Thermal history control method for thermal printing head, thermal printer and computer-readable storage medium

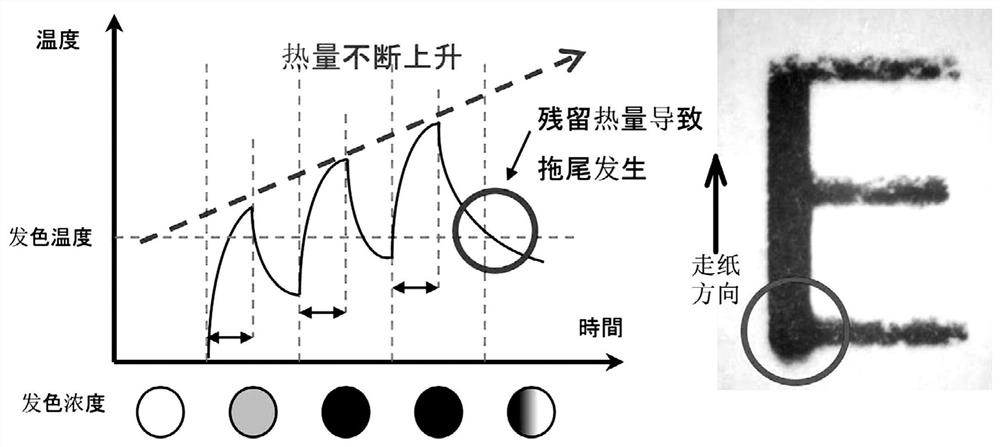

A technology of a thermal print head and a control method, applied to thermal printers and computer-readable storage media, in the field of thermal history control of thermal print heads, and can solve problems such as affecting printing quality, insufficient color density of font patterns, smearing, etc. problems, to achieve the effect of clear fonts or images, smooth heating, and avoid smearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

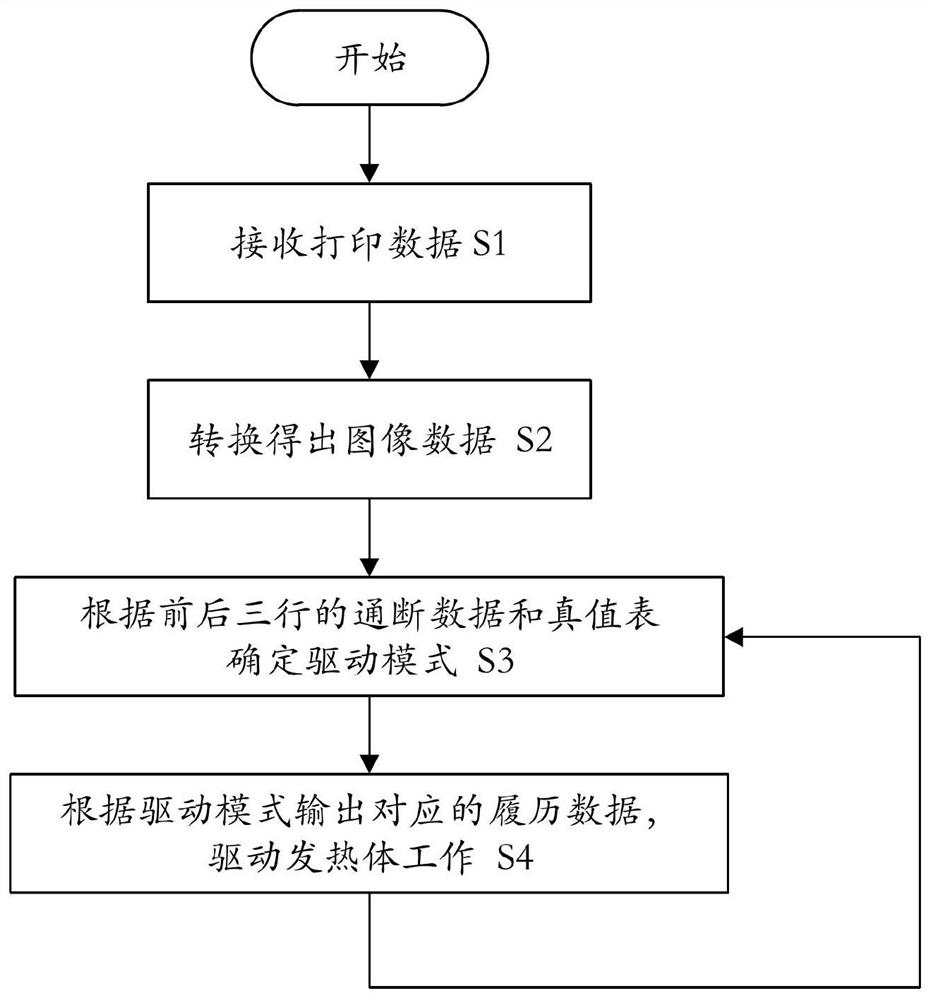

[0036] Embodiment of thermal history control method of thermal print head:

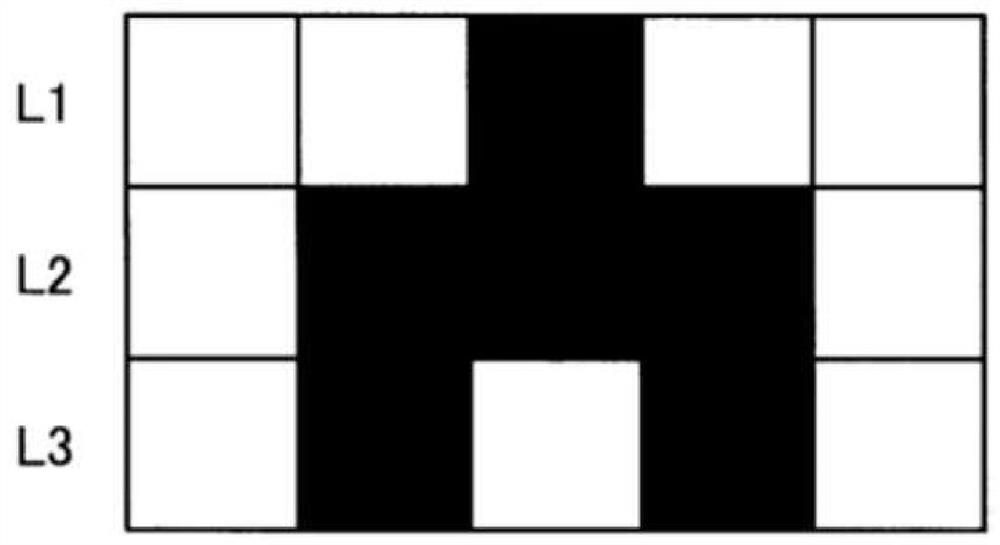

[0037] refer to figure 2 , the thermal printhead includes a thermal printhead, a processor and a memory, the processor is electrically connected to the thermal printhead, and when the processor executes the thermal history control method, it first executes step S1 to receive the print output from the computer, terminal or server data, and then execute step S2 to convert the image data according to the print data, refer to image 3 , image 3 It is a schematic diagram of image data. The image data is a dot matrix image converted from printing data, and then digitally processed to form image data. Each row of white pixels from L1 to L3 corresponds to the power-on cut-off (OFF) of the heating element, which is represented by "0" Indicates the state of energization and cut-off, and the black pixels in each row of L1 to L3 correspond to the heating element energization and conduction (ON). When "1" is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com