A high-speed wire rod compact non-porous rolling production line and production method

A high-speed wire rod, compact technology, used in metal rolling, metal rolling, rolls, etc., can solve the problems affecting the dimensional accuracy and surface quality of high-speed wire rod products, rolling temperature and rolling speed fluctuations, overall adaptability and general It can prevent zigzag folding defects, reduce the length of rolling line, and simple and controllable rolling rhythm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

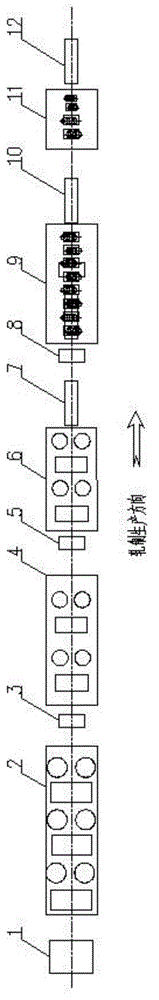

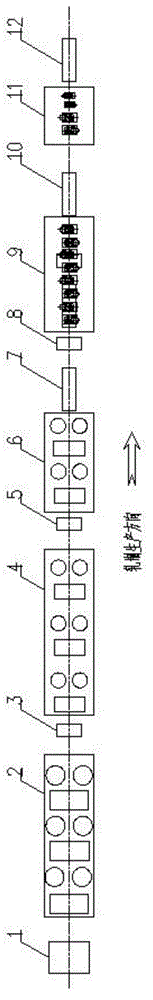

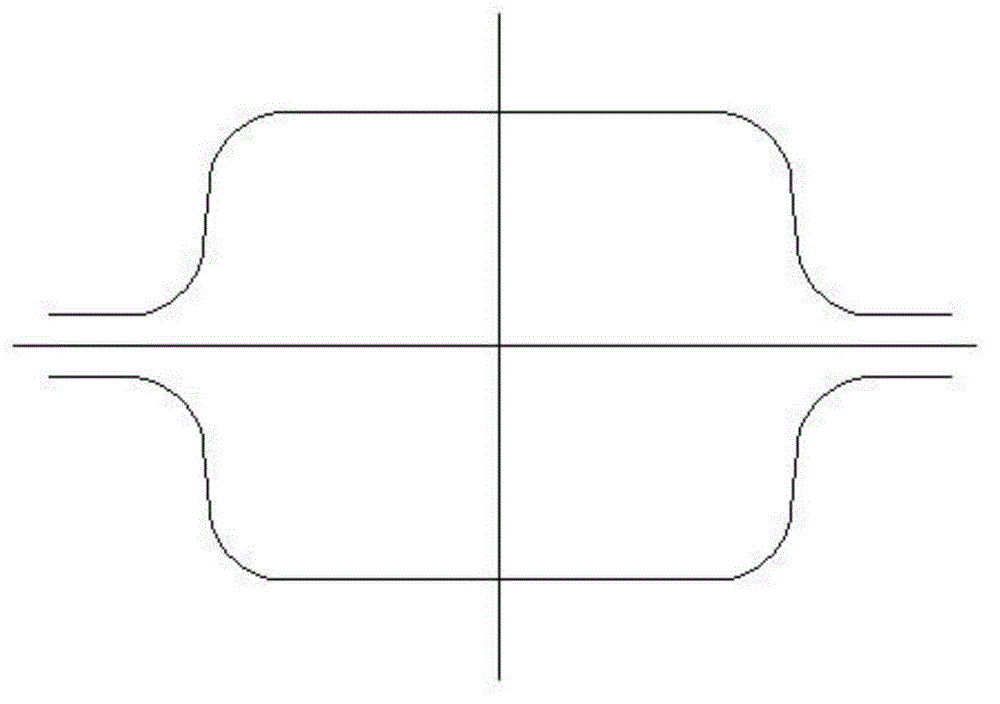

[0047] As shown in the figure, a high-speed wire rod compact non-porous rolling production line of the present invention includes a heating unit 1, a rough rolling unit 2, an intermediate rolling unit 4, a pre-finishing rolling unit 6 and a finishing rolling unit 9 arranged in sequence. The rough rolling unit 2 comprises a plurality of flat roll mills or a rolling mill in which flat rolls and vertical rolls are alternately arranged, and the middle rolling unit 4 comprises a plurality of flat roll mills or a rolling mill in which flat rolls and vertical rolls are alternately arranged. Unit 6 includes a multi-stand flat roll mill or a rolling mill with alternately arranged flat rolls and vertical rolls.

[0048] In this embodiment, the rough rolling unit 2 includes 6 rolling mills with flat rolls and vertical rolls alternately arranged, the intermediate rolling unit 4 includes 4 flat rolls and vertical rolls alternately arranged rolling mills, the pre-finishing rolling unit 6 It...

Embodiment 2

[0061] Another embodiment of the present invention is a compact non-porous rolling production line for high-speed wire rods, which includes a heating unit 1, a rough rolling unit 2, an intermediate rolling unit 4, a pre-finishing rolling unit 6 and a finishing rolling unit 9 arranged in sequence, The rough rolling unit 2 comprises a plurality of flat roll mills or a rolling mill in which flat rolls and vertical rolls are alternately arranged, and the intermediate rolling unit 4 comprises a plurality of flat roll mills or a rolling mill in which flat rolls and vertical rolls are alternately arranged. The rolling unit 6 includes a plurality of flat roll mills or a rolling mill with alternately arranged flat rolls and vertical rolls.

[0062] In this embodiment, the rough rolling unit 2 includes 6 flat roll mills or a rolling mill with alternately arranged flat rolls and vertical rolls, and the intermediate rolling unit 4 includes 6 flat roll mills or a rolling mill with alternate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com