Infrared Radiant Ceramic Heater

A ceramic heater and infrared radiation technology, applied in the direction of heating element shape, immersion heating device, etc., can solve the problem of not forming products, etc., and achieve the effect of high density and speed, low energy consumption and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

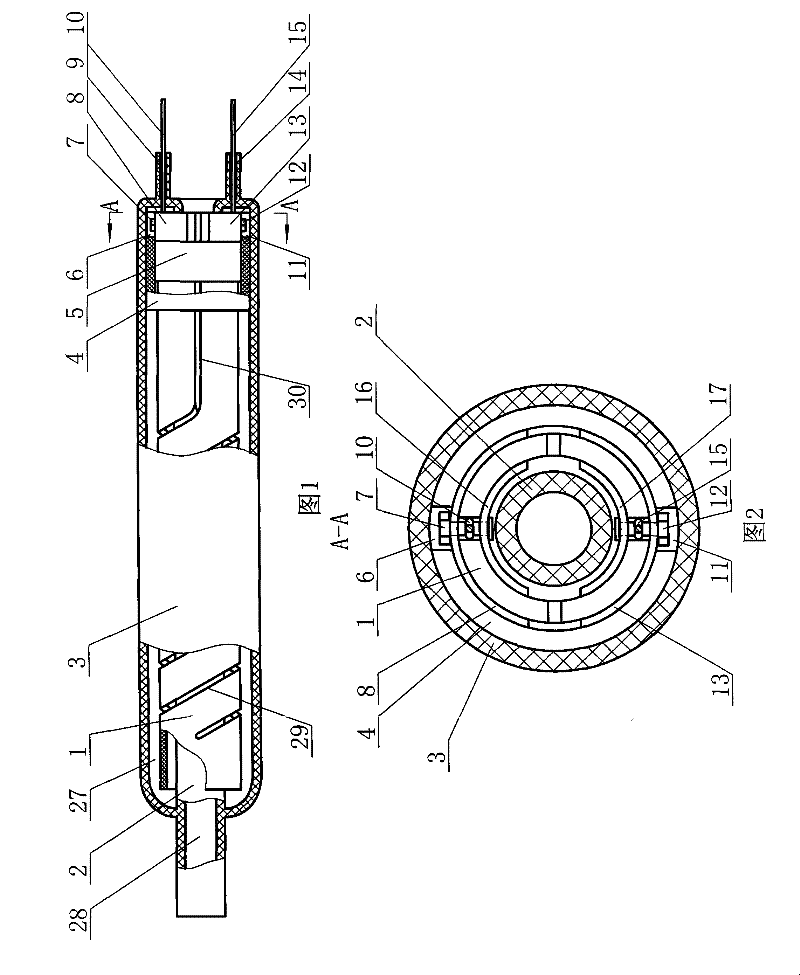

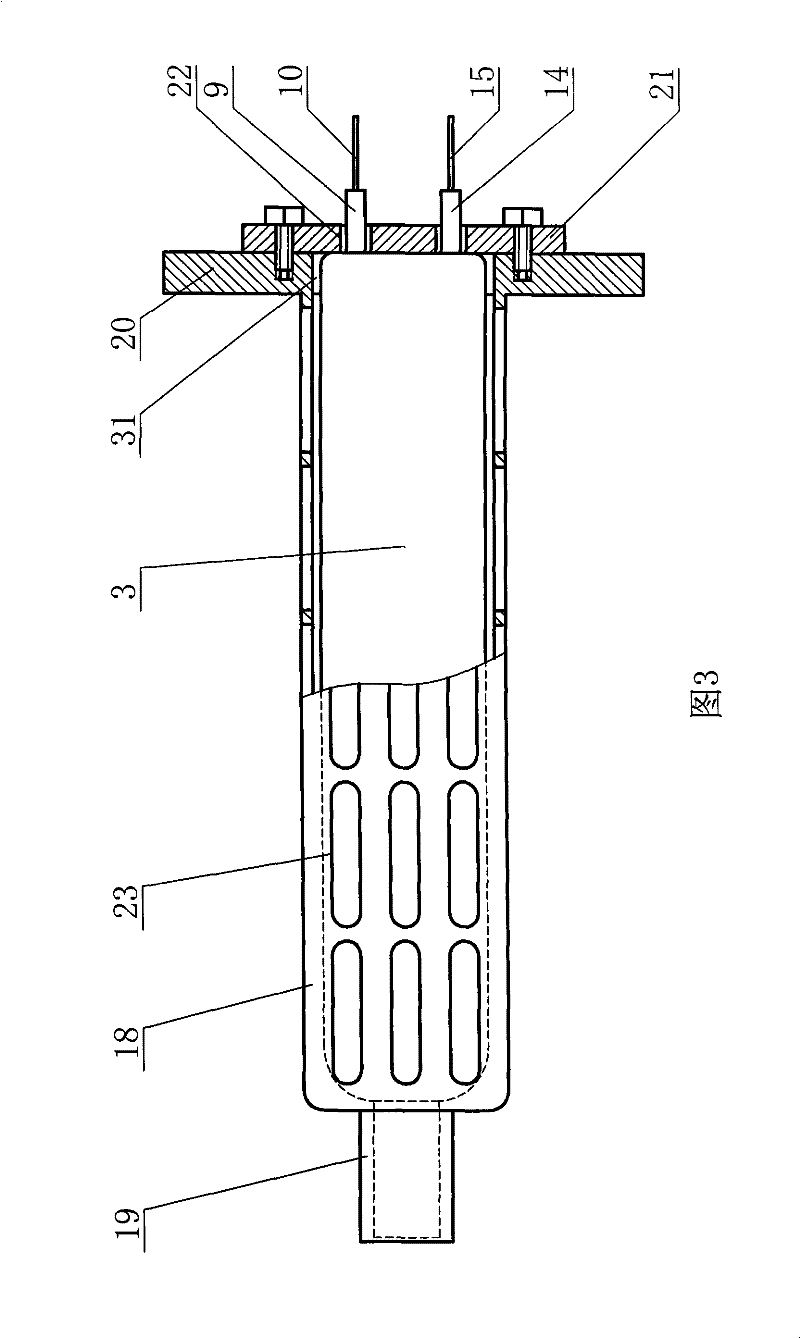

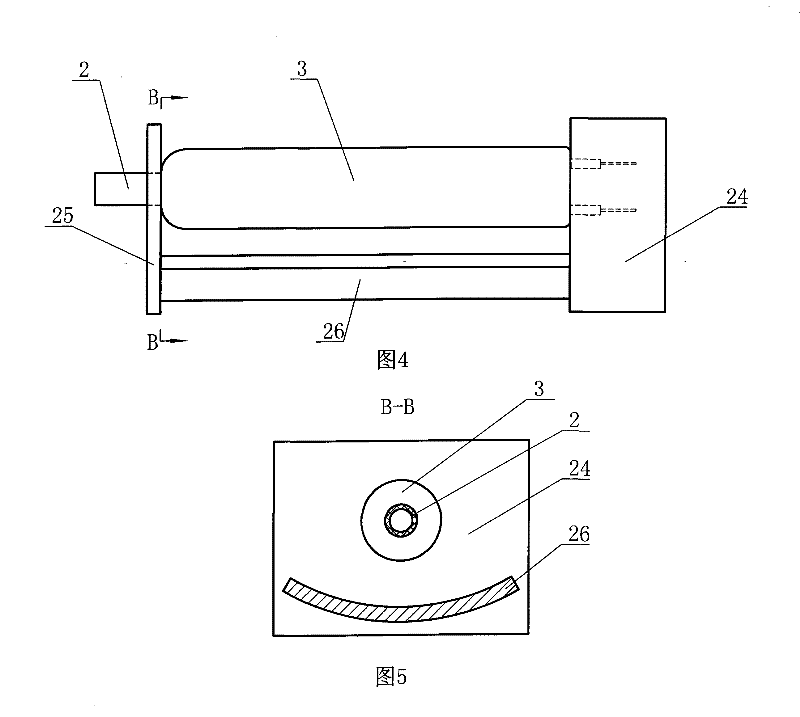

[0010] The main structure of the product of the present invention comprises a quartz outer tube 3 and a quartz inner tube 2, the two ends of the quartz outer tube 3 are respectively melted and sealed with the two ends of the quartz inner tube 2, and a space is arranged between the inner wall of the quartz outer tube 3 and the outer wall of the quartz inner tube 2. Cavity 27, silicon carbide rod 1 is installed in the cavity 27, the diameter of the through hole 28 arranged in the middle of the quartz inner tube 2 is equal to and greater than or equal to the length of the quartz outer tube 3, the end of the silicon carbide rod 1 is installed with an electrode, and the silicon carbide rod 1 A silica pad 5 is installed on the outer or inner wall of the terminal. When the product of the present invention is used to heat liquid, two electrodes are installed at one end of the heater, so that most of the structure of the heater can be placed in water to increase the heat transfer area. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com