Large reduction rolling method for magnesium alloy

A magnesium alloy and vector technology, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of unfavorable plate processing and deformation, plate anisotropy, etc., and solve the problems of rolling cracks and rolling fractures , Reduce the rolling temperature, increase the effect of single pass reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Select a hard liner with a thickness of 2.5 mm and smooth upper and lower surfaces;

[0030] (2) Spread the high-temperature lubricant evenly on the surface of the liner and the magnesium alloy, and put the magnesium alloy blank and the liner into the heating box at the same time to heat;

[0031] (3) After the temperature rises to 350°C, let it stand for 5 minutes;

[0032] (4) Place the liner on the lower surface of the magnesium alloy blank, and push the liner and the blank to the roll inlet at the same time;

[0033] (5) Repeat steps (2)-(4), the upper and lower surfaces of the magnesium alloy billet are not turned over during the rolling process, and the rolling is completed in two passes, and the reduction in each pass is successively 60% and 50%;

[0034] (6) The average grain size of the rolled sample is 1.3μm, the yield strength is 221MPa, the tensile strength is 291MPa, and the elongation at break is 15%.

Embodiment 2

[0036] (1) Select a hard liner with a thickness of 5-10 mm and smooth upper and lower surfaces;

[0037] (2) Spread the high-temperature lubricant evenly on the surface of the liner and the magnesium alloy, and put the magnesium alloy blank and the liner into the heating box at the same time to heat;

[0038] (3) After the temperature rises to 200-300°C, let it stand for 10-30 minutes;

[0039] (4) Place the liner on the lower surface of the magnesium alloy blank, and push the liner and the blank to the roll inlet at the same time;

[0040] (5) Steps (2)–(4) are repeated, and the magnesium alloy billet is turned upside down and sent to the roll between each adjacent pass, and the rolling is completed in four passes, and the reduction in each pass is 40%, 30%, 20% and 10%;

[0041] (6) Complete rolling.

Embodiment 3

[0043] (1) Select two hard liners with a thickness of 1 mm and smooth upper and lower surfaces;

[0044] (2) Spread the high-temperature lubricant evenly on the surface of the liner and the magnesium alloy, and put the magnesium alloy blank and the liner into the heating box at the same time to heat;

[0045] (3) After the temperature rises to 350°C, let it stand for 10 minutes;

[0046] (4) Place two liners on the upper and lower surfaces of the magnesium alloy billet respectively, and push the liner and the billet to the roll inlet at the same time;

[0047] (5) Rolling is completed in one pass, and the compression vector is 90%;

[0048] (6) The yield strength of the rolled sample is 180MPa, the tensile strength is 270MPa, and the elongation at break is 22%.

PUM

| Property | Measurement | Unit |

|---|---|---|

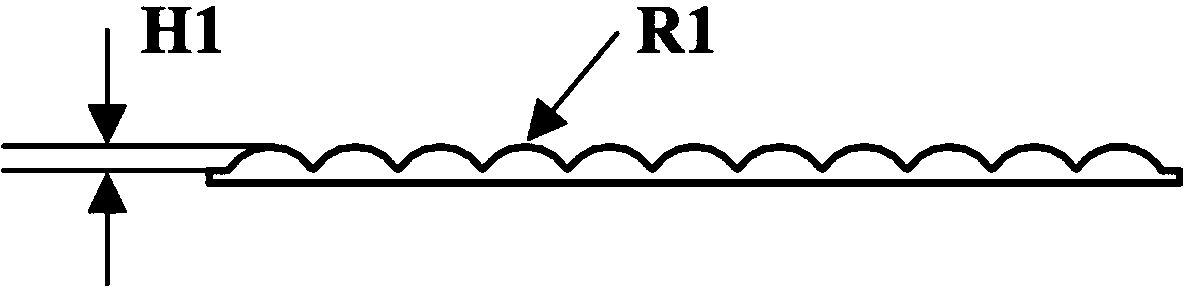

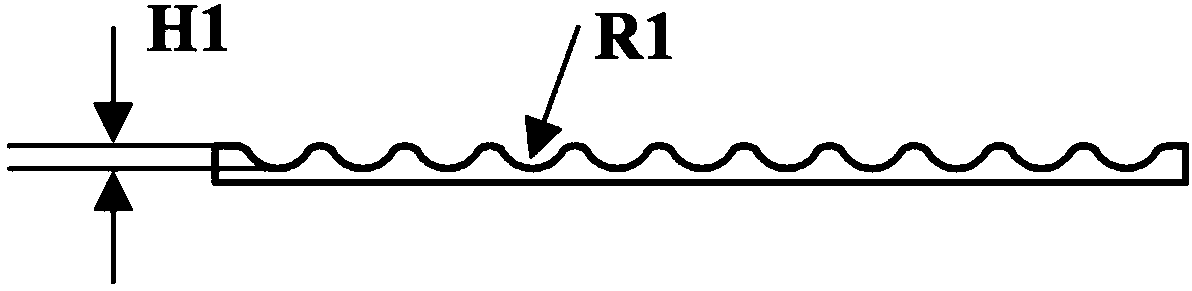

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com