Gas-fired, molten salt integrated steam boiler

A technology of steam boiler and molten salt, which is applied in the direction of steam superheating, steam generation, and burning fuel in a molten state. It can solve the problems of waste of consumables, large heat loss of heat conduction medium, and backward water supply mode, etc., and achieves enlarged heat exchange area and increased Effect of service life and increased safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

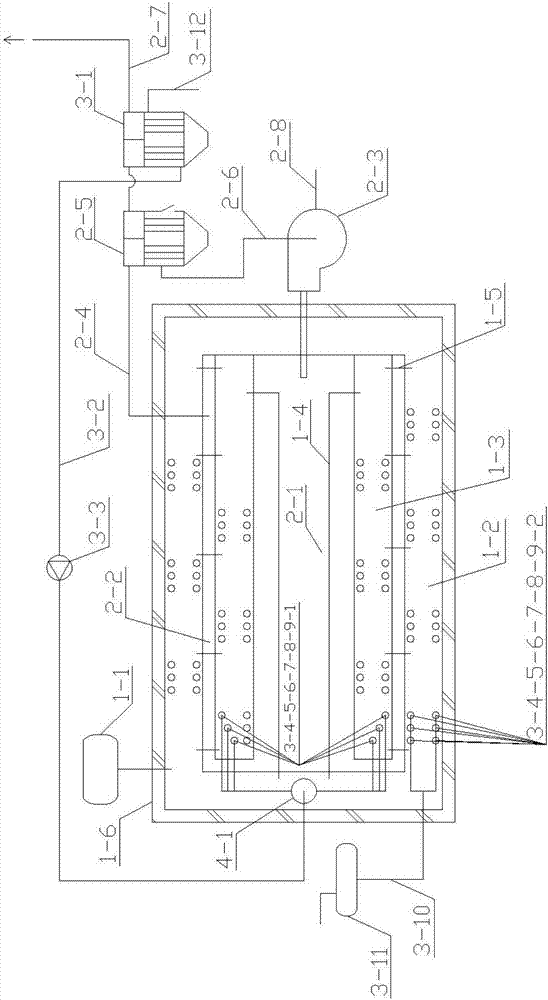

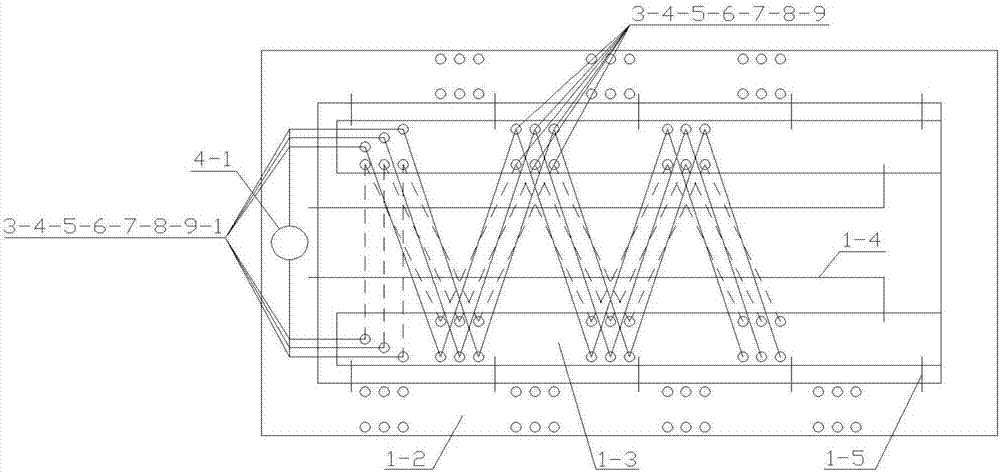

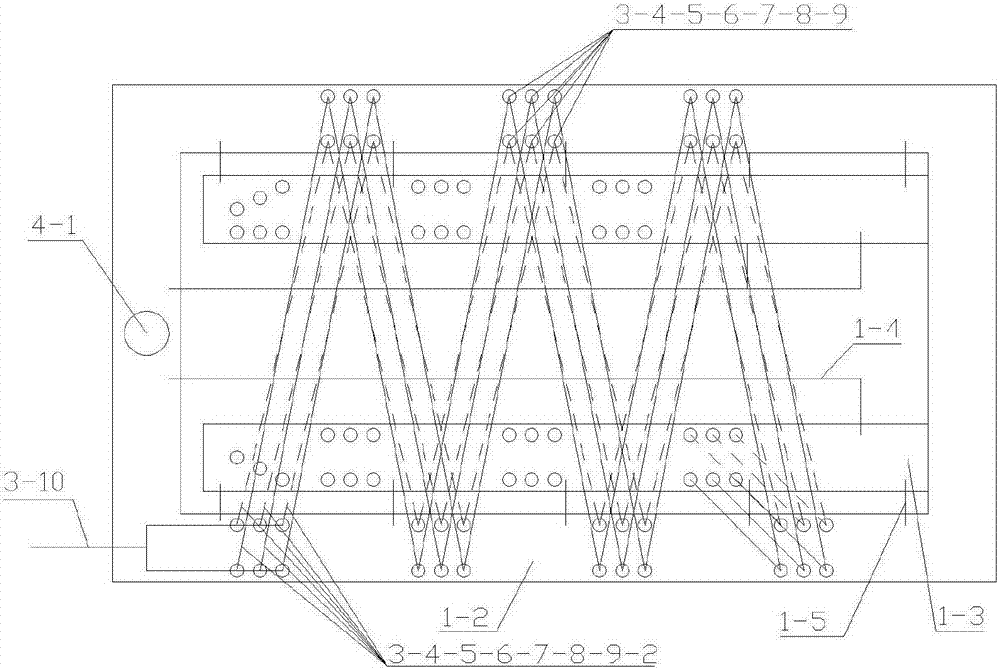

[0047] The present invention is a gas-fired, molten-salt integrated steam boiler using a brand-new structure. The main body is a molten-salt tank, and a steam coil is designed in the molten-salt tank. Molten salt is used as the convective internal circulation heat transfer medium to transmit heat energy and store energy at a constant temperature, and it can avoid excessive temperature difference between the inner and outer sides of the heating pipe, which greatly prolongs the service life of the equipment; the spray steam explosion steam production mode is adopted to reduce the water pressure After atomization, it is sent to the high-temperature steam coil, which greatly increases the heat exchange area. The steam and mist explode and expand in the tube, generating a large amount of internal energy and generating steam at a very high speed; continuous water injection, the system is always in the state of heating a small amount of water, Avoid a lot of waste of heat energy, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com