Low-temperature idle running heating control system and method of wind generating set

A wind turbine and heating control technology, which is applied to wind turbine components, wind turbine control, wind turbines, etc., can solve the problem of not being able to accurately judge whether the electric pump will be overloaded when starting at 0°C, and not considering whether the fan can safely enter this state. , Only consider the control of fans, electric pumps, etc., to achieve the effect of enhancing the low-temperature start-up capability and reliability, shortening the low-temperature start-up time, and reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

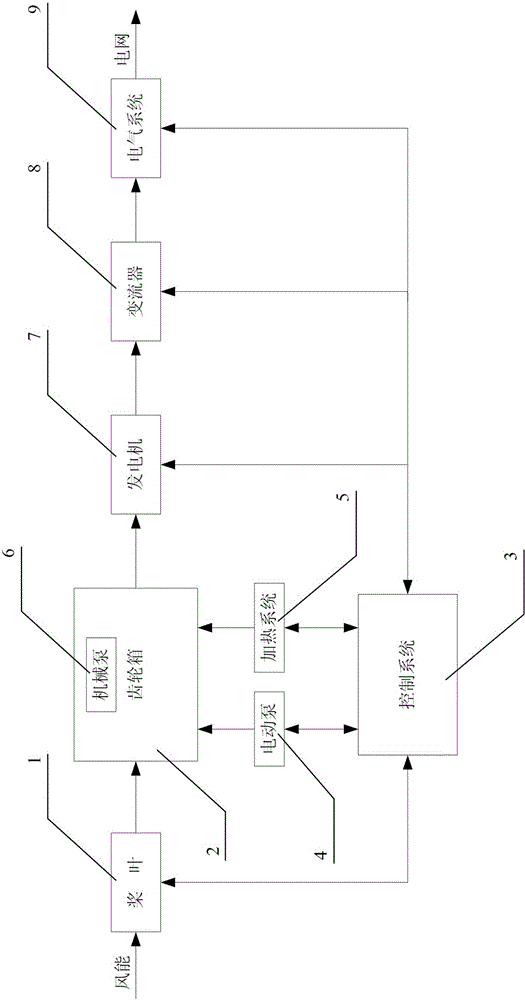

[0042] as attached figure 1 As shown, the entire wind power generation system includes: a blade 1 , a gearbox 2 , a control system 3 , a generator 7 , a converter 8 and an electrical system 9 . The wind energy drives the blade 1 of the wind turbine to rotate, the low-speed shaft of the gearbox 2 is connected to the blade 1, the blade 1 drives the gearbox 2 to rotate, the high-speed shaft of the gearbox 2 is connected to the generator 7, and the generator 7 converts mechanical energy After converting the electric energy through the converter 8, the electric energy is finally transmitted to the grid through the electrical system 9. The control system 3 realizes the control function of the whole wind power generation system. A specific embodiment of the heating control system for low-temperature no-load operation of wind turbines includes: a control system 3 , an electric pump 4 and a heating system 5 . When the oil temperature of the gearbox 2 is lower than a certain value and...

Embodiment 2

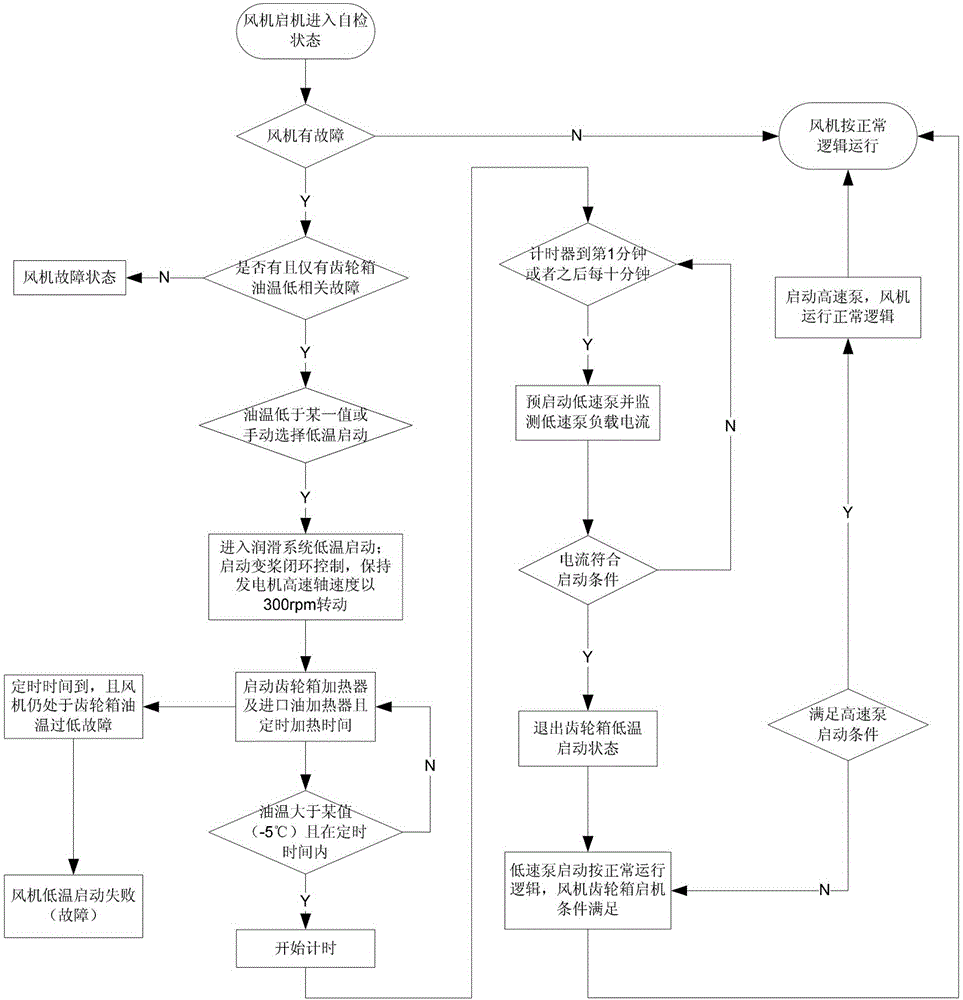

[0050] as attached figure 2 As shown, a specific embodiment of a heating control method for low-temperature no-load operation of a wind turbine includes the following steps:

[0051] S101: When the oil temperature of the gearbox 2 is lower than a certain value and the gearbox lubrication system enters the low-temperature startup state, the blade 1 of the wind turbine is pitched to a certain angle (automatically adjusted by the wind speed), and the gearbox 2 is kept rotating without load ( At this time, the generator 7 does not generate electricity) to stir the lubricating oil, and make the oil temperature of the gearbox 2 rise evenly;

[0052] S102: When the speed of the high-speed shaft of the gearbox 2 is maintained at the set value, the heating system 5 heats the gearbox 2, and at this time, the deterioration of the lubricating oil due to local heating will not be caused;

[0053] S103: When the oil temperature of the gearbox 2 reaches the minimum start-up oil temperature...

Embodiment 3

[0066] In this embodiment, taking the actual operating data of a 1.65MW wind power generating set as an example, the technical implementation scheme of the heating control system and method for low-temperature no-load operation of the wind power generating set of the present invention is described in detail.

[0067] When the wind turbine is shut down, the fan will judge the status of the fan, fault information and the lubricating oil temperature of the gearbox in the self-check state. When the wind turbine meets other conditions for normal startup except that the oil temperature of the gearbox is lower than a certain threshold, At this time, the wind turbine enters the low-temperature startup state of the gearbox lubrication system. If a fault occurs during the low-temperature startup, the wind turbine will stop due to failure. In order to allow the wind turbine to accelerate the heating speed as much as possible during the heating process of the lubricating oil in the gearbox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com