Supercritical steam colliding substance thermal decomposition boiling range condensation reduction sorting device

A supercritical and thermal decomposition technology, applied in the fields of boilers, thermal decomposition condensation reduction equipment, and steam generators, can solve the problems of unclear material classification, long extraction process time, high investment cost, and expand heat exchange. area, improving thermal efficiency, and the effect of low exhaust gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

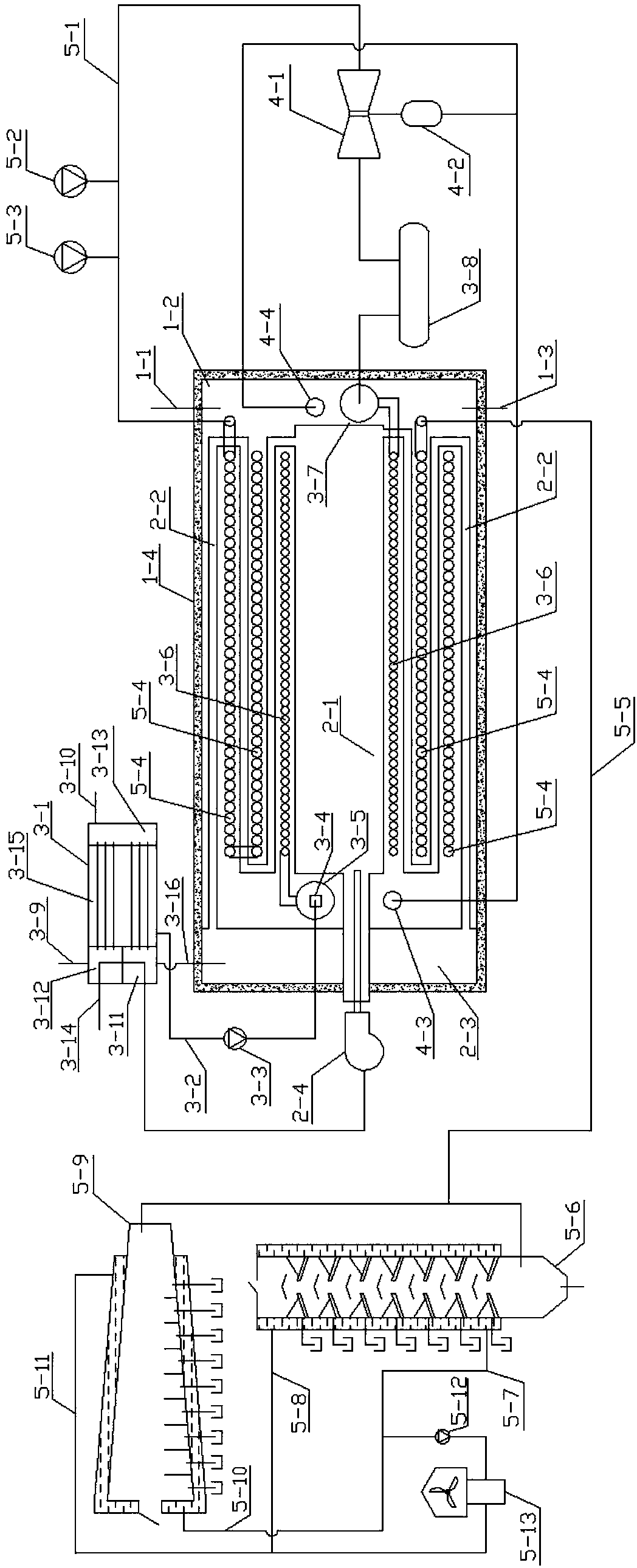

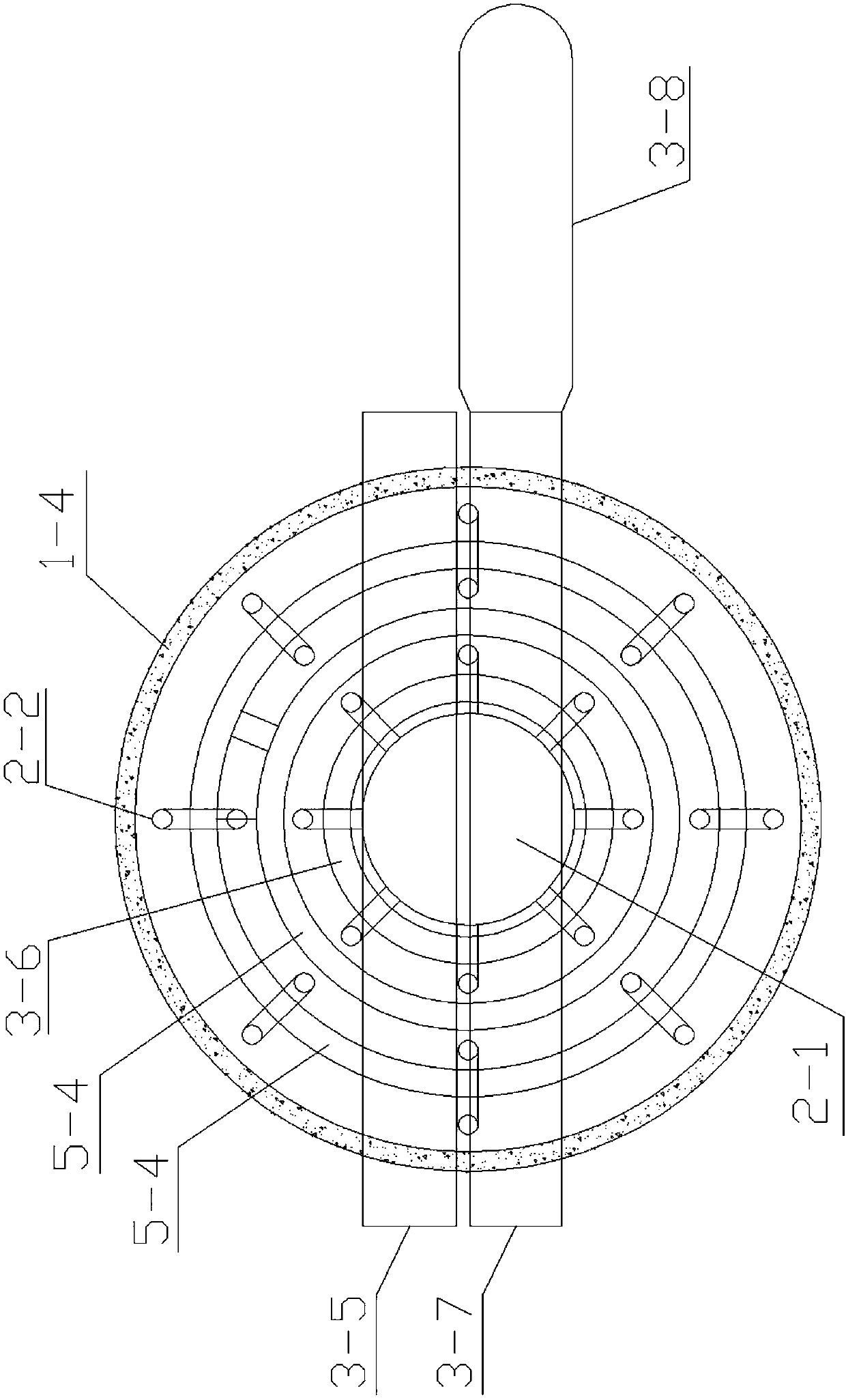

[0045] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation.

[0046] The supercritical steam colliding material thermal decomposition boiling range condensation reduction separation equipment structure of the present invention is as follows figure 1 , figure 2 As shown, the supercritical steam collision material thermal decomposition boiling range condensation reduction separation device consists of molten salt feeding pipe 1-1, molten salt tank 1-2, molten salt discharge pipe 1-3, insulation layer 1-4, combustion chamber 2-1, flue gas pipe 2-2, flue gas chamber 2-3, burner 2-4, waste heat recovery water tank 3-1, water outlet pipe 3-2, high pressure plunger pump 3-3, high pressure spray device 3- 4. Steam generator 3-5, steam coil 3-6, steam tank 3-7, sub-cylinder 3-8, smoke exhaust pipe 3-9, water inlet pipe 3-10, first smoke tank 3-11, The second flue gas tank 3-12, the third flue gas tank 3-13, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com