Production process of special-shaped material for mounting scraping strip, and production line

A technology of production process and special-shaped materials, which is applied in the directions of winding strips, transportation and packaging, and thin material processing, etc., can solve the problems of low delivery efficiency and roughness product consistency that cannot meet market demand, so as to improve production efficiency, Metallographic structure refinement, the effect of reducing the number of rolling mills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

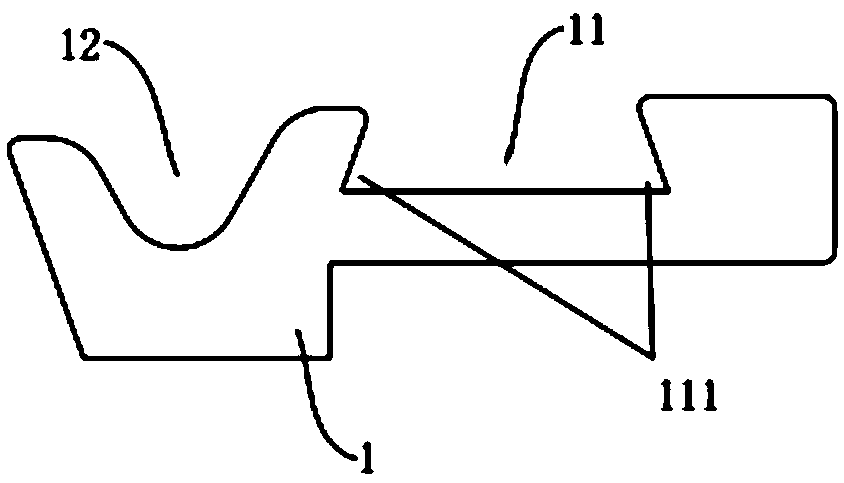

[0057] A production process for the profiled material used to install the scraping strip provided in this embodiment, as shown in the figure, includes:

[0058] S1: Material selection, choose flat steel coils with rectangular cross-section as raw materials;

[0059] S2: slot positioning, pass the raw material through the forming channel 53 on the rolling mill 5, and press out the basic contours of the V-shaped groove and the dovetail groove 11 on the raw material, so as to determine the positions of the V-shaped groove and the dovetail groove 11;

[0060] S30: preheating treatment, preheating the raw material before reaming and re-expanding, selecting a heat conducting member 42 bent from a metal heat conducting material into a spiral shape, and the heat conducting member 42 encloses a heat conduction channel 43 for the profile body 1, The two ends of the metal heat-conducting material are connected to the heating furnace 41, and the profile body 1 is first heated through the ...

Embodiment 2

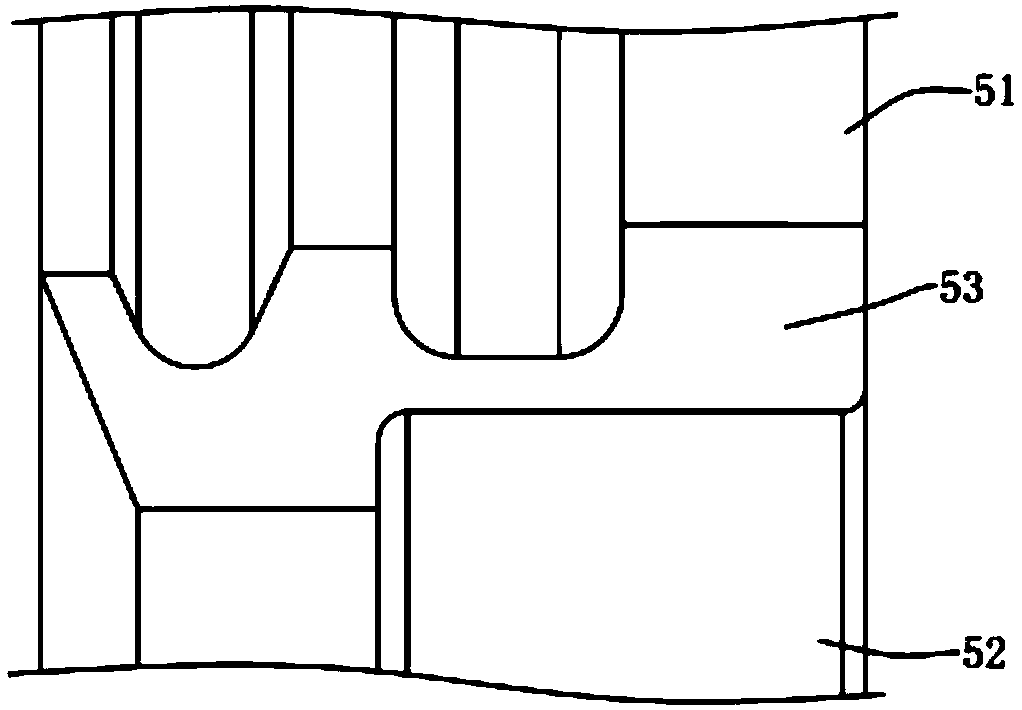

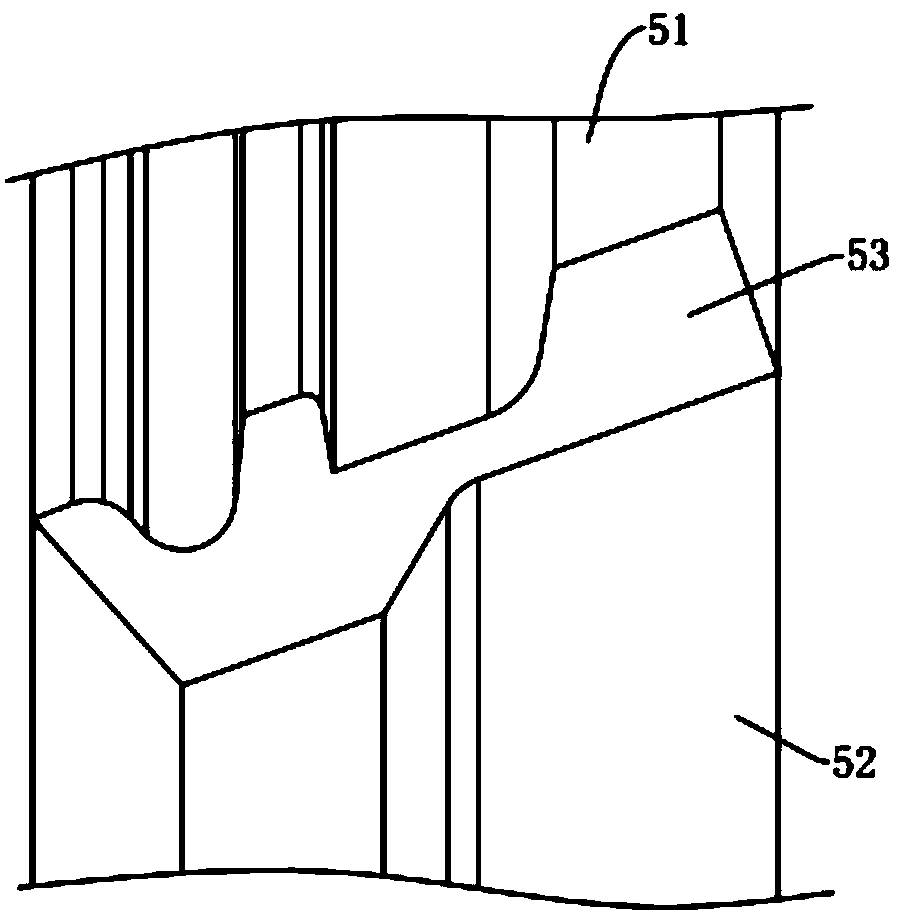

[0075] A production line for producing profiled materials according to any of the above schemes, as shown in the figure, includes an unwinding frame 2 for placing coiled materials, a winding mechanism 7 for collecting coiled materials, and an unwinding frame 2 and a winding mechanism The straightening mechanism 3, the preheating mechanism 4, and the rolling mill 5 are arranged sequentially along the flow direction of the coiled material among the 7. The rolling mill 5 includes a frame body 54, an upper pressure roller 51 and a lower pressure roller 52 that are detachably installed on the frame body 54 , the upper pressing roller 51 and the lower pressing roller 52 respectively have a molding groove, the molding groove forms a molding channel 53 for raw materials to pass between the two pressing rollers, and the frame body 54 is detachably installed on the base frame 55. A limiting component 541 is detachably installed on the frame body 54 . The limiting component 541 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com