Coating material horizontal continuous casting direct recombination forming apparatus and technology

A composite forming and horizontal continuous casting technology, which is applied to the equipment and process of cladding material horizontal continuous casting and direct composite forming. Problems such as application, interface can not be well compounded, and the curling mechanism is complex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

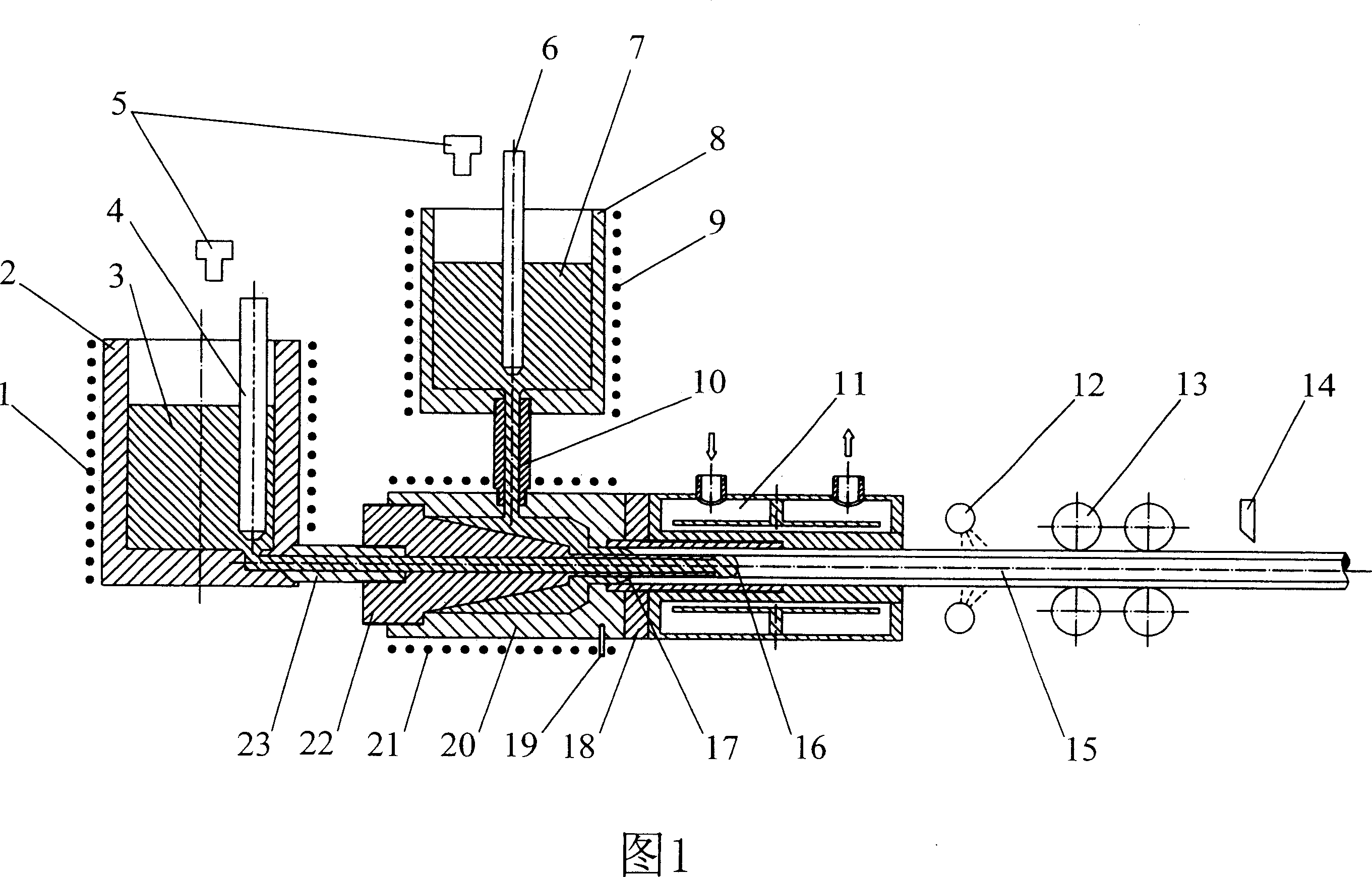

[0016]Fig. 1 is a kind of embodiment of the equipment of the present invention. Its equipment consists of clad metal temperature-controlling crucible 8, heating element 9, thermometer 5 and stopper rod 6 to form a cladding metal insulation system; the core metal temperature-controlling crucible 2, heating element 1, thermometer 5 and The stopper rod 4 constitutes the core metal heat preservation system; it consists of the clad metal flow guide pipe 10, the clad metal heat preservation cavity 20 and its heating element 21, the thermometer 19, the core metal flow guide pipe 23, and the core metal liquid The pouring pipe 22, clad metal crystallizer 11 and secondary cooling device 12 constitute a pouring and solidification system; the traction mechanism 13 and its controller, sawing device 14 constitute a continuous casting system. The heating elements 1, 9, 21 can adopt induction heating, resistance heating or flame heating. Core metal temperature-controlling crucible 2, coating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com