Wearing layer inlay coating sintering process

A technology of wear-resistant layer and sintering, which is applied in the direction of metal material coating process and coating, can solve the problems of wasting manpower, material resources and funds, affecting the economic benefits of enterprises, and short service life, so as to improve the service life of equipment and reduce The effect of spare parts consumption and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

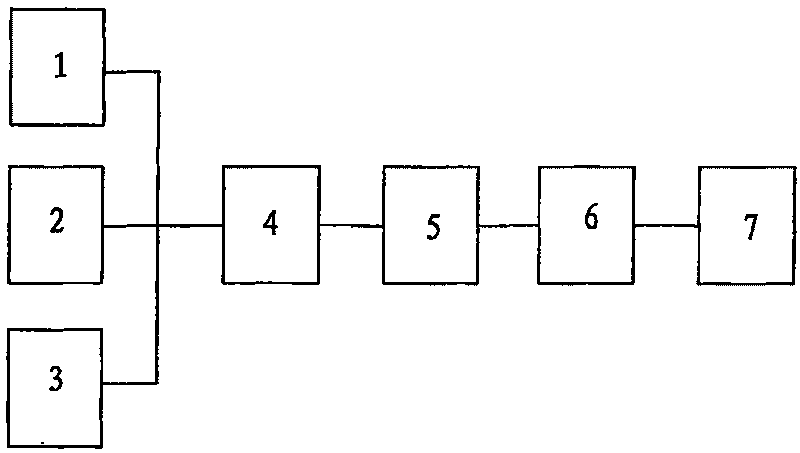

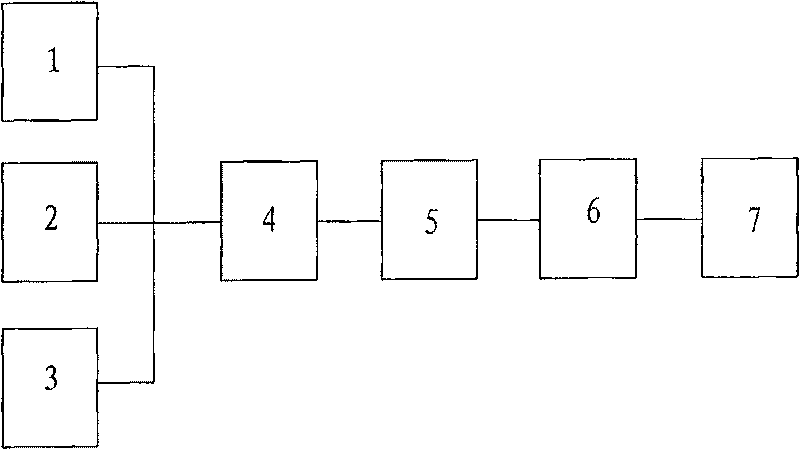

Method used

Image

Examples

Embodiment 1

[0040] Example 1: Repairing the pump lining of the slurry pump

[0041] At present, the pump lining of the slurry pump used in mines is made of Cr27 alloy pump lining, which has a short service life and needs to be replaced frequently, wasting a lot of money and manpower. Applying the inlaid coating and fusing process of the present invention, a wear-resistant layer is inlaid and fused on the scrapped high-chromium cast iron Cr27 alloy pump lining substrate, which greatly reduces the investment cost of replacing the wear-resistant parts.

[0042] Repair the wear-resistant layer of the pump lining of the slurry pump. The composition is: 15% nickel powder, 30% chromium powder, 10% manganese powder, 30% iron powder, 10% carbon powder, and 5% silicon powder. After mixing, internally heat to 1300° C. for 5 minutes. The drying temperature is 40 DEG C, and the drying time is 2 hours. The sintering temperature of the sintering furnace is 1300° C., the sintering time is 1 minute, the...

Embodiment 2

[0044] Example 2: Restoring the shovel teeth of the electric shovel

[0045] my country's mining enterprises now mostly use high-manganese cast steel manganese 13 shovel teeth, which have a short service life and need to be replaced frequently, which affects the profitability of the enterprise. Applying the inlaid coating and fusing process of the present invention, a layer of wear-resistant layer is inlaid and fused on the original discarded shovel tooth substrate, which greatly reduces unnecessary consumption of spare parts, and creates conditions for enterprises to reduce production costs and increase production and efficiency.

[0046] Repair the wear-resistant layer of electric shovel teeth, the composition is: nickel powder 15%, chromium powder 25%, manganese powder 10%, iron powder 30%, carbon powder 15%, silicon powder 5%, mix the above components evenly Then internally heated to 1200°C for 8 minutes. The drying temperature is 40 DEG C, and the drying time is 2.5 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com