Special-purpose numerically controlled lathe

A CNC lathe and bed technology, applied in the direction of automatic lathes/semi-automatic lathes, turning equipment, turning equipment, etc., can solve the problems of increased waste rate of tapes, reduced labor efficiency, and easy eye fatigue of operators, so as to reduce labor intensity, Effect of improving quality and production efficiency and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

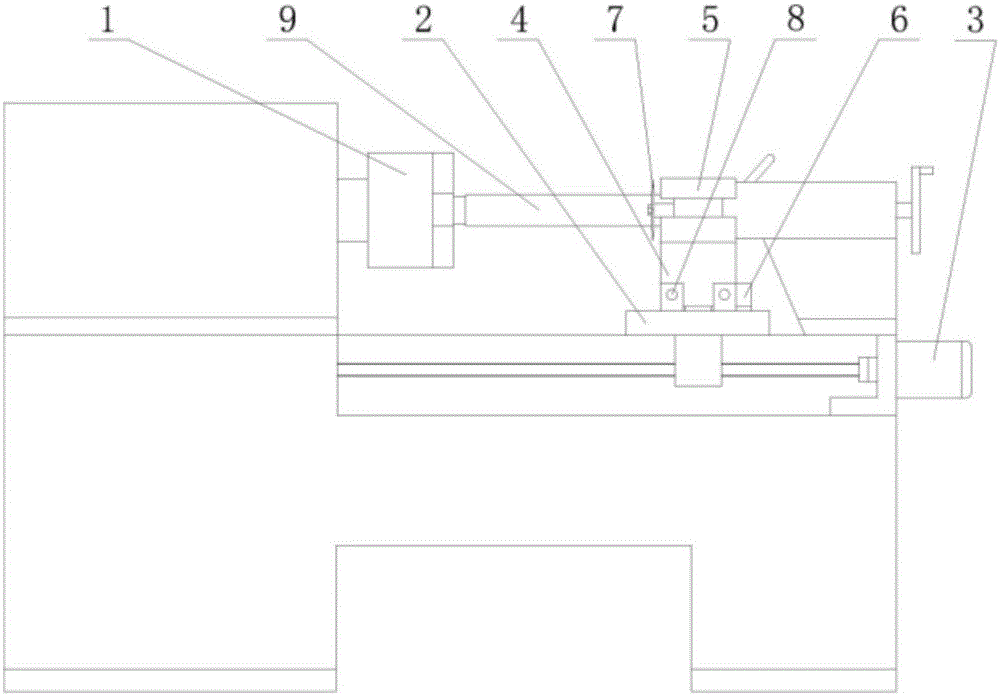

[0010] Such as figure 1 A CNC lathe for cutting tape mother roll 9 as shown, including a control system (not shown in the figure) and a bed, on which a headstock and a tailstock are fixed, the tailstock is located on the right side of the headstock, and the left end of the tailstock A rotary top is provided, and the right end of the rotating main shaft of the headstock is provided with a pneumatic chuck 1 for clamping the parent tape roll 9 .

[0011] There is a Z-direction slide rail on the bed, and a large carriage 2 that can slide on the Z-direction slide rail is provided between the headstock and the tailstock, and the large carriage 2 is driven by a Z-direction drive mechanism 3 arranged below it The Z-direction driving mechanism 3 includes a lead screw, a nut matched with the lead screw and fixed on the bottom of the large carriage 2, and a Z-direction stepping motor fixed on the bed through a bracket, and the Z-direction stepping motor drives the large carriage through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com