Process for rolling H steel using trio mill and heat rectification machine

A three-roll mill and process technology, applied in metal rolling and other directions, can solve problems such as web eccentricity and web corrugation, and achieve the effects of avoiding web eccentricity, improving rolling rhythm, and high equipment utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

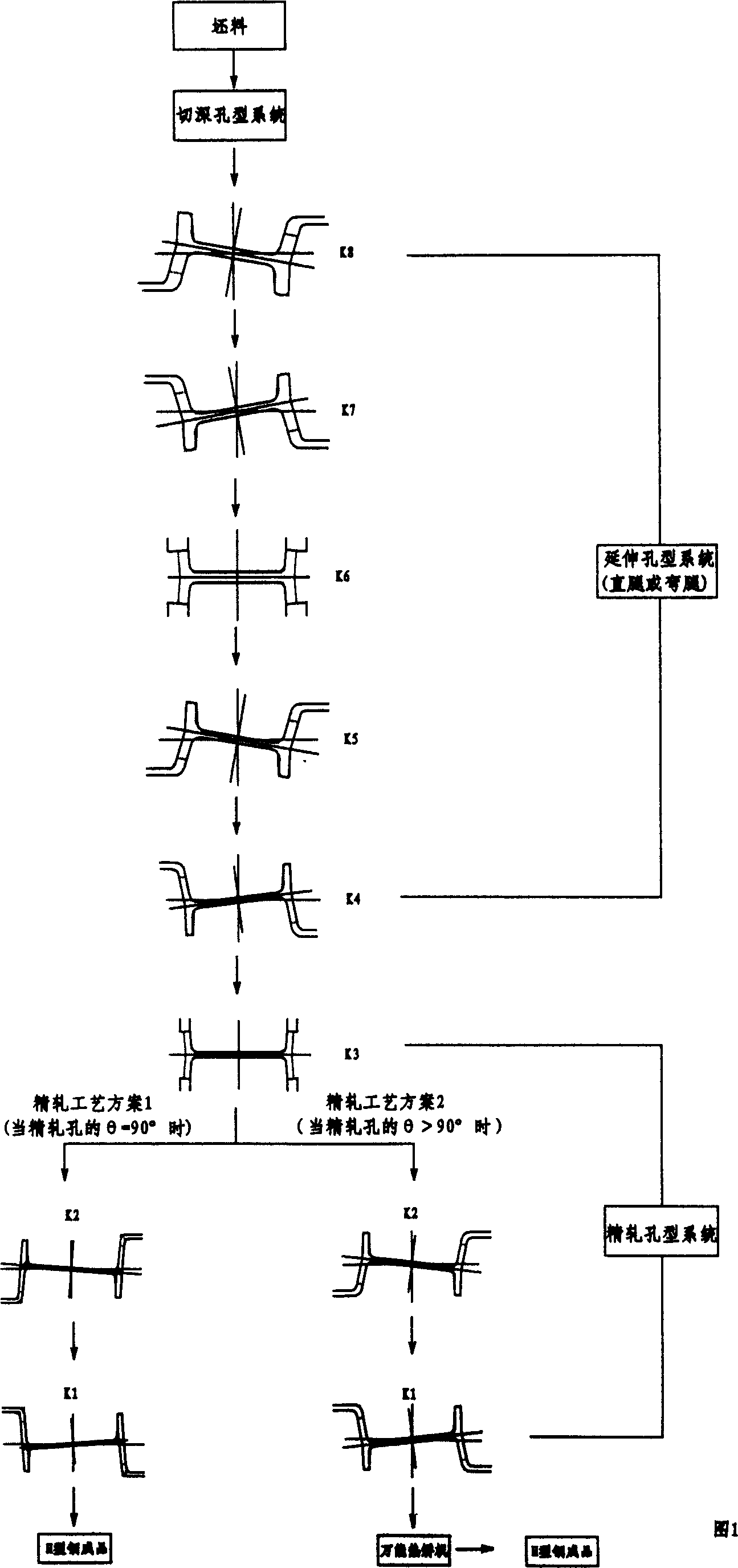

[0024] Embodiment 1. H150X75 (belonging to narrow-side H-shaped steel) is produced on a Φ5502+Φ5001 three-roller tandem rolling mill. The rolling mill has three stands, and the length of the roll body is 1500mm. Four passes can be configured on each roll. The process scheme is described below.

[0025] The steel billet adopted is a square billet of 150×150, with three deep-cut holes and four extension holes, all of which adopt the parallel flange of the present invention

[0026] Embodiment 1. H150X75 (belonging to narrow-side H-shaped steel) is produced on a Φ5502+Φ5001 three-roller tandem rolling mill. The rolling mill has three stands, and the length of the roll body is 1500mm. Four passes can be configured on each roll. The process scheme is described below.

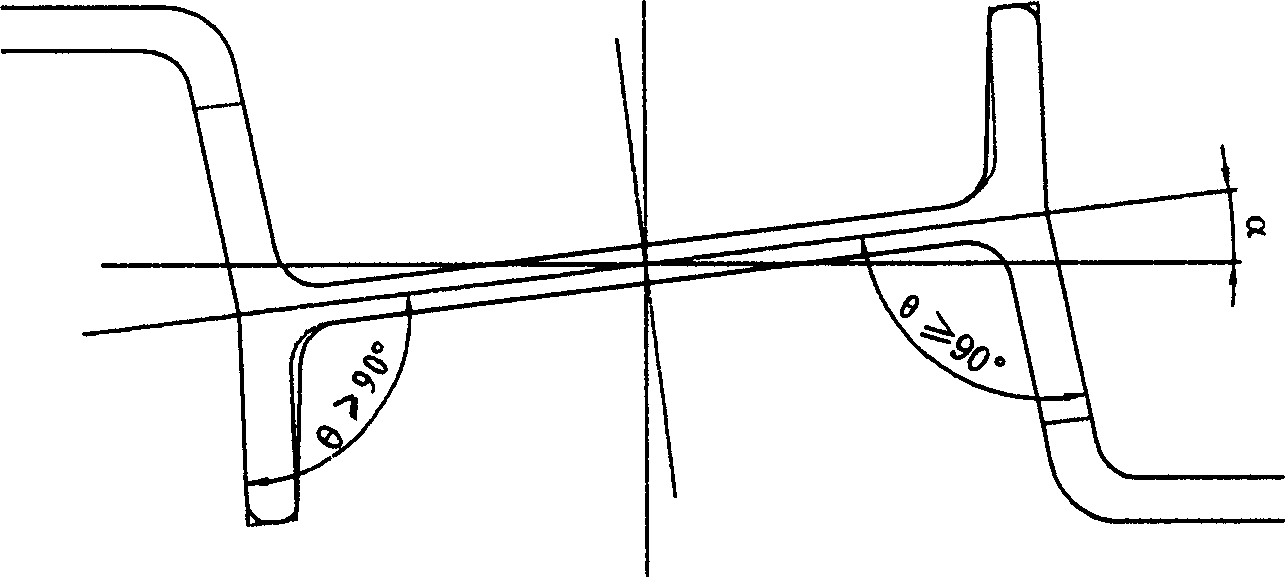

[0027] The steel billet used is a 150X150 square billet, with three deep-cut holes and four extended holes, all of which adopt the oblique rolling pass of the present invention for parallel flange bending, and inser...

Embodiment 2

[0032] H10010068 (belonging to wide-side H-beam) is produced on the Φ5502+Φ5001 three-roller tandem mill. There are three rolling mill stands, and the length of the roll body is 1500mm. Four passes can be configured on each roll. The process plan is:

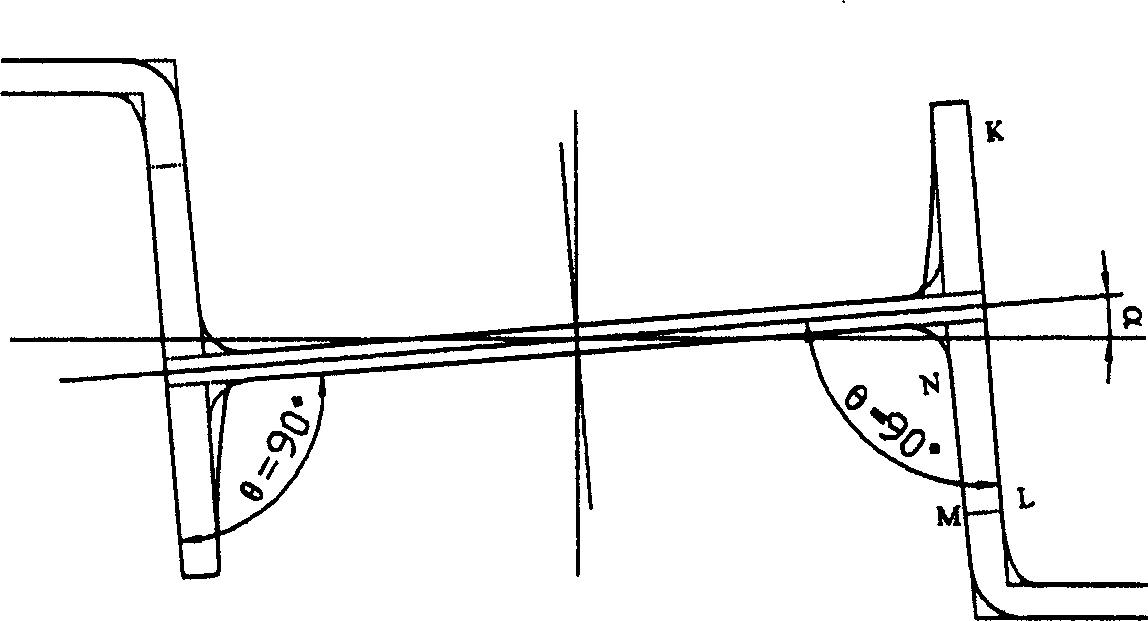

[0033] The 150×150 square billet is used as the raw material, and after being heated, it is rolled on a common two-roll rolling mill (or three-roll rolling mill) through three passes of deep hole cutting, and then enters the extended hole consisting of five parallel flange passes. Then the leg height and the shape of the leg end are controlled and corrected through a rolling hole; then the rolled piece is rolled in the oblique rolling pass of the parallel flange bent leg, and the θ angle is greater than 90. H-shaped steel, and finally the bent legs are corrected by a universal hot straightening machine to obtain a finished H-shaped steel.

[0034] The universal hot straightening machine is composed of two vertical rollers conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com