Multilayer metal coupling deformation rolling combined method and device

A rolling composite and multi-layer metal technology, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve serious problems and achieve the effects of improving production efficiency, reducing energy consumption, and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

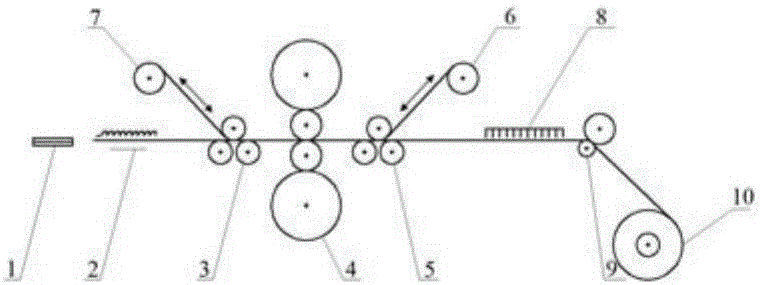

[0042] The composite billet 1 is sent to the heating furnace 2 by the transport roller table for heating. After being released from the furnace, it is dephosphorized by high-pressure water, and then enters the four-roll reversible rolling mill 4 for multi-pass reversible rolling. After rolling to the size of the intermediate billet, usually 20mm, after After the post-tension bending unit 5 is deformed, it enters the post-crimping heating furnace 6 for heat preservation and coiling. The plate tail during this process cannot be separated from the front bending unit 3 and the rolling mill 4. This is done to facilitate smooth strip threading in the coiling furnace during reverse rolling. coiled.

[0043]After the first rolling pass of coiling is completed, the four-high reversing rolling mill 4, the post-tension bending unit 5 and the post-crimp heating furnace 6 are reversely rotated to start reverse rolling. The strip tail after the first pass of rolling enters the front coiling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com