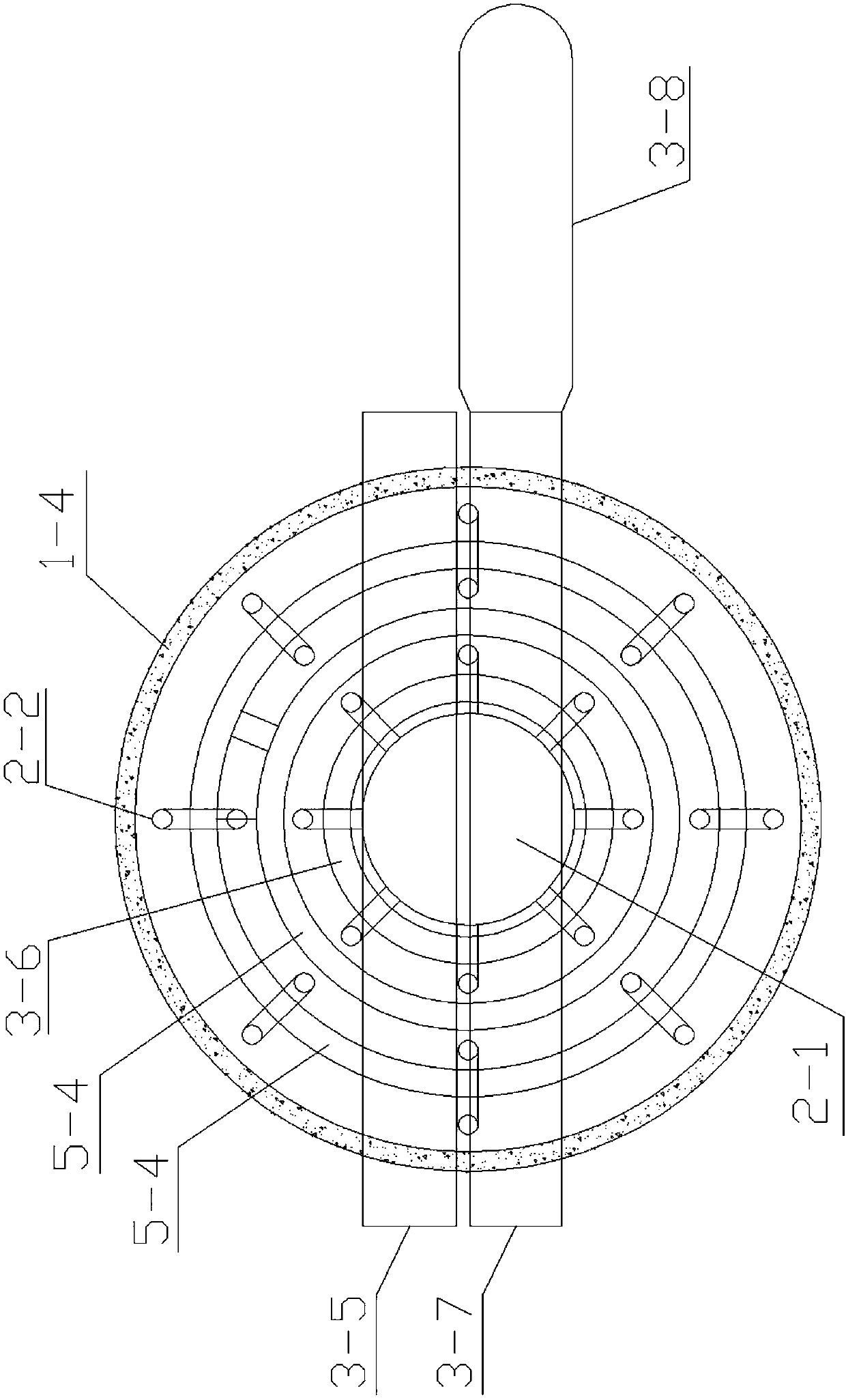

Stainless steel straight-through type medium-temperature heat collector

PendingCN109520146AIncrease the heat exchange areaNo scaleSolar heating energySolar heat collectors with working fluidsMetallurgyParaboloid

The invention relates to the field of medium-temperature solar heat collectors, in particular to a stainless steel straight-through type medium-temperature heat collector. The advantage of light gathering of a composite paraboloid CPC reflector plate and the advantage of heat collecting of a medium-temperature pipe are integrated, and the temperature can reach 200 DEG C. In addition, through the design of stainless steel pipes, flow resistance is reduced, compared with a U-shaped pipe type medium-temperature pipe heat collector, the stainless steel straight-through type medium-temperature heatcollector is more suitable for the large-area solar project, and probability of freezing blockage and overheating is reduced. The stainless steel straight-through type medium-temperature heat collector can be widely applied to the solar medium-temperature industry and agriculture projects.

Owner:SHANDONG LINUO PARADIGMA

Fuel-saving gas welding device

InactiveCN107249799BPrevent backflowPrevent backfireWelding/cutting auxillary devicesAuxillary welding devicesSolenoid valveTimer

The present invention relates to a fuel saving gas welding apparatus that comprises: an oxygen gas supply unit that supplies an oxygen gas to a welding torch (3); a fuel gas supply unit that supplies a fuel gas to the welding torch (3); an ignition gas supply unit that supplies flame required for the ignition of the welding torch (3); and a control means (2) that discharges the fuel gas with a delay of 0.2 to 1 second after the oxygen gas to prevent reverse flow and flash back, wherein the fuel gas (e.g., acetylene gas) is supplied with a delay of 0.2 to 1 second after the oxygen gas by using a delay timer (T), a relay (Ry), a switch (12), and solenoid valves (S1) (S2), which makes it possible to prevent reverse flow and flash back in the welding torch (3), to significantly reduce the fuel gas by 30% or more, and to enhance the productivity by 30% or more.

Owner:李昌熙

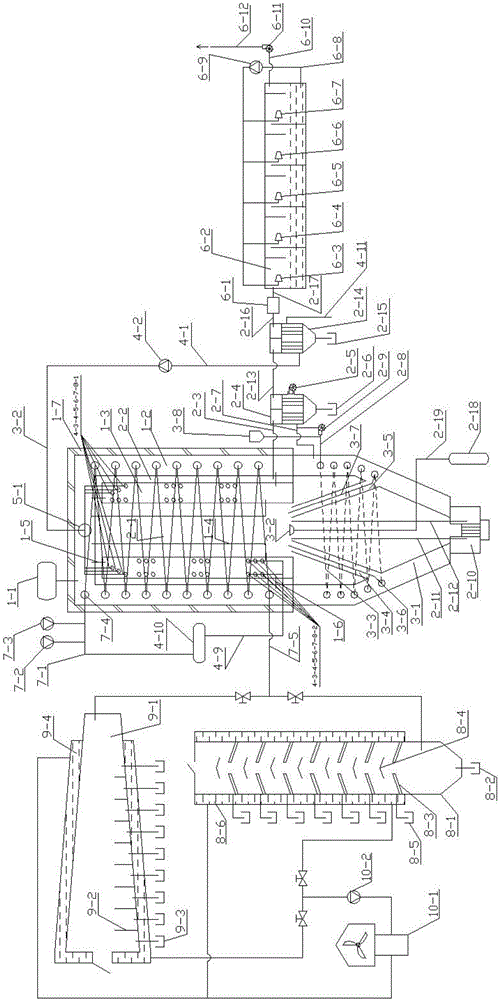

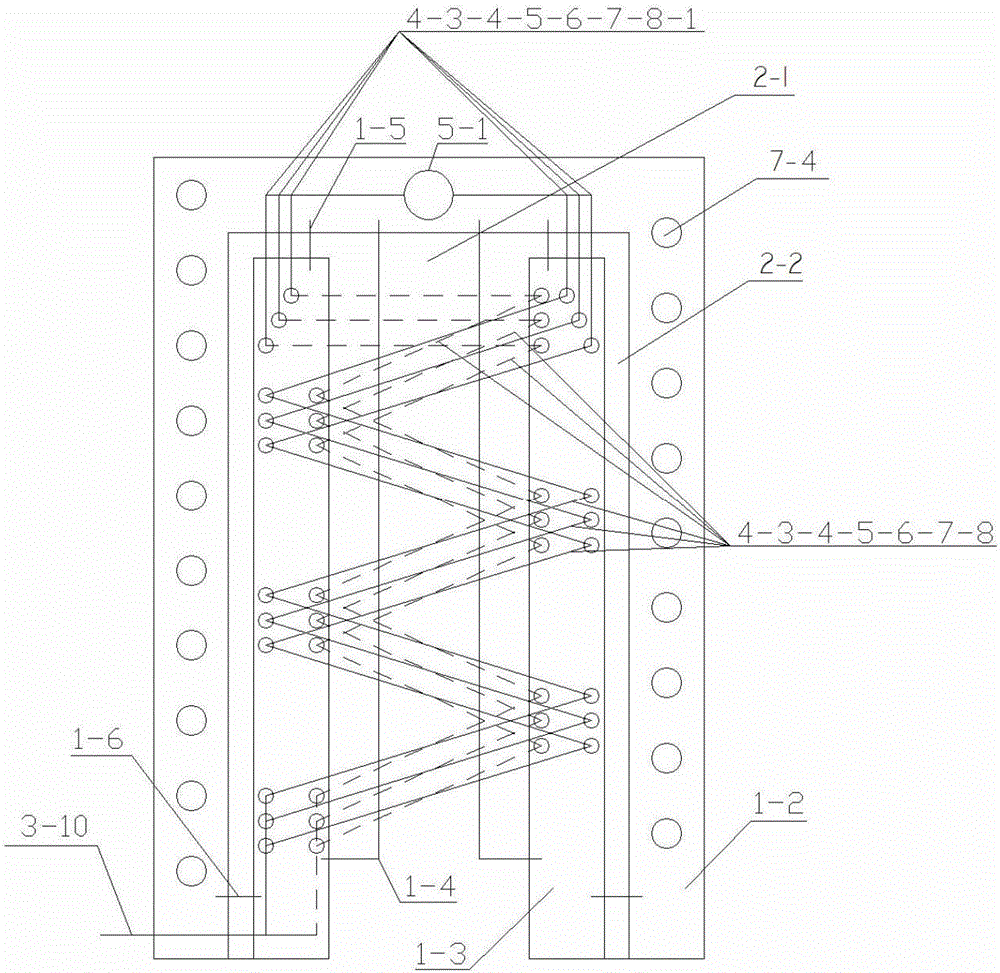

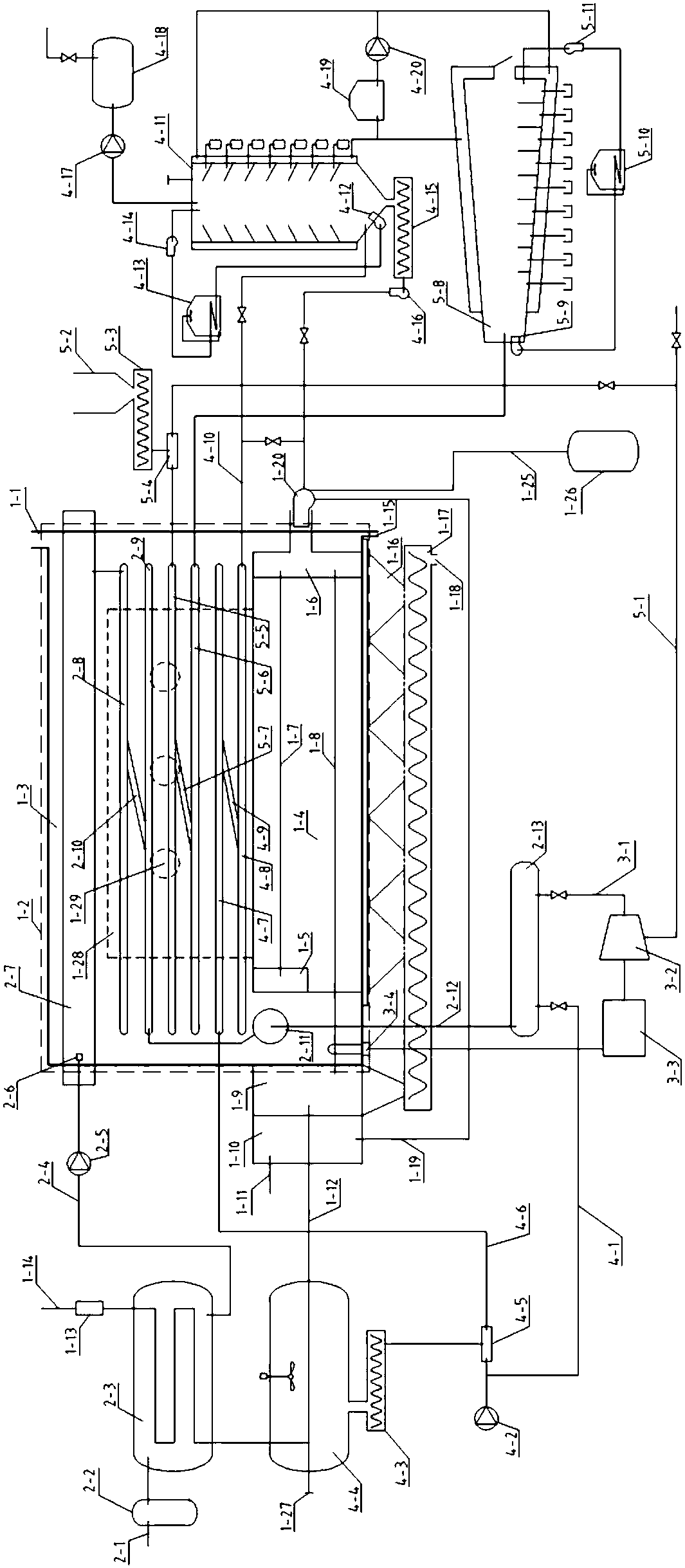

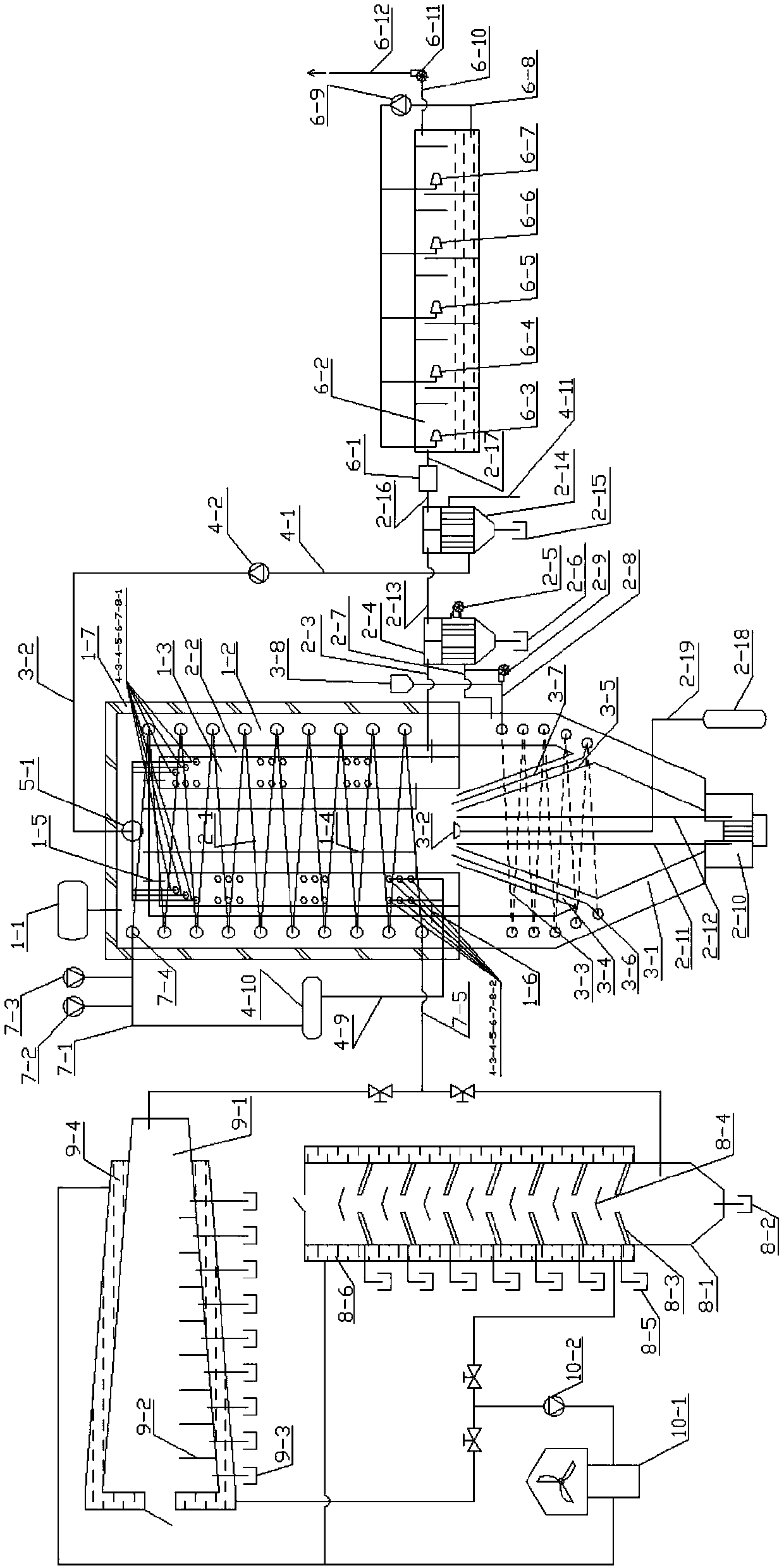

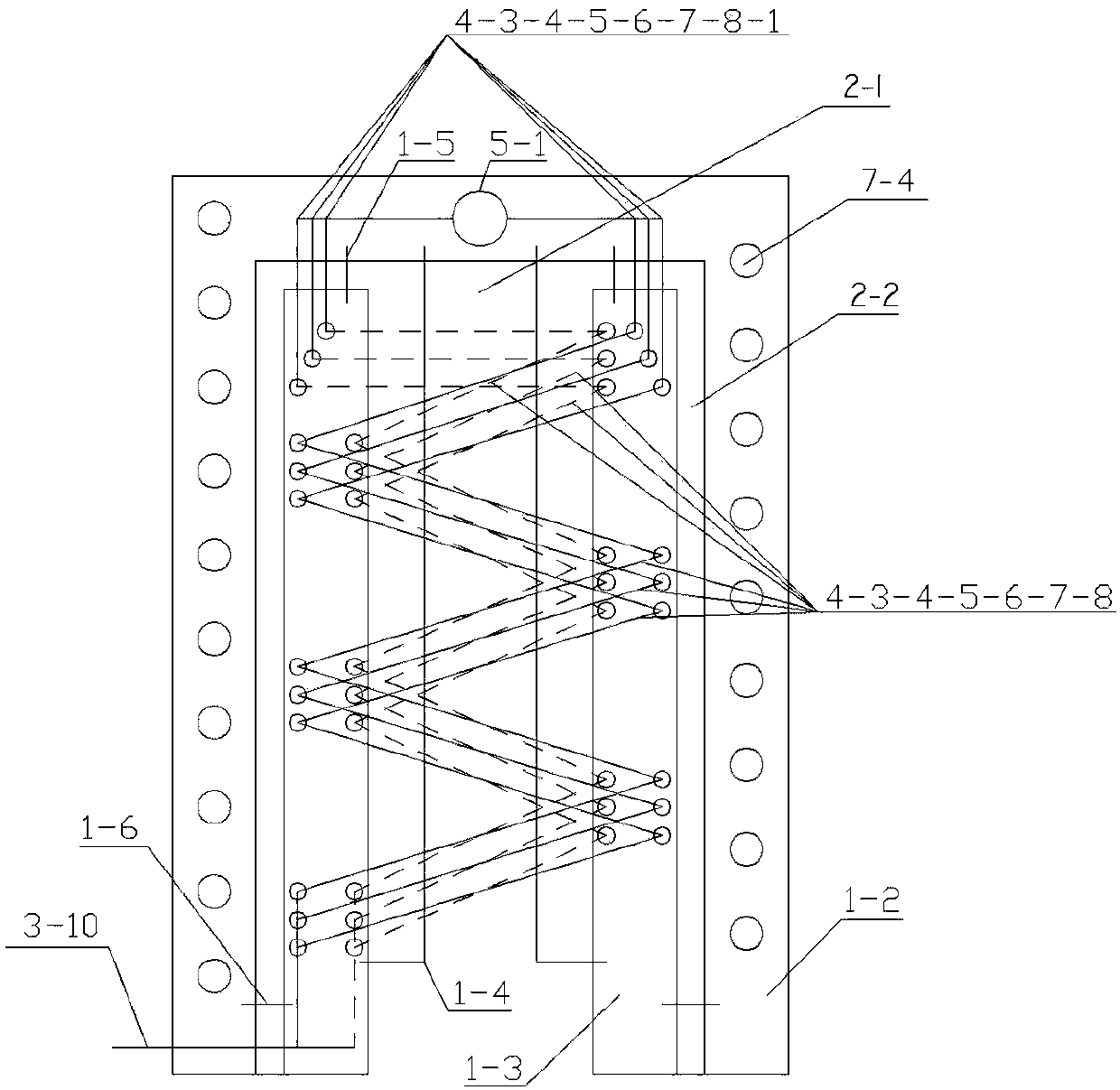

Gas-fired, molten salt integrated steam boiler

InactiveCN105910094BPromote expansionProduced quicklySuperheating controlFluidized bed combustionExpansion tankCombustion chamber

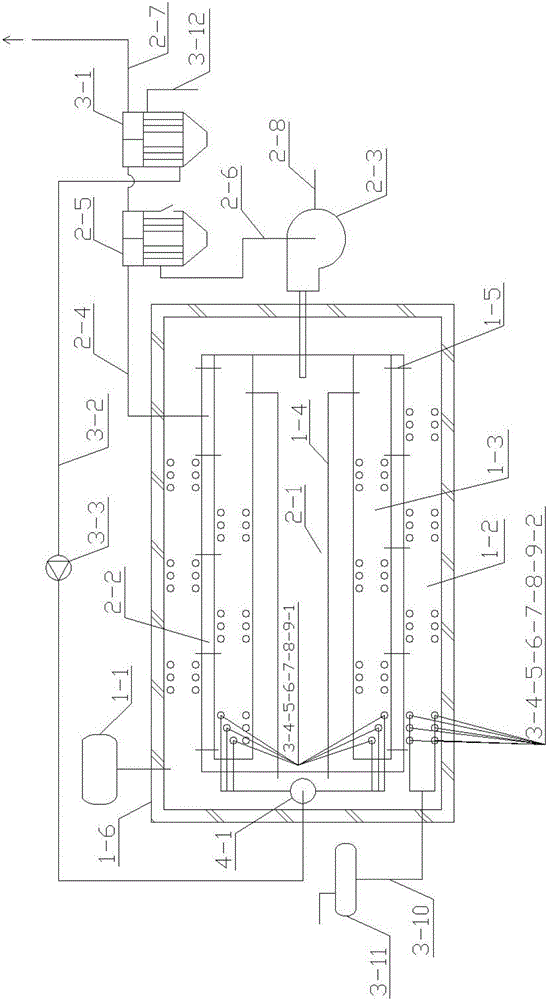

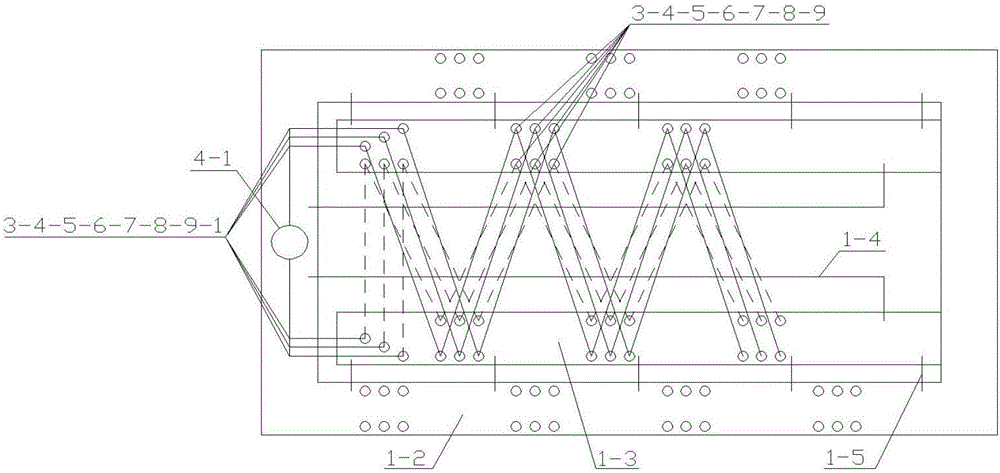

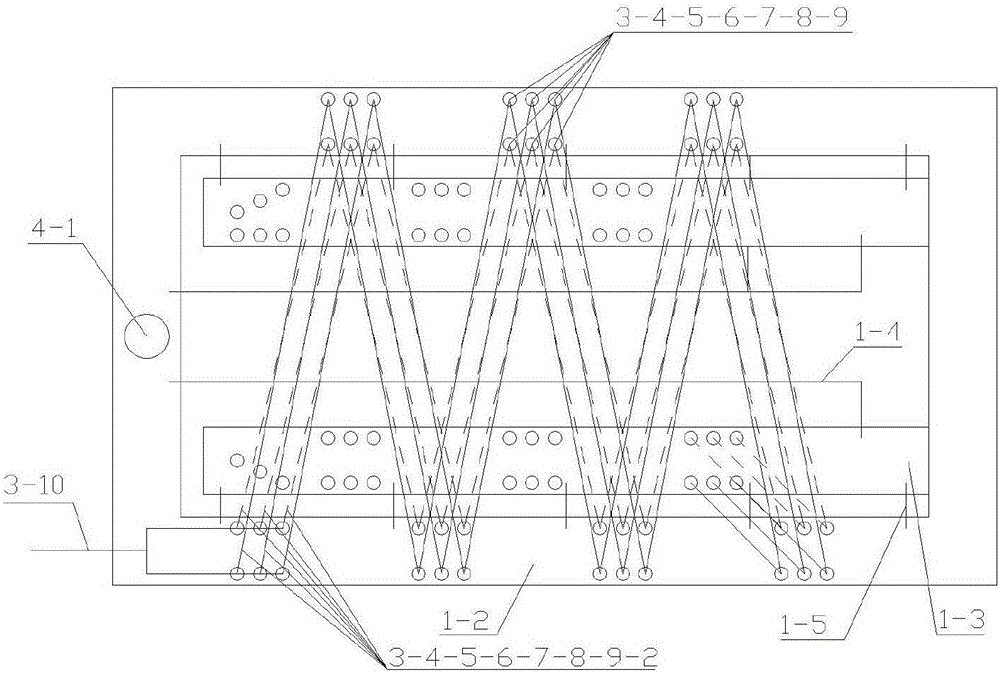

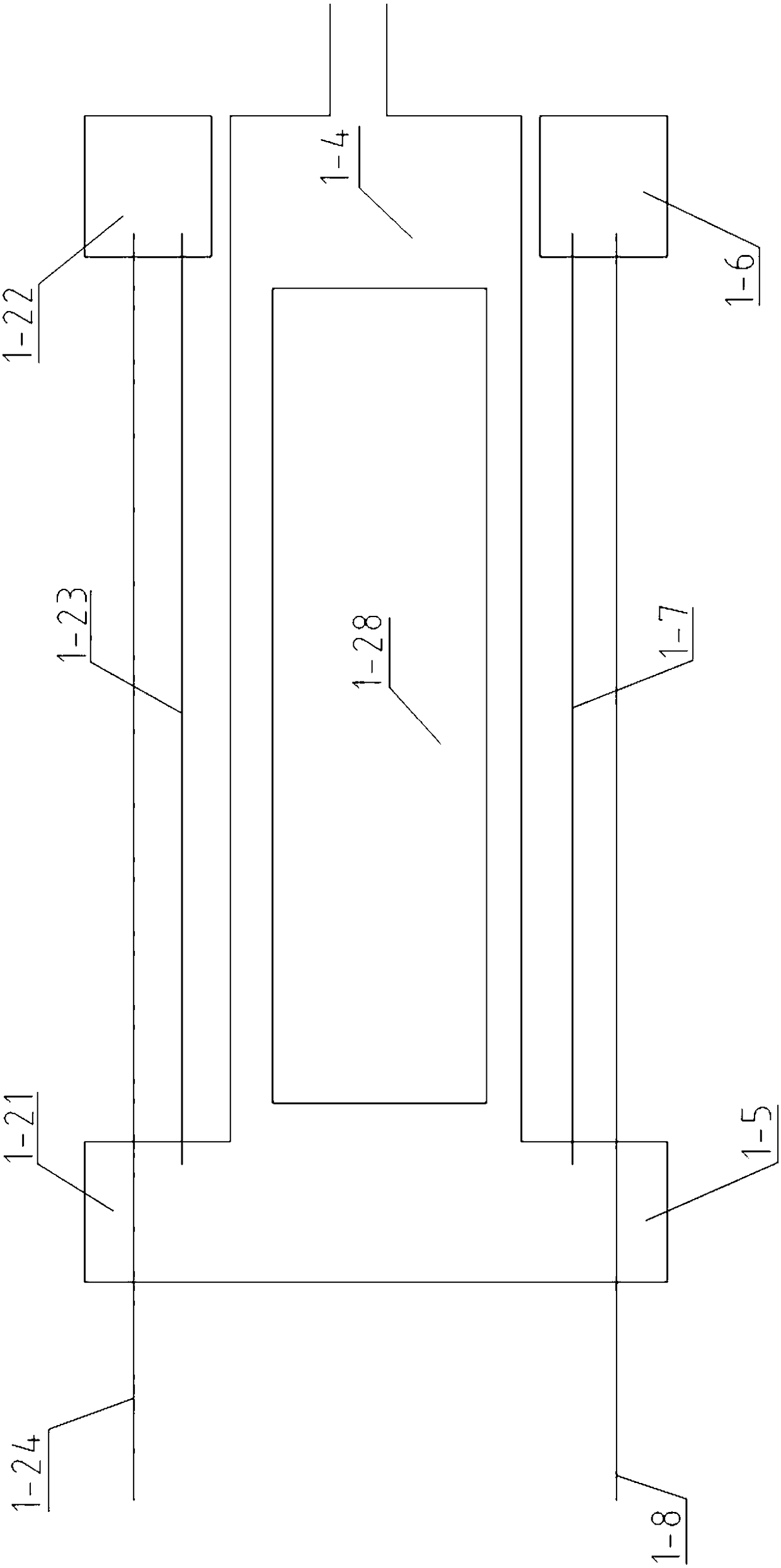

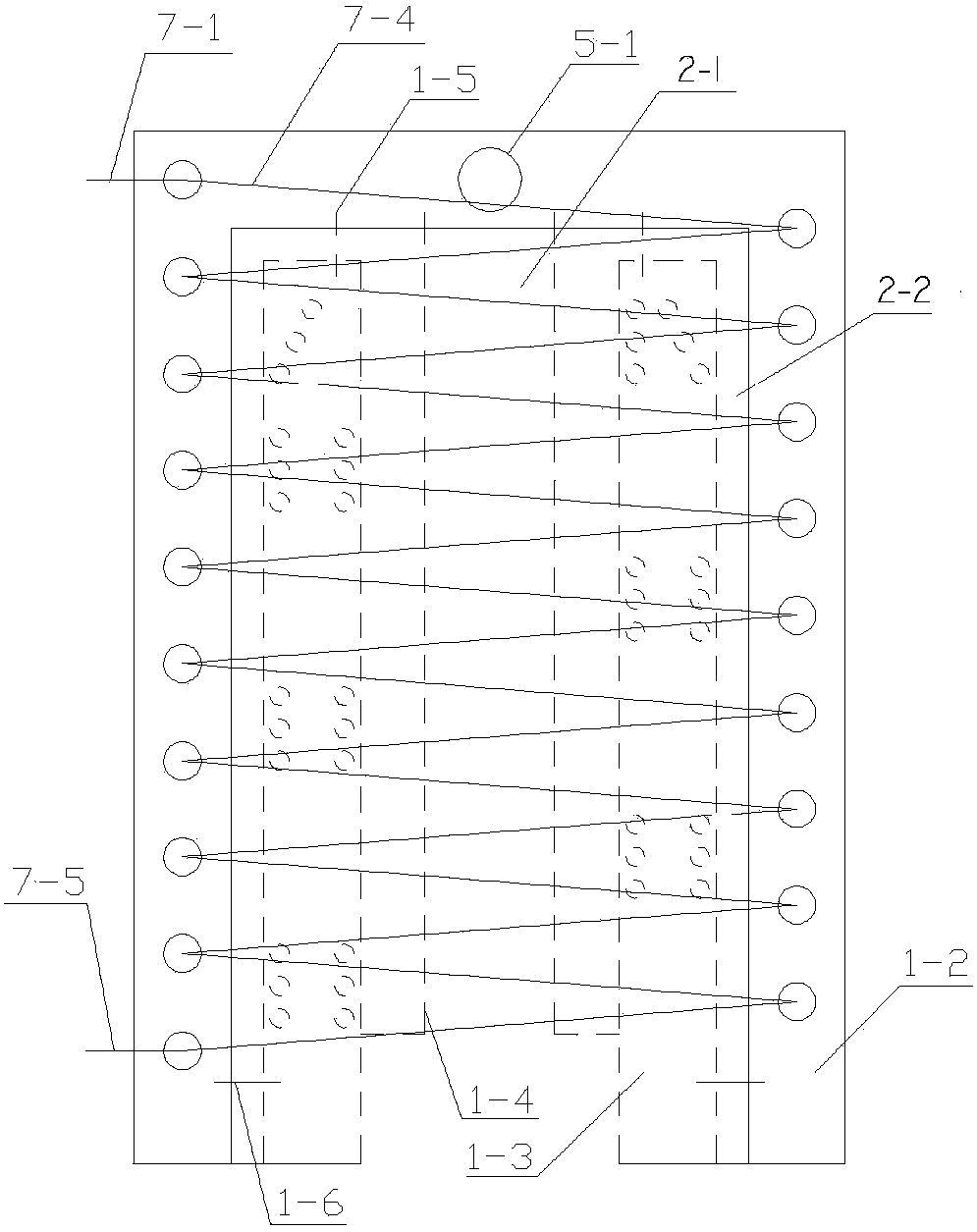

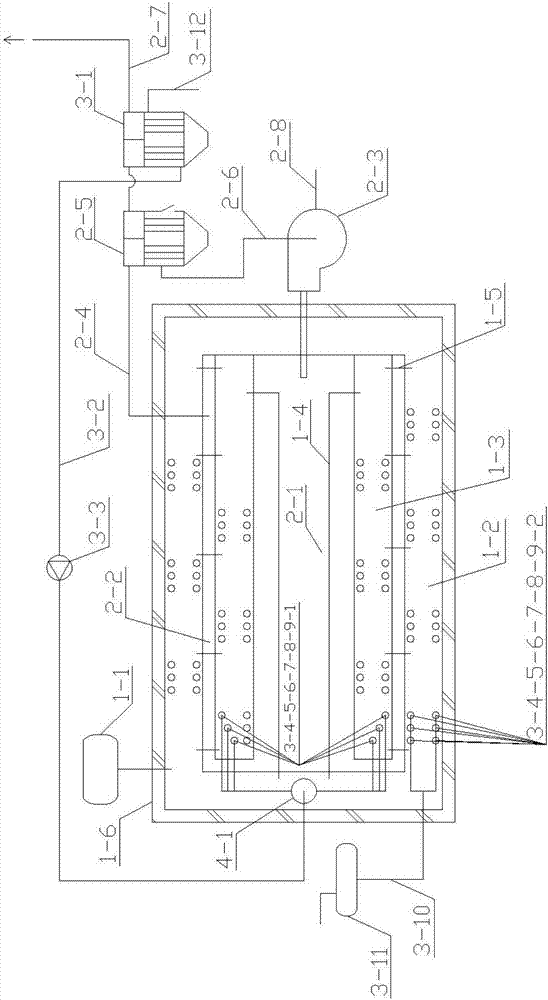

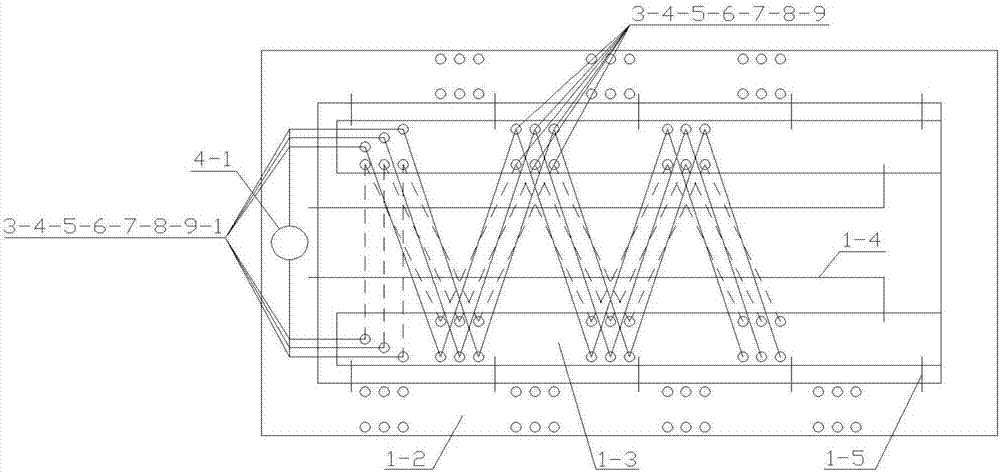

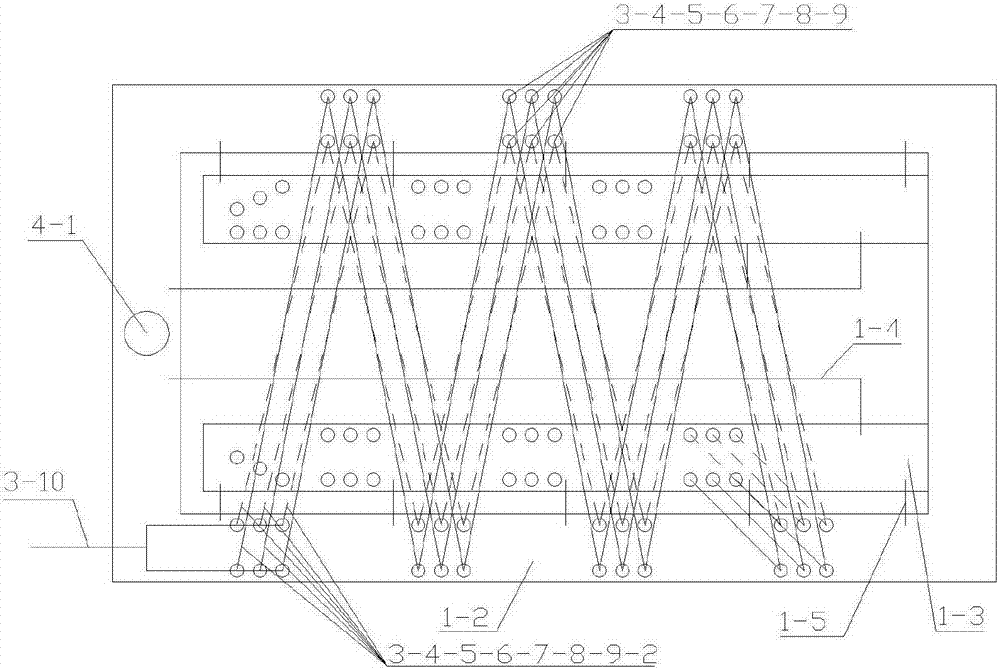

A fuel gas, fuel oil and fused salt integrated steam boiler mainly consists of an expansion tank (1-1), a fused salt tank (1-2, 1-3), a fused salt duct (1-4, 1-5), a thermal insulation layer (1-6), a combustion chamber (2-1), a combustor (2-3), an air preheating recoverer (2-5), a chimney (2-7), a waste heat recycling water tank (3-1), a high-pressure plunger pump (3-3), a steam pipe coil (3-4-5-6-7-8-9), a steam header (3-11), a steam generator main body (4-1), and a high-pressure spraying device (4-2, 4-3).

Owner:赖正平 +1

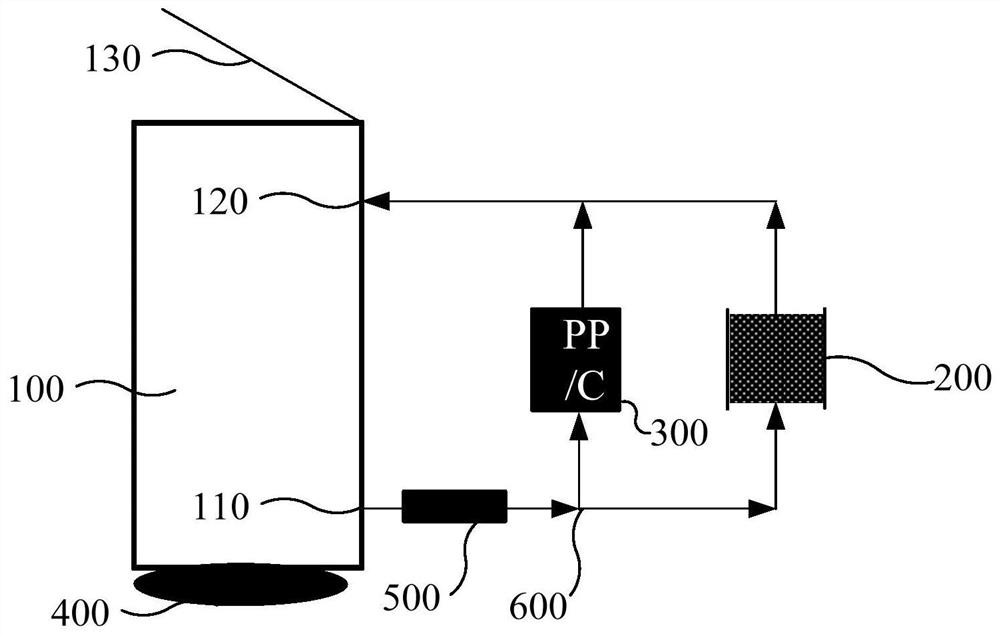

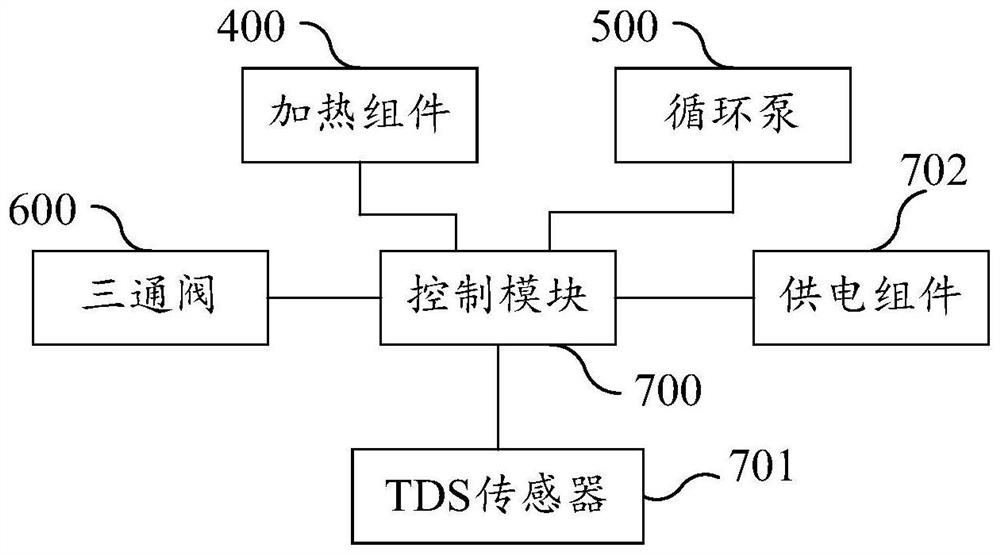

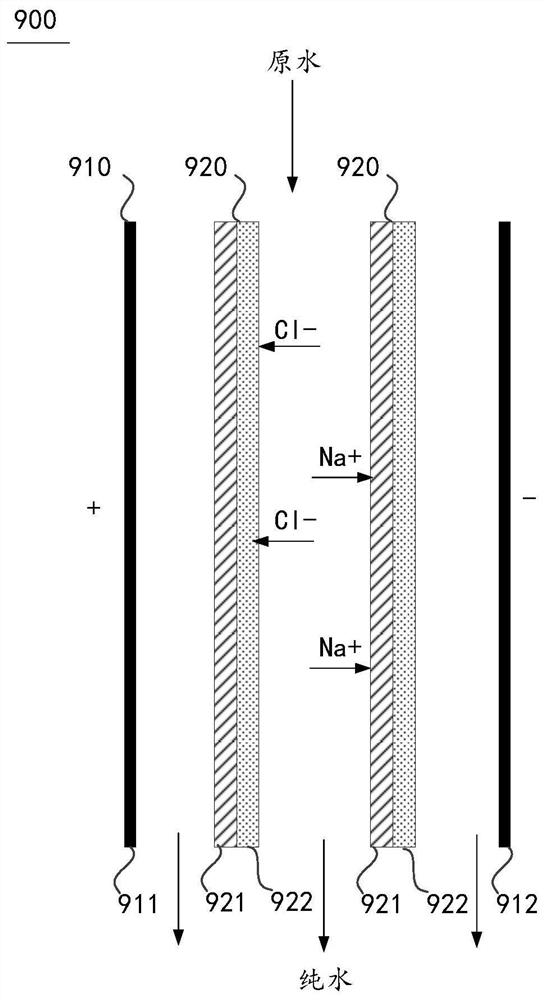

Control method of water boiling device, water boiling device and computer readable storage medium

InactiveCN113397375AAchieve purificationNo scaleWater treatment parameter controlTreatment involving filtrationDesalinationProcess engineering

The invention relates to the technical field of household water boiling, and particularly discloses a control method of a water boiling device, the water boiling device and a computer readable storage medium. The control method comprises the steps that a heating assembly is controlled to heat water in a water container, and the water temperature of the water in the water container is detected; when the water temperature is not higher than a first threshold value, a circulating pump is controlled to drive the water in the water container to pass through a filtering assembly, so that the water in the water container is filtered; and when the water temperature is not higher than a second threshold value, the circulating pump is controlled to drive the water in the water container to pass through a single-flow-channel desalination assembly so as to carry out desalination treatment on the water in the water container, wherein the first threshold value is not greater than the second threshold value. The water in the water container is purified through filtering treatment of the filtering assembly and desalting treatment of the single-flow-channel desalting assembly, so that the purpose that no scale is generated after the water is boiled is achieved.

Owner:FOSHAN VIOMI ELECTRICAL TECH +1

Pottery kiln cogeneration oil heat conduction device

InactiveCN103925805ALarge amount of water savingReduce manufacturing costEnergy industryIncreasing energy efficiencyCogenerationEnergy conservation

The invention relates to a pottery kiln cogeneration oil heat conduction device. The pottery kiln cogeneration oil heat conduction device comprises a water tank, a water feed pump, pottery kilns, a waste heat recovery system in each pottery kiln, a steam separator, a turbine and a generator, wherein the waste heat recovery system comprises two automatic heaters and an oil heat conduction device body, the automatic heaters are arranged at the position of a flue gas discharge port and at the upper end of a porcelain tube, and the oil heat conduction device body is arranged at the lower end of the porcelain tube. The pottery kiln cogeneration oil heat conduction device has the advantages of be capable of fully recycling waste heat of a pottery kiln roller way, achieving self-support of secondhand energy in enterprises, meanwhile, reducing production costs of the enterprises, and avoiding economic losses of the enterprises due to power failure influenced by factors such as power grid maintenance and natural weather; the oil heat conduction device is obvious in energy conservation, high in safety factor, environmental friendly, capable of achieving zero discharge, free of concentrated water and water scales, free from water softening, large in water saving amount, wide in use, long in service life, convenient to technically improve, and small in investment.

Owner:南志远

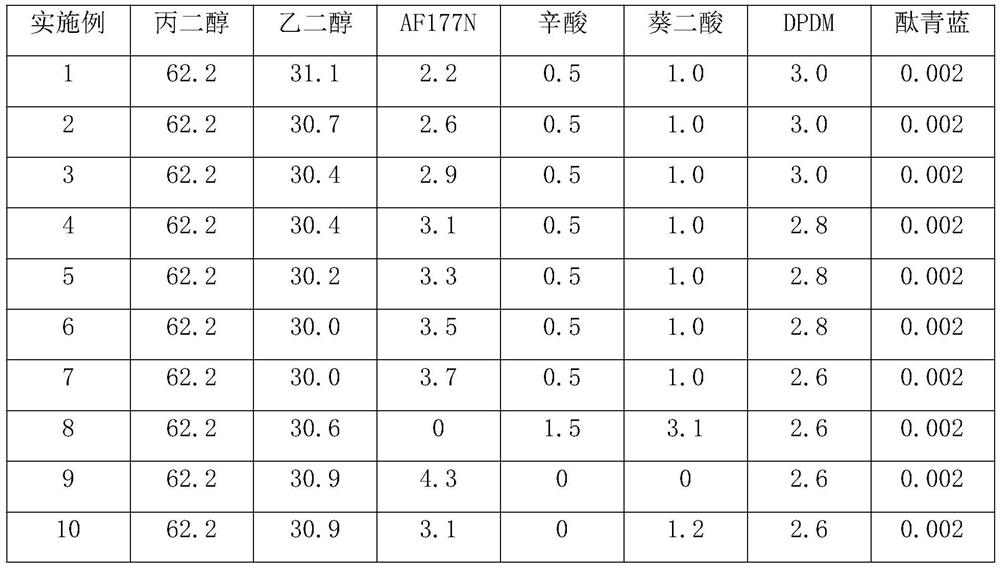

Long-acting anhydrous anti-freezing solution for automobile engine

ActiveCN111849429AExtended service lifeEquilibrium internal temperatureHeat-exchange elementsFuel oilCorrosion inhibitor

The invention provides a long-acting anhydrous cooling liquid for an automobile engine. The cooling liquid is prepared from the following components in percentage by mass: 92 to 95 percent of a base liquid, 2.2 to 3.7 percent of 6-(N-allyl-1, 1, 2, 2-tetrahydroperfluorodecyl) amino-2-sulfydryl-1, 3, 5-triazine-4-sodium mercaptide, 1.2 to 1.8 percent of medium-chain fatty acid, 2.5 to 3.5 percent of dipropylene glycol dimethyl ether and 0.002 to 0.004 percent of a coloring agent, wherein the basic liquid is propylene glycol or / and ethylene glycol, and the medium-chain fatty acid is a mixed acidof monobasic fatty acid and dibasic fatty acid. The corrosion inhibitor is used for preventing metal corrosion; all parts, capable of making contact with a medium, of the whole system can be protected; the heat conduction capacity of the cooling liquid is good, local overheating and friction force of parts are reduced, fuel oil is combusted more completely, the efficiency of the fuel oil is improved, and the oil amount is reduced.

Owner:深圳市百顺源节能科技有限公司

Waste liquid treatment method for CMC or sodium sarcosinate or laundry detergent

InactiveCN108862938AEfficient removalSimple designWater contaminantsTreatment with aerobic and anaerobic processesInorganic saltsChemical oxygen demand

The invention relates to a waste liquid treatment method for CMC or sodium sarcosinate or laundry detergent, the waste liquid is brine waste, the brine waste is evaporated through MVR, 80% of inorganic salt is removed, a solution containing 10% to 15% of salt, 40% to 50% of moisture and 35 to 50% of organic matter is left, the COD (chemical oxygen demand) of the solution which is called as mothersolution for short reaches 0.3 million mg / L, the mother solution is prepared into a solution of which the COD (chemical oxygen demand) is 0.01 million to 0.14 million mg / L in a solution preparation tank, then the prepared waste solution is pumped into USAB tank for treatment, and the waste solution sequentially flows into an anoxic tank, a PACT tank, an intermediate settling tank, a hydrolysis acidification tank, a contact oxidation tank and a secondary settling tank in an overflow way for treatment, detection and discharging is performed after the treatment is finished. The waste liquid treatment method provided by the invention has the advantages that the design is perfect, the convenience in use is realized, the salt in the waste liquid is effectively removed and a number of recycled water up to industrial reuse standards is produced after the treatment, the water quality is further improved by using twice settling through the intermediate settling tank and the secondary settling tank, and no incrustation is produced during use.

Owner:JIANGSU TAILIDA NEW MATERIAL CO LTD

Wearing layer inlay coating sintering process

InactiveCN101348911BBonded firmlyStrong metallurgical bondMetallic material coating processesPorosityWear resistant

The invention relates to the technical field of coating wear-resistant layers, in particular to a wear-resistant layer coating-melting process. The process is characterized by comprising the followingsteps that: a wear-resistant layer alloy block with the contact surface in the same shape with the contact surface of a matrix is manufactured; the wear-resistant layer alloy block and the matrix arecoated by use of binder; the matrix coated with the wear-resistant layer alloy block is sent into a drying chamber to be dried; the dried matrix coated with the wear-resistant layer alloy block is sentinto a melting furnace to be melted; a melted product is sprayed with cold water for cooling in the melting furnace and then sent to a testing room for test. The invention has the advantages that the process is firm in melting and does not damage the matrix; the melting is not limited by the shape and structure of the matrix; melting thickness is not limited; melting porosity is zero; the meltedproduct cannot be oxidized; and the procedure of the melting process has no noise or pollution, thereby meeting the requirements on environmental protection, etc. The process is suitable to be popularized and applied in enterprises using wear-resistant vulnerable equipment in the metallurgy, mining, power, coal, chemical, building material and other industries.

Owner:尹春久

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com