Continuous production method for rubber oil boom

A production method and rubber technology, which is applied in the field of continuous production of rubber ropes, can solve problems such as difficult placement of unvulcanized rubber materials, inability to achieve rapid quantification, and uncompetitive production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

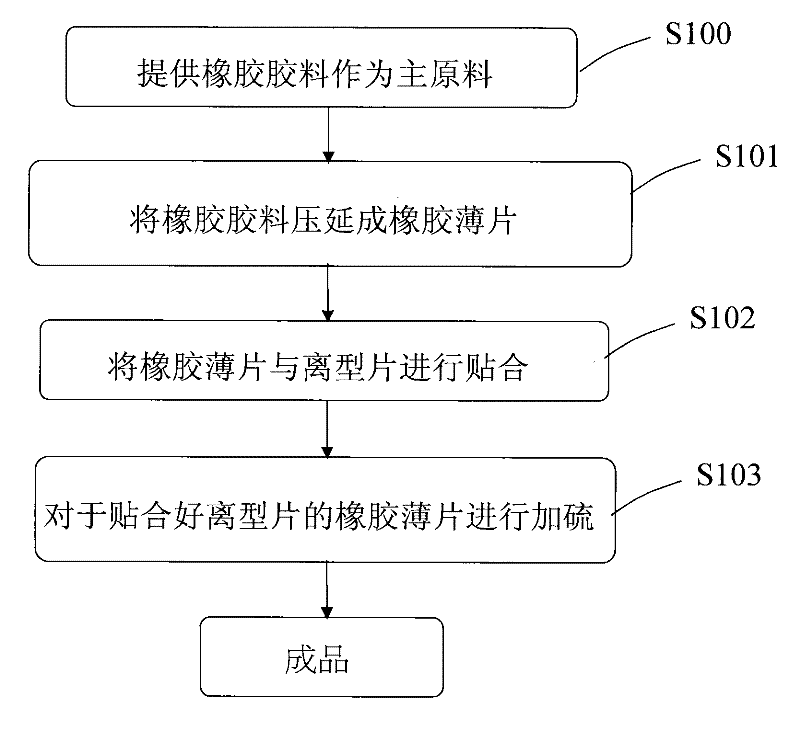

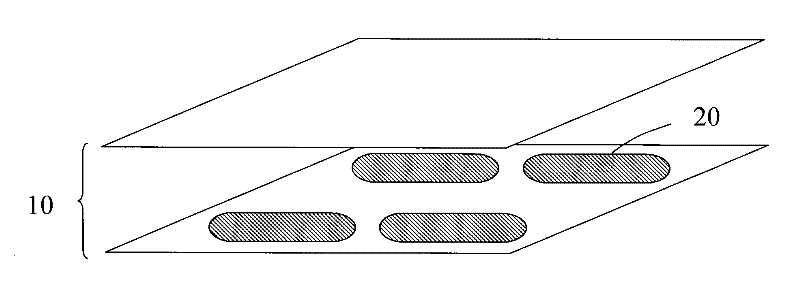

[0033] The rubber compound is sent to the calender to be rolled into a rubber sheet of the required thickness. At this time, the temperature of the calender is set at 80-110°C, the thickness of the rubber sheet is set at 0.50-0.60mm, and the width is 48 inches; then , the rubber sheet and the release sheet are bonded together continuously. The release sheet material used in the present embodiment is nylon (Nylon) cloth, which is sent into the tank vulcanization device for vulcanization, and the steam pressure is 4~8kg / cm 2 , the time is 3 to 6 hours, after the vulcanization is completed, the rubber rubber with a hollow inflatable rubber oil trap can be obtained.

Embodiment 2

[0035] Using the same rubber calendering procedure as in Example 1, the rubber sheet containing the reinforcing material is continuously produced, and the rubber sheet containing the reinforcing material is bonded to the release sheet. The release sheet used in this embodiment The material is high-temperature release paper with TPX surface treatment. After lamination, it is directly sent to the rotary heating wheel for vulcanization. The vulcanization temperature is 140-170°C, and the vulcanization speed is 1-30 yards / min. Rubber skids with hollow inflatable rubber ropes are produced.

[0036] Based on the above, according to the continuous production method of the rubber oil-stop rope disclosed in the present invention, the production process is simple and low-cost, and it is very suitable for continuous and high-speed mass production, and there is no problem of solvent volatilization, so that the production of the oil-stop rope The efficiency can be greatly improved, and at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com