Manufacturing method and auxiliary equipment of cobalt/iron composite pipe for coronary stent

A technology of composite pipe material and manufacturing method, which can be applied in the direction of metal rolling, etc., can solve the problems of large size and stenosis of focal blood vessels, and achieve the effects of excellent mechanical properties, simple process and high economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

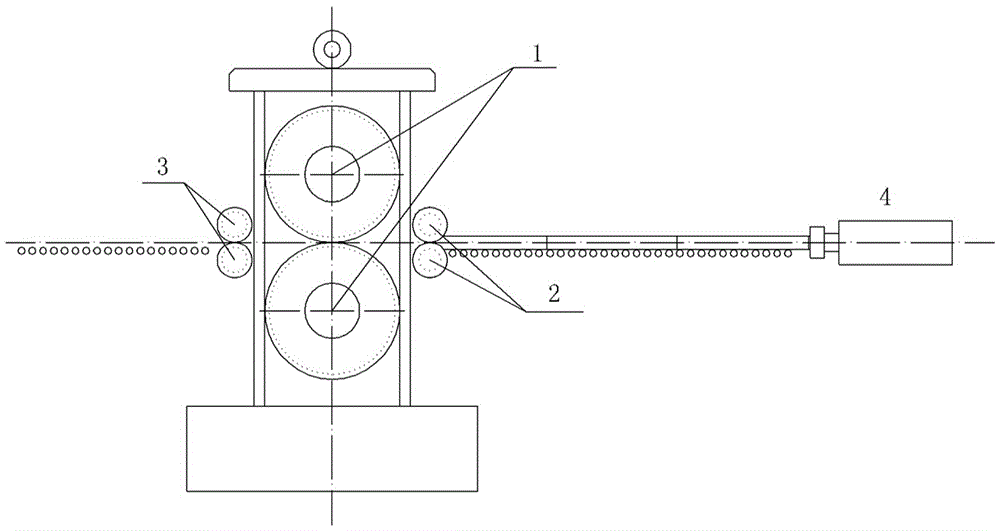

Image

Examples

Embodiment

[0032] The processing method of the cobalt / iron composite pipe used in the bracket of the present invention, its technological process is: smelting → forging → hot rolling → hot rolling piercing → internal and external surface boring, washing and grinding → pipe blank assembly → initial cold rolling and compounding → annealing → cold rolling / drawing Pulling→annealing-cold rolling / drawing is repeated many times→finished product. Specific steps are as follows:

[0033] Step 1: Cobalt-based alloy and pure iron are obtained by smelting in a vacuum induction furnace. Take the cobalt-based alloy ingot and pure iron ingot prepared by smelting, heat them in a protective atmosphere (argon) furnace to 1200°C, and then heat them at 1180°C Next, use a fast forging machine to forge it to a bar with a diameter of 40mm. In the present invention, by weight percentage, the purity of pure iron is 99.99%, and the cobalt-based alloy composition is: C: 0.10; Cr: 20.0; Ni: 10.0; W: 15.0; Mn: 1.5; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com