Severe plastic deformation technology of magnesium alloy board

A large plastic deformation, magnesium alloy technology, applied in the direction of metal rolling, can solve the problems of many processes, low efficiency, high cost, etc., and achieve the effect of simple process, high strength and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

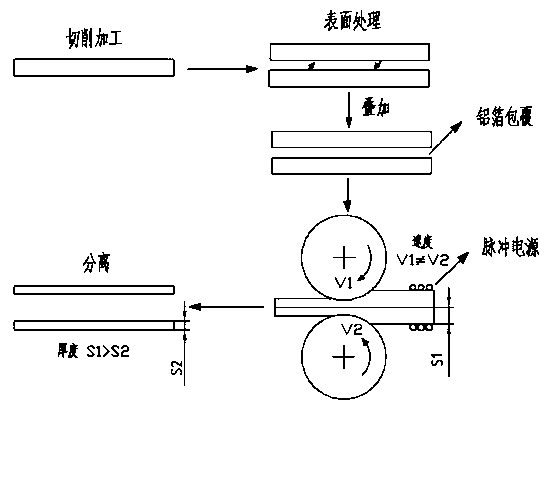

Method used

Image

Examples

Embodiment 1

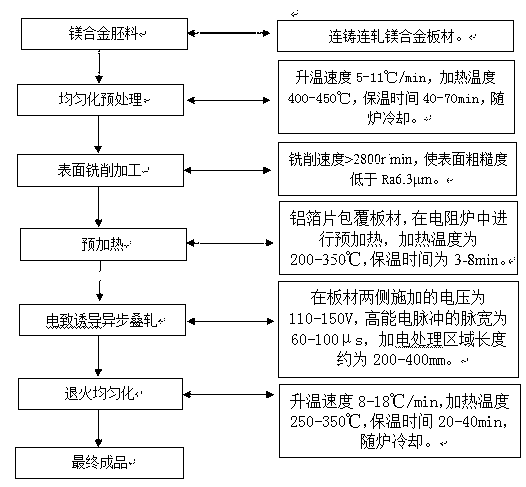

[0020] 1) Magnesium alloy sheet preparation: first prepare the sheet for electro-induced asynchronous stack rolling, pre-cutting and then reserve.

[0021] 2) Homogenize the plate with a heating rate of 5°C / min, a heating temperature of 400°C, a holding time of 40min, and cooling with the furnace.

[0022] 3) Milling the surface of the homogenized magnesium alloy plate, the milling process requires high-speed milling, the milling cutter speed is greater than 2800r / min, and the surface roughness is lower than Ra6.3μm.

[0023] 4) Ultrasonic cleaning is performed on the plate treated in step 3). Clean with acetone to remove impurities and oil.

[0024] 5) Wrap the two pieces of magnesium alloy plates after the above operations with pure aluminum foil, and age at room temperature.

[0025] 6) The voltage applied on both sides of the plate is 110V, the pulse width of the high-energy electric pulse is 60μs, and the length of the electrified treatment area is about 300mm. Start t...

Embodiment 2

[0029] It is basically the same as Embodiment 1, the difference is that:

[0030] The process parameters of the homogenization treatment in step 2) are heating rate 8°C / min, heating temperature 420°C, holding time 50min, and cooling with the furnace.

[0031] Step 3) The speed of medium and high-speed milling is 2900r / min, and the surface roughness is Ra3.2μm.

[0032]Step 5) Wrap the three magnesium alloy plates after the above operations with pure aluminum foil, and preheat in a resistance furnace at a heating temperature of 200°C and a holding time of 3-8 minutes.

[0033] Step 6) Take out the plate in step 5), the voltage applied on both sides is 115V, the pulse width of the high-energy electric pulse is 70μs, the length of the electrified treatment area is about 250mm, the speed of the upper and middle rolls is 1.5m / min, and the speed of the lower roll is 0.8m / min. The rolling process was completed at 200°C in one pass, with a 45% downforce and a sheet strain rate of 1...

Embodiment 3

[0037] It is basically the same as Embodiment 1, the difference is that:

[0038] The process parameters of the homogenization treatment in step 2) are heating rate 10°C / min, heating temperature 440°C, holding time 60min, and cooling with the furnace.

[0039] Step 3) The speed of medium and high speed milling is 3000r / min, and the surface roughness is Ra3.2μm.

[0040] Step 5) Wrap the four magnesium alloy plates after the above operations with pure aluminum foil, and preheat in a resistance furnace at a heating temperature of 300°C and a holding time of 3-8 minutes.

[0041] Step 6) Take out the plate in step 5) and apply a voltage of 115V on both sides, a pulse width of high-energy electric pulse of 80μs, a length of energized treatment area of about 250mm, a speed of upper and middle rolls of 2m / min, and a speed of lower rolls of 1.2m / min. min. The rolling process was completed at 300°C in one pass, with a 40% downforce and a sheet strain rate of 1.8 s-1.

[0042] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com