Rolling process of high-speed wire combined type final forming unit with few stands

A high-speed wire rod and combined technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of complex process technology control system and production management, more gear ratios in gearboxes, and increased machinery investment costs. , to achieve the effect of compact equipment structure, less number of rolling mills, and guaranteed wire rod forming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

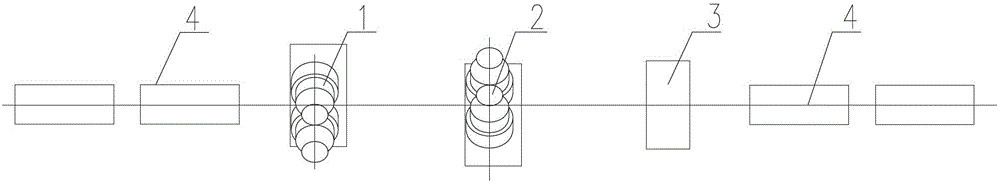

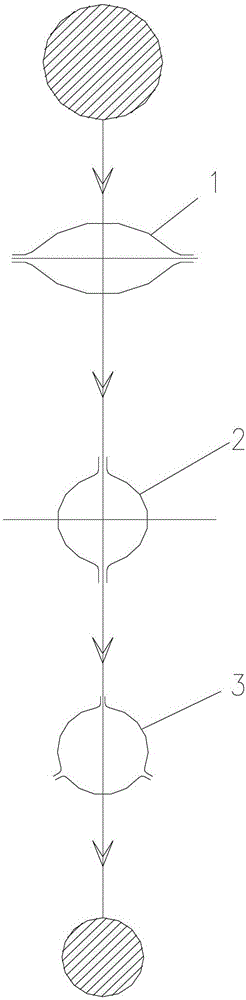

[0029] Embodiment 1: As shown in the figure, the high-speed wire combined type final forming unit with few stands in this embodiment includes the first rolling pass stand 1, the second rolling pass stand 2 and the second rolling pass stand arranged in sequence. Three rolling pass stands 3, the first rolling pass stand 1 includes two work rolls, and the pass formed by the two work rolls is elliptical, and the second rolling pass stand 2 includes Two work rolls, and the pass formed by the two work rolls is circular, and the third rolling pass frame 3 includes three work rolls arranged in 120° equal divisions, and the hole formed by the three work rolls The shape is round. The arrangement of three work rolls at 120° is a professional term for the arrangement of work rolls in the cold rolling industry. Specifically, it means that the round angle of the pass section on each work roll is 120°.

[0030] Since the third rolling pass frame adopts the three-roll pass, compared with the...

Embodiment 2

[0033] Embodiment 2: The rolling process of the high-speed wire combined type final forming unit with few racks in this embodiment, the rolling elongation of the first rolling pass stand 1 is 1.0, and the second rolling pass The rolling elongation of stand 2 is 1.0, the rolling elongation of stand 3 in the third rolling pass is 1.0, and the total rolling elongation of the three rolling passes is 1.0. In this embodiment, the rolling temperature of each rolling pass is controlled at 950°C.

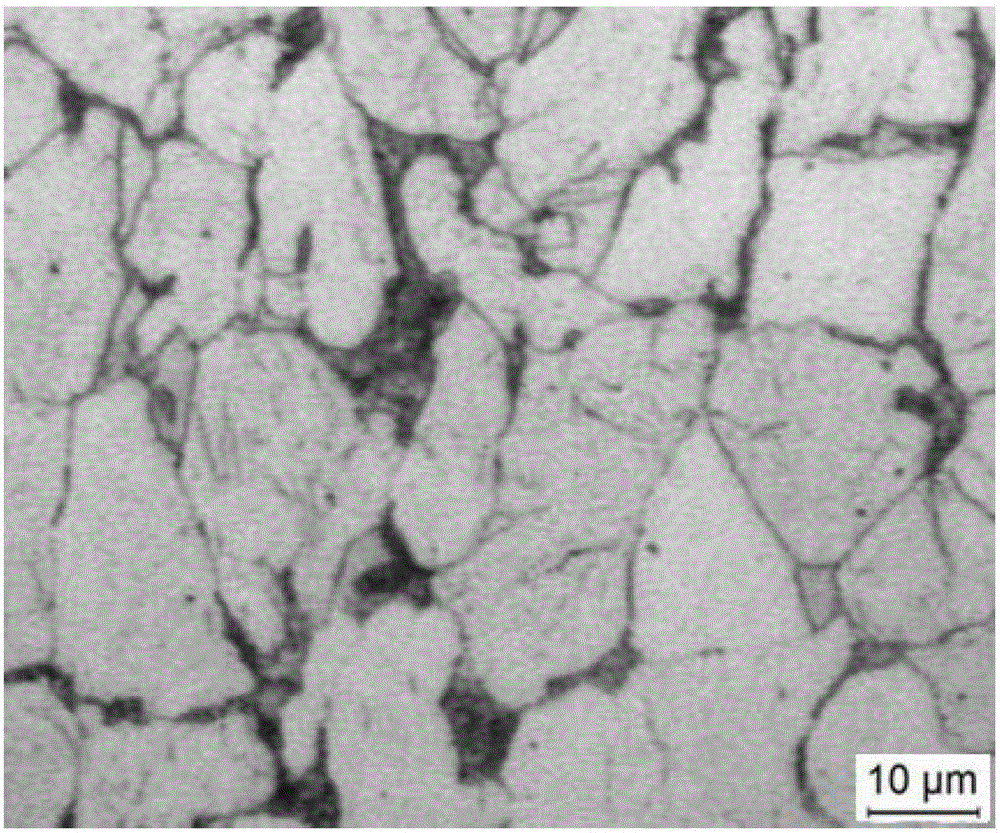

[0034] The microstructure of Q345 obtained by adopting 950°C non-deformation and single-pass large-pressure deformation system (total elongation rate 1.0) and continuous cooling at 1°C / s is shown in Figure 4 , image 3 It is the metallographic diagram of the rolled piece before rolling. It can be seen that when it is not deformed, the structure is ferrite, pearlite and bainite distributed along the grain boundary; through Figure 4 and image 3 In comparison, it can be seen that the micr...

Embodiment 3

[0035] Embodiment 3: The rolling process of the high-speed wire rod combination type final forming unit with few stands in this embodiment, the rolling elongation of the first rolling pass stand 1 is 1.2, and the second rolling pass The rolling elongation of stand 2 is 1.2, the rolling elongation of stand 3 in the third rolling pass is 1.1, and the total rolling elongation of the three rolling passes is 1.6. In this embodiment, the rolling temperature of each rolling pass is controlled at 950°C.

[0036] The Q345 microstructure obtained by adopting 950°C non-deformation and single-pass large-pressure deformation system (total elongation rate 1.6) and continuous cooling at 1°C / s is shown in Figure 5 , Figure 5 The ferrite and pearlite grains in the medium are uniformly distributed, and Figure 5 Tissue ratio Figure 4 It can be seen that the greater the deformation under large pressure, the more conducive to the refinement of the structure, which can improve the mechanical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com