Machining method of heat exchanger tube plate build-up welding

A processing method and heat exchanger technology, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve problems such as heavy workload, production complexity and cost increase, and high cost of welding consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Take HRQ12-082 regenerative bottom reboiler of heat exchanger equipment in a factory as an example:

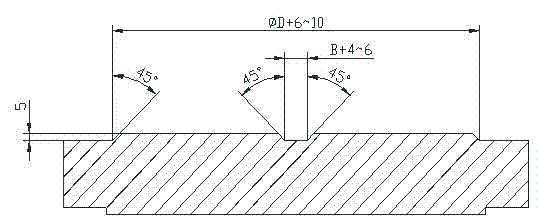

[0011] Step 1: Reduce the outer diameter of the φ1687×50mm sealing surface by 6~10mm, the depth is 5mm, and chamfer 45°, the width of the partition groove is increased by 4~6mm, the depth is 5mm, and chamfer 30~60° on both sides Ordering; second step: surfacing 3mm stainless steel composite layer on the sealing surface of the tube sheet; third step: leveling with a plate rolling machine, and processing after leveling; fourth step: performing sealing surface and inner and outer circles Turning, drilling.

[0012] The previous processing method required about 240 kg of welding material and about 288 kg of flux. After using this invention, it needs 150 kg of welding material and about 180 kg of flux. The material is 90kg, and the flux is about 108 kg; in terms of personnel cost, the traditional processing method needs 2 people and 5 days to complete, and this method takes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com