Long-acting anhydrous anti-freezing solution for automobile engine

A car engine, long-term technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., to achieve the effect of reducing emissions, prolonging service life and improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-13

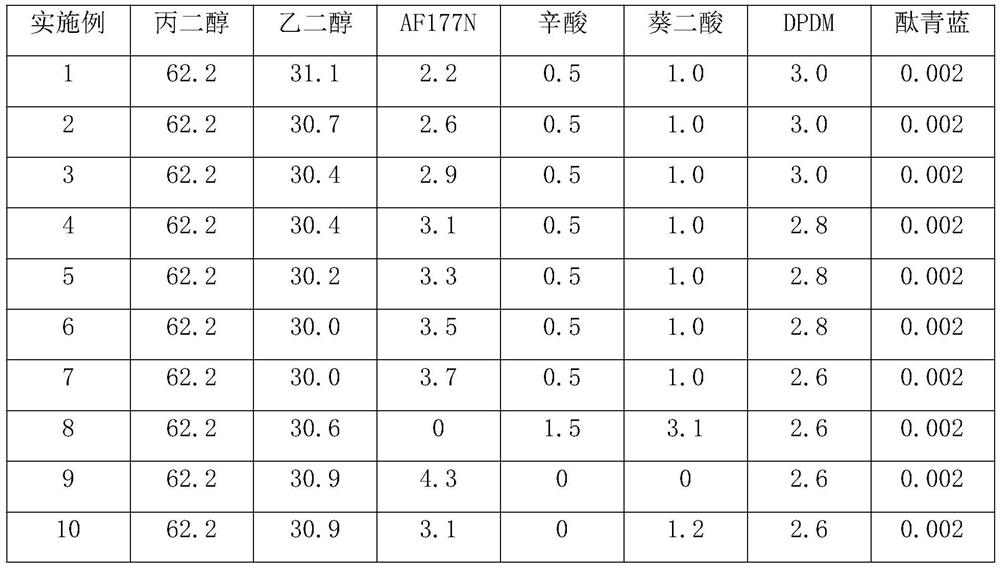

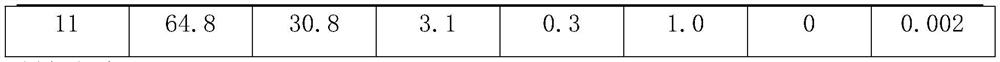

[0023] Embodiment 1-13: the preparation of anhydrous antifreeze

[0024] Table 1: Anhydrous antifreeze formula (unit: %)

[0025]

[0026]

[0027] Preparation:

[0028] (1) Weigh propylene glycol and ethylene glycol, mix them as a base liquid, add octanoic acid to the base liquid and mix well, then add sebacic acid, stir to dissolve;

[0029] (2) Add 6-(N-allyl-1,1,2,2-tetrahydroperfluorodecyl)amine-2-mercapto-1,3,5- Sodium triazine-4-thiolate, heated to about 55°C, while stirring until completely dissolved;

[0030] (3) Add dipropylene glycol dimethyl ether to the mixed solution obtained in step (2), stir to mix evenly, and make a clear and transparent anhydrous antifreeze solution.

Embodiment 2

[0031] Embodiment 2: Corrosion test of anhydrous antifreeze

[0032] Using the glassware corrosion test method (SH / T 0085-2000), the test pieces made of red copper, brass, steel, cast iron, cast aluminum, and solder were weighed after polishing and cleaning, and then completely immersed in the air flow rate of In (100±10)mL / min antifreeze, at 88±2°C, test for (336±2)h. Three parallel test pieces were used for each type of antifreeze. After the test, the test piece was taken out, cleaned and weighed again, and the average mass loss before and after the test was recorded.

[0033] Table 2: Weight loss of test pieces (unit: mg)

[0034] Example Copper brass steel cast iron cast aluminum Solder 1 2.2 2.7 0.9 1.8 14.0 9.1 2 2.6 2.5 0.7 1.7 13.5 8.6 3 2.3 2.2 0.8 1.5 13.4 8.7 4 2.0 2.2 0.5 1.4 13.5 8.5 5 1.8 2.1 0.6 1.1 13.4 8.3 6 1.6 2.0 0.5 0.9 13.2 8.3 7 1.5 1.9 0.5 0.8 13.0 8.3 8 15....

Embodiment 3

[0035] Embodiment 3: Freezing point, boiling point and foam tendency test experiment of anhydrous antifreeze

[0036] After testing, the freezing point of the anhydrous mixed solution prepared in Example 1-11 is around -40°C (the testing method is SH / T0090-1991), and the boiling point is higher than 190°C, at about 198°C (the testing method is SH / T 0089 -1991). Carry out foam tendency research to all samples and find that the foam volume of the anhydrous antifreeze of embodiment 1-10 is all less than 150mL, and the foam disappearance time is all less than 5 seconds, but the anhydrous antifreeze prepared in embodiment 11 has a foam volume of 292ml , the foam disappearing time is greater than 10 seconds (the detection method is SH / T 0066-2002).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com