Pre-shrinking machine capable of rotationally switching heating rollers

A technology of heating rollers and pre-shrinkers, which is applied in the direction of compressing water, textiles and papermaking, and fabric surface trimming. It can solve the problem that the heating time of pre-shrinker fabrics cannot be adjusted, and achieve the effect of simple structure and favorable shrinkage rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

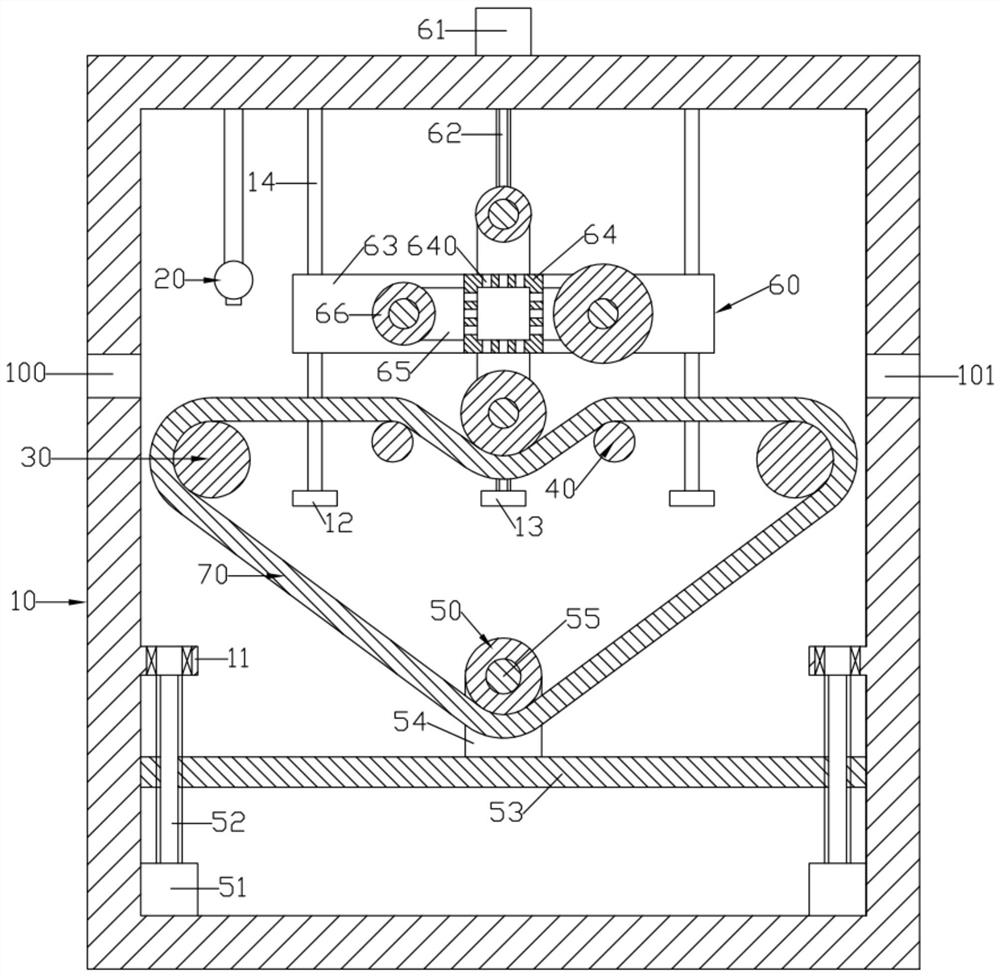

[0013]Such asfigure 1As shown, a pre-shrinking machine with rotating and switching heating rollers includes a cabinet 10 and a switching device 60; the upper part of the left side wall of the cabinet 10 is formed with a feed inlet 100, and the upper part of the right wall is formed with a discharge port 101; A pair of left-right symmetrical auxiliary rollers 40 and a pair of left-right symmetrical conveying drive rollers 30 are rotatably arranged between the front and rear side walls; a tension roller 50 is set up and down in the lower part of the interior of the chassis 10; a pair of auxiliary rollers 40 are located in a pair of conveying Between the driving rollers 30; a pair of auxiliary rollers 40, a pair of conveying driving rollers 30, and a tension roller 50 are provided with a rubber blanket 70; the switching device 60 includes a pair of front and rear support plates 63 that are symmetrically arranged front and rear; a pair of front and rear support plates 63 is synchronousl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com