Device for thermal separation of solid fuel and molten salt integrated boiler

A solid fuel and heat separation technology, which is applied in the direction of dry gas arrangement, superheated temperature control, fuel burning in melting state, etc., can solve the problems of large heat loss of heat transfer medium, bulky boiler equipment, large amount of heat transfer medium, etc., to achieve The effect of increasing the service life of the equipment, fast action speed, and expanding the heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

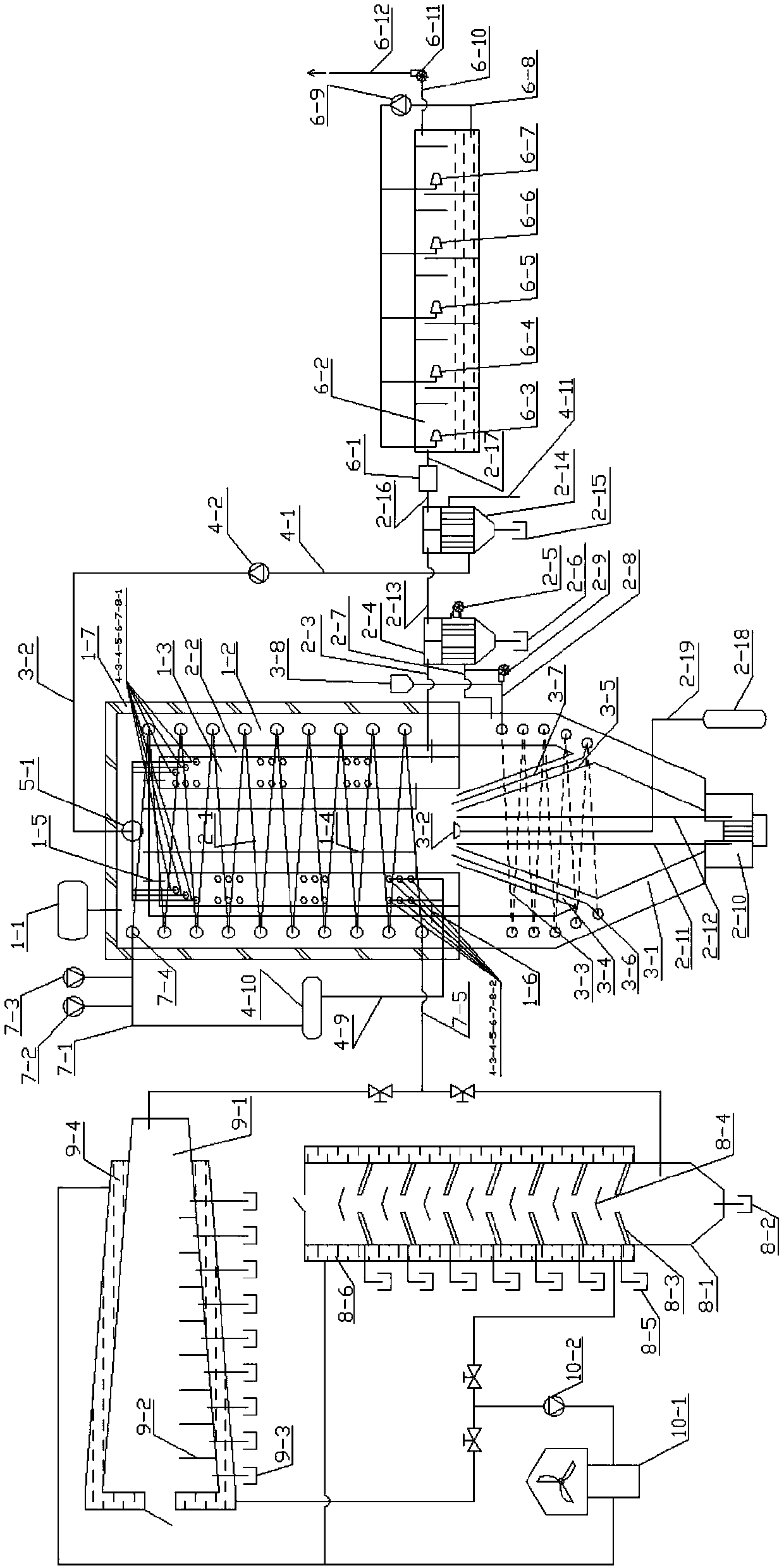

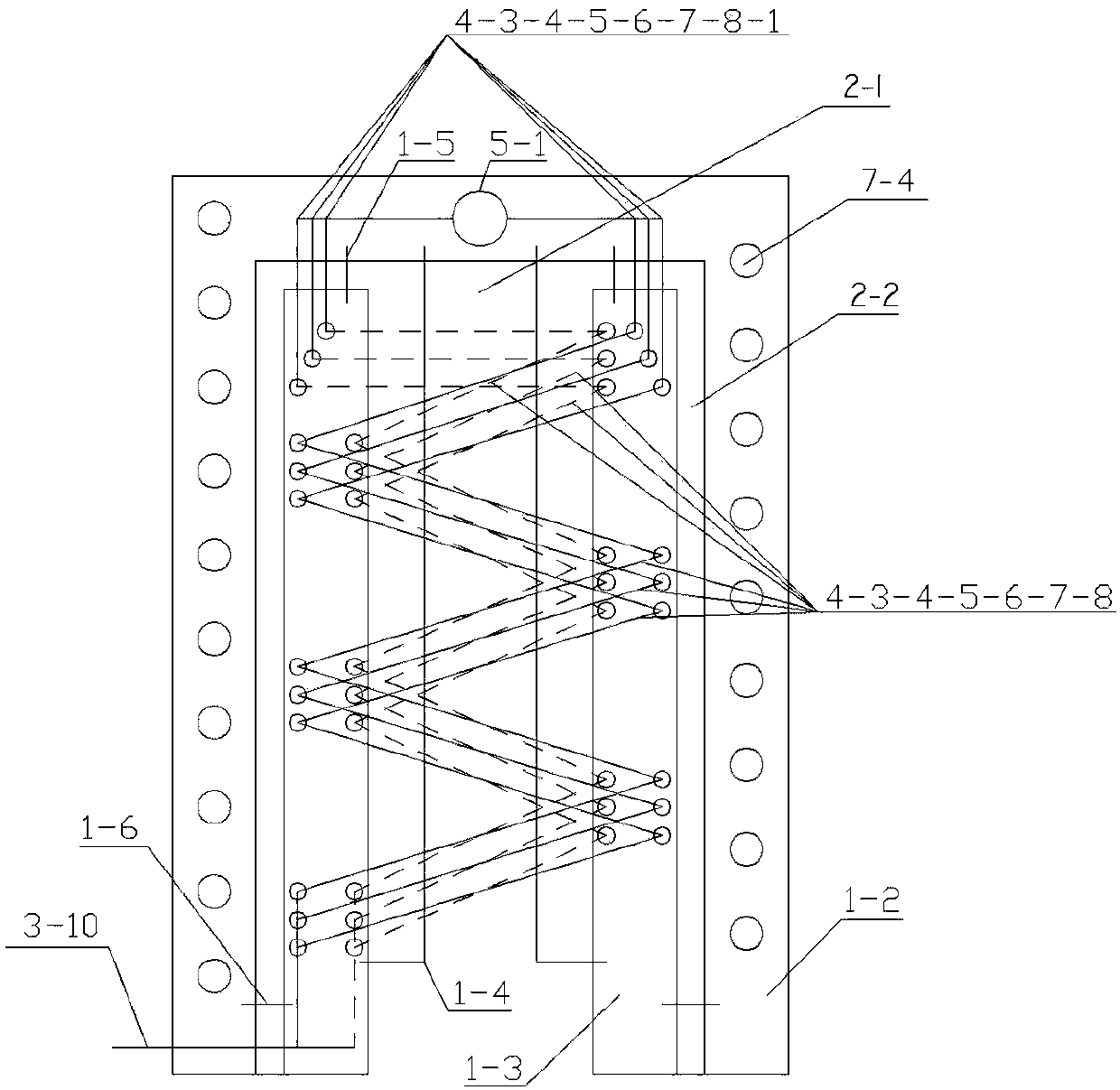

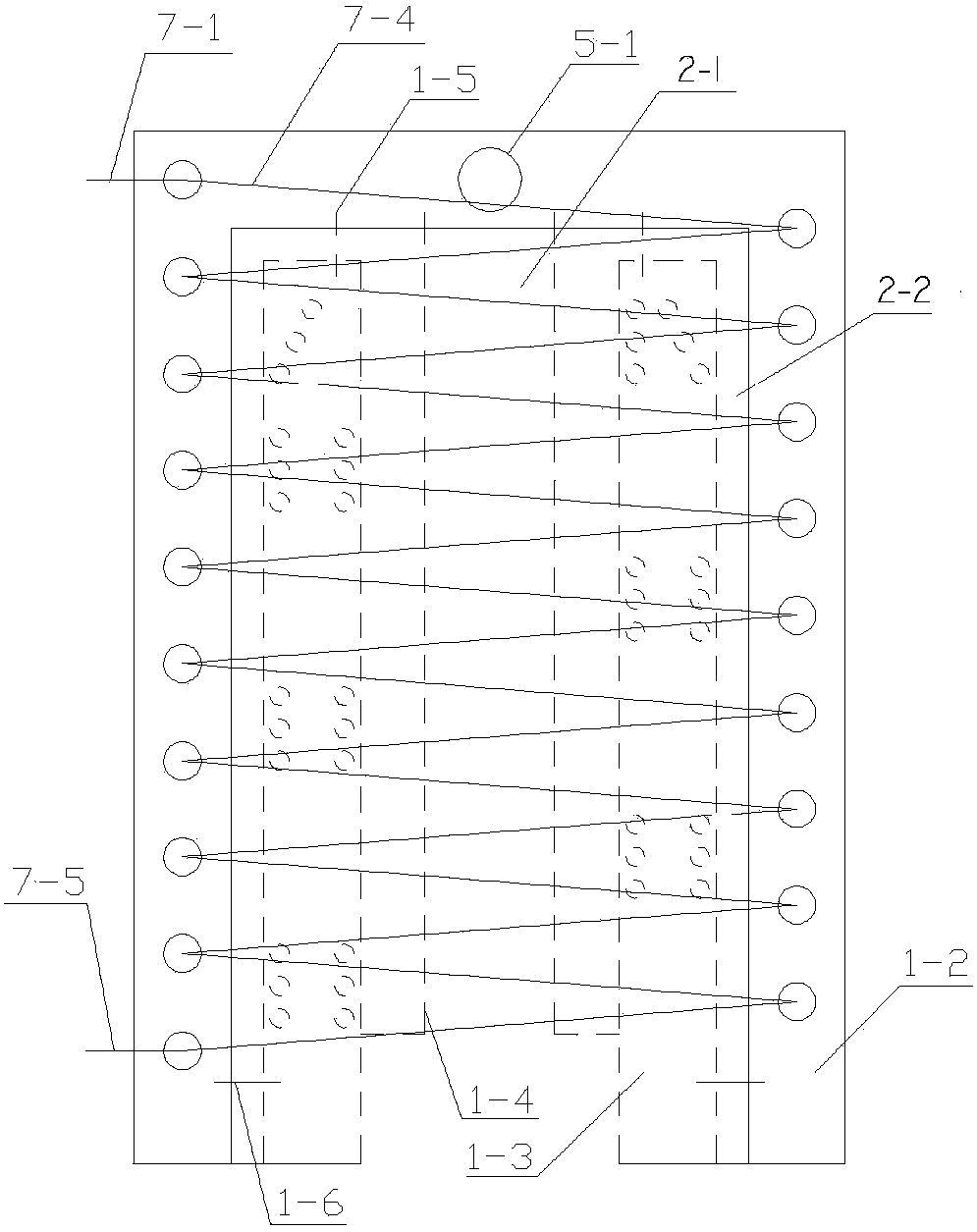

[0066] The device for thermally separating substances of solid fuel and molten salt integrated boilers of the present invention can directly produce superheated steam, which can be high-pressure and high-temperature, high-pressure and low-temperature, low-pressure and high-temperature, high-pressure and low-temperature; steam decomposition and separation technology is used to process substances; the system can be opened and closed instantly Closed; two-way waste heat recovery of smoke and water; exhaust treatment and collection are complete. The invention completely changes the structure of the traditional boiler, saves the construction cost and improves the thermal efficiency; the molten salt is poured into the tank body to make the heat transfer of the equipment uniform, prolong the service life and improve the steam quality; the mist spray water supply improves the thermal efficiency; the gas explosion expansion produces Gas accelerates the steam generation process and impro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com