Multipurpose spray explosion-type high-pressure temperature-adjustment vapor decomposition drying steam generator

A steam generator and multi-purpose technology, which is applied in the field of multi-purpose explosion-type high-pressure temperature-adjusted gas decomposition steam generators, can solve the problems of high investment cost, complex multi-stage, and cumbersome machines, so as to shorten the process flow and reduce production. Significant effect of cost and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation.

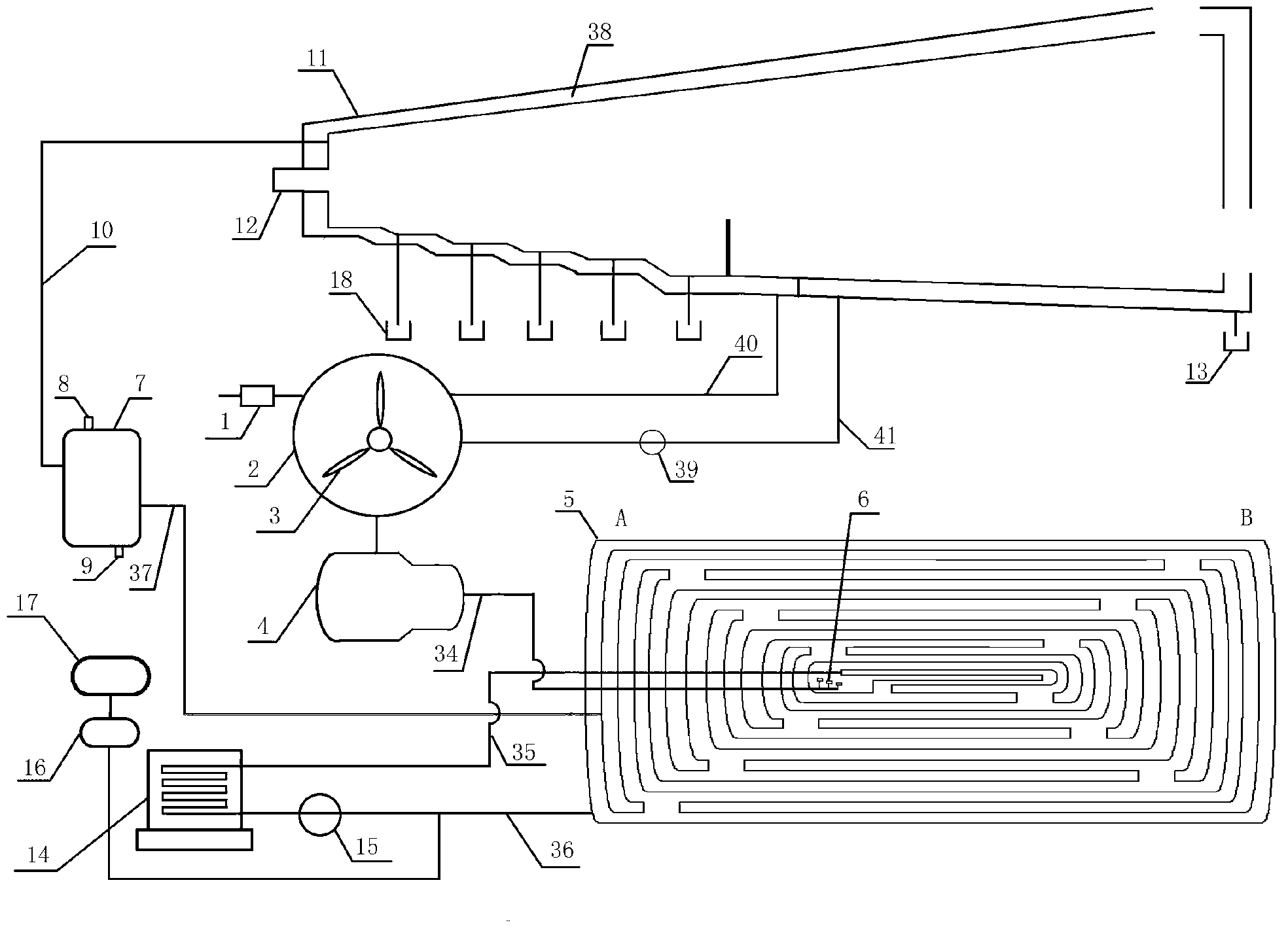

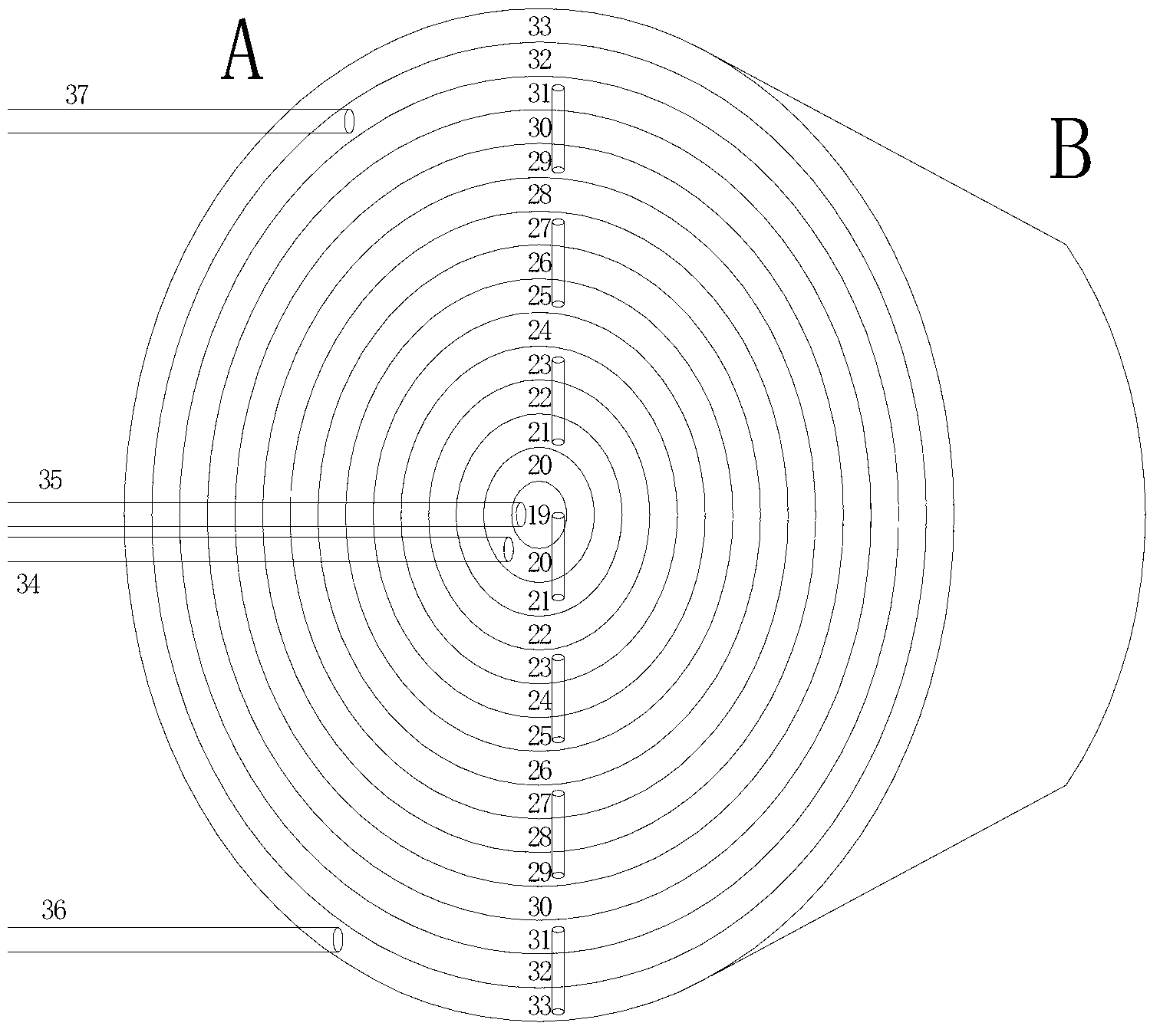

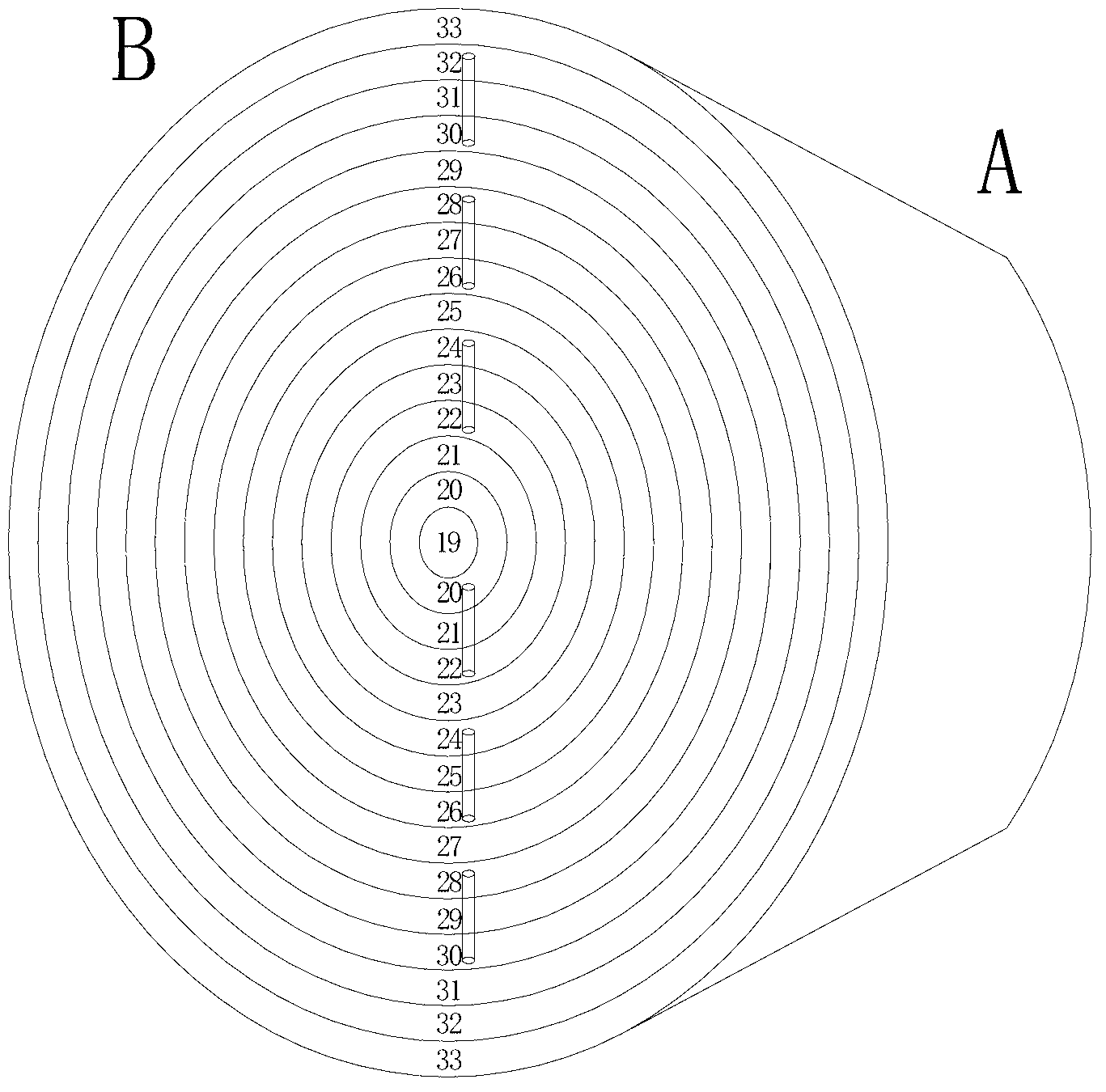

[0040] The structure of the multi-purpose spray explosion type high-pressure temperature-regulated gas decomposition and drying steam generator is as follows: figure 1 As shown, the multi-purpose explosion-type high-pressure temperature-regulating gas decomposition and drying steam generator mainly consists of a liquid feed filter 1, a liquid raw material pool 2, a high-pressure plunger pump 4, a steam generator 5, a high-pressure spray device 6, Primary separation tank 7, connecting pipeline 10, high pressure plunger pump outlet pipeline 34, heat transfer oil inlet pipeline 35, heat transfer oil outlet pipeline 36, vapor layer outlet pipeline 37, concentrated dry gas decomposition chamber 11, constant temperature furnace 14, circulation pump 15. Composed of high-level expansion tank 16, low-level oil storage tank 17, step decomposition mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com