Direct-drain-type water-saving toilet with up-down-displaced sewage draining exit

A technology for sewage outlets and toilets, which is applied in the field of bathroom supplies, and can solve problems such as easy clogging, waste water for toilet sewage discharge, etc., achieve clean flushing, less water consumption, and solve the effects of pipe blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

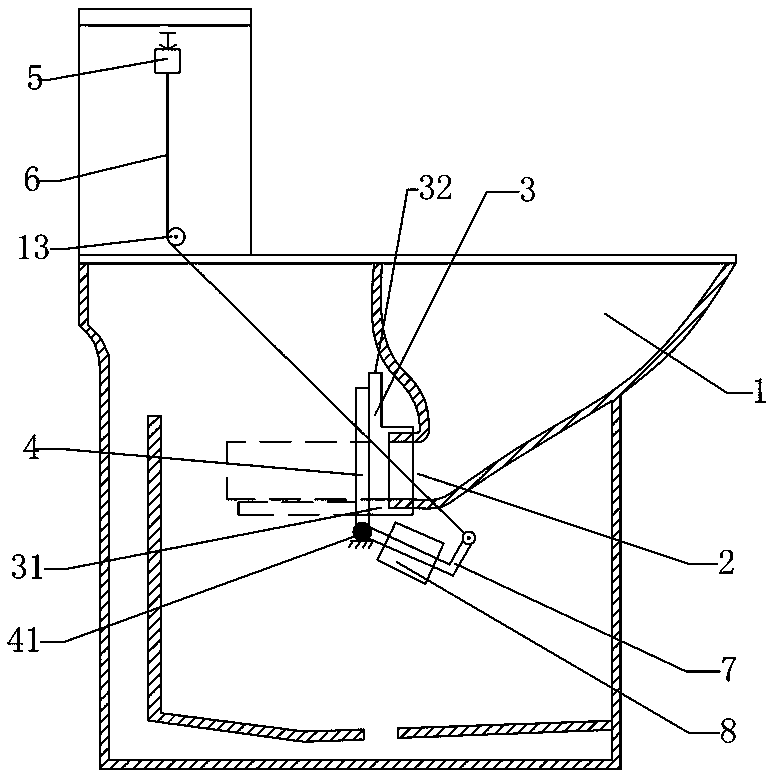

[0040] like figure 1 As shown, the vertical water-saving water-saving toilet with a sewage outlet that can be moved up and down includes a toilet body, and the water parts on the toilet can be conventional water parts. A flexible sleeve 3 is sleeved on the port 2 . The flexible sleeve 3 is made of water-loving soft material with toughness, acid resistance, alkali resistance, and high strength yield load, and is firmly sleeved on the water outlet port 2 as an extension of the water outlet port 2 for sewage discharge. The fixed end where the flexible sleeve 3 is socketed with the water outlet port 2 is a sewage inlet 31 , and the free end is a sewage discharge port 32 . The opening direction of the water outlet port 2 on the urinal 1 is provided with a turning plate 4, the turning plate 4 has a rotating shaft 41, and it rotates and swings with the rotating shaft 41 as the axis under the control of the turning plate control structure to complete the adjustment of the flexible sl...

Embodiment 2

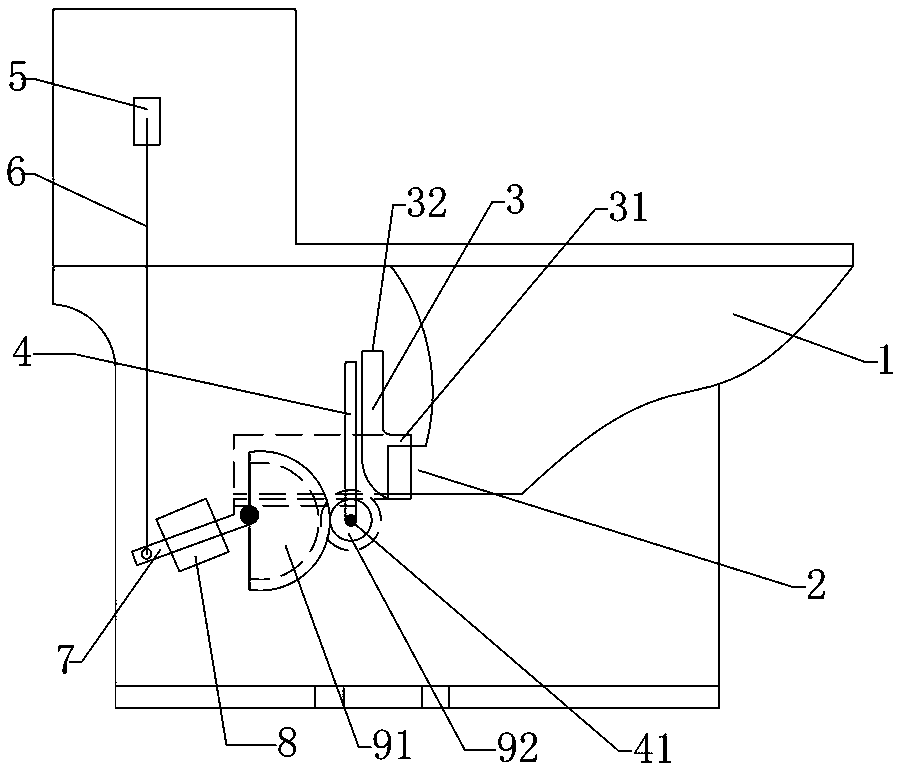

[0048] The toilet in this embodiment adopts a gear-type flap control mechanism, such as figure 2 As shown, the flap control mechanism includes a button 5, a stay cord 6, a pull rod 7, a counterweight 8 and a flap opening and closing mechanism, and the flap opening and closing mechanism includes a semicircular gear 91 and a circular gear 92, and one end of the stay cord 6 It is connected with the button 5, and the other end is connected with the pull rod 7. A counterweight 8 is arranged on the pull rod 7. The other end of the pull rod 7 is coaxially fixed with the semicircular gear 91, and the circular gear 92 is coaxial with the flap 4. Fixed connection, semicircular gear 91 and circular gear 92 mesh.

[0049] When it is necessary to discharge the sewage, press the button 5 downward, and through the principle of leverage, the pull rope 6 drives the pull rod 7 to rotate clockwise, so that the flap 4 rotates counterclockwise with its rotation axis 41 as the axis, eliminating th...

Embodiment 3

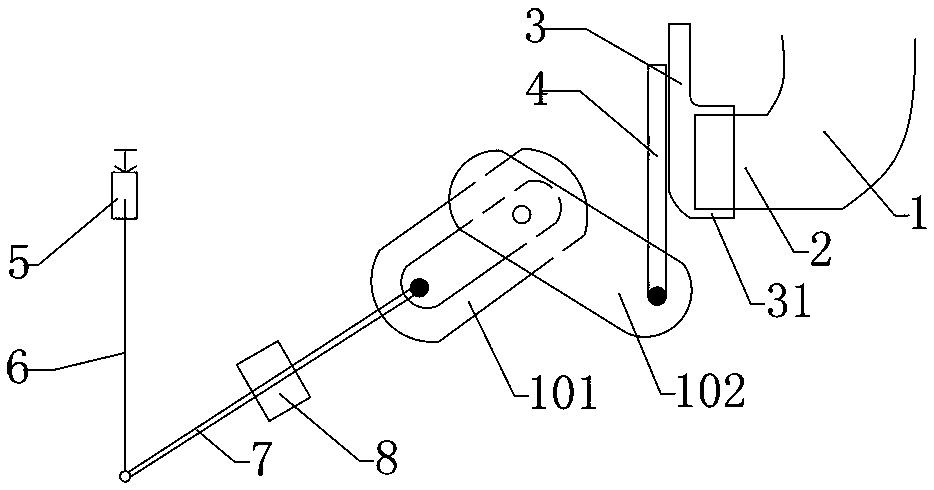

[0052] The toilet in the present embodiment adopts the wheel-type flap control mechanism, such as image 3 As shown, the flap control mechanism includes a button 5, a stay cord 6, a draw bar 7, a counterweight 8 and a runner, the upper end of the stay cord 6 is connected with the button 5, and the lower end is connected with the draw bar 7, and the draw bar 7 is provided with a matching Weight 8. The runners include a first runner 101 and a second runner 102, the right end of the first runner 101 is hinged to the left end of the second runner 102, and the left end of the first runner 101 is coaxially fixed to the right end of the pull rod 7; The right end of the two runners 102 is fixedly connected with the turning plate 4 coaxially.

[0053] When the button 5 is pressed down, the pull cord 6 drives the pull rod 7 to move clockwise, thereby causing the second wheel 102 to move counterclockwise, and the turnover plate 4 moves counterclockwise with its rotation axis 41 as the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com