H-shaped steel rolling equipment and method

A rolling equipment, H-beam technology, applied in metal rolling and other directions, can solve the problem of high cost of H-beam rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

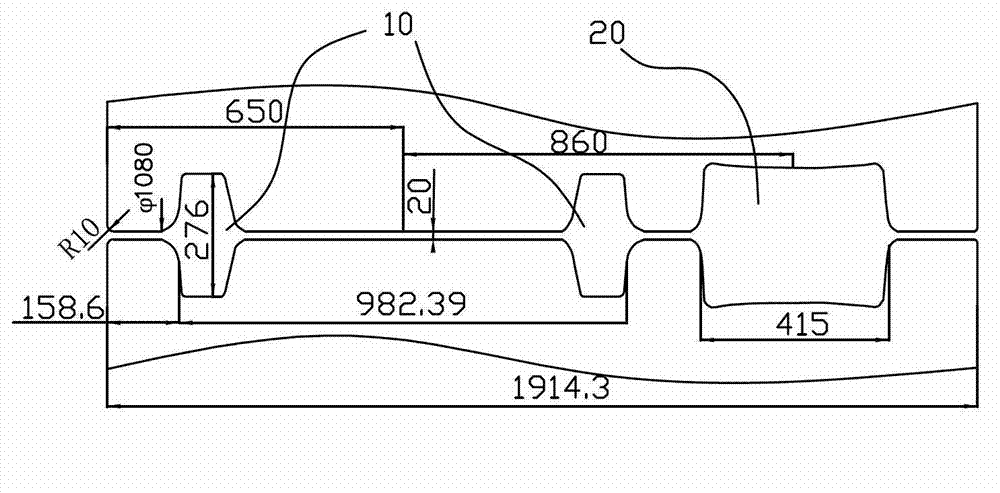

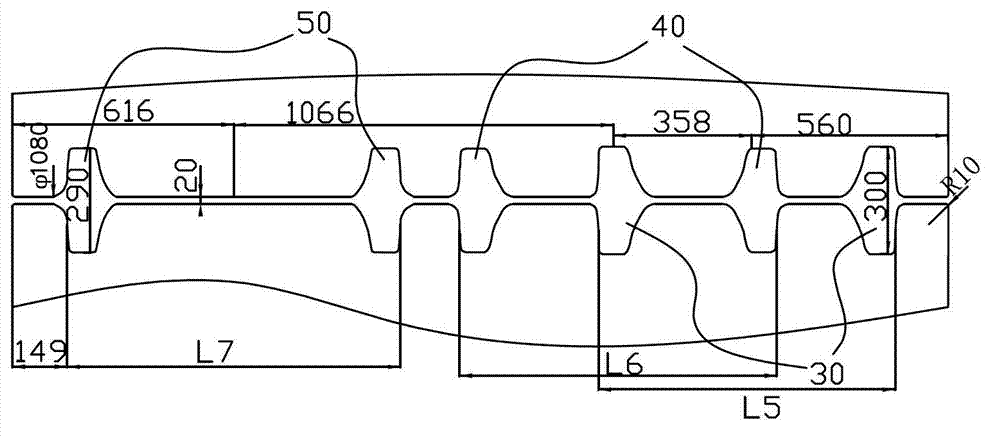

[0021] The invention provides a low-cost H-shaped steel rolling equipment. Like the prior art, the equipment includes a blanking mill and a finishing mill. The billet rolling mill has a variety of rolling passes. Such as image 3 As shown, the multiple rolling passes of the blooming mill in the embodiment of the present invention include a first horizontal rolling pass 30 , a second horizontal rolling pass 40 and a third horizontal rolling pass 50 .

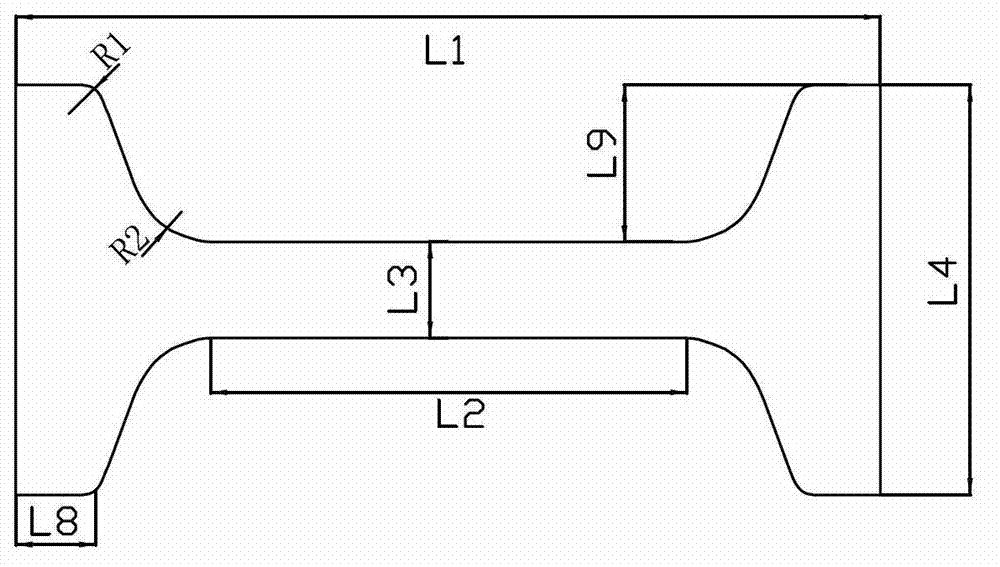

[0022] The lengths between the outer sides of the first horizontal rolling pass 30 , the second horizontal rolling pass 40 and the third horizontal rolling pass 50 increase sequentially, that is, the lengths L5 , L6 , and L7 increase sequentially. In addition, the rolling center lines of the pass types 30, 40, and 50 are exactly the same.

[0023] In this embodiment, the first horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com