Automatic detection method for broken wires of automobile front windshield wired glass

A technology of automatic detection and wired glass, applied in radiation pyrometry, measuring electricity, measuring devices and other directions, it can solve the problems of many tungsten wires, inability to deicing in some areas of the front block, easy to miss detection, etc., reducing the number of tungsten wires. The number of missed inspections, the overall temperature of the glass is constant, and the effect of controlling the heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

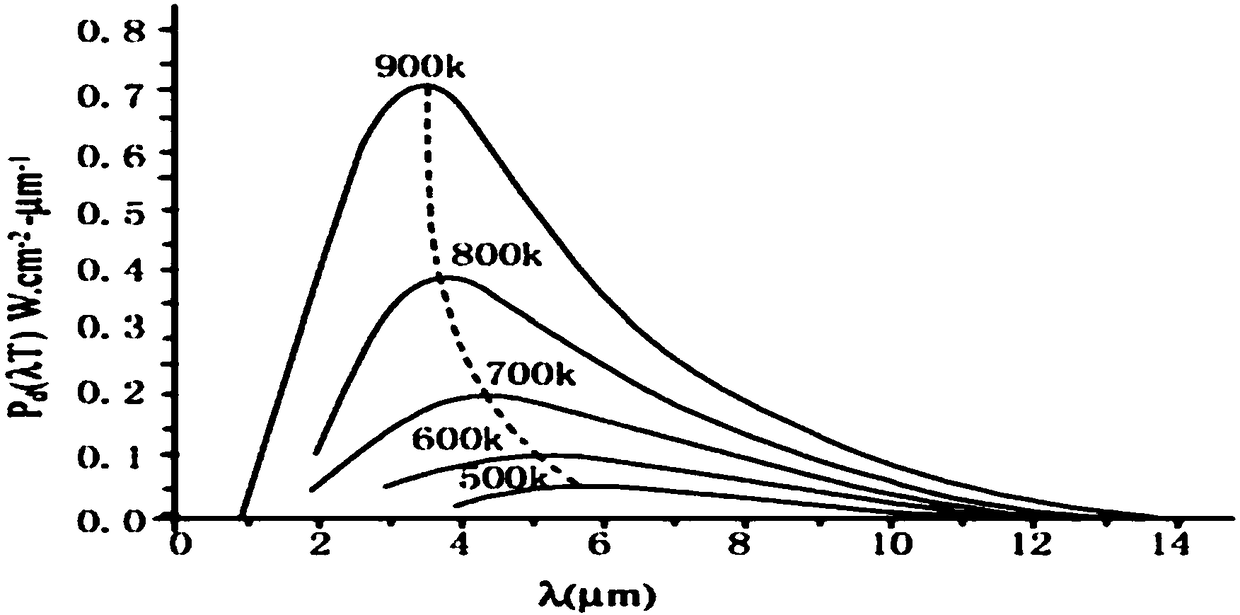

[0028] Infrared radiation is one of the most widespread electromagnetic radiations in nature. It is based on the fact that any object will produce its own molecular and atomic irregular movements in a conventional environment, and continuously radiate thermal infrared energy, molecular and atomic movements. The more intense, the greater the energy of the radiation, and vice versa, the smaller the energy of the radiation.

[0029] Objects with a temperature above absolute zero will radiate infrared rays due to their own molecular motion. After the power signal radiated by the object is converted into an electrical signal by the infrared detector, the output signal of the imaging device can completely simulate the spatial distribution of the surface temperature of the scanned object one by one. After being processed by the electronic system, it is transmitted to the display screen and obtained The thermal image corresponding to the heat distribution on the surface of the object....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com