Supercritical flashed and pyrolyzed gas material condensation and reduction device

A pyrolysis gas and supercritical technology, applied in the field of boilers, can solve the problems of bulky boilers, simple understanding, non-compliance, etc., and achieve the effects of expanding heat exchange area, high fuel combustion rate, and increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

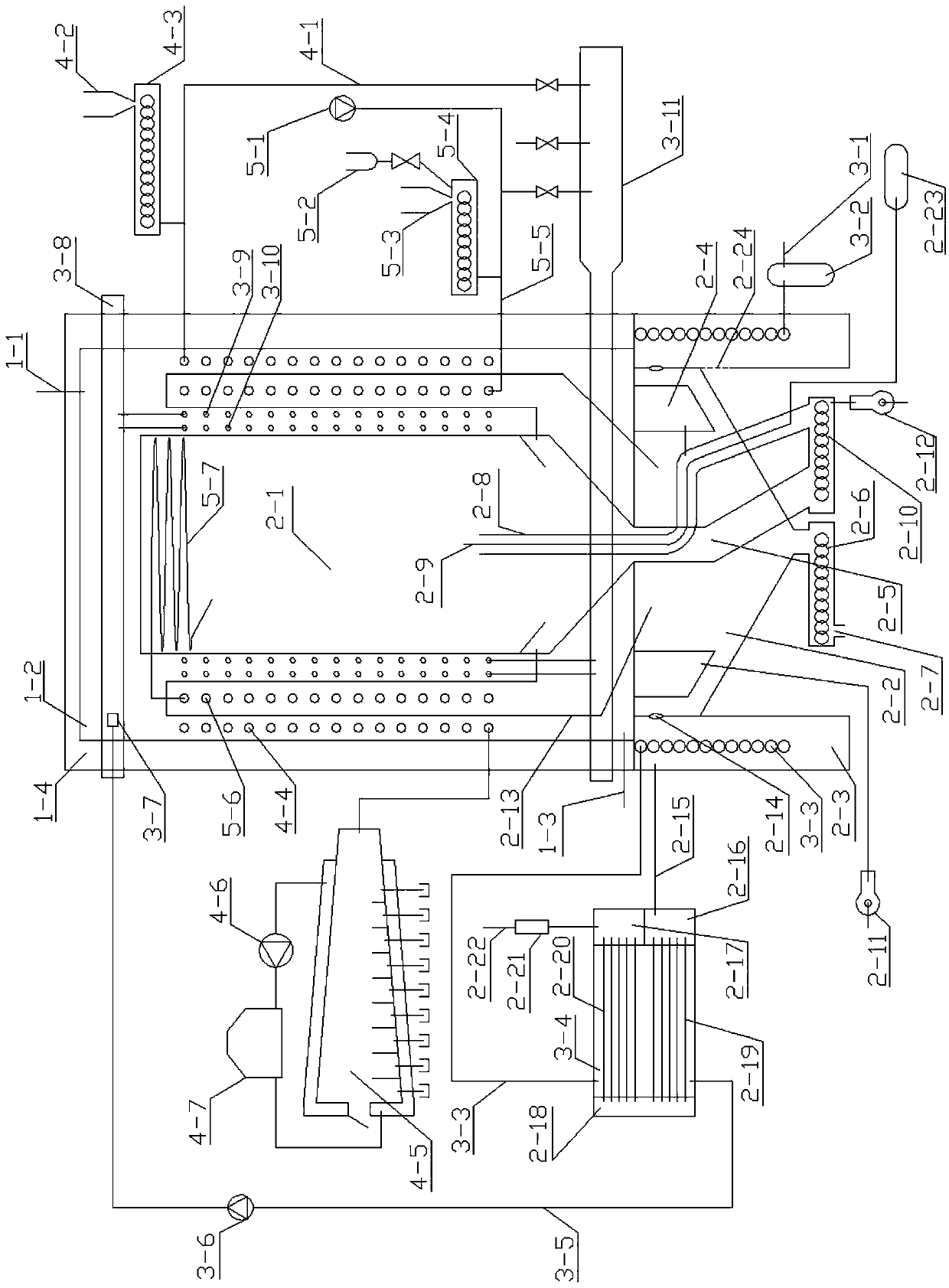

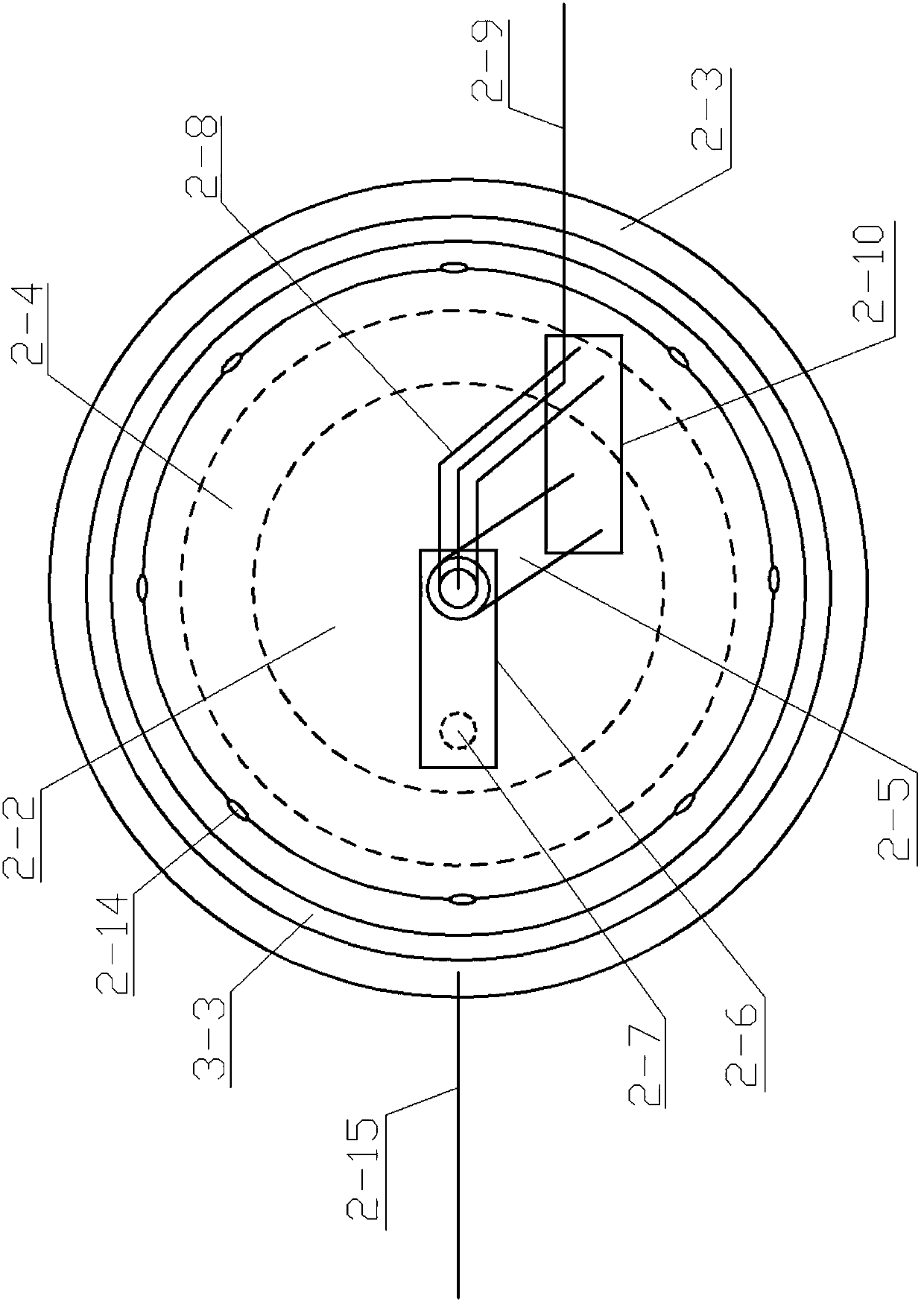

[0060]The present invention will be further described below in conjunction with the accompanying drawings and specific implementation.

[0061] The supercritical steam colliding material thermal decomposition boiling range condensation reduction separation equipment structure of the present invention is as follows figure 1 , figure 2 As shown, the supercritical flash pyrolysis gas substance condensation reduction device consists of a molten salt feeding pipe 1-1, a molten salt tank 1-2, a molten salt discharge pipe 1-3, an insulation layer 1-4, a combustion chamber 2-1, Ash discharge funnel 2-2, annular waste heat recovery box 2-3, dust removal air preheater 2-4, fuel collection pipe 2-5, ash conveyor 2-6, ash discharge port 2-7, fluidized combustion Pipe 2-8, gas delivery pipe 2-9, fuel conveyor 2-10, primary blower 2-11, secondary blower 2-12, three-pass heat exchange pipe 2-13, smoke hole 2-14, exhaust Smoke pipe 2-15, first flue gas slot 2-16, second flue gas slot 2-17,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com