Non-groove rolling method for high speed wire bar intermediate rolling train

A rough rolling unit and high-speed wire rod technology, applied in the direction of rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of reducing the number of roll reloads, increasing roll consumption, and affecting the productivity of the rolling mill, so as to reduce roll consumption and Production cost, improvement of rolling mill operating rate and productivity, and the effect of increasing the number of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

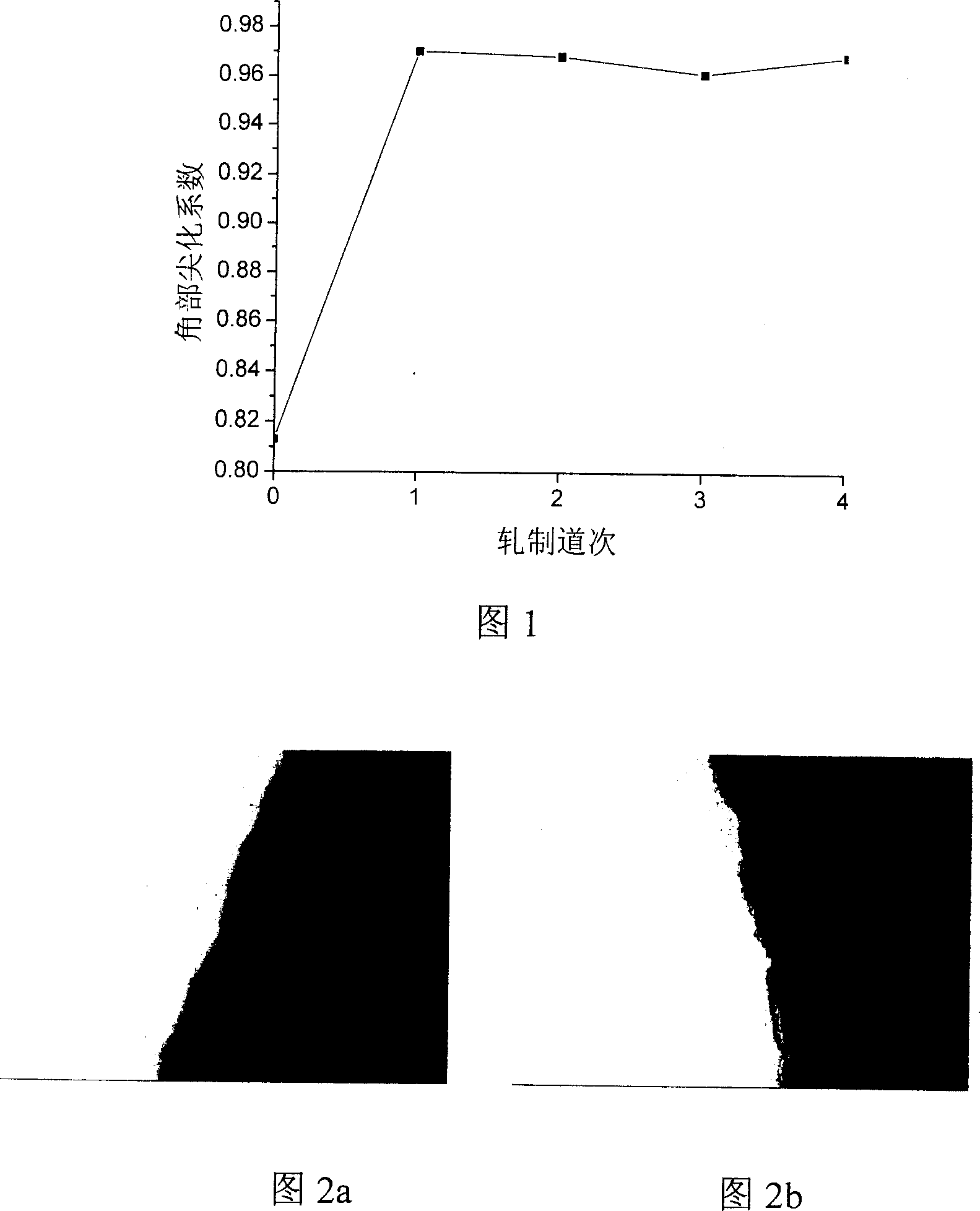

[0027] Embodiment 1: Take the two-pass grooveless rolling method as an example:

[0028]

[0029]

[0030] When the wire rod is rolled by this scheme, the biting condition of the rolled piece from the 2V stand rolled without holes to the 3H stand rolled with holes is normal. The rolling process is equally stable, and the size and cross-section fully meet the rolling requirements of the subsequent rolling group.

Embodiment 2

[0031] Embodiment 2: Four-pass grooveless rolling method

[0032]

[0033] When the wire rod is rolled by this plan, the biting condition of the rolled piece from the 4V stand rolled without holes to the 5H stand rolled with holes is normal, and the cross section of the rolled piece at the exit of the rough rolling unit is the same as the original one with holes The rolling process is equally stable, and the size and cross-section fully meet the rolling requirements of the subsequent rolling group.

Embodiment 3

[0034] Embodiment 3: Six-pass grooveless rolling method

[0035]

[0036]

[0037] When the wire rod is rolled by this plan, the biting condition of the rolled piece from the 6V stand without the groove to the 7H stand with the groove is normal, and the cross section of the rolled piece at the exit of the rough rolling unit is the same as the original one with the groove. The rolling process is equally stable, and the size and cross-section fully meet the rolling requirements of the subsequent rolling group.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com