Preparation method of reinforced Cu-Nb composite wire

A composite wire, cu-nb technology, applied in the direction of metal rolling, etc., can solve the problems of decreased electrical conductivity, inapplicable, difficult to break through 1GPa, etc., to achieve increased elongation, improved quality and performance, and obvious core wire thinning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment includes the following steps:

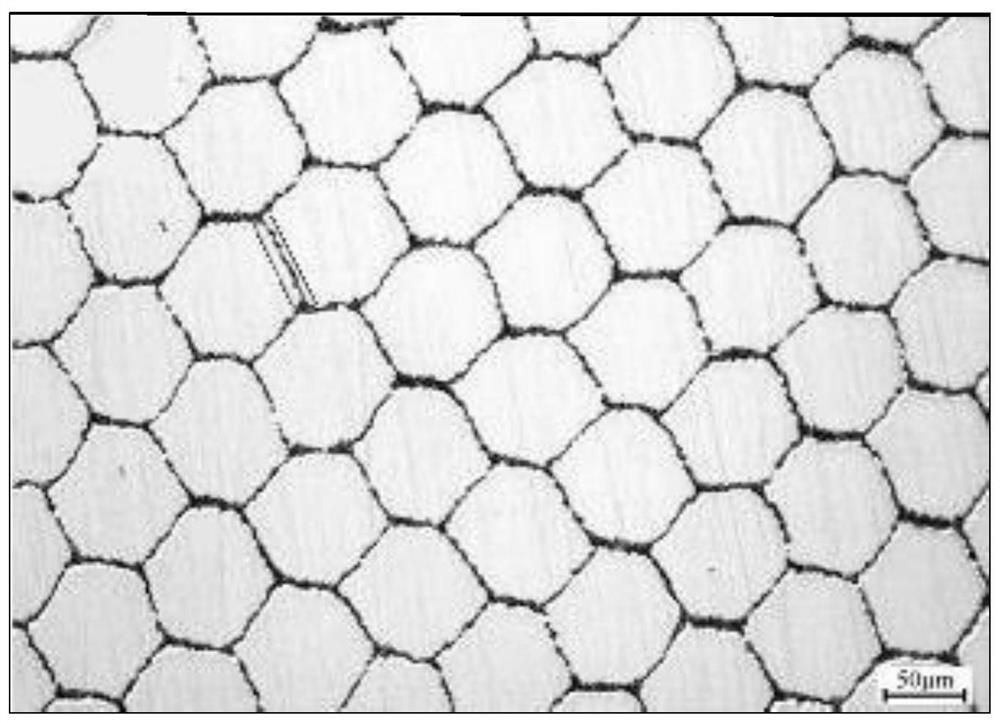

[0027] Step 1. The Cu-Nb tertiary composite wire prepared by the cluster drawing method is plastically drawn to a diameter of 7.74 mm, and then annealed at a temperature of 700 ° C for 4 hours;

[0028]Step 2. Carrying out continuous multi-roll pass cold rolling to the Cu-Nb three-time composite wire rod after the annealing treatment in step 1 to obtain the Cu-Nb composite wire rod intermediate; the rolling deformation of the multi-roll pass rolling 60%, the speed is 0.1m / s;

[0029] Step 3. Plastic drawing processing is carried out on the Cu-Nb composite wire rod intermediate obtained in step 2 to obtain a reinforced Cu-Nb composite wire rod with a diameter of 2.02 mm; the pass processing rate of the plastic drawing processing is 5% to 5%. 10%.

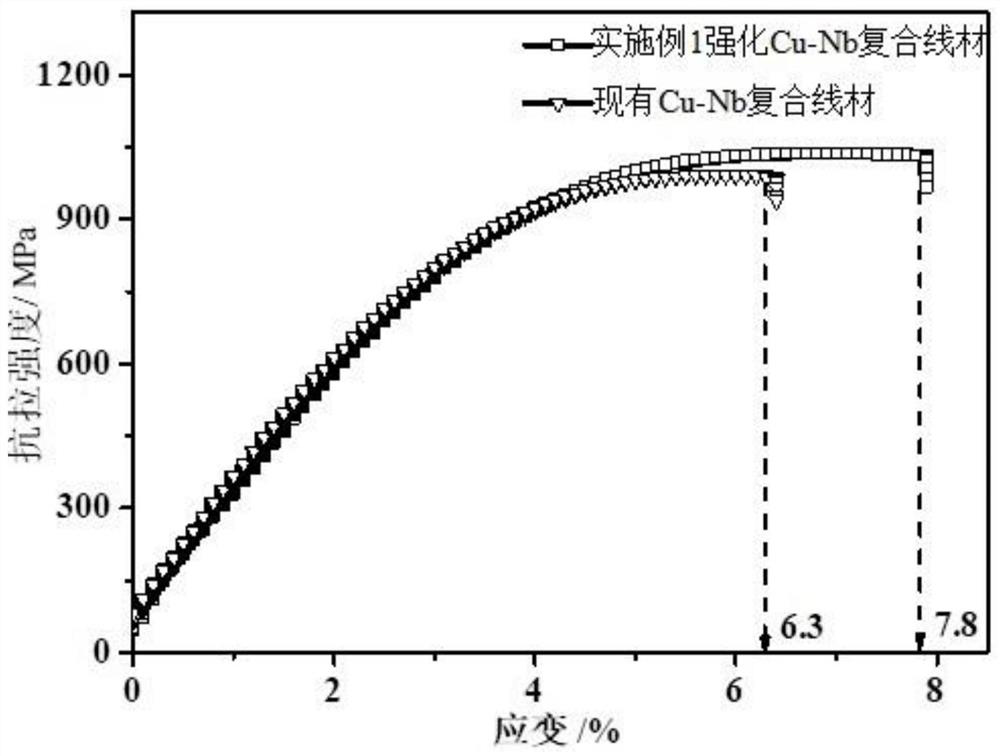

[0030] After testing, the room temperature tensile strength of the strengthened Cu-Nb composite wire prepared in this example is 1038MPa, which is 5% higher than that of the Cu...

Embodiment 2

[0035] This embodiment includes the following steps:

[0036] Step 1. The Cu-Nb tertiary composite wire prepared by the cluster drawing method is plastically drawn to a diameter of 7.74 mm, and then annealed at a temperature of 780° C. for 4 hours;

[0037] Step 2. Carrying out continuous multi-roll pass cold rolling to the Cu-Nb three-time composite wire rod after the annealing treatment in step 1 to obtain the Cu-Nb composite wire rod intermediate; the rolling deformation of the multi-roll pass rolling 60%, the speed is 0.1m / s;

[0038] Step 3. Plastic drawing processing is carried out on the Cu-Nb composite wire rod intermediate obtained in step 2 to obtain a reinforced Cu-Nb composite wire rod with a diameter of 2.02 mm; the pass processing rate of the plastic drawing processing is 5% to 5%. 10%.

[0039] After testing, the room temperature tensile strength of the strengthened Cu-Nb composite wire prepared in this example is 891MPa, which is 4% higher than that of the Cu...

Embodiment 3

[0041] This embodiment includes the following steps:

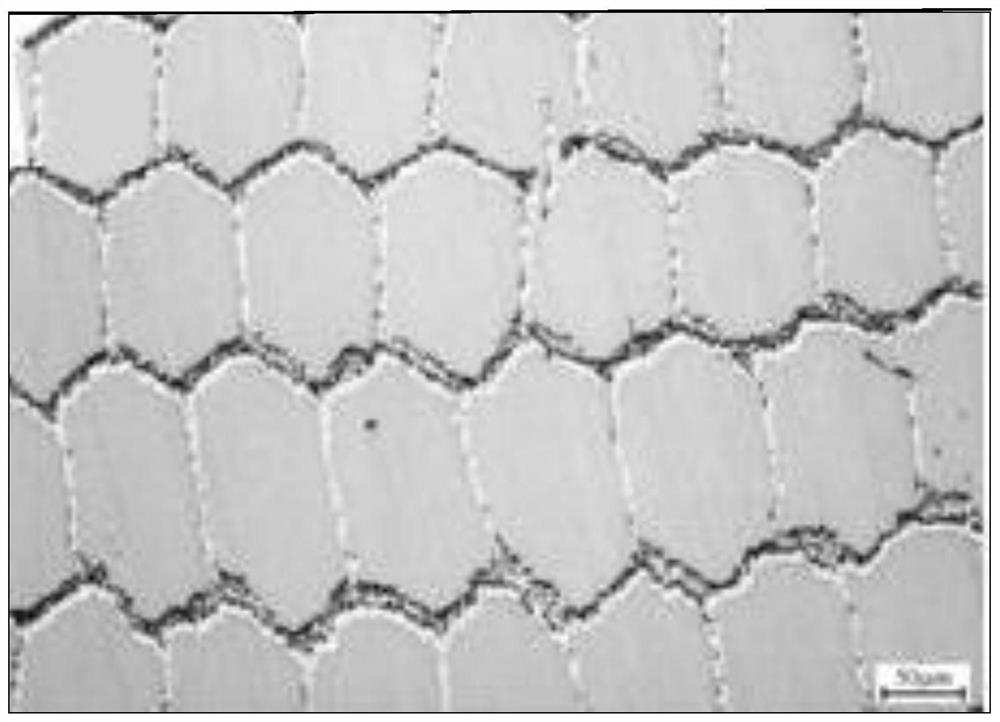

[0042] Step 1. The Cu-Nb tertiary composite wire prepared by the cluster drawing method is plastically drawn to a diameter of 8.66 mm, and then annealed at a temperature of 700 ° C for 4 hours;

[0043] Step 2. Carrying out continuous multi-roll pass cold rolling to the Cu-Nb three-time composite wire rod after the annealing treatment in step 1 to obtain the Cu-Nb composite wire rod intermediate; the rolling deformation of the multi-roll pass rolling 70%, the speed is 0.3m / s;

[0044] Step 3. Plastic drawing processing is carried out on the Cu-Nb composite wire rod intermediate obtained in step 2 to obtain a reinforced Cu-Nb composite wire rod with a diameter of 2.02 mm; the pass processing rate of the plastic drawing processing is 5% to 5%. 10%.

[0045] After testing, the room temperature tensile strength of the reinforced Cu-Nb composite wire prepared in this example is 1096MPa, which is 11% higher than that of the Cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com