Production method of invar steel wire with high surface quality

A production method and high surface technology, applied in the field of metallurgy, can solve the problem of not taking peeling treatment, and achieve the effect of reducing the amount of residues, reducing production costs, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The production method of the high surface quality invar wire material of the present invention is suitable for producing invar wire material with a diameter of 3.0-6.5mm, including vacuum melting, electroslag remelting, forging billet, rolling, cold drawing, aging heat treatment process, specific process steps As described below:

[0030] (1) Rolling process: including high-temperature preliminary rolling, high-temperature replenishment, and water-cooling steps for spinning. Control the heating temperature of the billet before high-temperature initial rolling to 1150-1250°C, and the holding time is 2-4h; Immediately after water cooling.

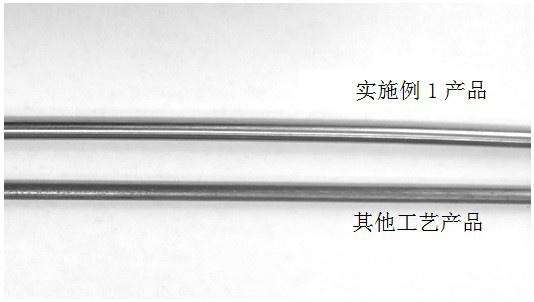

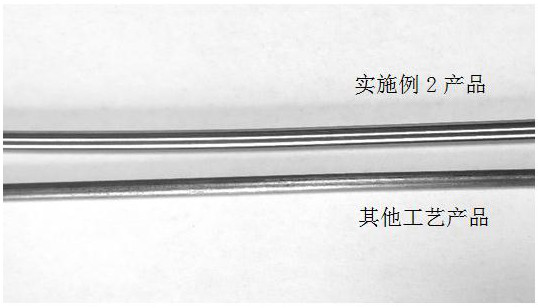

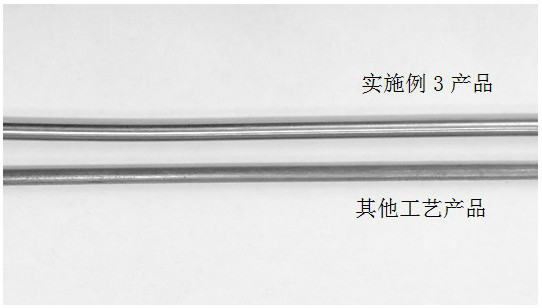

[0031] (2) Cold drawing process: single-pot drawing is adopted, and an online film machine is used to coat the film agent during the drawing process. Before drawing to the penultimate pass or when drawing to D>d+0.8mm, perform peeling and double abrasive belt grinding, and then continue drawing; where D is the mm diameter of the wire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com