Fuel-saving gas welding device

A gas welding device and an economical technology, used in auxiliary devices, gas flame welding equipment, welding equipment, etc., can solve the problems of increased fuel gas loss, prolonged operation time, low productivity, etc., to prevent gas tank explosions and improve safety. The effect of improving sex and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. When describing the embodiment of the present invention, the same member uses the same symbol in the accompanying drawings, and the relevant known structures or functions are omitted in order to clearly express the purpose of the present invention, and the expression content on the accompanying drawings is to simply illustrate the embodiment of the present invention The illustrations are for purposes of illustration and may differ from the actual form.

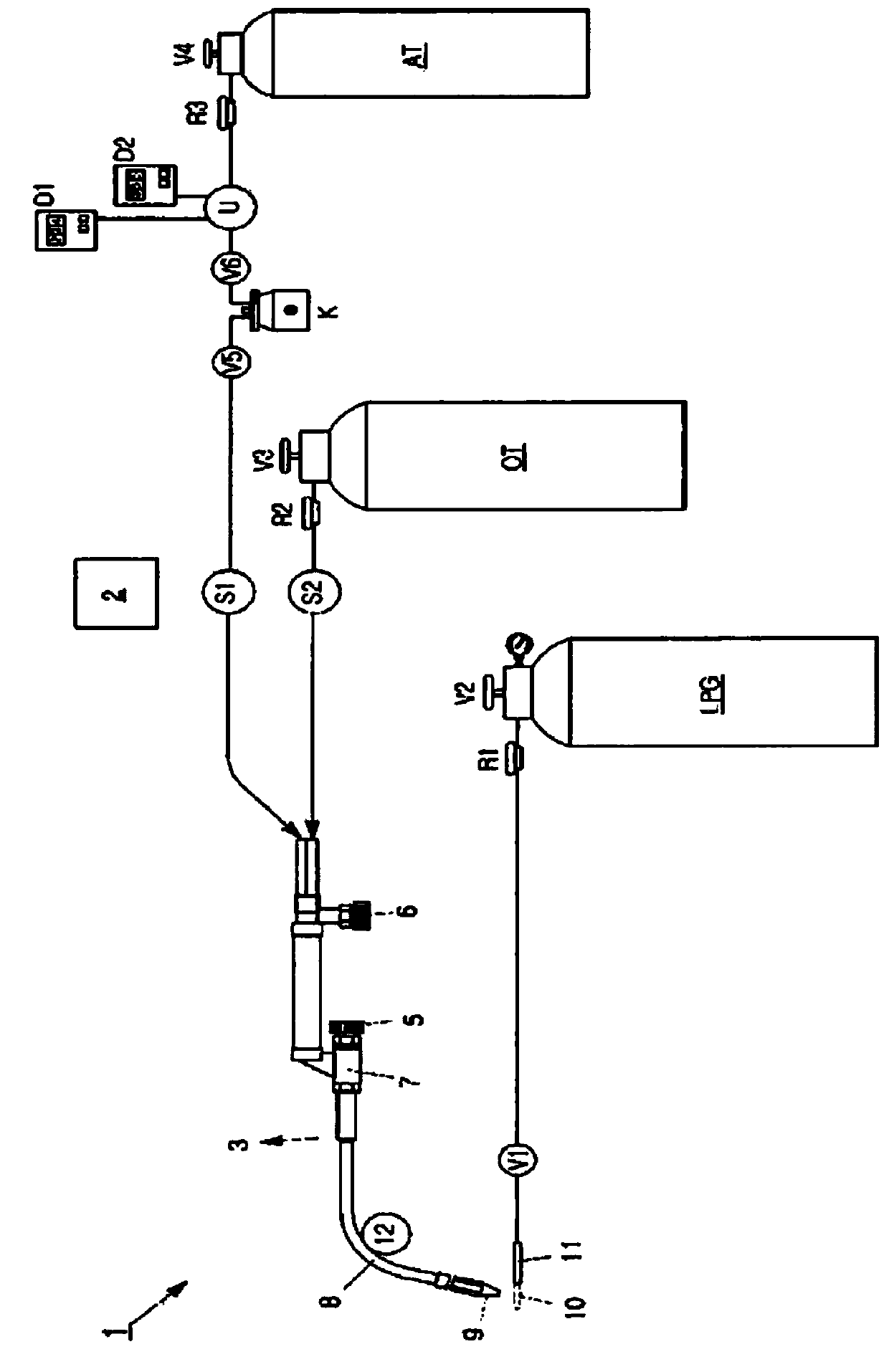

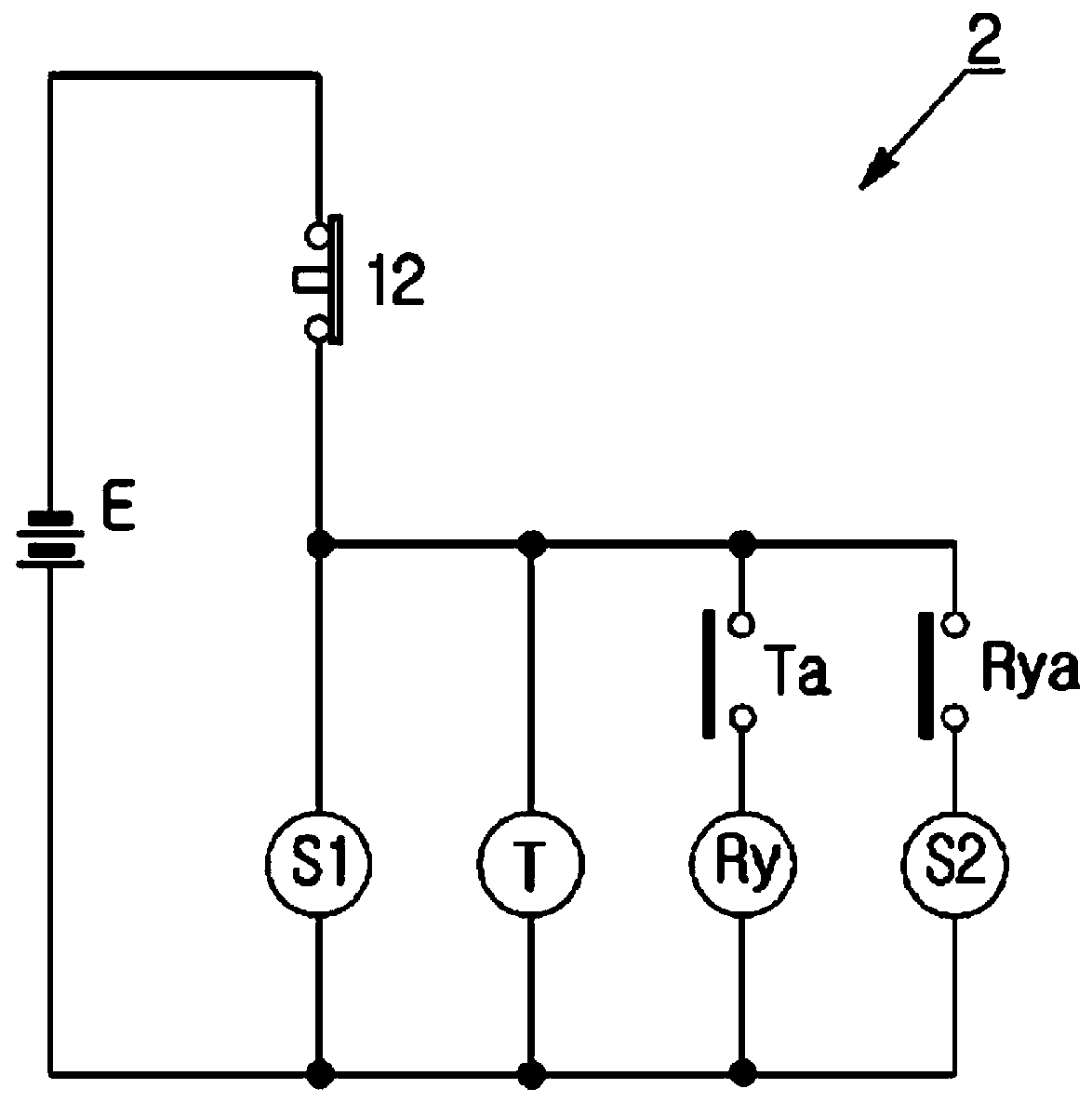

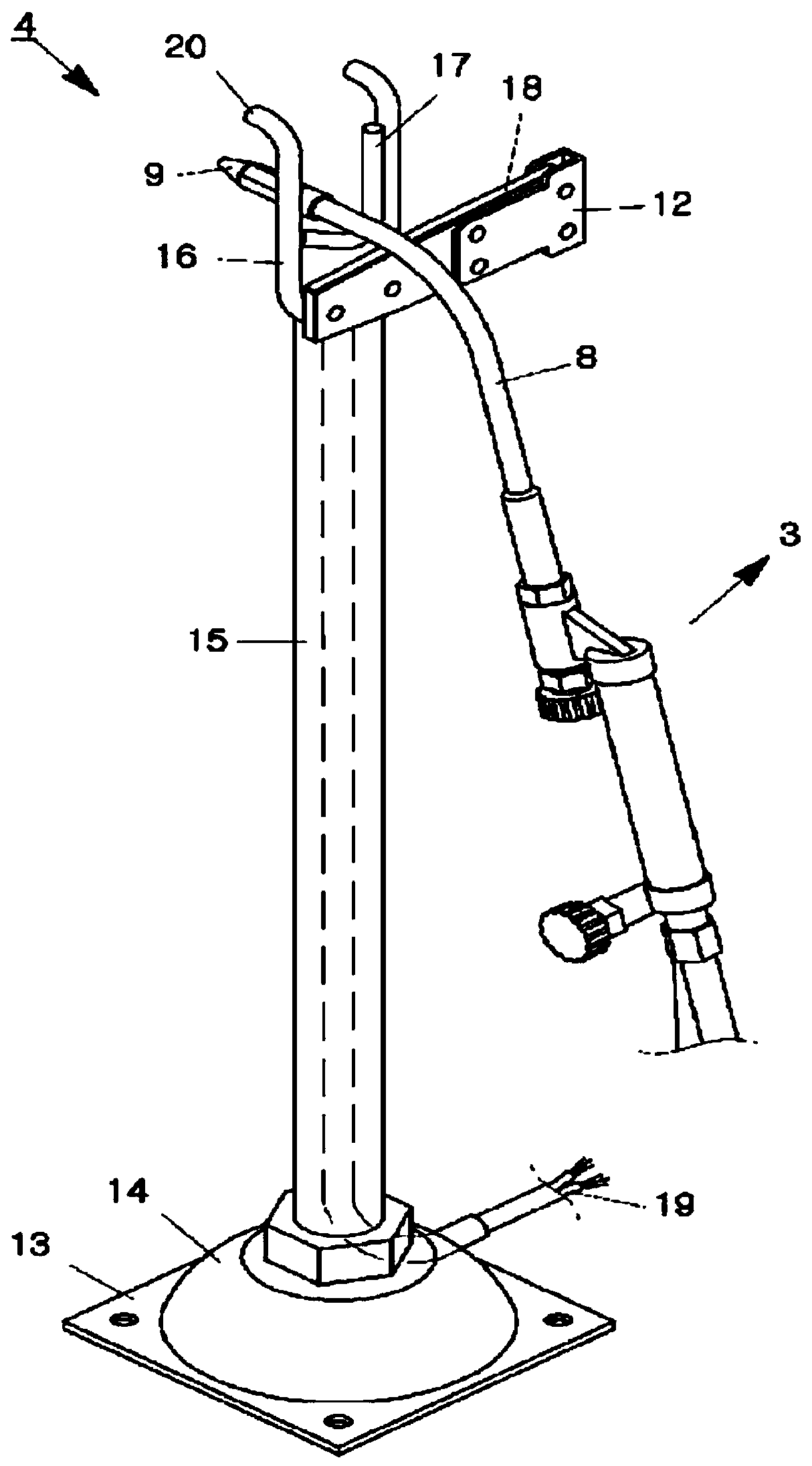

[0046] figure 1 It is a structural diagram of the fuel-saving gas welding device 1 of the present invention, figure 2 It is a circuit structure diagram of the control device 2 for preventing backflow and backfire by delaying the spit out of fuel gas (such as acetylene gas) than oxygen, image 3 , 4 is a perspective view of the support frame 4 on which the welding torch 3 is mounted.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com