Differential-speed extrusion forming method of magnesium alloy high performance cup-shaped piece

A technology of extrusion forming and magnesium alloy, which is applied in the direction of metal extrusion dies, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

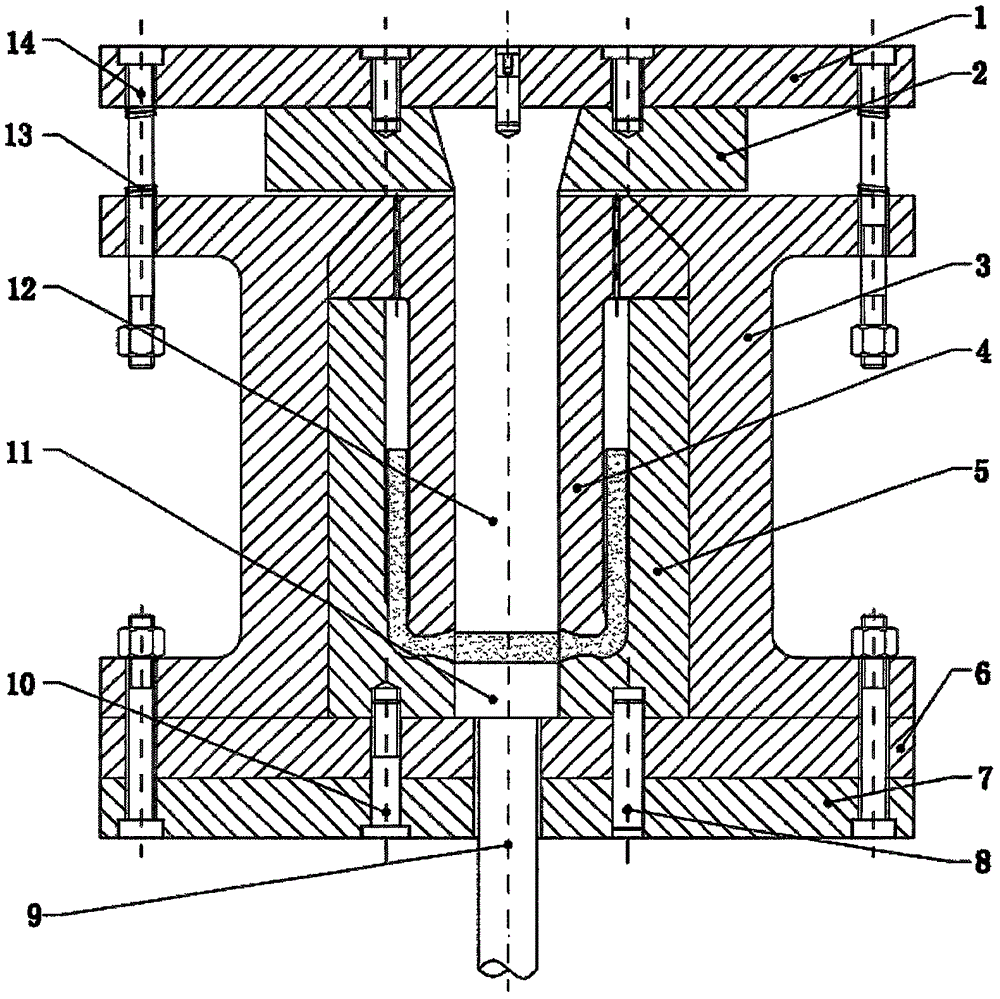

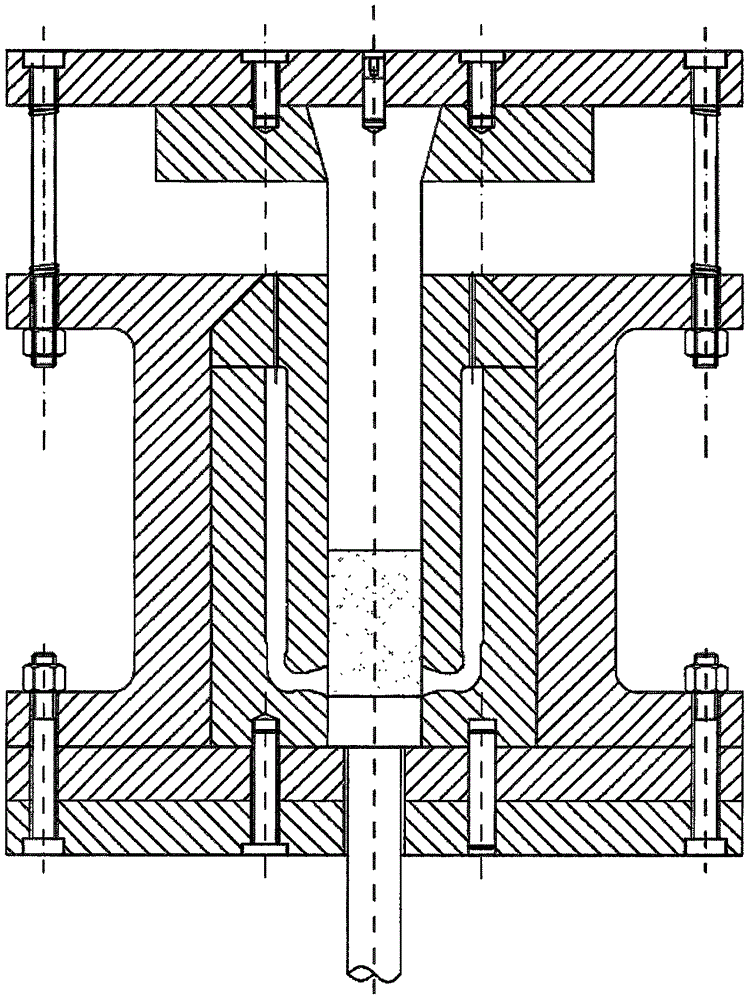

[0052] Take the preparation of an AZ31 magnesium alloy cup with an outer diameter of 200 mm and an inner diameter of 170 mm as a specific example.

[0053] The blank size used is H=360mm, diameter D 1 =80mm, "T" shape upper die 4 cavity diameter D 2 = 90mm, D 1 2 . The whole mold is preheated to 400°C for 2 hours, and the magnesium alloy billet is heated to the forming temperature of 350°C and held for 2 to 4 hours. The extrusion speed of the punch is 1 mm / s.

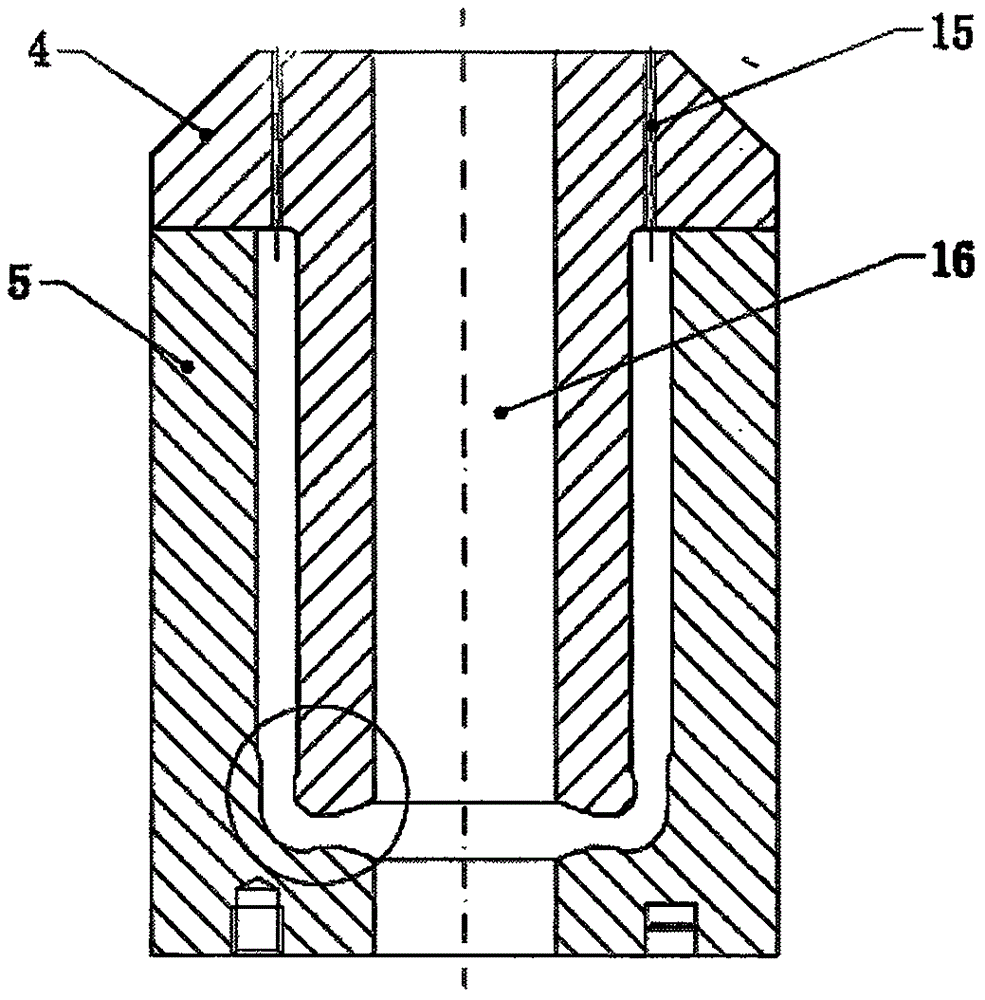

[0054] Such as Figure 3-1 As shown, 4 to 8 vertical holes are provided on the upper end of the "T" shaped upper die 4 along the axial equidiameter as the small holes for feeding lubricant.

[0055] Such as Figure 3-2 As shown, the length L2 of the sizing belt of the "T"-shaped upper die 4 is 8.8mm, and the length L1 of the sizing belt of the "U"-shaped lower die 5 is 24mm; Considering the pressure angle, the connection surface between the sizing belt at the lower end of the "T"-shaped upper die 4 and the horizo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com