Large complex curvature component accurate forming method

A technology of curvature and components, which is applied in the field of variable curvature roll bending-creep aging forming of aerospace components with complex curvatures, can solve the problems of difficult vacuum bag sealing operations, broken components, uneven force, etc., to eliminate Injury potential safety hazards, increase operational feasibility, and avoid the effect of vacuum bag rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

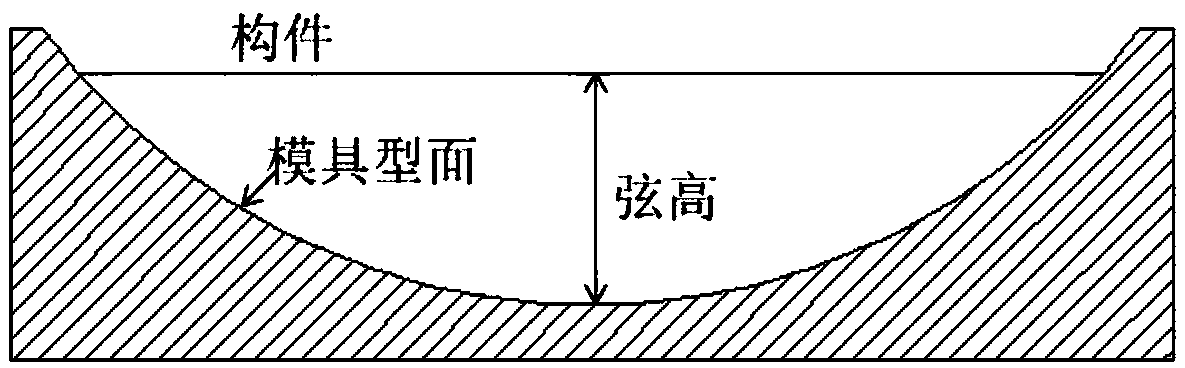

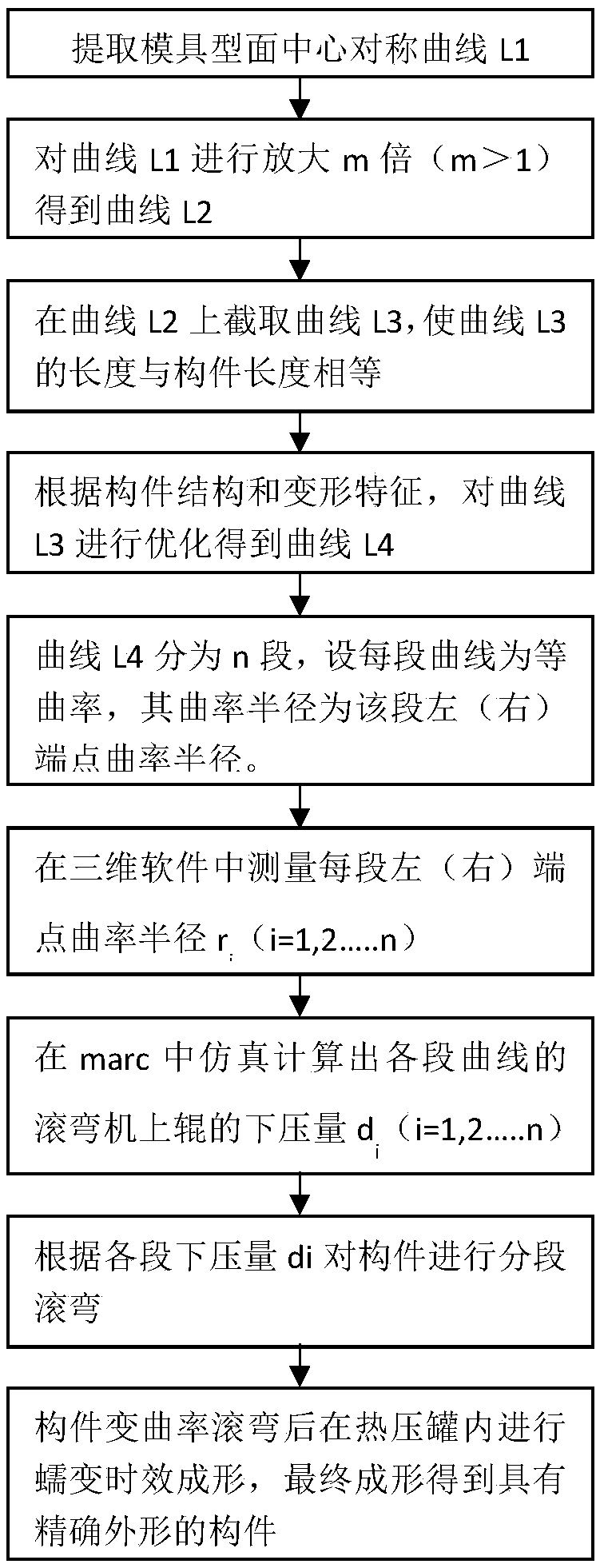

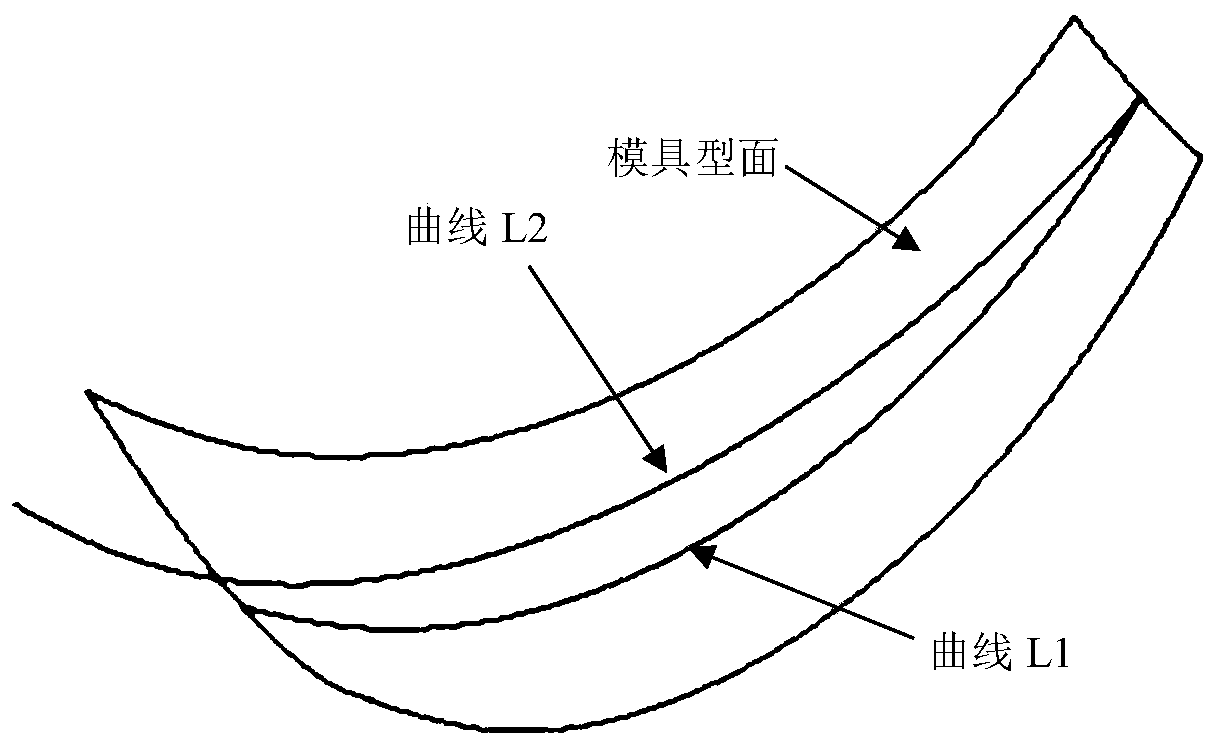

[0028] The theoretical basis of the present invention is: according to the deformation characteristics of the component, the bending of the component based on the shape-dependent curvature of the mold surface is higher than that of the single-curvature rolling, and the shape precision obtained after the creep aging compound forming is higher. Variable curvature roll bending-creep aging compound precise forming method for large complex curvature components. On the one hand, the chord height between the component and the mold surface is reduced after roll bending, which makes the operation simple; on the other hand, the roll bending-creep aging forming of the component based on the mold surface is relatively simple curvature roll bending-creep aging forming. The shape precision obtained by aging forming is higher.

[0029] The components have the characteristics of large size and complex shape. The size of the component is between 0.5m and 10m, and it can even be larger. As the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com