Process for rolling H steel using trio mill

A three-roll mill and process technology, applied in metal rolling and other directions, can solve problems such as web eccentricity and web corrugation, and achieve the effects of avoiding web eccentricity, reducing quality requirements and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

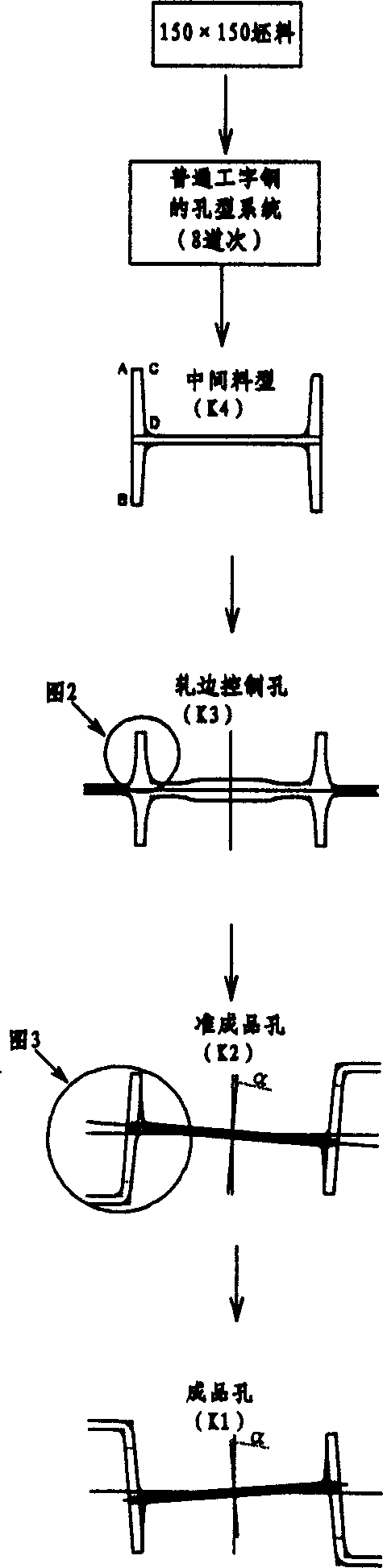

[0020] Embodiment 1, produce H150×75×5×7 (belonging to narrow side H-shaped steel) on Φ550×2+Φ500×1 three-roller tandem rolling mill, the process scheme is as follows figure 1 shown

[0021] The rolling mill has three stands, the length of the roll body is 1500mm, and each roll can be configured with four passes.

[0022] The steel billet used is a 150×150 square billet. Both the deep-cut hole and the extended hole adopt the bending oblique rolling method. A total of 7 passes are rolled to obtain an I-shaped intermediate billet, and then enter the edge rolling control hole to obtain the basic thickness of the leg. A uniform rolled piece enters two parallel straight-leg oblique rolling passes with opposite opening directions to obtain standard H150×75×5×7 products.

[0023] The main pass sizes are:

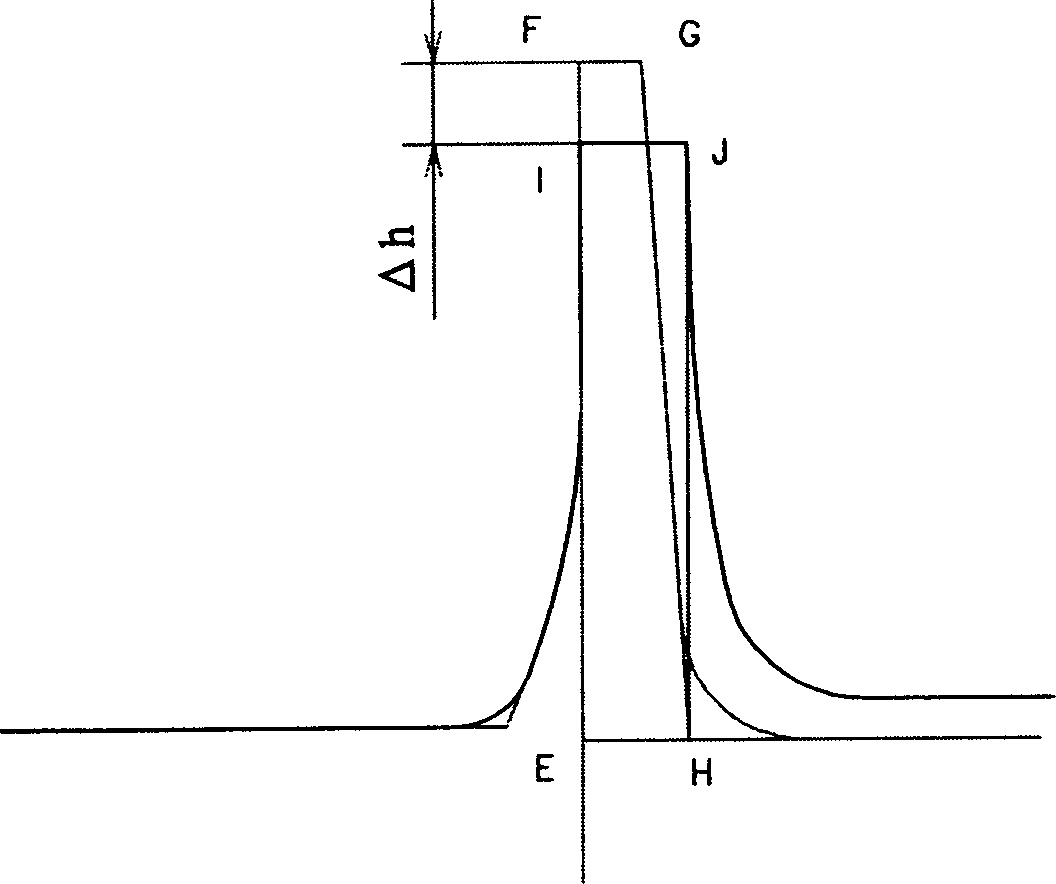

[0024] Edge control hole: the leg end width is 7mm, and the leg height is 37mm.

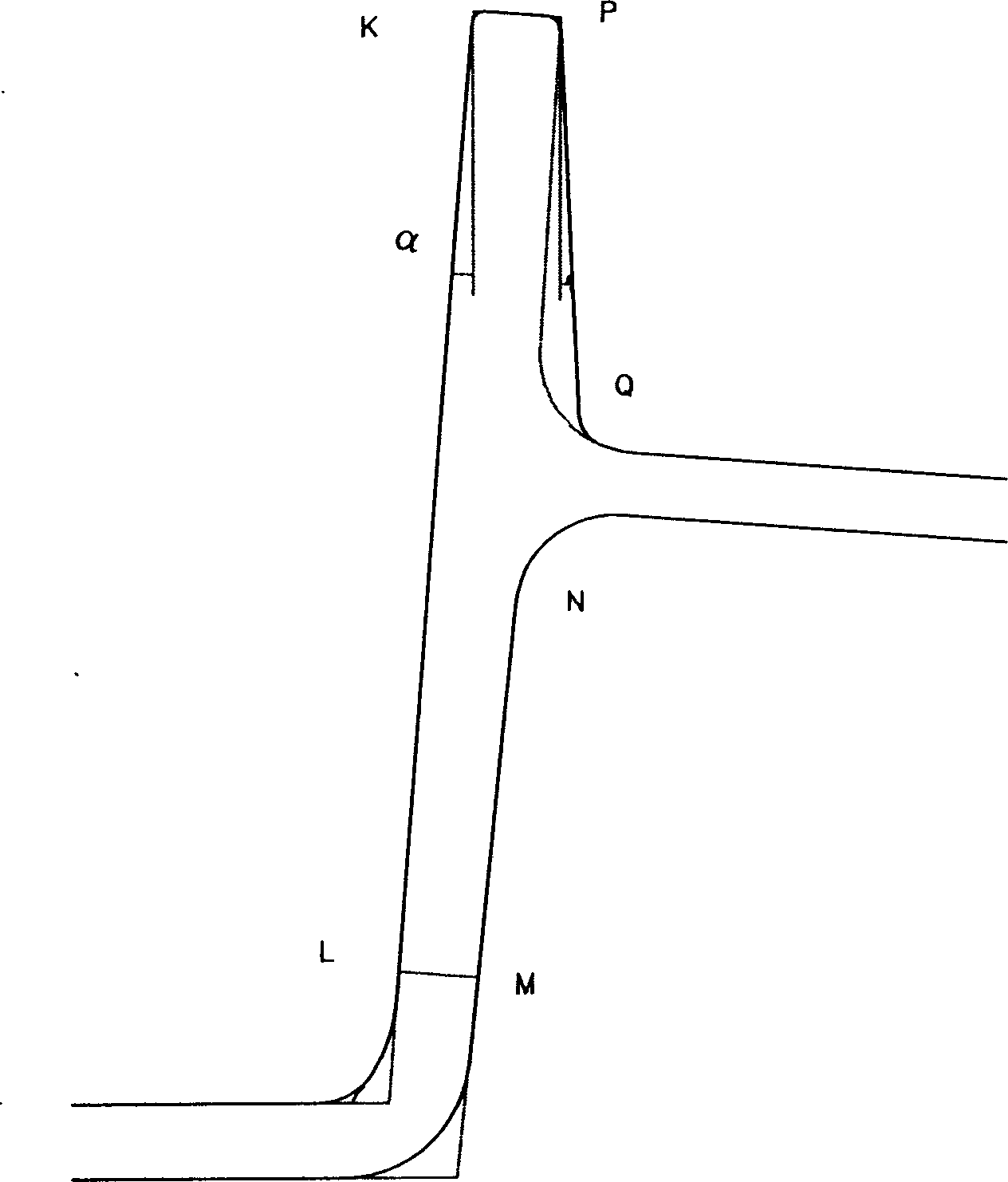

[0025] Parallel straight leg oblique rolling hole: the thickness of the opening leg of the fini...

Embodiment 2

[0027] H100×100×6×8 (belonging to wide-side H-beams) is produced on the Φ550×2+Φ500×1 three-roller tandem mill. The process plan is as follows figure 1 shown

[0028] The rolling mill has three stands, the length of the roll body is 1500mm, and each roll can be configured with four passes.

[0029] The steel billet used is a rectangular billet of 120×200. Both the deep-cutting hole and the extending hole adopt the bending oblique rolling method, and a total of 9 passes are rolled. The I-shaped intermediate billet obtained is then entered into the edge rolling control hole to obtain the leg. A rolled piece with a substantially uniform thickness enters two parallel straight-leg oblique rolling passes with opposite opening directions to obtain a standard H100×100×6×8 product.

[0030] The main pass sizes are:

[0031] Edge control hole: leg end width 8mm, leg height 48mm.

[0032] Parallel straight leg oblique rolling hole: the thickness of the opening leg of the finished hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com