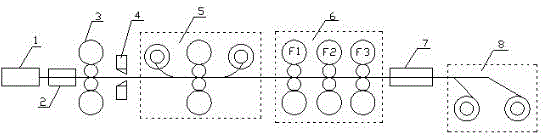

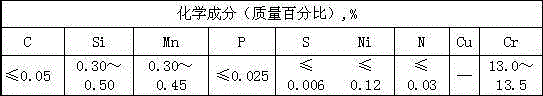

Method and system for rolling 410S ferrite stainless steel

A technology of stainless steel and ferrite, applied in the direction of metal rolling, etc., can solve the problems of low efficiency, large thickness deviation of steel strip head and tail, unstable product quality, etc., and achieve the goal of reasonable production process, obvious effect and strong market competitiveness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The specifications of the slab to be rolled (thickness * width * length): 200×1525×10000mm, and the specifications of the rolled product (thickness * width): 3.5×1520mm.

[0036] Roll according to the following method:

[0037] The dwell time of the billet in the multi-stage walking beam reheating furnace 1: 210 minutes (cold billet charging furnace), the furnace is in a weak oxidizing atmosphere, the residual oxygen content is 3.7% by volume, and the furnace temperature is 1152°C. The heated plate The slab is descaled by the slab descaling machine 2 and then enters the four-high rough rolling mill 3 for 7 passes to form an intermediate slab. The slab descaling pressure is 23.75Mpa.

[0038] Four-high roughing mill 3 rolling 7 passes reduction ratio: 1st pass, 20.3%; 2nd pass, 25.7%; 3rd pass, 28%; 4th pass, 27.3%; 5th pass , 26.6%; the sixth pass, 26%; the seventh pass, 20.2%, the thickness of the intermediate billet is 26.9mm.

Embodiment 2

[0042] The specification of the slab to be rolled (thickness*width*length): 200×1530×10000mm, and the specification of the rolled product (thickness*width): 3.7×1520mm.

[0043] Roll according to the following method:

[0044] The dwell time of the billet in the multi-stage walking beam reheating furnace 1: 215 minutes (cold billet charging furnace), the furnace is in a weak oxidizing atmosphere, the residual oxygen content is 4.1% by volume, and the furnace temperature is 1150°C. The heated plate The slab is descaled by the slab descaling machine 2 and then enters the four-high rough rolling mill 3 for 7 passes to form an intermediate slab. The slab descaling pressure is 24 Mpa.

[0045] Four-high roughing mill 3 rolling 7 pass reduction ratio: 1st pass, 19%; 2nd pass, 25%; 3rd pass, 27%; 4th pass, 26%; 5th pass , 25%; the sixth pass, 26%; the seventh pass, 20%, the thickness of the intermediate billet is 29mm.

[0046] After cutting the head and tail of the intermediate billet by t...

Embodiment 3

[0049] The specification of the slab to be rolled (thickness * width * length): 200×1250×10800mm, and the specifications of the rolled product (thickness * width): 4.95×1240mm.

[0050] Roll according to the following method:

[0051] The dwell time of the billet in the multi-stage walking beam reheating furnace 1: 240 minutes (cold billet charging furnace), the furnace is in a weak oxidizing atmosphere, the residual oxygen content is 5.0% by volume, and the furnace temperature is 1155°C. The heated plate The slab is descaled by the slab descaling machine 2 and then enters the four-high rough rolling mill 3 for 7 passes to form an intermediate slab. The slab descaling pressure is 23.7Mpa.

[0052] Four-high roughing mill 3 rolling 7 pass reduction ratio: 1st pass, 18%; 2nd pass, 23%; 3rd pass, 26%; 4th pass, 25%; 5th pass , 24%; the sixth pass, 24%; the seventh pass, 22%, the thickness of the intermediate billet is 32mm.

[0053] After cutting the head and tail of the intermediate bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com