Superhigh-strength high-toughness steel plate for ocean engineering and production method thereof

A technology of marine engineering and production methods, applied in the field of steel, can solve the problems of low strength and achieve the effects of excellent low-temperature toughness, stable production process, and fine grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

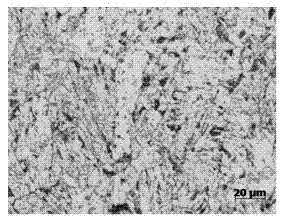

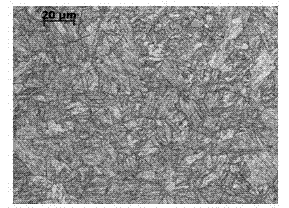

Image

Examples

Embodiment Construction

[0036] According to the production process of the present invention, a total of two furnaces are smelted, and the smelting process is molten iron pretreatment → converter smelting → LF furnace refining → RH vacuum treatment → continuous casting machine continuous casting → billet stacking and slow cooling → billet inspection → casting Billet judgment → casting billet acceptance. After desulfurization treatment, the carbon content in the molten iron is controlled to [S]≤0.002%. After blowing, the end-point temperatures of the converter are 1601 and 1620°C, respectively, and the LF temperatures are 1551 and 1569°C, respectively. The aluminum deoxidation method is used for deoxidation. The residence time in the LF furnace is 40-50 minutes. The atmosphere in the bag is controlled by micro positive pressure operation. RH vacuum treatment, the holding time is 30 minutes under the condition of high vacuum degree (≤5.0mbar). After the RH breaks the vacuum, the pure calcium wire is f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com