Acid pickling method of calcified clinker

A technology of calcified clinker and acid leaching, applied in the field of metallurgy, can solve the problems of limited site conditions, slow reaction, intense reaction, etc., and achieve the effect of ensuring the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

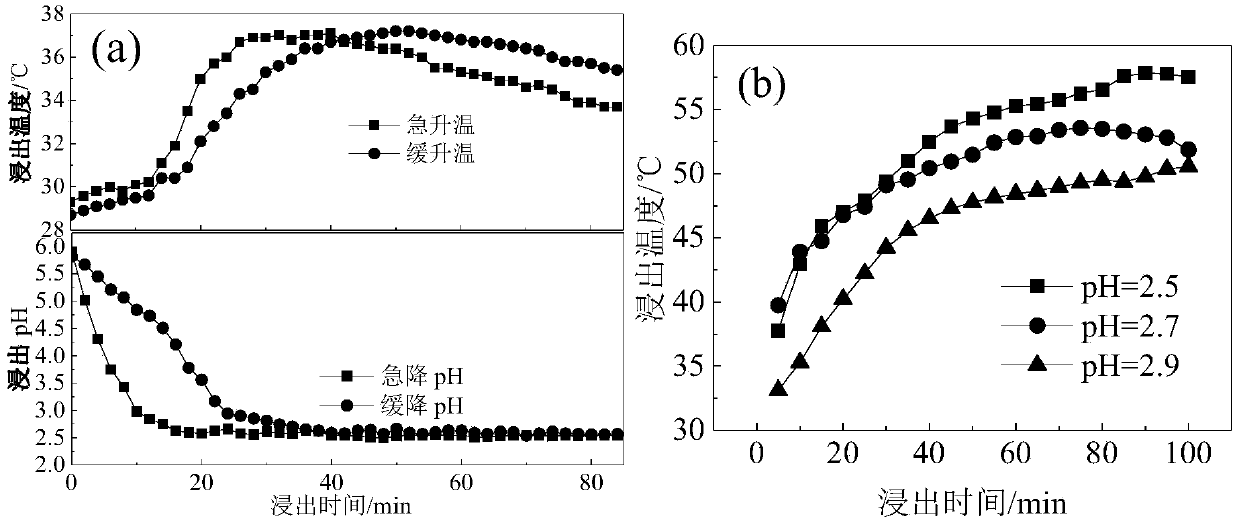

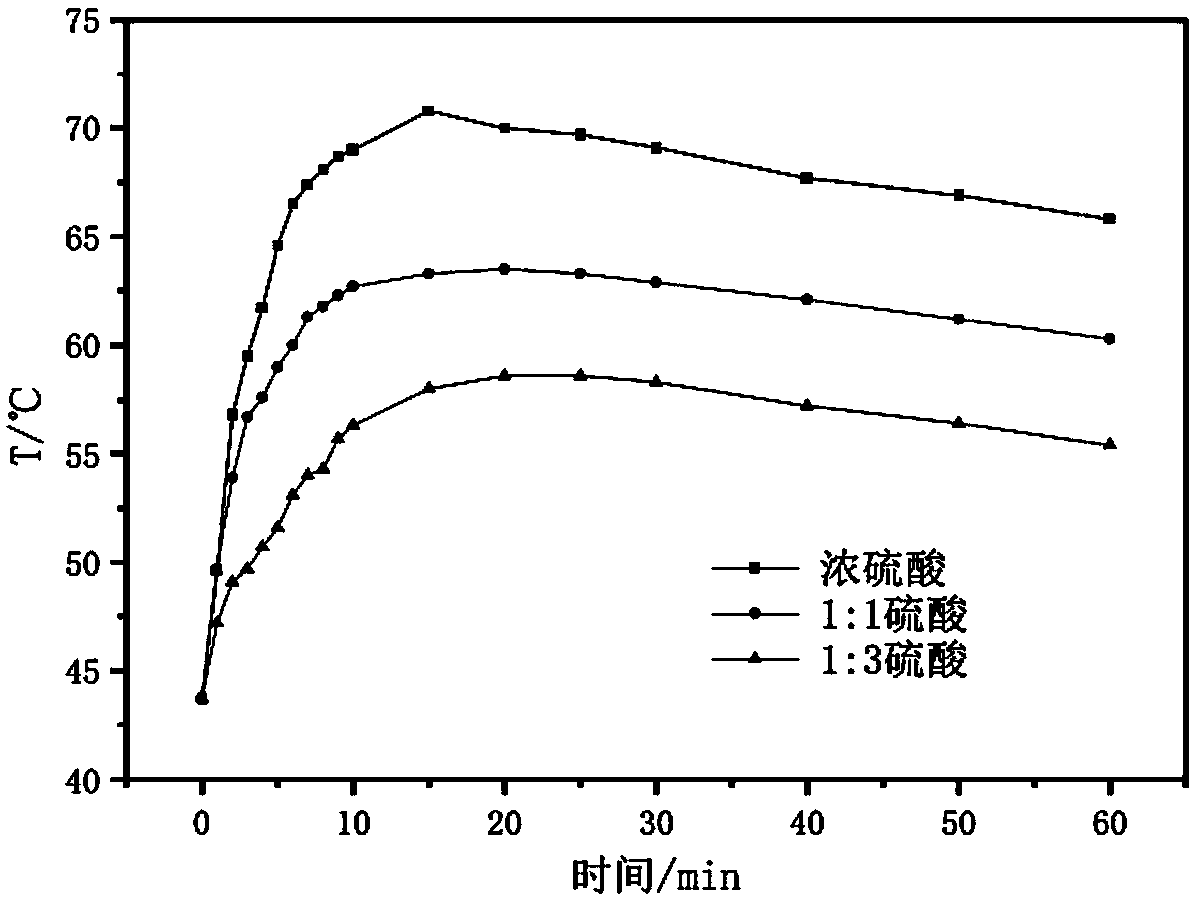

[0051] Embodiment 1 clinker or / and T 环境 <10℃(low temperature)

[0052] The clinker property parameter R is 0.73 and / or the ambient temperature is 7°C.

[0053] The amount of mother liquor and the amount of clinker are set at a liquid-solid ratio of 1.9 (the amount of mother liquor L is 15m 3 , clinker amount S is 8 tons) mixed to obtain acid leaching slurry;

[0054] Sulfuric acid with a mass concentration of 73.4% was slowly added dropwise to the above-mentioned slurry in 6 minutes, and the pH of the slurry was reduced to 2.3-2.5, and leached at a constant pH and temperature for 90 minutes;

[0055] Through the above operations, the temperature of the acid leaching system rose to 52.48°C in 6 minutes.

[0056] The leaching rate of clinker obtained in this embodiment is 97.45%. If it is leached according to the conventional method, the temperature of the acid leaching system is as high as 32.57°C, and the obtained vanadium leaching rate is 82.57%.

Embodiment 2

[0057] Example 2 without 0.85 or / and T 环境 =10~20℃ excluding 20℃(medium temperature)

[0058] The clinker property parameter R is 0.83 and / or the ambient temperature is 15°C.

[0059] The amount of mother liquor and the amount of clinker are based on a liquid-solid ratio of 2.3 (the amount of mother liquor L is 16.5m 3 , clinker amount S is 7.2 tons) mixed to obtain acid leaching slurry;

[0060] Sulfuric acid with a mass concentration of 55.09% was slowly added dropwise to the above slurry in 13 minutes to reduce the pH of the slurry to 2.5-2.7, and leached at a constant pH and temperature for 65 minutes;

[0061] Through the above operations, the temperature of the acid leaching system rose to 53.17°C in 13 minutes.

[0062] The leaching rate of clinker obtained in this embodiment is 98.36%. If it is leached according to the conventional method, the temperature of the acid leaching system is as high as 43.63°C, and the obtained vanadium leaching rate is 93.59%.

Embodiment 3

[0063] Example 3 or / and T 环境 >30℃(high temperature)

[0064] The clinker property parameter R is 0.93 and / or the ambient temperature is 34°C.

[0065] The amount of mother liquor and the amount of clinker are calculated according to the liquid-solid ratio of 3.2 (the amount of mother liquor L is 17.5m 3 , clinker amount S is 5.5 tons) mixed to obtain acid leaching slurry;

[0066] Sulfuric acid with a mass concentration of 31.51% was slowly added dropwise to the above slurry in 24 minutes to reduce the pH of the slurry to 2.9-3.1, and leached at a constant pH and temperature for 30 minutes;

[0067] Through the above operations, the temperature of the acid leaching system rose to 54.57°C in 24 minutes.

[0068] The leaching rate of clinker obtained in this embodiment is 98.65%. If it is leached according to the conventional method, the temperature of the acid leaching system can be as high as 67.61°C, and the obtained vanadium leaching rate is 73.59%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com