Multi-stable velocity amplifying and frequency-increasing composite vibration energy harvester and its collection method

A vibration energy harvesting and speed amplification technology, which is applied to generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve the problem of low utilization rate, complicated magnetic field setting, and inability to miniaturize and other issues to achieve the effect of improving efficiency, increasing low-frequency work efficiency, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

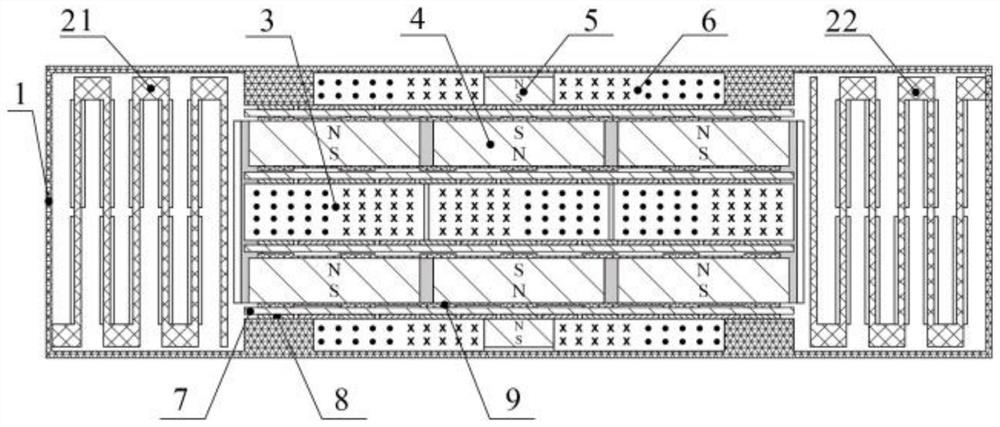

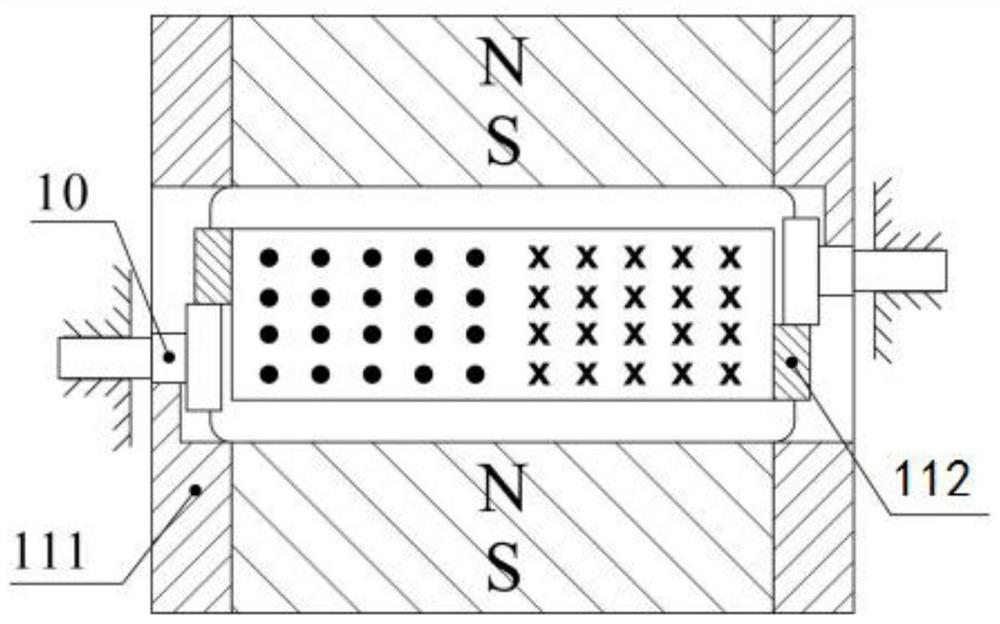

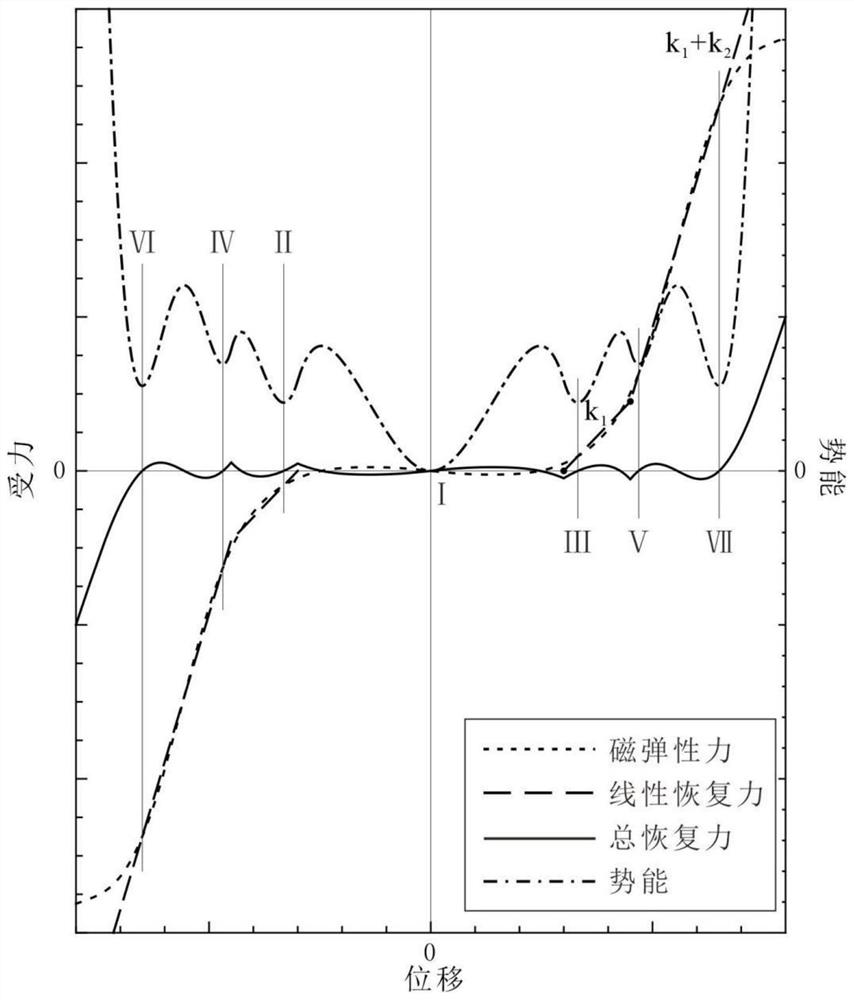

[0037] Referring to the drawings, the multi-stable motion amplifying and up-converting composite vibration energy harvester in the present invention includes a housing 1, a first high-frequency piezoelectric cantilever beam 21, a second high-frequency piezoelectric cantilever beam 22, and a movable induction coil Group 3, movable permanent magnet array 4, fixed permanent magnet array 5, fixed induction coil group 6, tetrafluoroethylene film 7, plane tooth comb electrode 8, nylon electrode 9, coaxial transmission gear 10, rack and permanent magnet array fixed Rack 111 and rack 112 .

[0038] The movable permanent magnet array 4 is formed by six rubidium iron boron permanent magnets divided into upper and lower rows and arranged according to the polarity shown in the drawings. The upper and lower rows of magnets are attached to the outer metal frame to prevent mutual attraction. The movable induction coil group 3 is located in the middle cavity of the movable permanent magnet a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com