Waste liquid treatment method for CMC or sodium sarcosinate or laundry detergent

A technology for waste liquid treatment and sodium creatine ammonia, which is applied in chemical instruments and methods, biological water/sewage treatment, heating water/sewage treatment, etc. Lifting, scale-free, well-designed results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

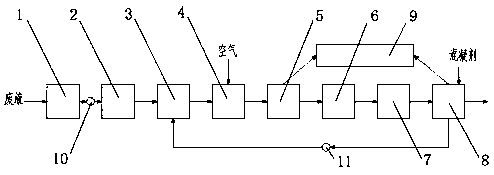

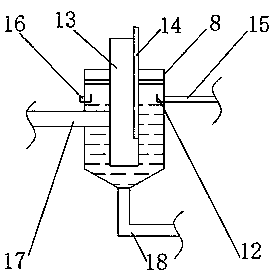

[0028] Such as Figure 1-2 As shown, a waste liquid treatment method of CMC or sodium creatine ammonia or laundry detergent, the waste liquid is saline waste water, and the saline waste water is evaporated by MVR to remove 80% of inorganic salts, and the rest is salty 10-15 %, water 40-50% and organic matter 35-50% solution, the chemical oxygen demand COD of this solution is as high as 300,000 mg / L or more, referred to as the mother liquor; the mother liquor is prepared into the chemical oxygen demand COD1 in the distribution tank 1 10,000-14,000 mg / L solution, and then the prepared wastewater is pumped into UASB pool 2 through pump 10 for treatment, and then flows into facultative oxygen pool 3, PACT pool 4, middle sedimentation pool 5, hydrolytic acidification in sequence through overflow Pool 6, contact oxidation tank 7 and secondary settling tank 8 are processed, and after the treatment is completed, detection and discharge are carried out; the middle settling tank 5 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com