Patents

Literature

43results about How to "Smooth inner and outer surfaces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device and method for preparing hollow heteromorphic bacteria cellulose material

ActiveCN101921700AHigh strengthSmooth inner and outer surfacesBioreactor/fermenter combinationsBiological substance pretreatmentsNutrientNerve fiber

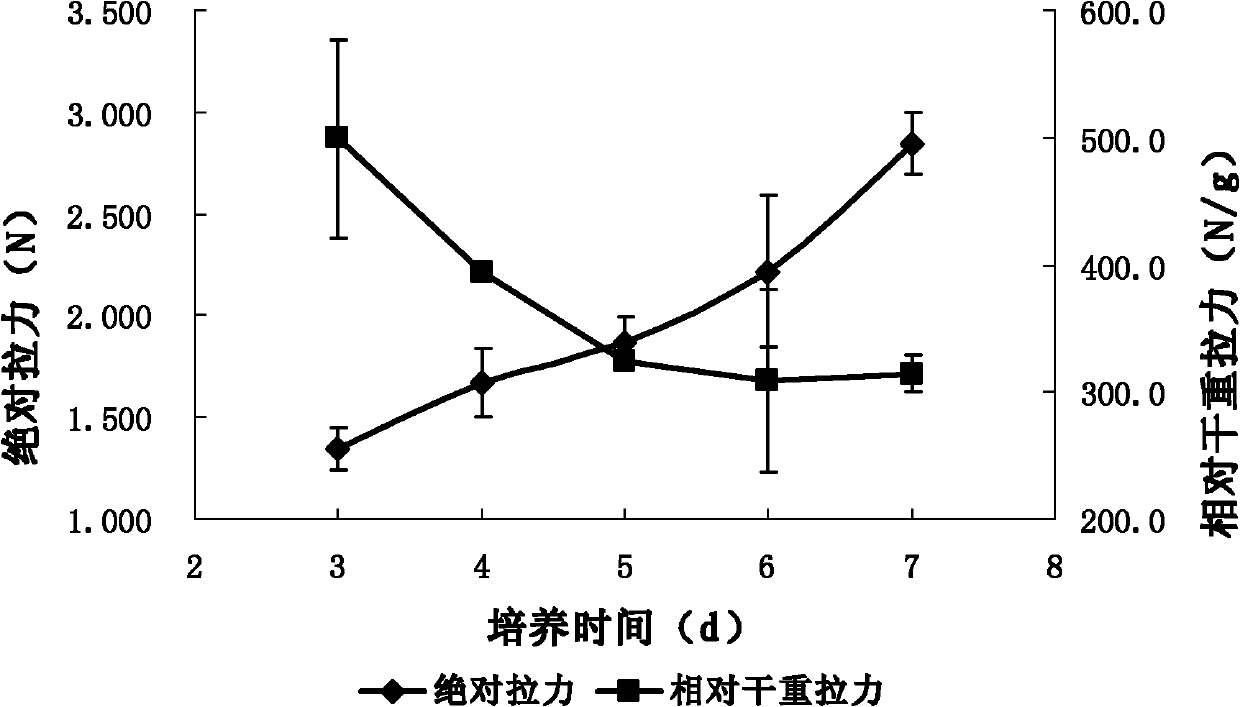

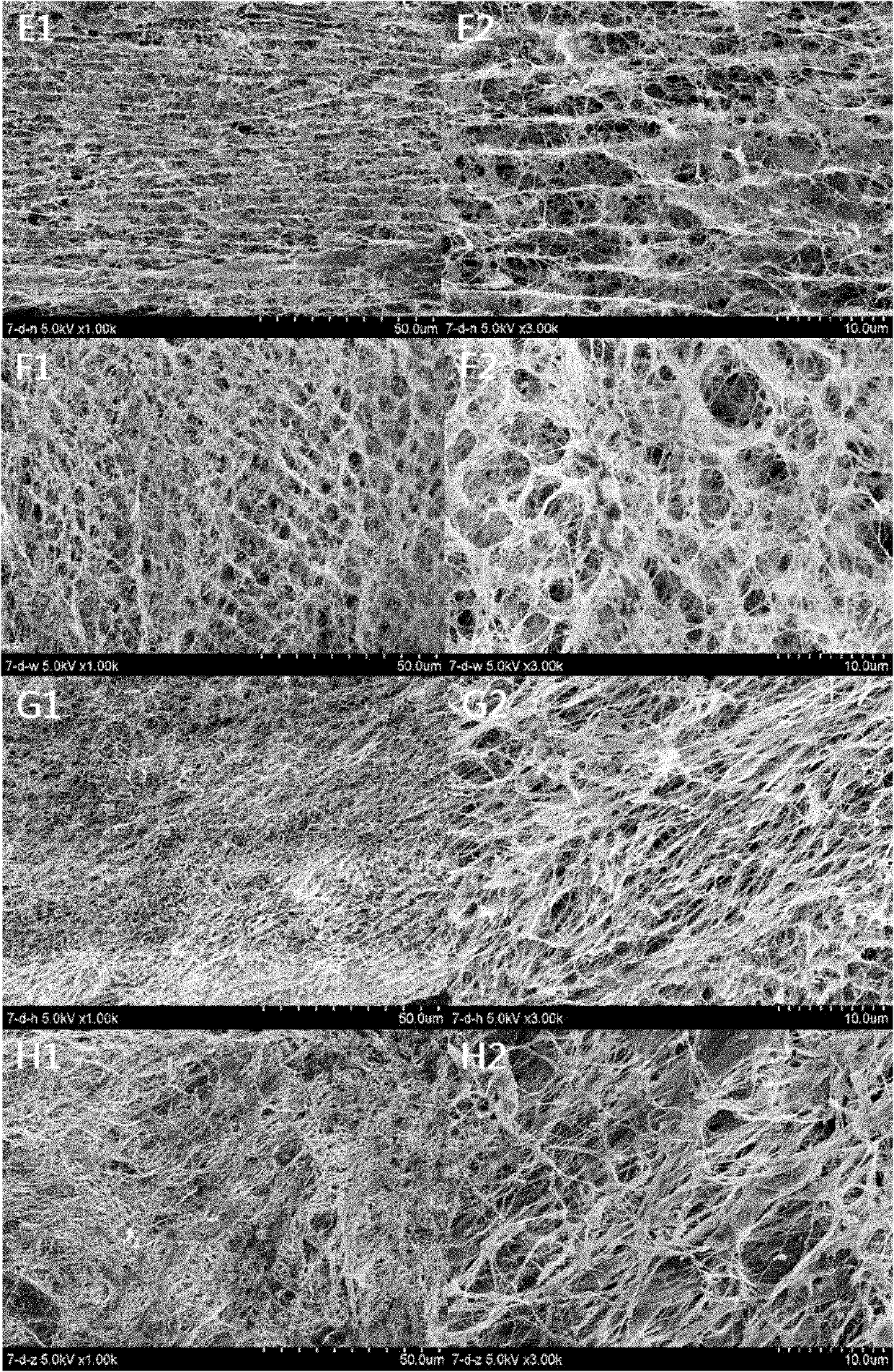

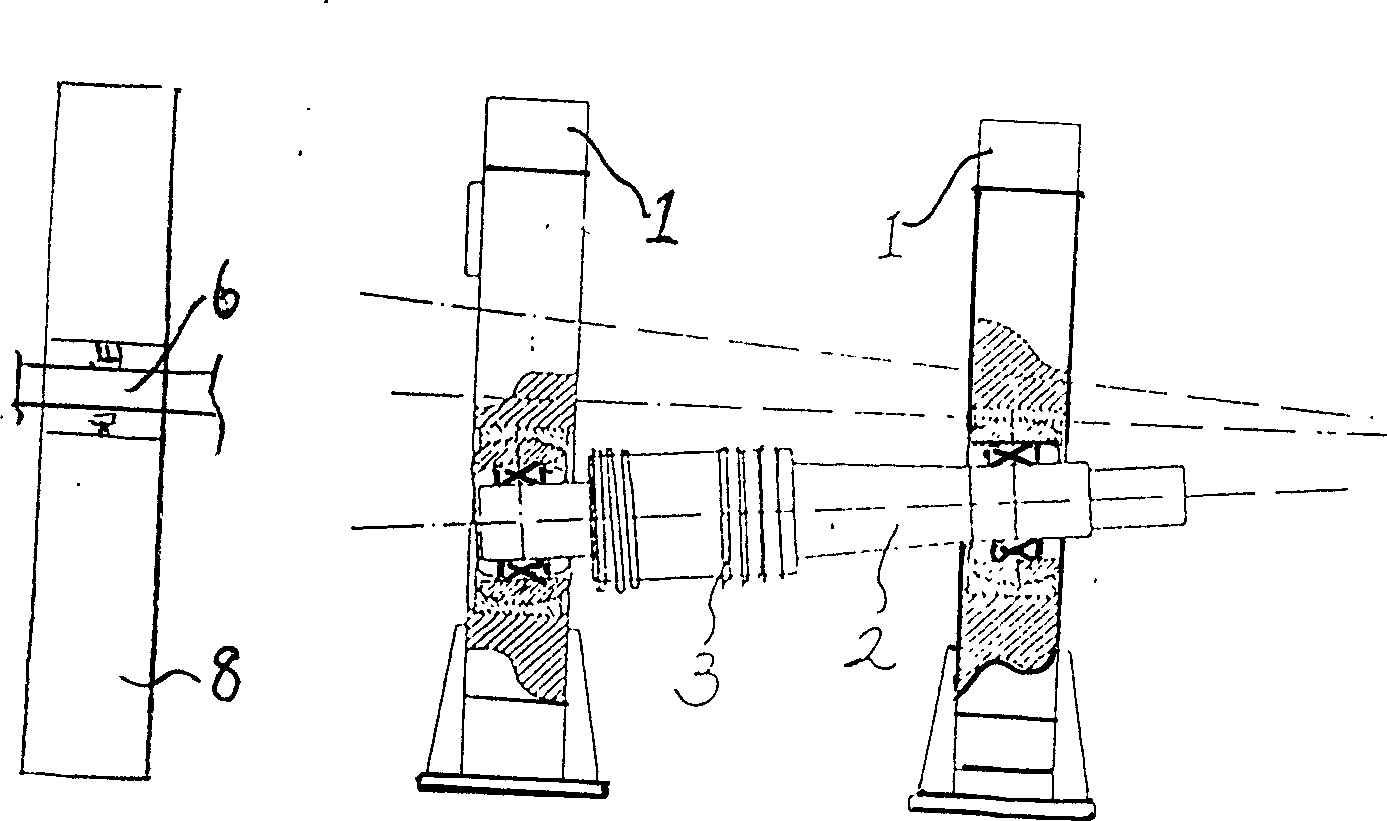

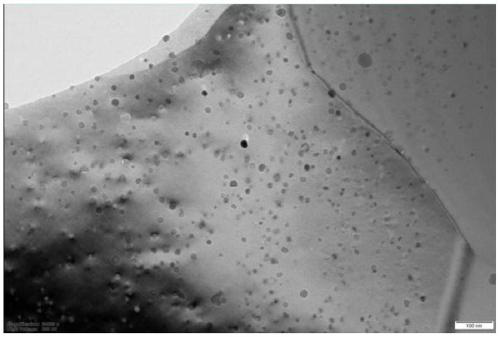

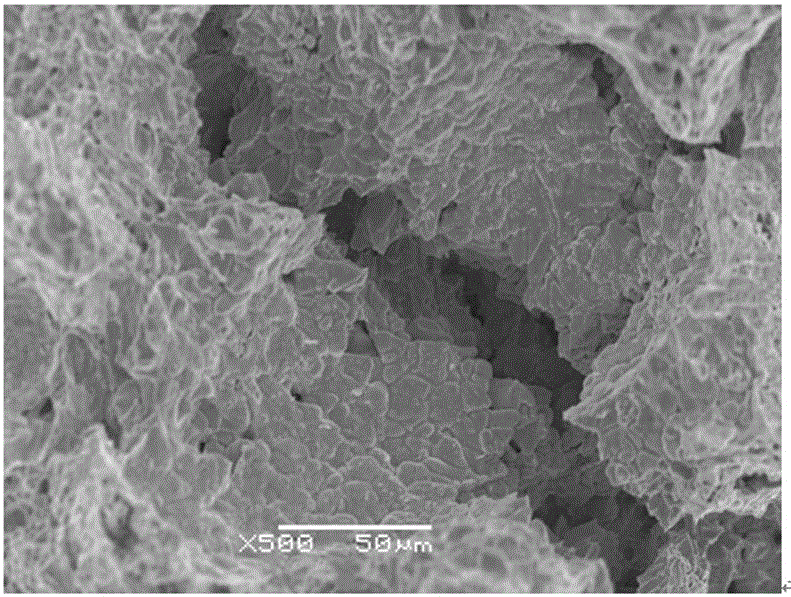

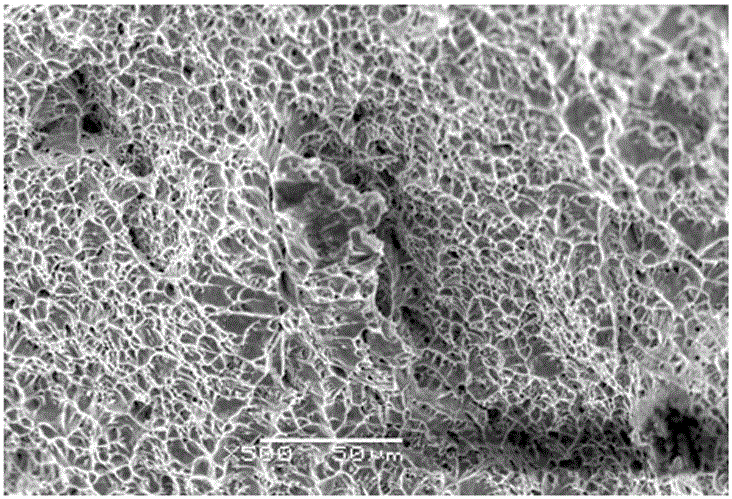

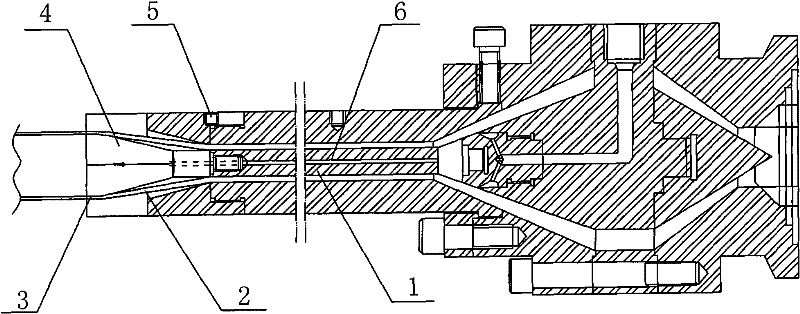

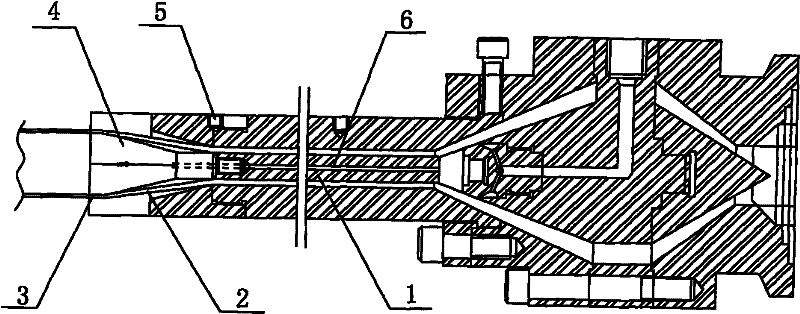

The invention relates to a device and method for preparing a hollow heteromorphic bacteria cellulose material. The device comprises an airtight container, a second tubular component, a first tubular component and a cylindrical hollow plug, wherein the first tubular component and the second tubular component are coaxially sheathed inside the lumen of the second tubular component; an opening of the second tubular component is sealed with the first tubular component by the cylindrical hollow plug; and the gap between the first tubular component and the second tubular component is a space for storing fermentation medium. The method comprises the following steps: after inoculating fluid nutrient medium with bacterial cellulose-producing strain for spread cultivation, transferring the bacterial cellulose-producing strain to a fermentation device with an oxygen permeability mould, and culturing to obtain the heteromorphic bacteria cellulose material. The hollow heteromorphic bacteria cellulose (BC) material prepared by the invention not only has controllable size and shape, but also has the detachable and reused mould of the fermentation device, can be widely applied to substitute goods of hollow organs, such as artificial vascular grafts, nerve fiber conduits and the like, and can be served as the material for packing the foods, such as casings for meat products, jelly coatings and the like.

Owner:DONGHUA UNIV

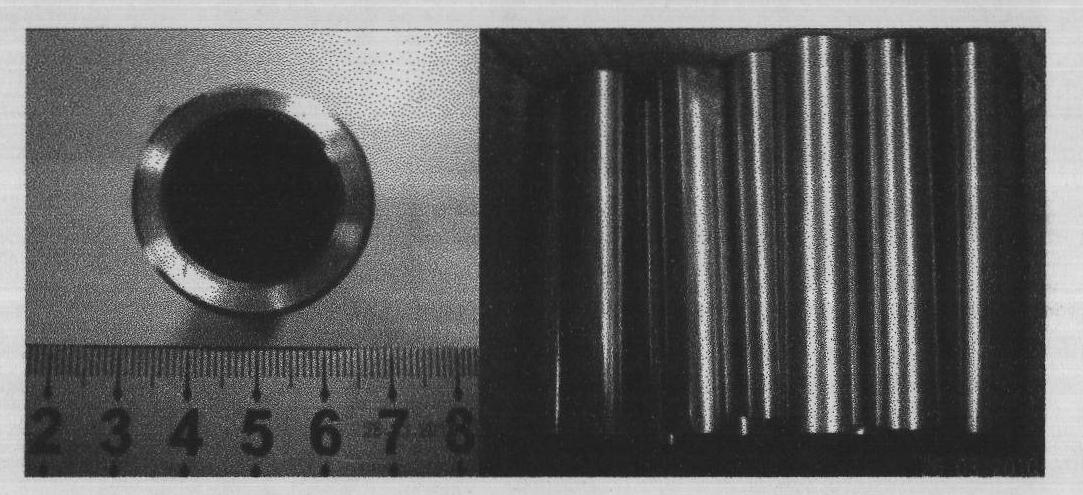

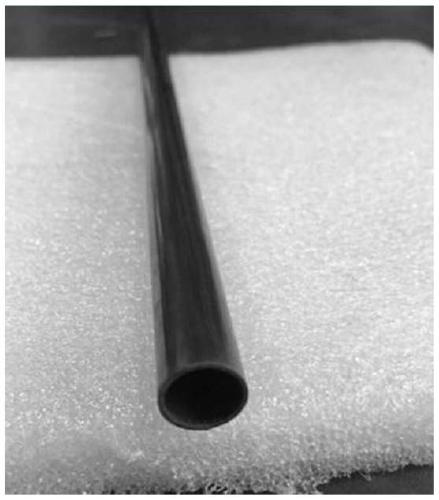

A method of processing cobalt-base alloy superfine thin-walled tubes for stents

ActiveCN102363256AHigh dimensional accuracySmooth inner and outer surfacesRoll mill control devicesMetal rolling arrangementsLoad carryingControllability

The invention relates to a forming technology of superfine thin walled tubular products for vessel stents in the field of treatment, specifically to a method of processing cobalt-base alloy superfine thin walled tubes for novel coronary artery stents. The method solves the problems of great difficulty in tubular product processing and low yield of tubular products in a conventional technology. The method for forming finished products comprises the successive technological processes of smelting, forging, hot rolling, hot rolling punching, honing and cleaning of inner surfaces and outer surfaces, annealing, cold rolling / drawing, annealing, and repeated cold rolling / drawing. During overall process of the repeated cold rolling, diameter reducing deformation of the tubular products should be controlled in each pass, and match relationship between the diameter reducing deformation and wall reducing deformation should be well adjusted for guaranteeing that load carrying capability of inner walls does not exceed sigma b (breaking strength) and thus for preventing horizontal microscopic breakage. With rough blanks of the tubular products being acquired in high temperature conditions and the cobalt-base alloy tubular products being acquired through rolling at a room temperature, the processing method guarantees high dimensional precision, bright and clean inner and outer surfaces and excellent mechanical property of the tubular products; and is easy to realize and has high controllability and high economic benefit.

Owner:JIANGSU FENGYUAN MEDICAL DEVICES CO LTD

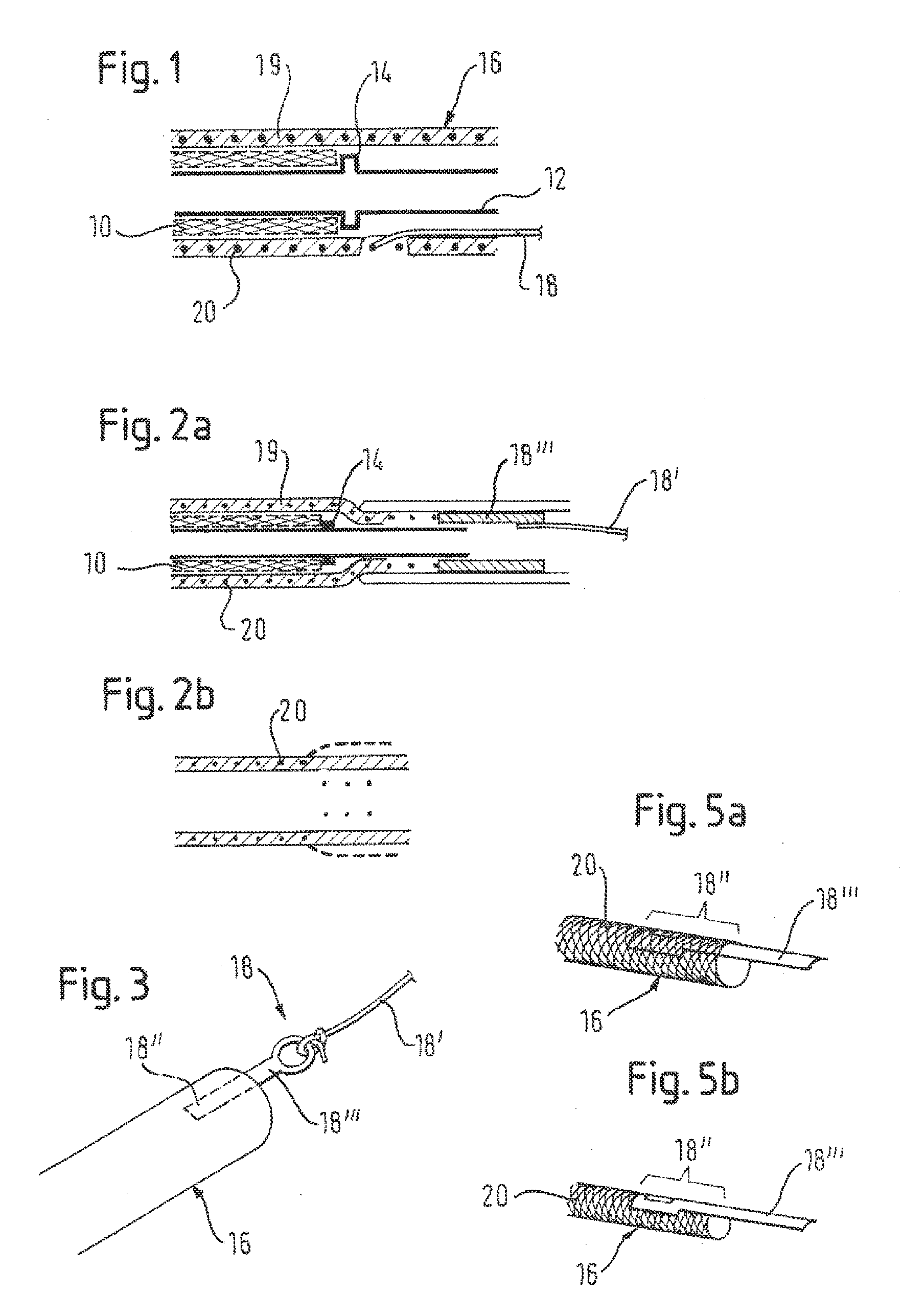

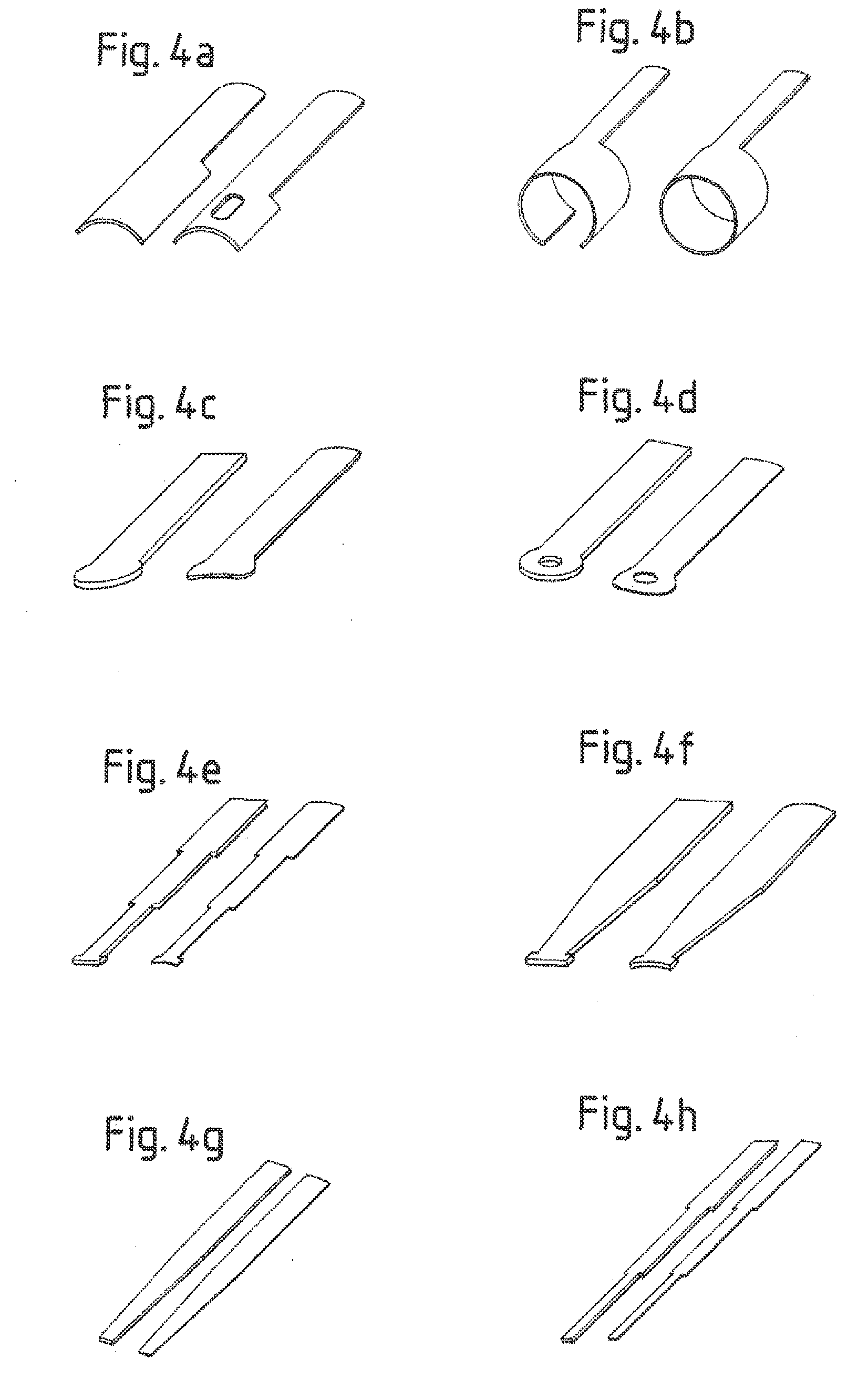

Retractable catheter

InactiveUS20100145430A1Smooth connectionIncrease the outer diameterStentsCatheterPull forceDistal portion

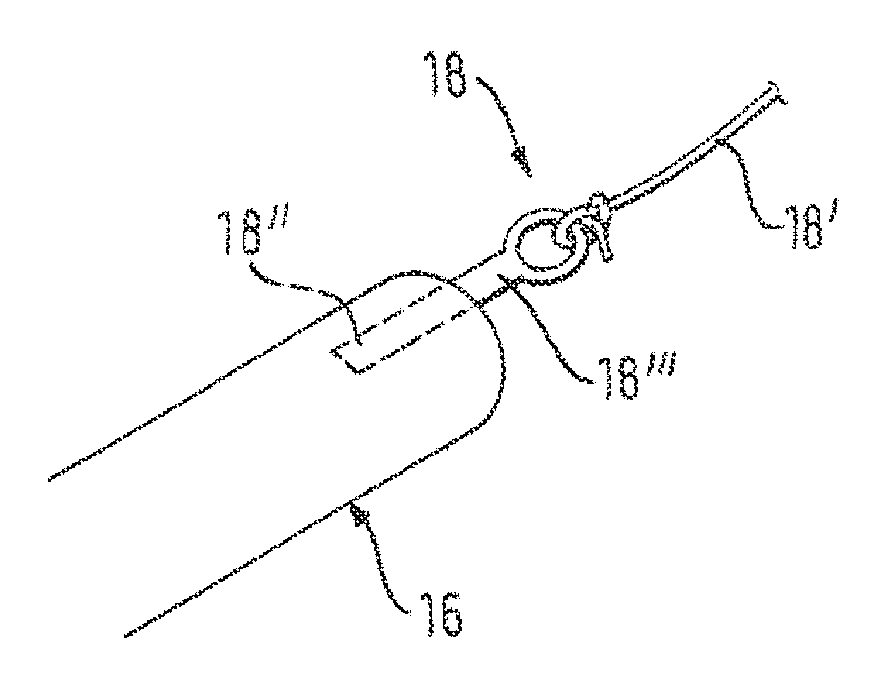

A retractable catheter including an elongate tubular sheath having at least in a distal portion made of a relatively flexible material, a reinforcing structure made of a relatively inextensible material incorporated in the relatively flexible material of the sheath along at least a portion thereof, and a pull element for transmitting a pull force longitudinally to the sheath and the reinforcing structure, wherein the pull element is connected directly to a portion of the reinforcing structure exposed from the relatively flexible material to transmit the pull force directly to the reinforcing structure.

Owner:CR BARD INC

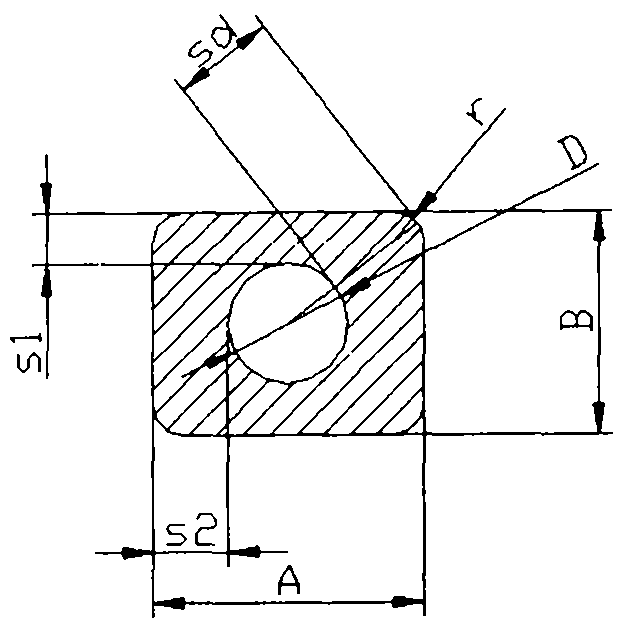

Large-diameter thin-wall cupronickel tube short process production method

The invention discloses a large-diameter thin-wall cupronickel tube short process production method and belongs to the technical field of metal materials. Specific to the problems that large-scale extrusion equipment up to 5000 tons is needed to produce large-diameter thin-wall cupronickel tubes through a traditional technique of semi-continuous casting solid ingot casting, punching, extruding, acid pickling, drawing and annealing, the finished product rate is low and the cost is high, the invention provides a method for producing the large-diameter thin-wall cupronickel tubes. Hot and cold combination casting horizontal continuous casting is adopted to producing large-size cupronickel tube blanks, and then a hole enlargement or / and hole shrinkage drawing is adopted to machining and forming the large-diameter thin-wall cupronickel tubes. The method has the advantages of being small in equipment investment, short in technical process, free of acid pickling and the like. The outer diameter of horizontal continuous casting tube blanks is 110-350 mm, the wall thickness is 5-30 mm, the elongation coefficient of hole enlargement drawing pass is 0.80-1.0, and the elongation coefficient of hole shrinkage drawing pass is 1.1-1.5; the outer diameter of machined products is 100-320 mm, and the wall thickness is 3-20 mm.

Owner:UNIV OF SCI & TECH BEIJING

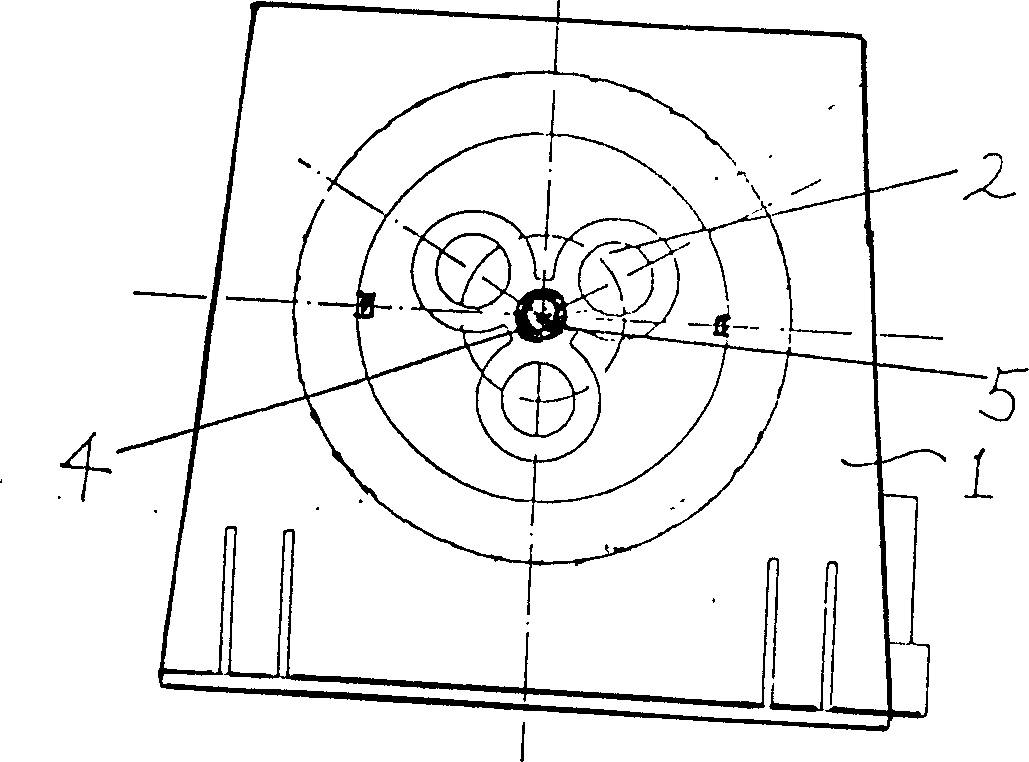

Process for preparing pipe by punching high temperature alloy bar

ActiveCN106180194ASmooth inner and outer surfacesImprove rolling qualityTemperature control deviceMetal rolling arrangementsHeating timeHigh frequency

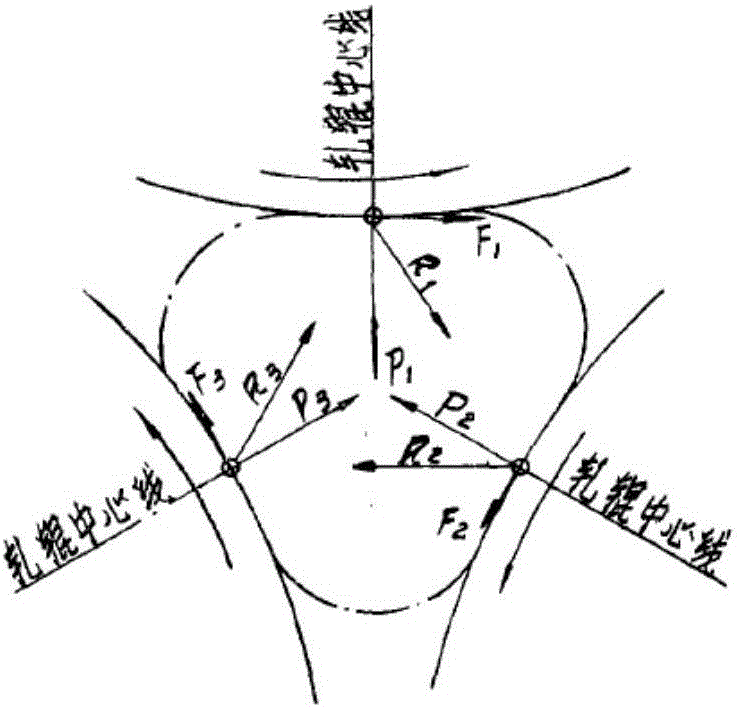

The invention relates to a process for preparing a pipe by punching a high temperature alloy bar. Firstly, a high temperature alloy ingot is subjected to hammer cogging at 900-1200 DEG C to obtain a bar blank; secondly, bar blank induction heating is conducted under the condition that the heating temperature is 1000-1300 DEG C and the heating time is 10-60 min; and finally, ejection headers are arranged at the front ends of rollers of a three-roller planetary rolling mill, and the bar is directly punched into the pipe during rolling. The method for preparing the pipe is simple, steps are easy to implement, high-frequency induction heating is adopted during bar blank punching and rolling, the working efficiency is high, and pollution is avoided; the wall thickness of the punched pipe is even, the inner surface and the outer surface of the punched pipe are smooth, no crack is caused, and the application range of the specifications and materials of the bar blank is wide.

Owner:JIANGSU LONGDA SUPERALLOY MATERIAL CO LTD

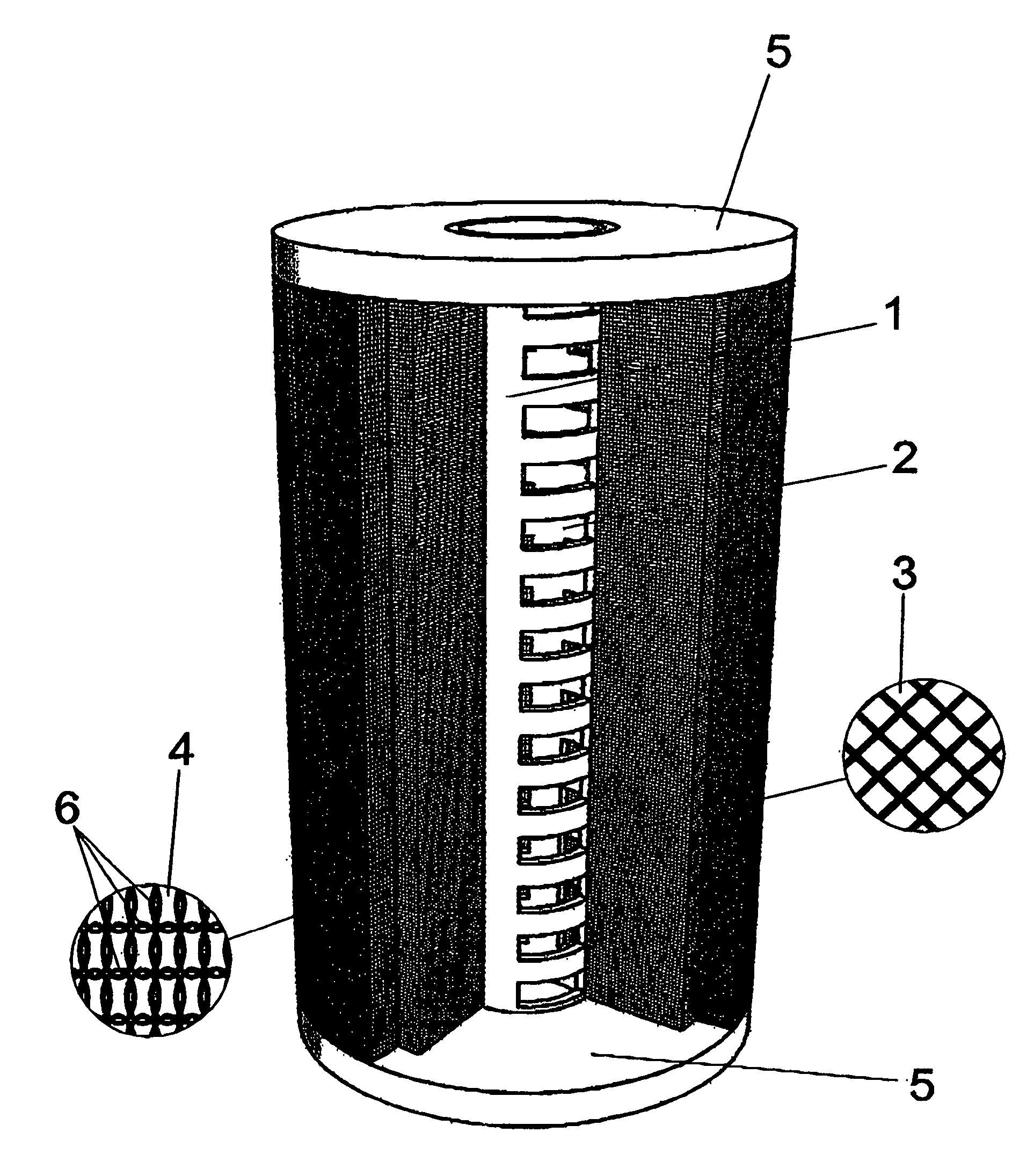

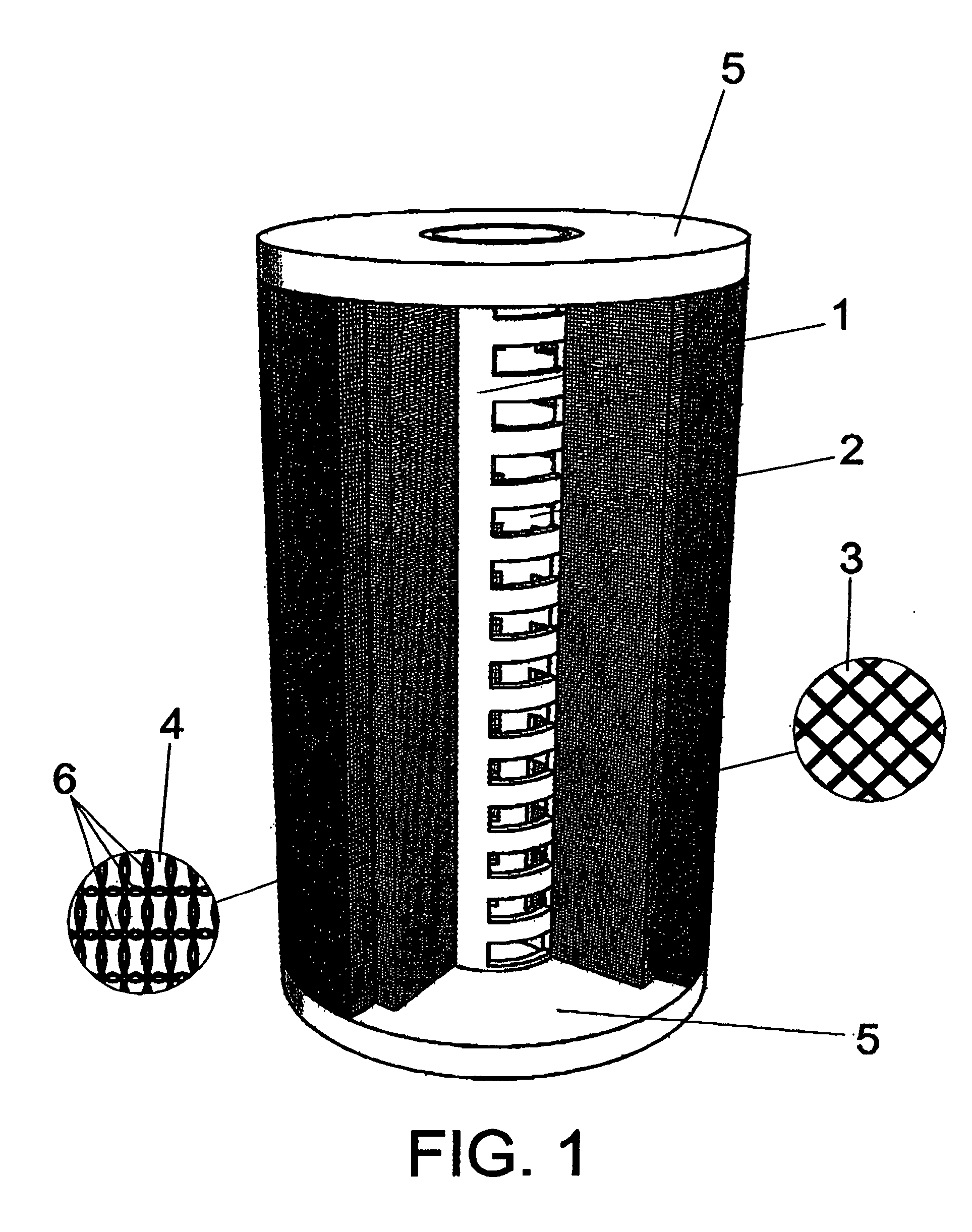

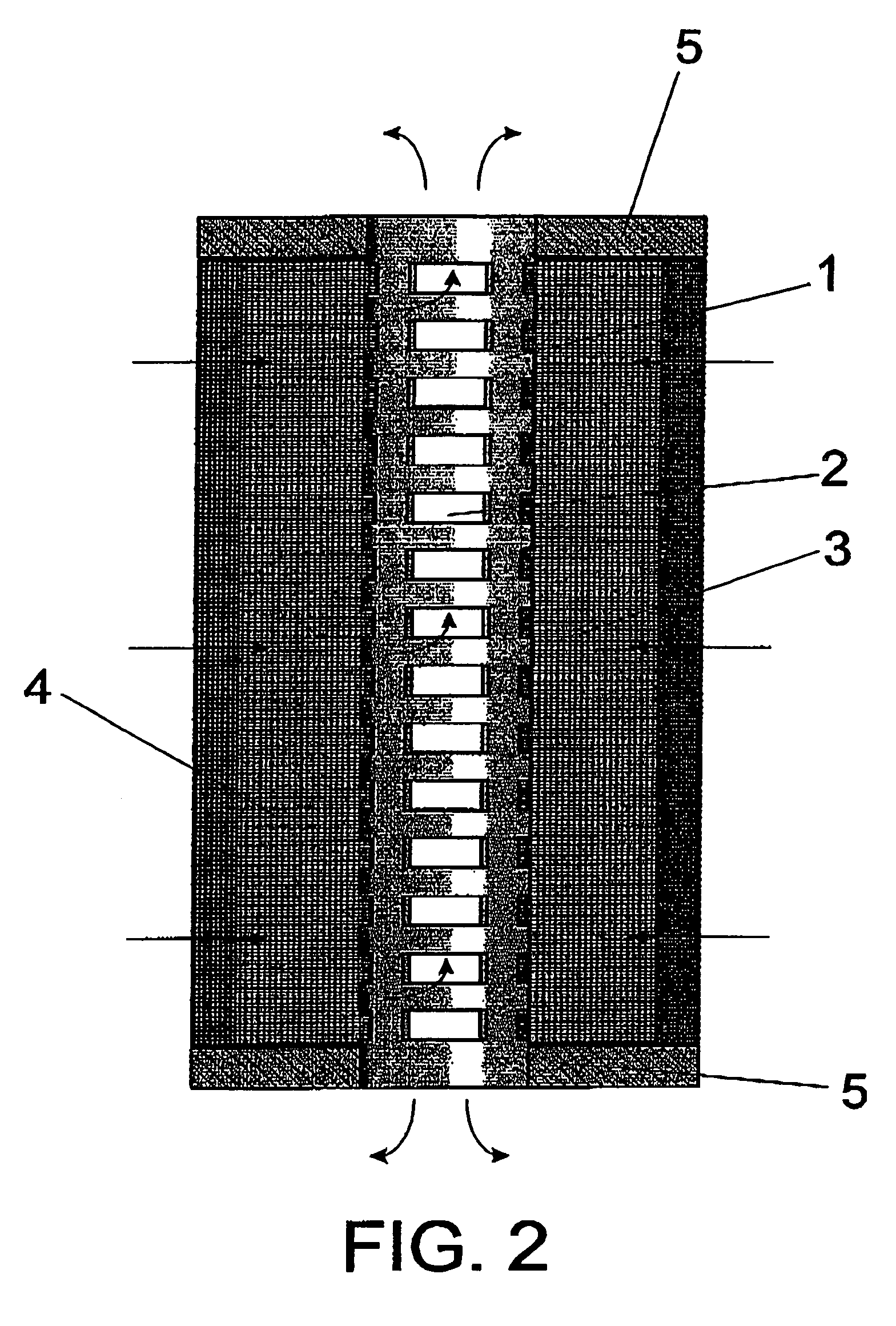

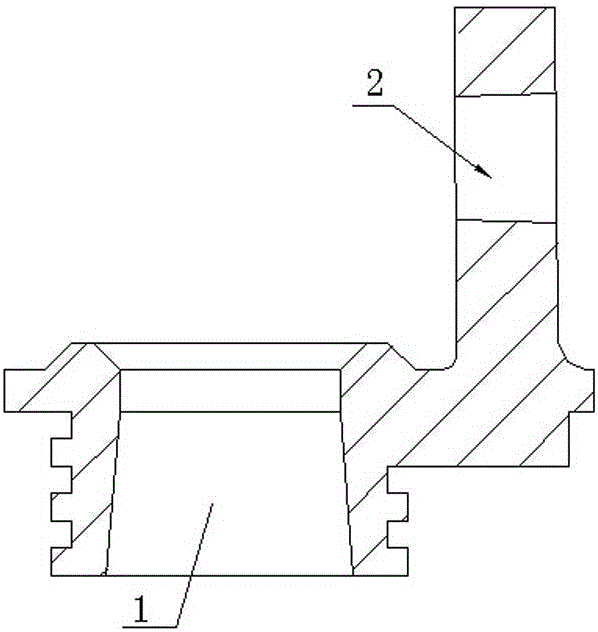

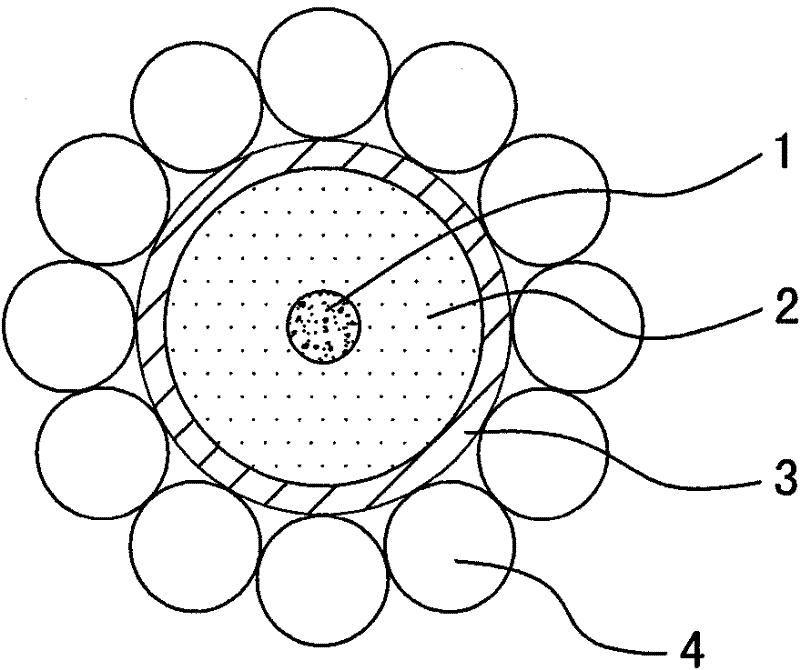

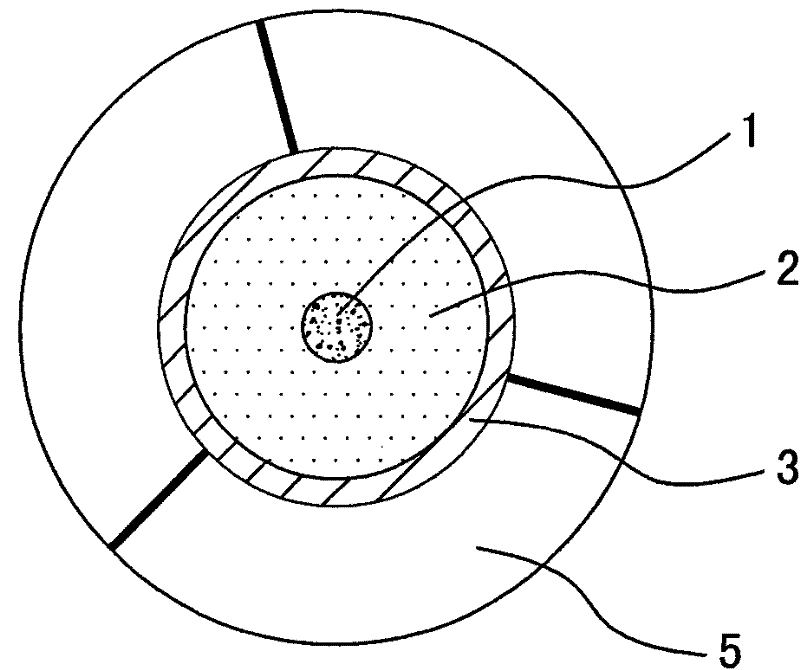

Multi-layer filtering cartridge for filtration of liquids

InactiveUS20060231480A1Quality improvementHigh mechanical strengthElectrical controlComputer controlFiltrationBiomedical engineering

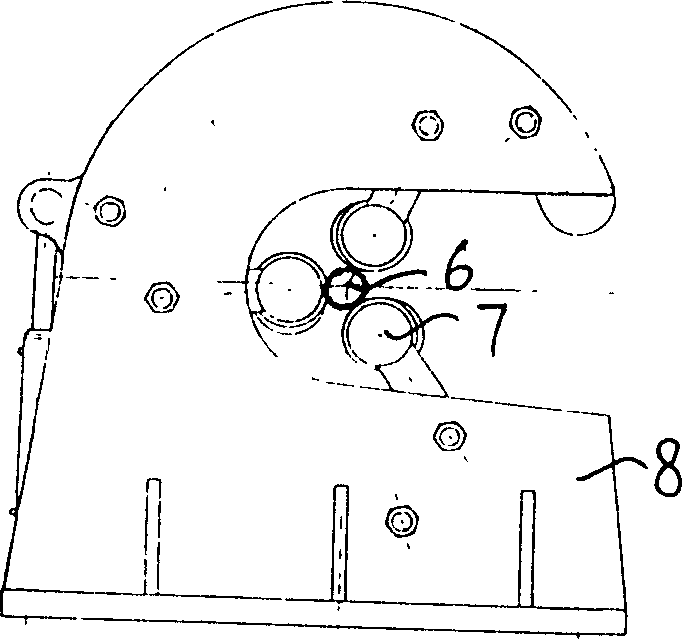

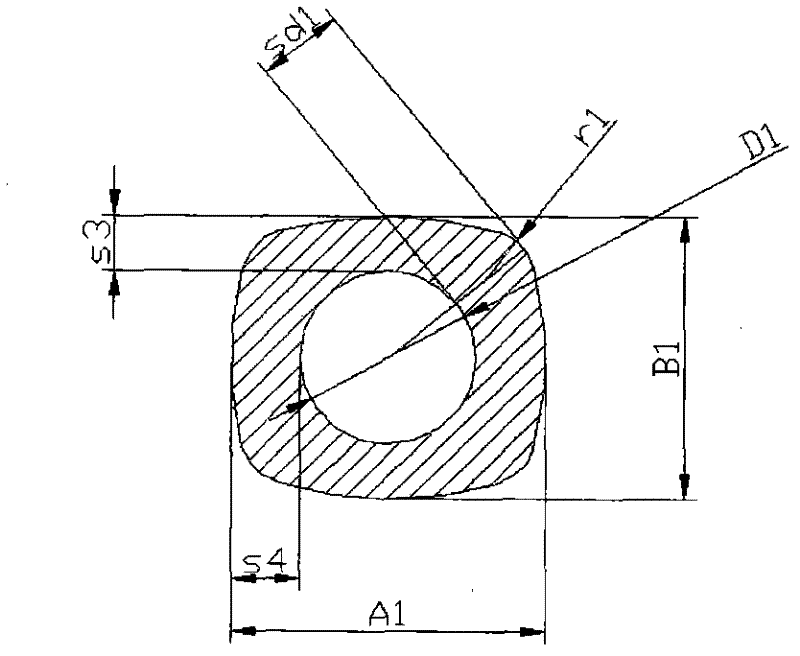

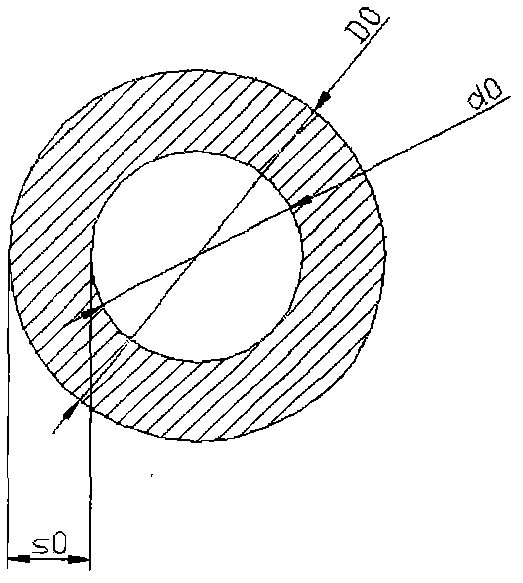

This comprises a central tube (1) provided with vents or holes (2) for the passage of liquid, covered with a grille-type laminar support rolled in a spiral. This assembly is covered with an outer layer of porous filtering material (4) which is also rolled in a spiral with the desired number of sub-layers depending on the pore size. The ends are sealed with circular covers (5) with an axial hole that matches the central tube (1).

Owner:ACCIONA AGUA

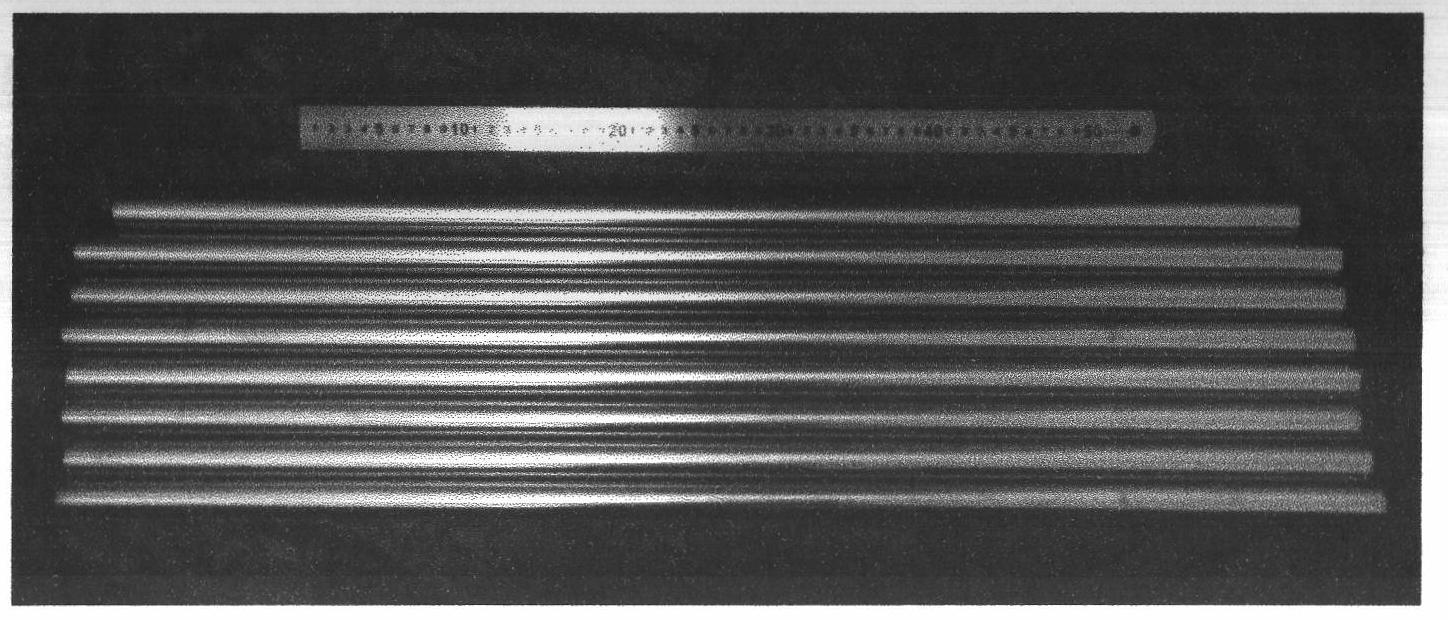

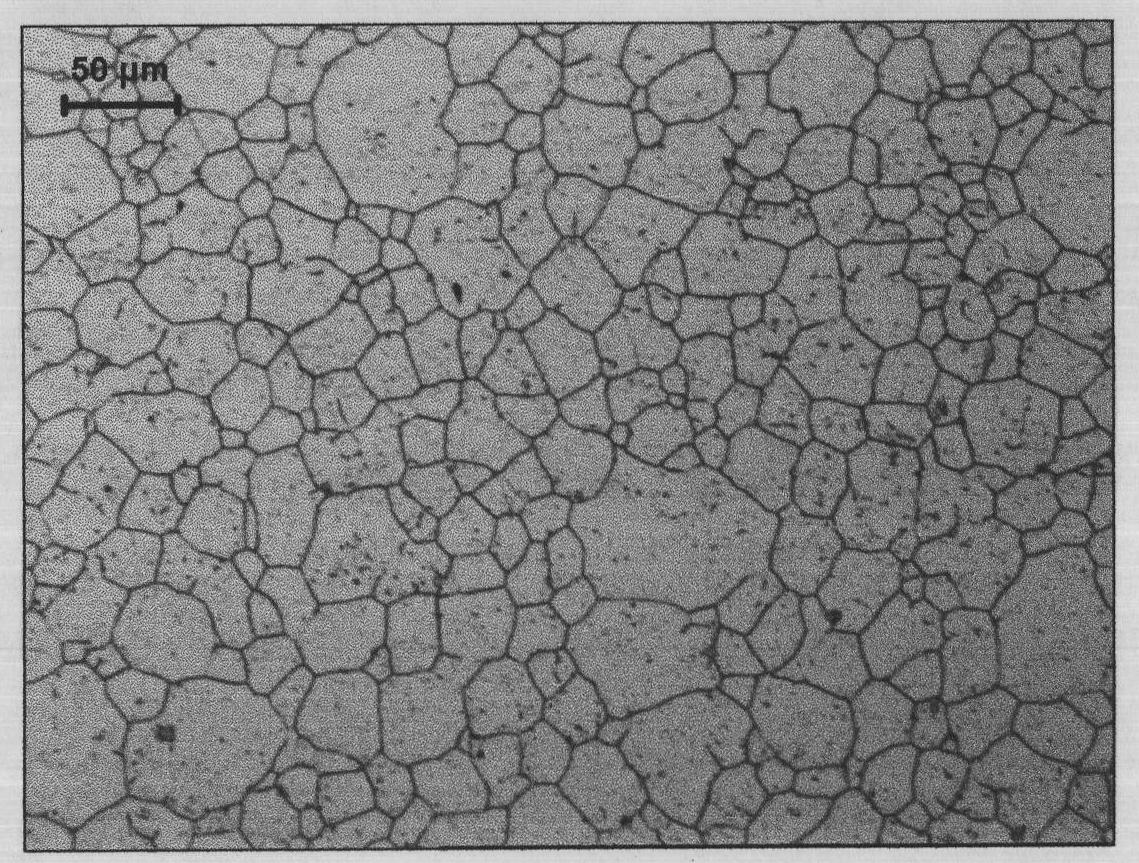

Process for preparing GH4145 alloy pipes

InactiveCN102397889AHigh dimensional accuracySmooth inner and outer surfacesRoll mill control devicesMetal rolling arrangementsSize reductionSmelting

The invention aims to provide a process for preparing GH4145 alloy pipes, and in particular relates to a method for rolling GH4145 alloy precision pipes. In the method, the deformation quantity of pipe blanks and the deformation gradient of outer diameters (wall thicknesses) of the pipes are controlled by a cold rolling and annealing method to reduce non-uniform deformation, obtain uniform and appropriate tissue and qualified precision pipes and meet higher using requirements. The method comprises the following processes of: smelting, forging, performing solid solution heat treatment, machining, drilling, performing cold rolling and annealing repeatedly (3 to 15 times generally) and thus obtaining finished products. The method is characterized in that: the forging temperature is between 1,100 and 1,200 DEG C, and the deformation quantity is between 35 and 80 percent; the temperature of the solid solution heat treatment is between 950 and 1,040 DEG C, and is kept for 20 to 60 minutes; and in the cold milling process, a ratio of sizing reduction to wall reduction in each pass is controlled to be 2 to 4.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

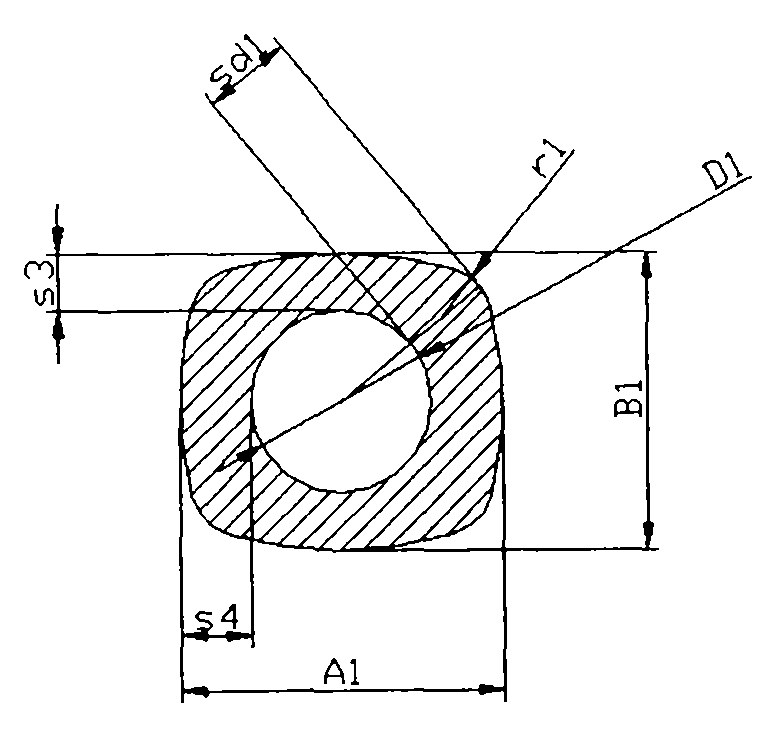

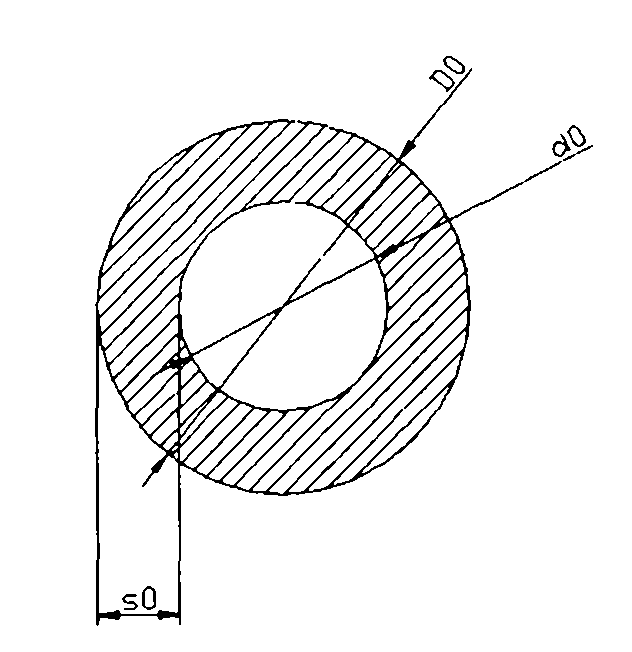

Method for processing rectangular round-hole wire copper pipe of dual water internal cooling generator

The invention discloses a method for processing a rectangular round-hole wire copper pipe of a dual water internal cooling generator, which comprises the steps of: selecting a pipe blank, casting, extruding and stretching the selected pipe blank to form a circular pipe blank; rolling the formed pipe blank; annealing the rolled pipe blank; carrying out transitional stretching on the annealed pipe blank; and then, stretching the pipe blank after transitional stretching to form a finished product. The processing method solves the problems of large material consumption of a coil, large volume of a unit, poor cooling effect of the coil and finally short unit use life because the material of the coil is solid or has a rectangular inner hole adopted in the prior art. The processing method has the advantages of material saving, long service life and the like.

Owner:上海飞轮有色新材料股份有限公司 +1

Method for casting motorcycle parts by use of low-pressure casting process

The invention discloses a method for casting motorcycle parts by use of the low-pressure casting process. The method has the characteristics of short production period, short machining process flow, low equipment input, high yield, low production cost, small tool loss, high utilization ratio of raw materials, good production quality stability, and the like. Three-dimensional modeling software is utilized to perform three-dimensional modeling on motorcycle parts needing to be cast, a metal-type low-pressure casting process is used together to determine casting process parameters, and three-dimensional blank casting is finished according to the casting process parameters including alloy material chemical components, a gating system, machining allowance and a parting surface. The alloy material chemical components comprise the following ingredients by weight percent: less than or equal to 0.5% of C, less than or equal to 1.2-1.8% of Cu, less than or equal to 1.8-2.4% of Mn, less than or equal to 0.5-.8% of Si, less than or equal to 1.2-1.5% of Zn, less than or equal to 0.2-0.5% of Ni, less than or equal to 1-1.8% of Mg, less than or equal to 2-6% of AL, less than or equal to 0.3-0.8% of Ti, and the balance of Fe. The modeling of a casting mold is designed, and the designed modeling of the casting mold is used for manufacturing a metal-type low-pressure mold.

Owner:重庆市合川区银窝铸造厂

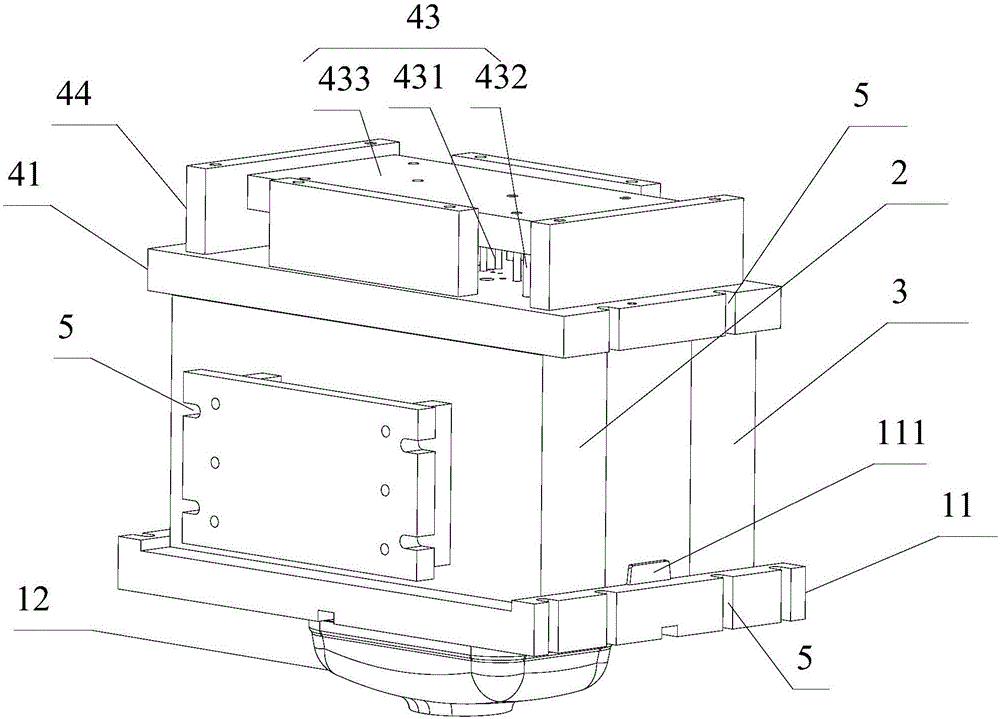

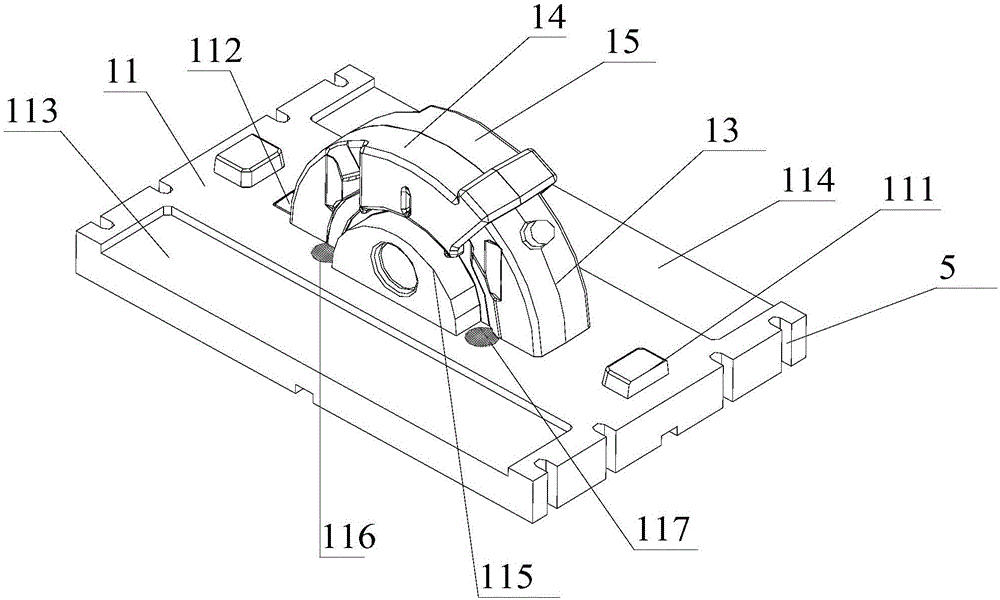

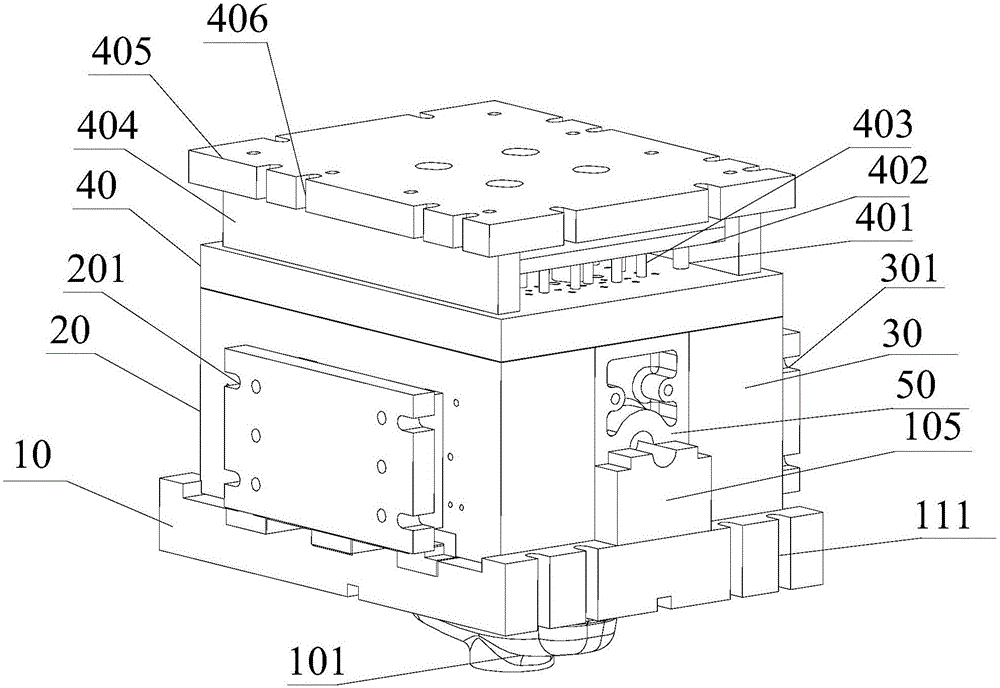

Metal mold low-pressure casting die for box body on cast aluminum gearbox of high-speed train

The invention provides a metal mold low-pressure casting die for a box body on a cast aluminum gearbox of a high-speed train. The metal mold low-pressure casting die comprises a lower die body, an upper die body, a first sliding block and a second sliding block. A casting cavity is defined by the lower die body, the upper die body, the first sliding block and the second sliding block. The lower die body comprises a lower die base and a sand core. The side, away from a lifting pouring basin, of the lower die base is provided with a sand core positioning groove, a first sliding block limiting groove and a second sliding block limiting groove, wherein the first sliding block limiting groove and the second sliding block limiting groove are symmetrically formed in the two sides of the sand core positioning groove. The two ends of the sand core positioning groove are symmetrically provided with two upper die limiting blocks in the extension direction. The sand core is clamped in the sand core positioning groove. The first sliding block is clamped in the first sliding block limiting groove. The second sliding block is clamped in the second sliding block limiting groove. The upper die body comprises an upper die base. The side, away from a third molding groove, of the upper die base is provided with an ejection connecting mechanism. A produced casting is dense in structure, clear in outline, stable in mechanical performance and good in dimensional stability consistency, the inner surface and the outer surface are smooth, an inner cavity and an oil return groove are more clearly molded, and the casting yield is high.

Owner:LAIAN KELAIXING IND CO LTD

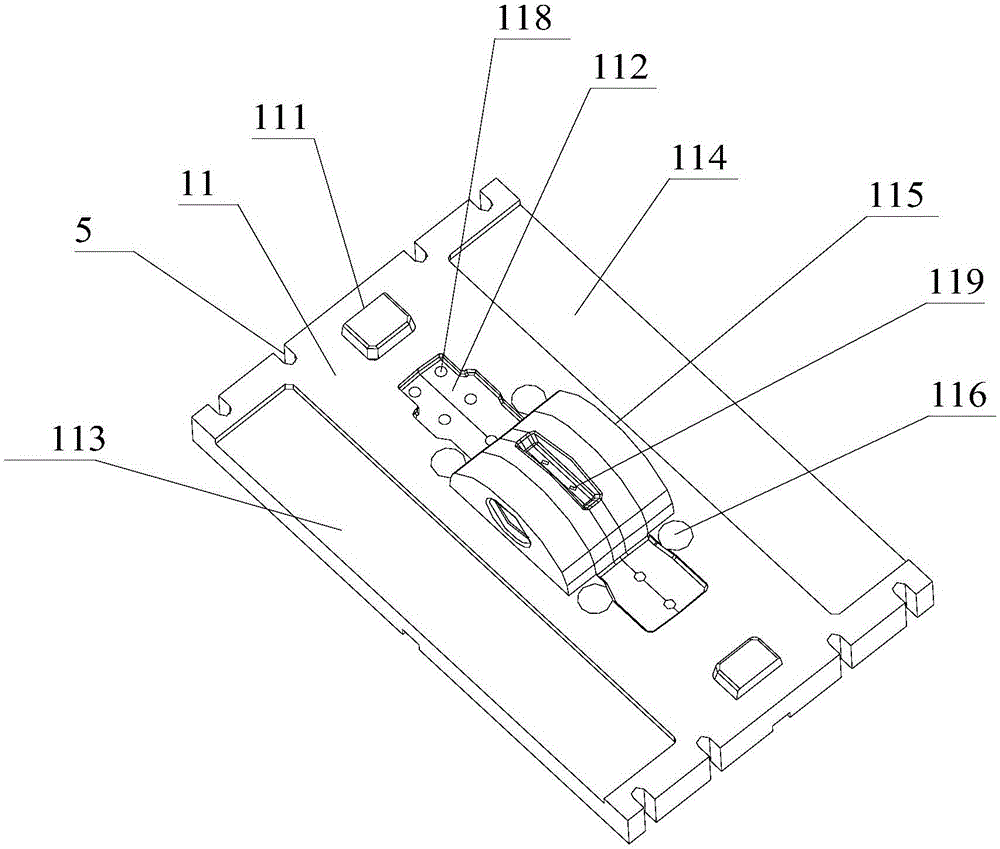

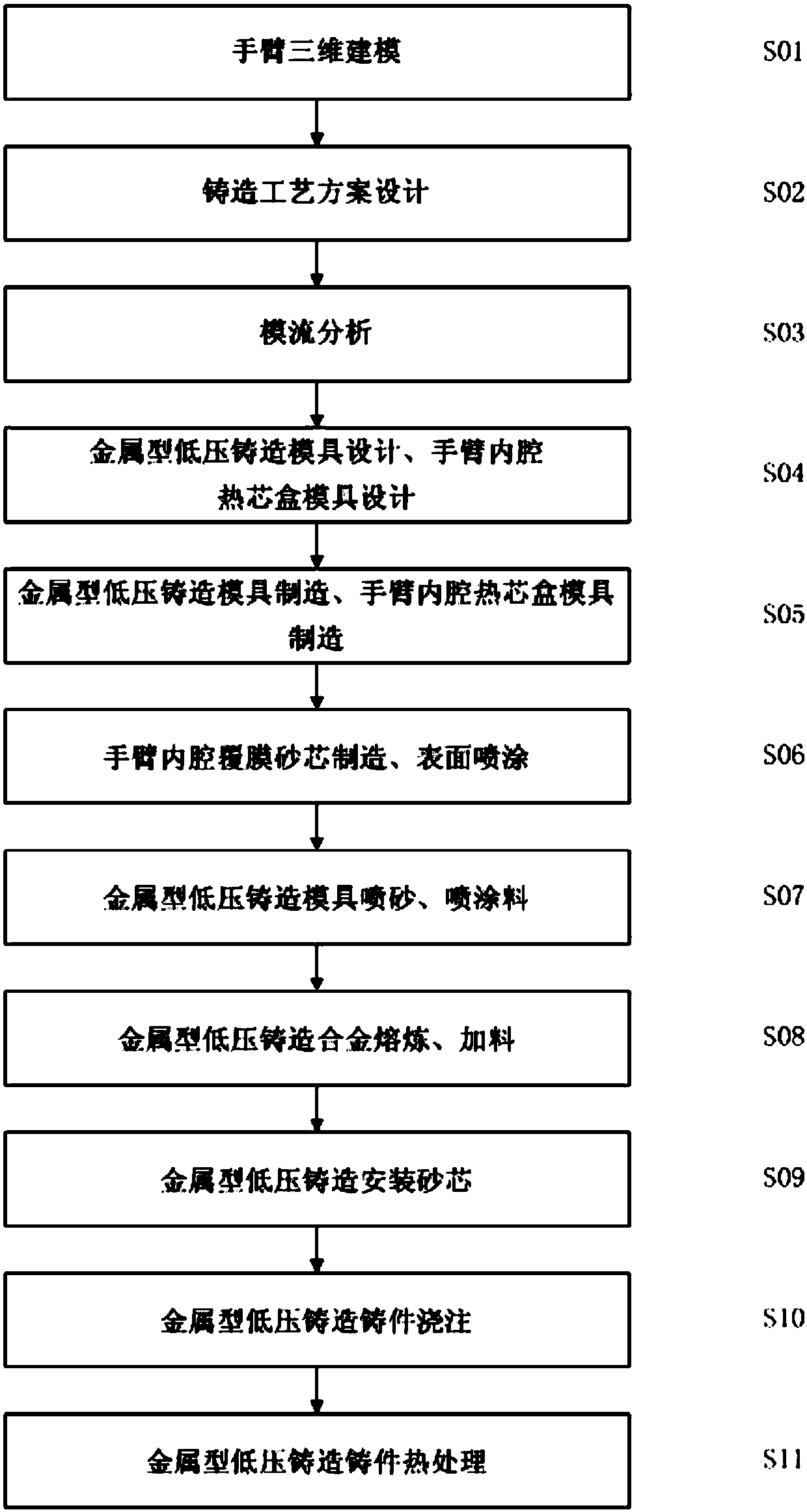

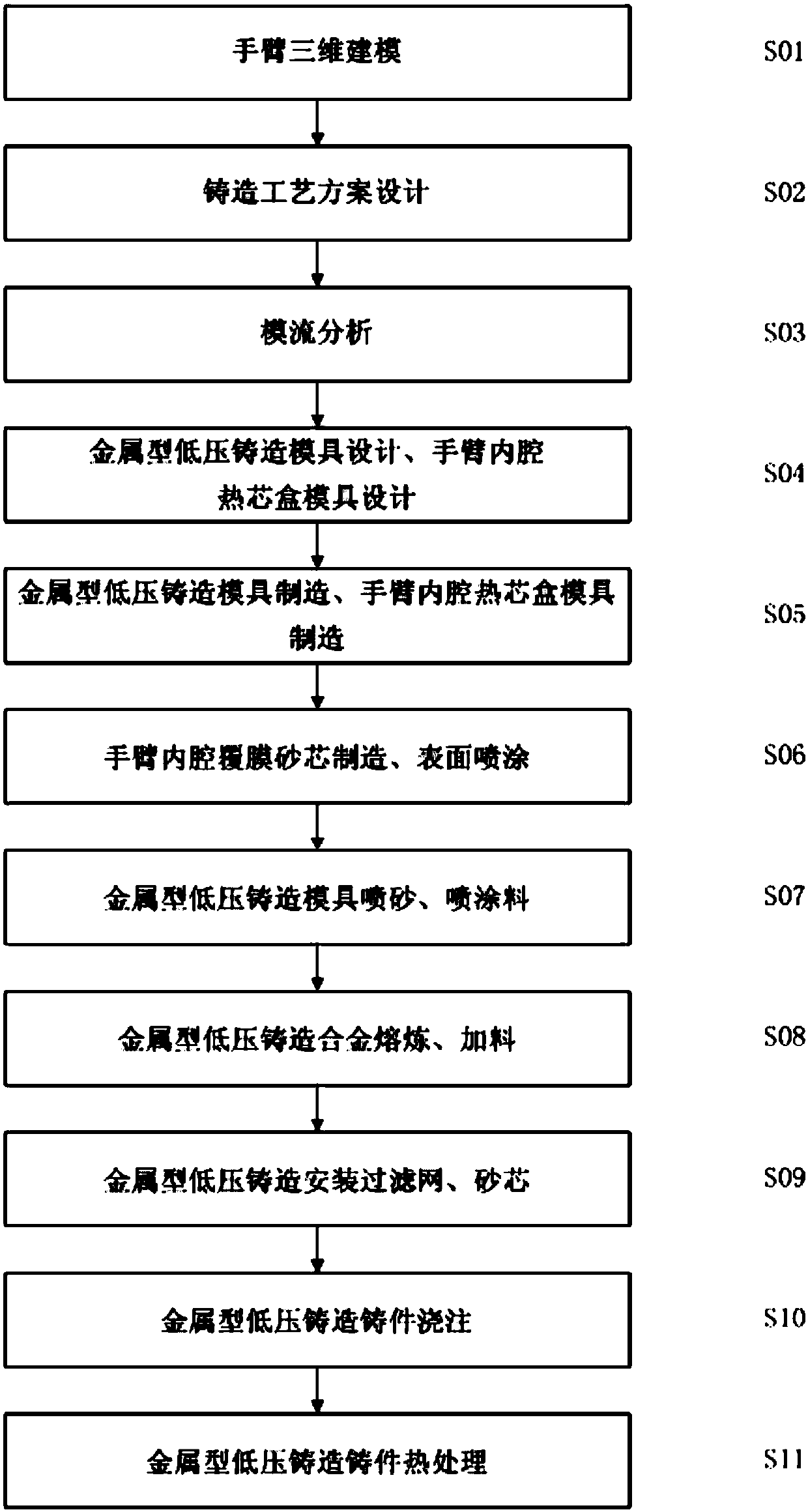

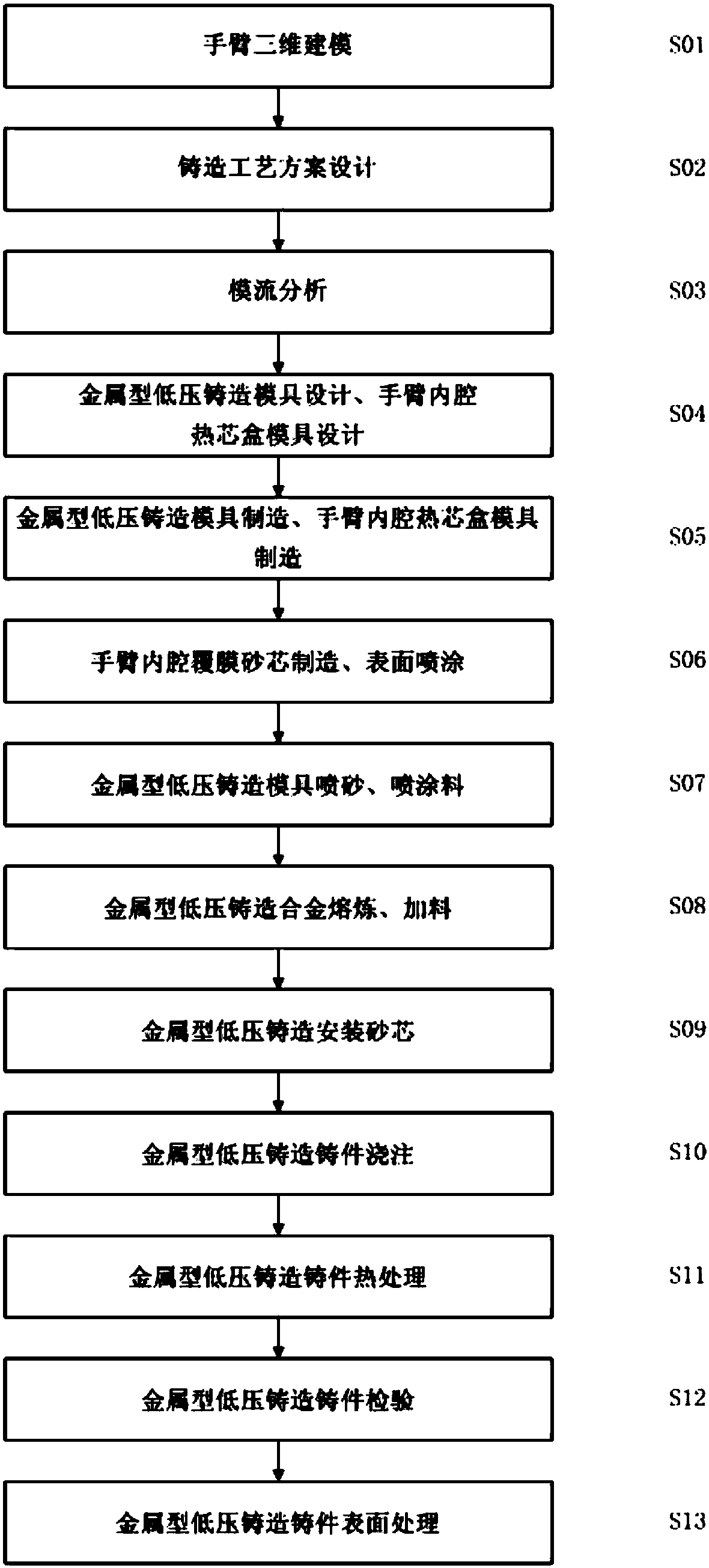

Aluminum alloy metal mold low-pressure casting technological method for collaborative robot arm

The invention discloses an aluminum alloy metal mold low-pressure casting technological method for a collaborative robot arm. The method comprises the following steps of 1, three-dimensional modelingof the arm; 2, design of a casting technological scheme; 3, mold flow analysis; 4, design of a metal mold low-pressure casting mold and an arm inner chamber hot box mold; 5, manufacturing of the metalmold low-pressure casting mold and the arm inner chamber hot box mold; 6, manufacturing of an arm inner chamber film-coated sand core, and surface coating; 7, sand blasting and paint spraying of themetal mold low-pressure casting mold; 8, smelting and feeding of a metal mold low-pressure casting alloy; 9, mounting of the sand core through metal mold low-pressure casting; 10, pouring of metal mold low-pressure casting castings; and 11, heat treatment of the metal mold low-pressure casting castings. The collaborative robot arm manufactured through the method has the beneficial effects of beingsmall in weight, high in rigidity, high in inner chamber precision and attractive and delicate in outer surface.

Owner:张希波

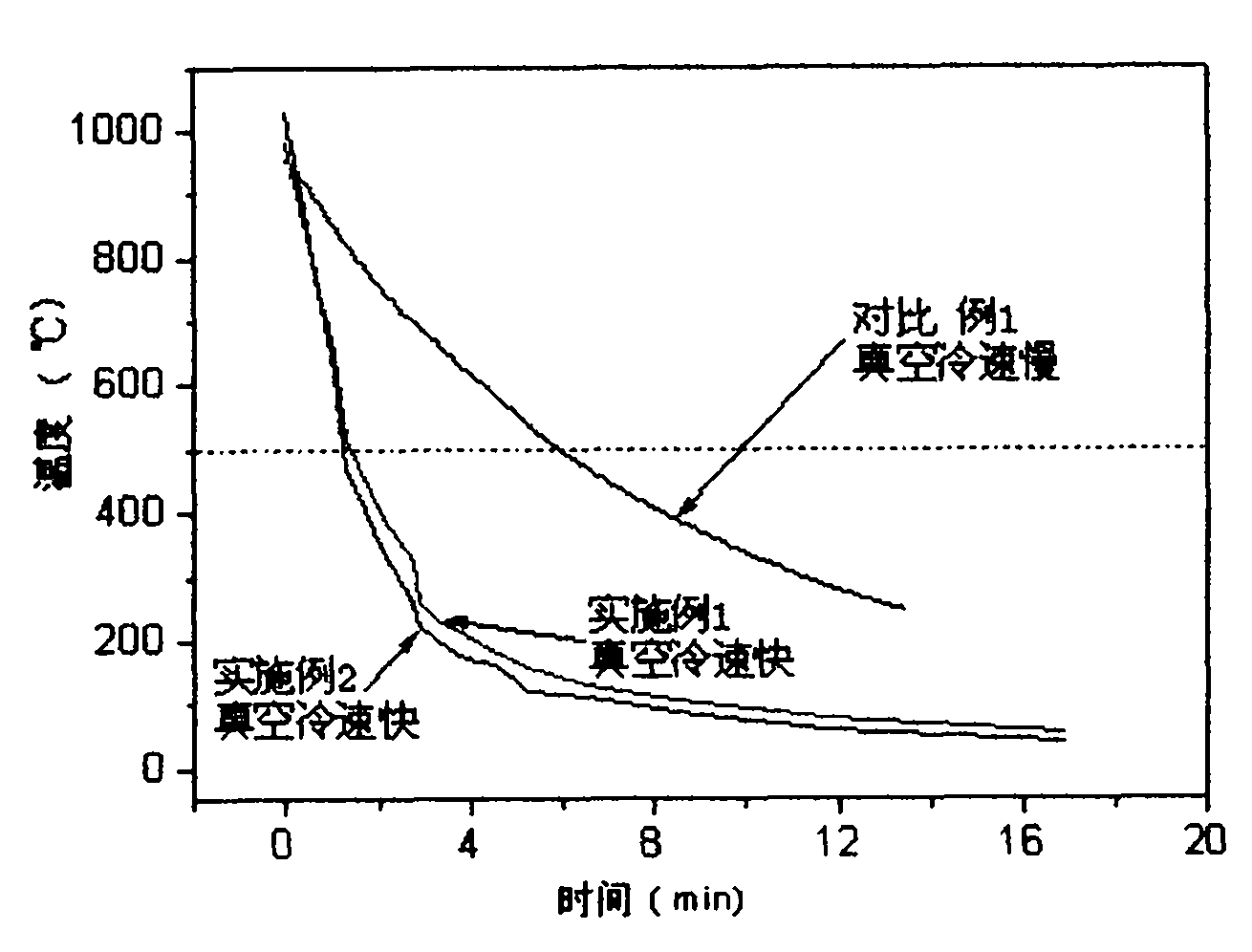

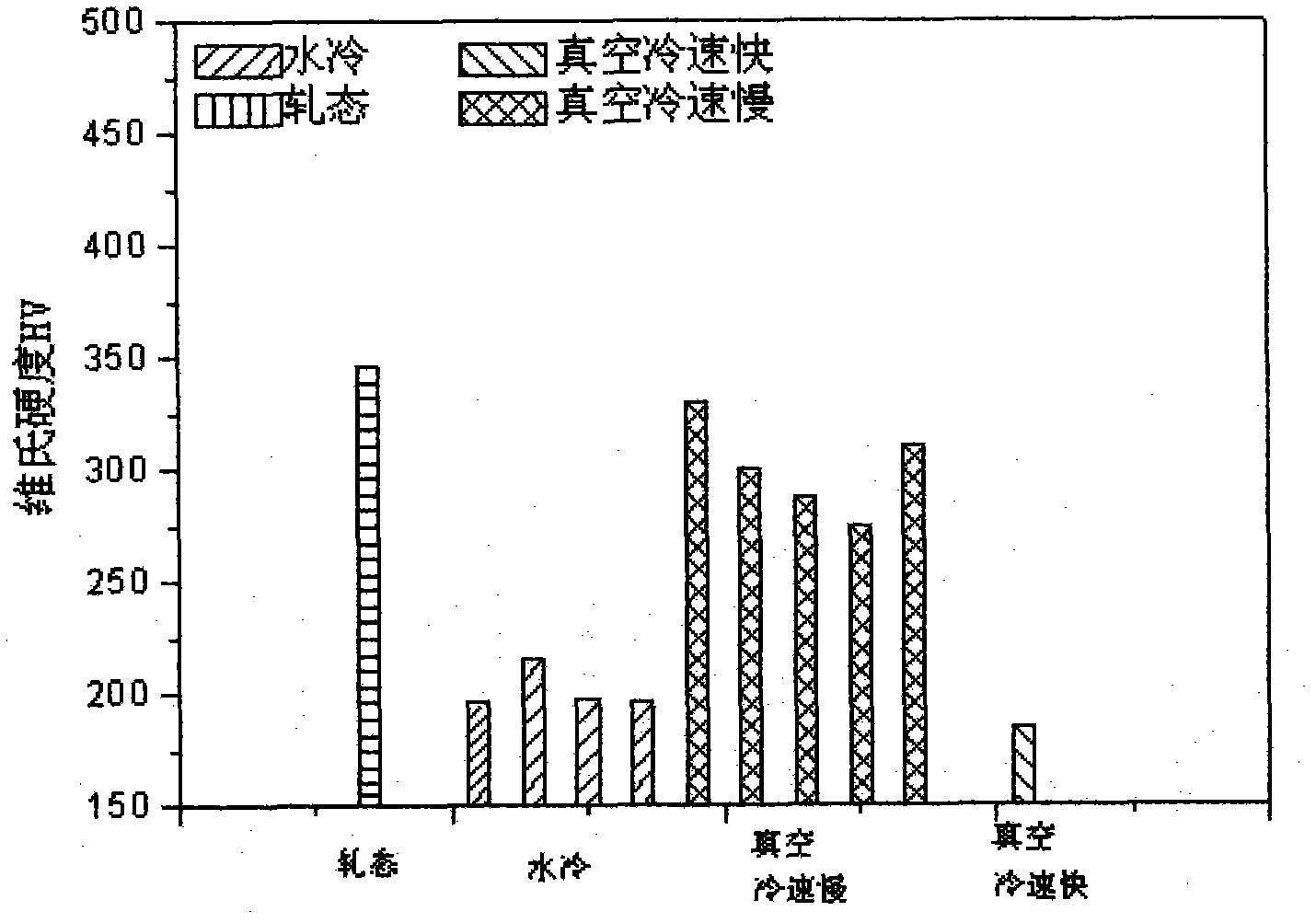

Heat treatment process for improving GH4145 alloy pipe

InactiveCN102399961AReduce hardnessSmooth inner and outer surfacesFurnace typesHeat treatment furnacesNitrogenAlloy

The present invention specifically provides a heat treatment process for improving a GH4145 alloy pipe. The heat treatment process is characterized in that: the technical process comprises: (1) adopting a vacuum gas quenching furnace to carry out sectional heating for the pipe along with the furnace, wherein the two-stage heating process comprises that: in the first stage heating process, heatingalong with the furnace to the temperature of 600 DEG C, holding the temperature for 15-20 minutes, and eliminating harmful gas impurities; in the second stage heating process, heating to the temperature of 970-1040 DEG C from the temperature of 600 DEG C, holding the temperature for 15-20 minutes, eliminating the residual stress force, and stabilizing the organization; (2) carrying out rapid cooling: wherein the cooling pressure is 4-6 bar, the cooling rate is more than 350 DEG C per minute before the temperature is reduced to 500 DEG C so as to avoid the precipitation of the gamma' strengthening phase; (3) obtaining the finished product. According to the present invention, the vickers hardness of the heat-treated pipe is less than or equal to 240; the cooling gas is nitrogen or argon.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

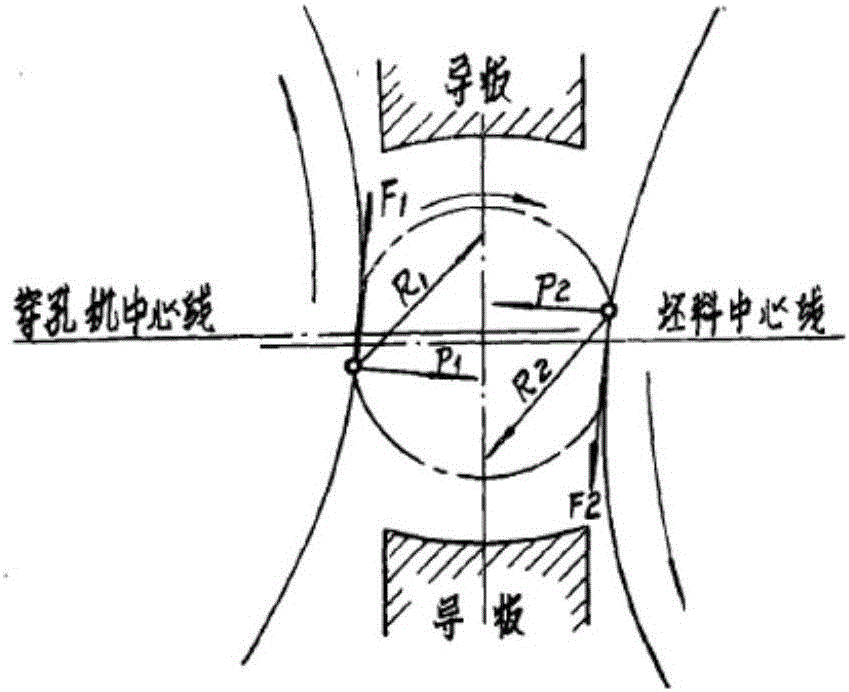

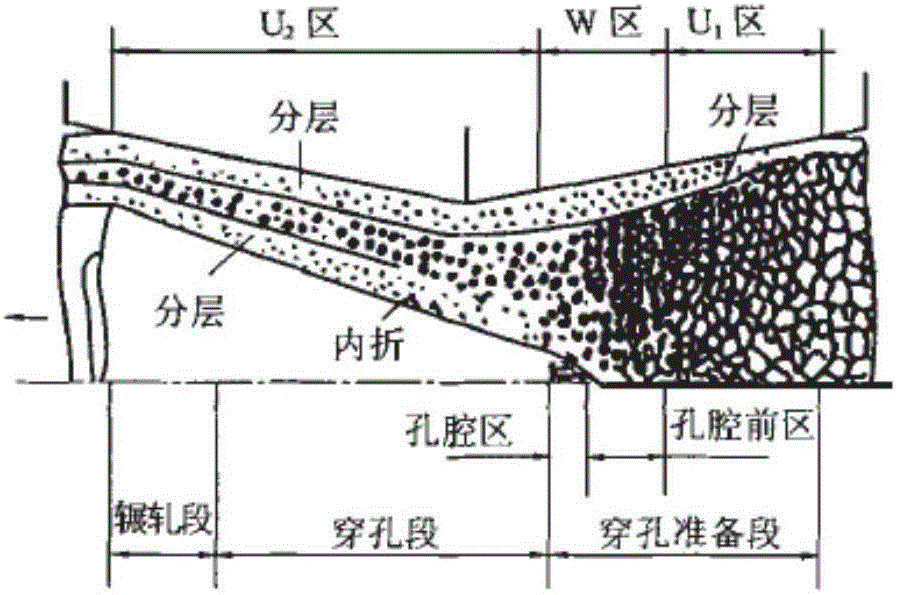

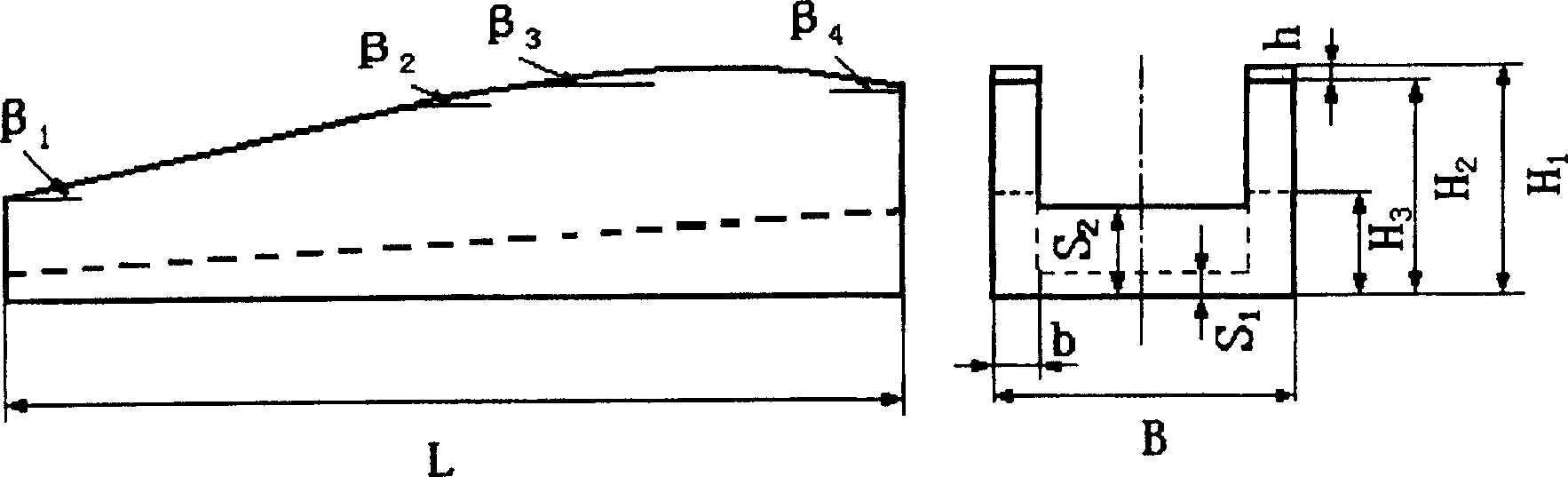

Roller trio skew rolling method for cold perforating and cold chambering ingot

InactiveCN1695839AReduce consumptionReduce deformation resistanceMetal rolling stand detailsRollsIngotMechanical engineering

The present invention discloses a roller trio skew rolling method for cold perforating and cold chambering ingot, wherein surface of three rollers of the roller trio skew rolling machine is arranged to be structure having multi-groove, projecting loop, and large distortion zone is formed among the three rollers; casting blank to be processed is transmitted to the large distortion zone among the three rollers to be rolled, meantime, head of the head mechanism is transmitted into the process section; three rollers are rotated at same time to activate the rotation of the rolled piece to produce spire movement and project the processing casting blank. The invention overcomes the defect of pure hot rolling, additional heating device is unnecessary, which saves the equipment advertisement and energy consumption, and achieves perforating and chambering ingot of cold perforating and cold chambering ingot, and roll scale is not produced on the rolling piece.

Owner:江苏包罗铜材集团股份有限公司

Preparation method for oxide dispersion strengthened FeCrAl alloy pipe

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +3

A short-process production method for large-diameter thin-walled copper-nickel pipes

The invention discloses a short-process production method of a large-diameter thin-walled white copper pipe, which belongs to the technical field of metal materials. Aiming at the traditional "semi-continuous casting solid ingot-piercing extrusion-pickling-drawing-annealing" process to produce large-diameter thin-walled copper-nickel pipes requires more than 5,000 tons of large-scale extrusion equipment, and the yield is low and the cost is high. The present invention proposes a method of horizontal continuous casting of large-sized white copper pipe blanks using hot and cold combined molds, and then adopts diameter expansion or / and diameter reduction drawing to process and form large-diameter thin-walled white copper pipes, which has the advantages of small equipment investment, short process flow, No pickling and other advantages. The outer diameter of the horizontal continuous casting tube blank is 110~350mm, the wall thickness is 5~30mm, the extension coefficient of the drawing pass for expanding diameter is 0.80~1.0, the extension coefficient for drawing pass for reducing diameter is 1.1~1.5, and the outer diameter of the processed product is 100~ 320mm, wall thickness 3~20mm.

Owner:UNIV OF SCI & TECH BEIJING

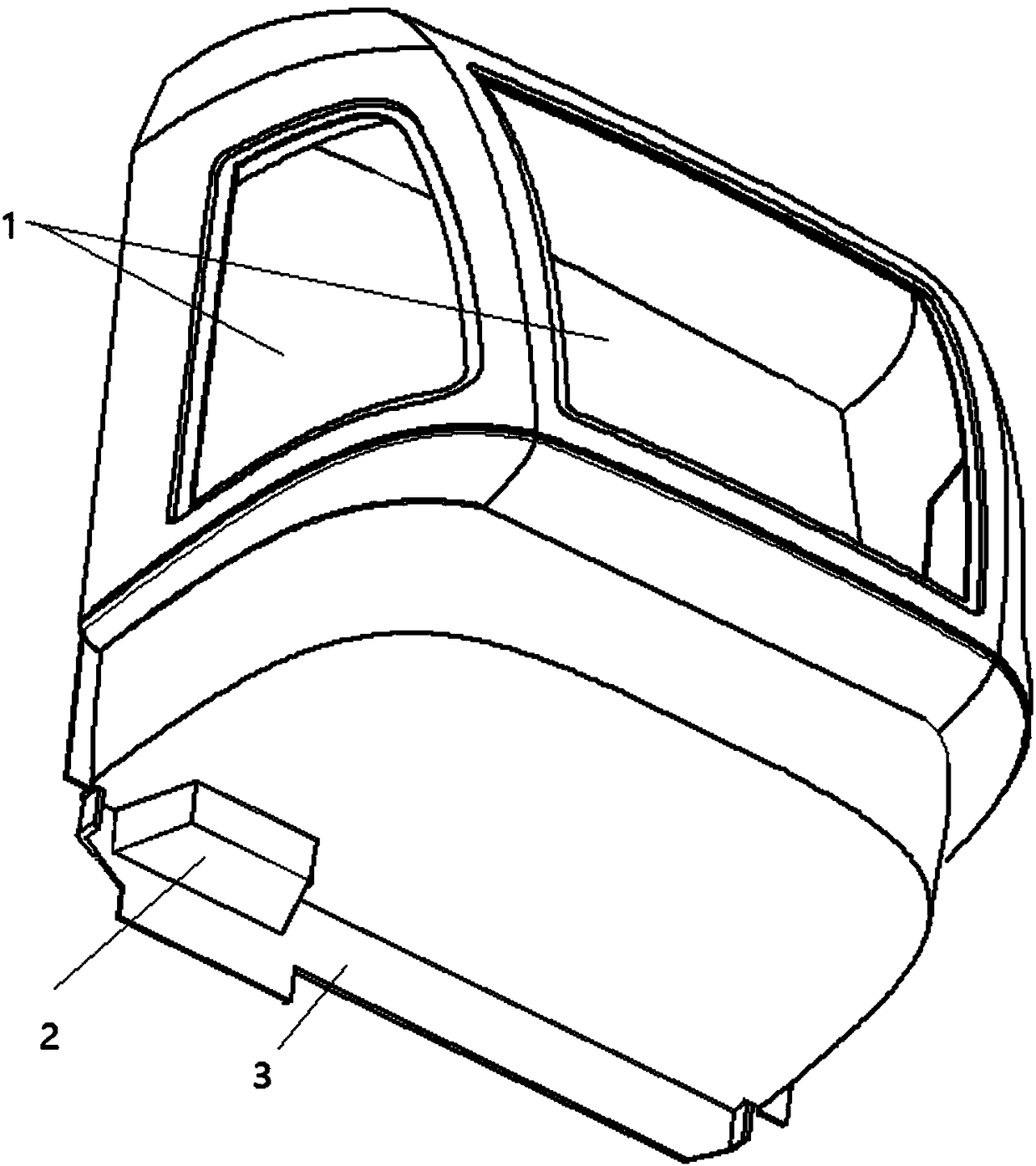

Method for manufacturing glass fiber reinforced plastic shell through die

The invention relates to a manufacturing method of a glass fiber reinforced plastic shell, in particular to a method for manufacturing the glass fiber reinforced plastic shell through a die. The method includes the steps of (1) gel coat layer spraying, (2) glass fiber reinforced plastic layer pasting, (3) foam layer splicing, (4) die assembly grinding, (5) final die assembly, (6) post curing, (7)demolding and (8) product paint spraying. According to the method, the die is used for manufacturing the glass fiber reinforced plastic shell, the technological step is simple, and operation is easy;through an up and down die assembly manner, it is guaranteed that the inner and outer surfaces of a molded product are both flat and smooth; through measurement of the thickness of a die cavity in dieassembly grinding, the problems about uneven pasting thickness, pasting missing and the like of the molded product are avoided, and the final molding quality of the molding product is guaranteed; andin addition, the molded product is the glass fiber reinforced plastic product with a foam sandwich, the strength of a driving cab shell is guaranteed, meanwhile, the weight is smaller, and cost is lower.

Owner:唐山宏正机械设备有限公司

Machining method for magnesium alloy thin-walled pipe for degradable and absorbable support

The invention belongs to the technical field of biomaterials, and discloses a machining method for a magnesium alloy thin-walled pipe for a degradable and absorbable support. The technological processof the method comprises the steps of smelting, casting, extruding, extruding punching, boring and cleaning of the inner surface and the outer surface, annealing, drawing, repeated conduction of annealing and drawing and obtaining of finished products. In the whole repeated drawing process, the reducing deformation amount of the pipe needs to be controlled during each pass, and the matching relation between the reducing deformation amount and the wall reduction deformation amount is well adjusted at the same time. The pipe obtained through the process is high in precise, the inner surface andthe outer surface are smooth and clean, the mechanical performance is excellent, and the whole process is simple, good in controllability and high in economic benefits.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

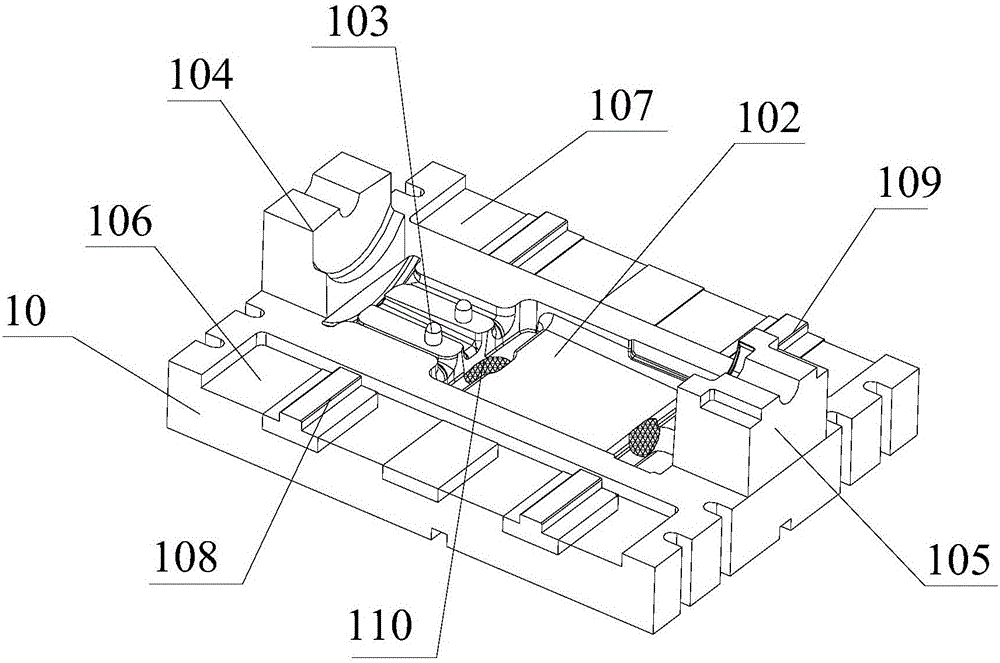

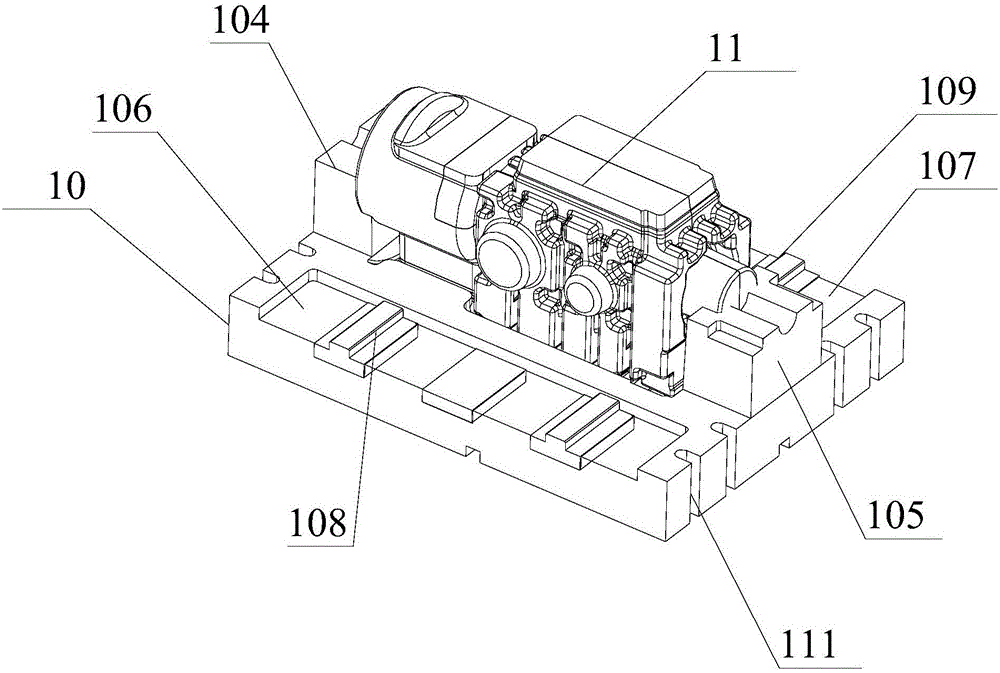

Metal mold low-pressure casting mold for crankcase of motor train unit air compressor

The invention provides a metal mold low-pressure casting mold for a crankcase of a motor train unit air compressor. The metal mold low-pressure casting mold comprises a lower mold, a first sliding block, a second sliding block, an upper mold, a manual loose core and a feeding head sand core. A casting cavity is defined by the lower mold, the first sliding block, the second sliding block, the upper mold and the feeding head sand core. The lower mold comprises a lower mold base and an inner cavity sand core. The inner cavity sand core is clamped into a first sand core positioning groove. The first sliding block and the second sliding block are symmetrically arranged on the two sides of the inner cavity sand core. The side, away from the lower mold base, of the first sliding block is provided with a second sand core positioning groove matched with the feeding head sand core. The side, away from the lower mold base, of the second sliding block is provided with a third sand core positioning groove matched with the feeding head sand core. The manual loose core is connected with the lower mold base. The feeding head sand core is arranged in a feeding head sand core positioning groove. The upper mold base is connected with the lower mold base through a first positioning block. The metal mold low-pressure casting mold is adopted, the labor intensity of workers is low, and the mechanical performance of produced castings is stable.

Owner:LAIAN KELAIXING IND CO LTD

Tool for compression molding of carbon fiber rectangular cross section thin-wall pipe fitting

InactiveCN111169035ASolve the problem of not being able to put in smoothlySolve the flatnessTubular articlesCompression moldingFiber

The invention discloses a tool for compression molding of a carbon fiber rectangular cross section thin-wall pipe fitting. The tool comprises a female die (1) and a male die (2), wherein a cavity forpaving and pasting prepreg (4) is formed in the female die (1); a movable block (5) forms one side wall of the cavity and can move along the direction perpendicular to the side wall to change the transverse width size of the cavity, so that a steel core (3) can be conveniently placed; and in addition, a silicone rubber layer (6) is arranged on the outer side of the movable block (5) and is heatedto expand to apply pressure to the movable block (5) to further apply pressure to the side wall of the rectangular cross section thin-wall pipe fitting. The tool solves the problems that thermal expansion or air bulking formation carried out in the rectangular cross section thin-wall pipe fitting causes that the inner wall of the pipe fitting is not smooth and the wall thickness of the pipe fitting is not uniform, adoption of a fixed die cavity die causes that the steel core cannot be smoothly placed after laying carbon fiber cloth layers, and the moulding process cannot compress the side wall, parallel with the compressing direction, in the rectangular cross section pipe fitting.

Owner:AVIC COMPOSITES

Method for processing rectangular round hole conductor copper pipe of double-water internal cooling generator

The invention discloses a method for processing the rectangular round hole conductor copper pipe of a double-water internal cooling generator, comprising the following steps: selecting a pipe blank; casting, extruding and stretching the selected pipe blank to form a round pipe blank; rolling the shaped pipe blank; annealing the rolled pipe blank; transiting and stretching the annealed pipe blank; and stretching the transited and stretched pipe blank to form a finished product. With the method, the technical problems of large coil consumable amount, large unit volume, poor coil cooling effect and short service life of the unit because the coil material adopted in the prior art is solid or has a rectangular bore can be solved, and the method has the advantages of material conservation, long service life and the like.

Owner:徐宗保

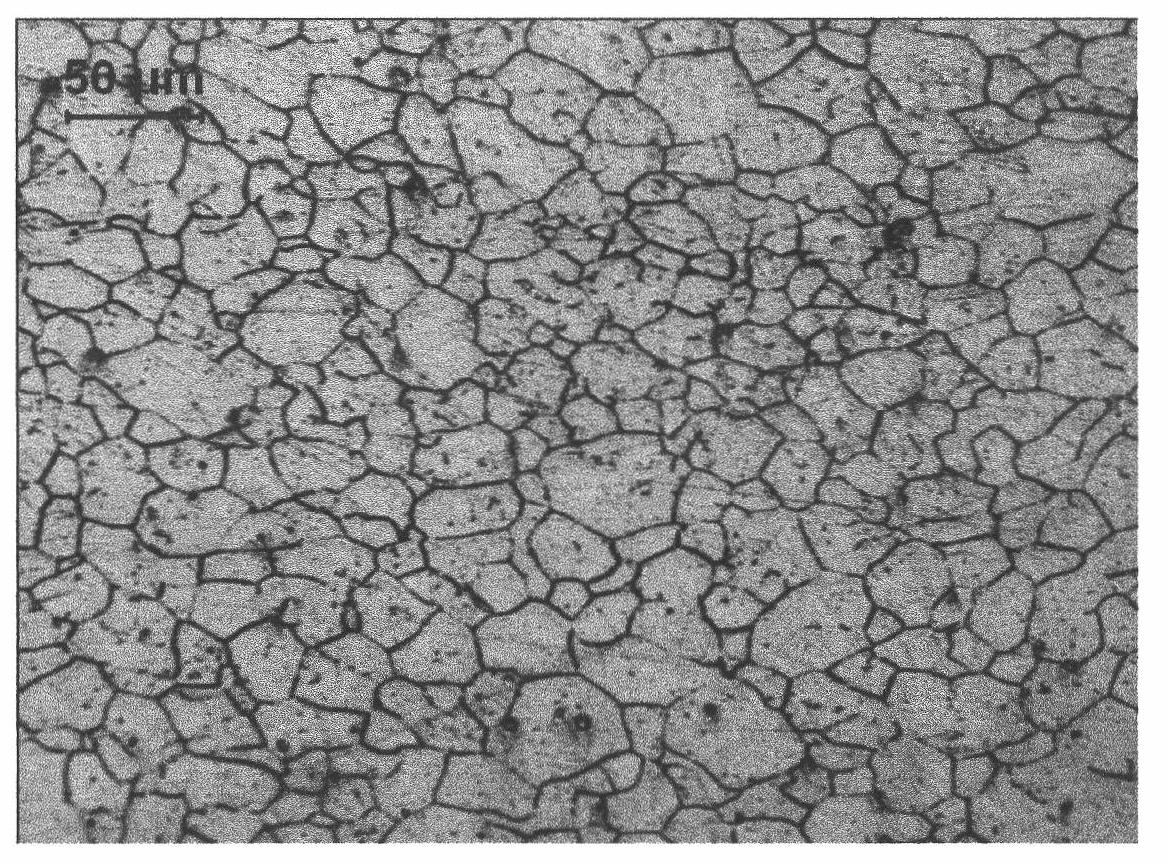

Preparation technology of FeCrAl pipe material for nuclear fuel element

InactiveCN108165717AHigh dimensional accuracySmooth inner and outer surfacesMaterials preparationNuclear power

The invention relates to a preparation method of a FeCrAl pipe material for a nuclear fuel element, and belongs to the technical field of nuclear power pipe material preparation. The preparation method comprises the technological processes that alloy ingot is obtained through smelting, the alloy ingot is forged into bars and then machined to obtain a pipe blank, and the alloy pipe material is prepared by adopting a finish rolling technology. The preparation method is characterized in that cold rolling total deformation is controlled within the range of 10% to 50%, the cold rolling feeding amount is controlled within the range of 0.5 to 2, the rolling pass is controlled within the range of 3 to 15, the rotation speed is controlled within the range of 15 r / min to 60 r / min, the annealing temperature ranges from 700 DEG C to 1,100 DEG C, and heat preservation is conducted for 20-60 min. The method has the characteristics of being simple in technology, high in production flexibility and lowin cost.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +3

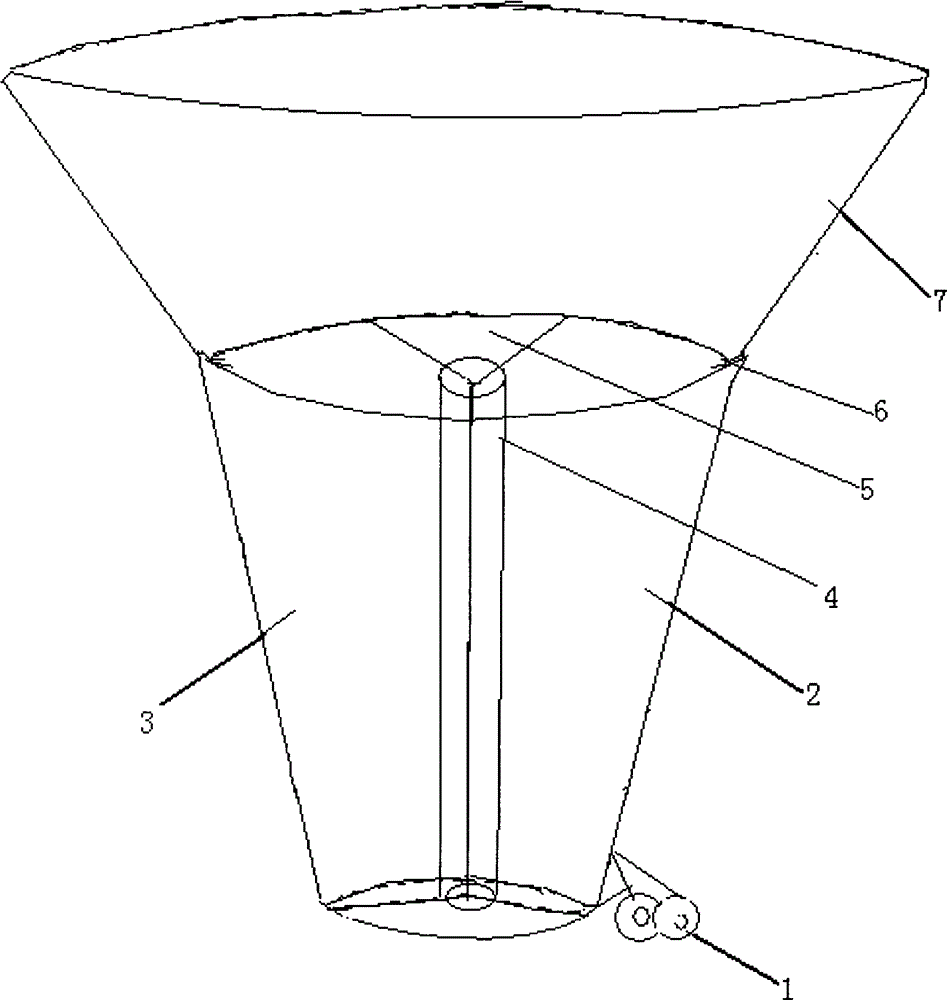

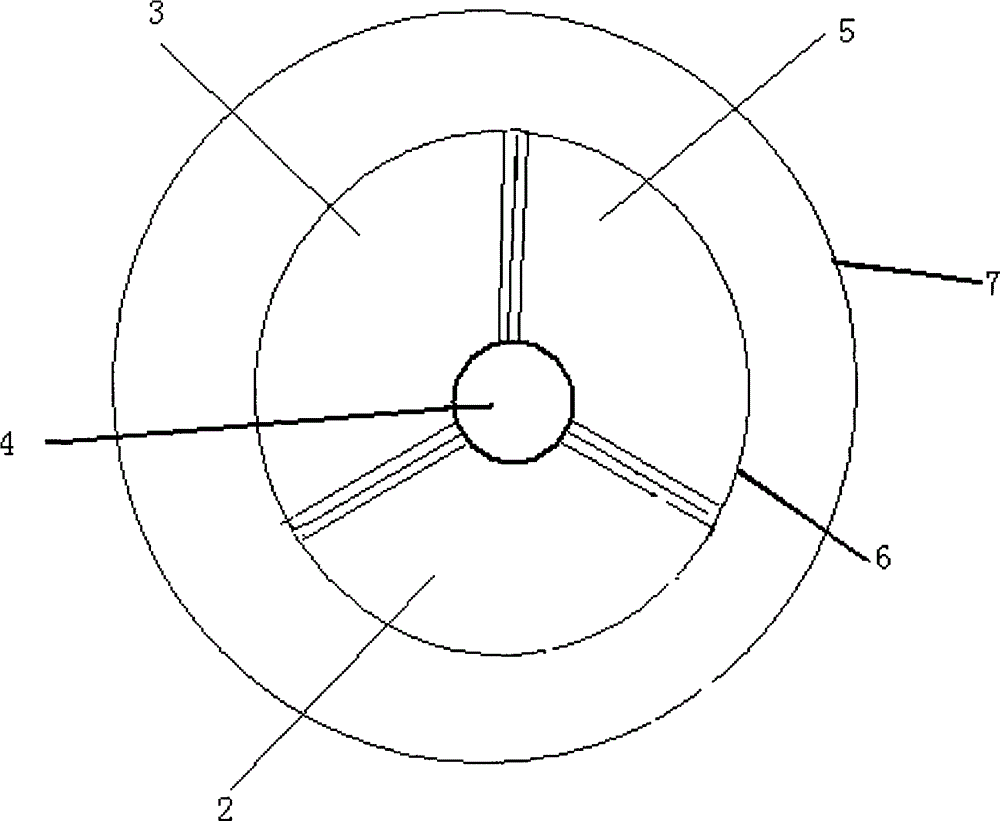

Funnel type detachable classification trash can

InactiveCN104029954AIncrease the receiving areaCan't throw wrongWaste collection and transferRefuse receptaclesLitterEngineering

A funnel type detachable classification trash can comprises a funnel, wherein the funnel is connected with a funnel bottom, the funnel bottom is connected with a recyclable bin, a unrecyclable bin and a poisonous and harmful bin, strong magnetic iron columns are installed at the centers of the recyclable bin, the unrecyclable bin and the poisonous and harmful bin, and double rear wheels are installed at the bottom of the recyclable bin. The open funnel can greatly increased the receiving area of the trash can and enables the recovery efficiency to be greatly improved, and burden of cleaners is relieved. The trash can is divided into the recyclable bin, the unrecyclable bin and the poisonous and harmful bin, so that people naturally put articles belonging to the type of used batteries into the poisonous and harmful bin. The trash can is provided with double rear wheel for load, can step over stairs or roadside steps, the inner and outer surfaces are smooth, and complete garbage pouring and cleaning are facilitated. The funnel type detachable classification trash can meets the ergonomics and is light, durable and flexible to move. In addition, three separated bins are attracted through strong magnetic columns, so that the separation is simple and convenient, and the bins can be dismounted in a separated mode.

Owner:周帆

FeCrAl alloy tube material for light water reactor cladding and rolling method thereof

InactiveCN110918649ABest plastic elongation stateMeet subsequent rolling needsFurnace typesMetal rolling arrangementsAlloyUltimate tensile strength

A FeCrAl alloy tube material for light water reactor cladding and a rolling method thereof are disclosed. The alloy tube material includes the following components: 78.5% of Fe, 12% of Cr, and 5.2% ofAl. The rolling method includes the following steps: annealing a FeCrAl alloy tube at a temperature of 1150 degrees centigrade, thermally insulating the FeCrAl alloy tube for 60 min, and water-cooling the FeCrAl alloy tube; removing scales on the inner and outer surfaces of the tube, chamfering a tube port, and coating the surface with lubricating oil; selecting three rollers and polishing and derusting the surface of a mandril; setting rolling parameters, installing the rollers, the mandril, a mandrel and applying lubricating oil, and finally feeding the material; firstly slowly starting a rolling mill until the rollers completely roll the tube, at the end of the first pass, rolling the tube again based on the sequence of the above steps. The rolled alloy tube of the invention has an elongation of 20.1%, a tensile strength of 675 MPa, a yield strength of 560 MPa, a hardness of 261 HV, is improved in plasticity and significantly improveed in workability, and can meet the requirementsof subsequent rolling of the tube.

Owner:宁夏北鼎新材料产业技术有限公司

Corner terminal of storage battery

InactiveCN105047850ACompact structureDifferent technical effectsContact member manufacturingSmall-sized cells cases/jacketsStructure analysisAlloy

The invention provides a corner terminal of a storage battery. The corner terminal of the storage battery is manufactured by the steps of melting a lead alloy and forming a blank through pouring, performing cold-press extrusion forming on the poured blank through an extrusion mold, and then further forming the blank by trimming extruded burrs; the pressure of the extrusion mold is 63T-100T. According to the cold-pressed corner terminal, the poured blank is only extruded and formed in a cold pressed mode by use of the extrusion mold; although the pattern of change is simple, the resulting technical effect is completely different, and the obtained part is compact in structure, free of bubbles at the internal section and smooth in internal and external surfaces; due to the extrusion mold pressure of 63T-100T, the yield of the extruded blanks can be 100%. Compactness inspection, a thermal drying-resistant test, an immersion test and metallurgical structure analysis all prove that the compactness of the cold-pressed terminal is better than that of a pressure-cast terminal; as a result, a good acid leakage prevention effect can be achieved.

Owner:十堰奕朗工贸有限公司

Online biaxial-orienting PVC extrusion molding mould

ActiveCN101670665BGuaranteed smooth expansionTimely setting and coolingUltimate tensile strengthPolymer chemistry

The invention relates to an online biaxial-orienting PVC extrusion molding mould comprising a skelp molding area, an expansion transition area and an annular expansion and molding area and also provided with an expansion mold core. A heating pressure channel is arranged in the skelp molding area. The section ratio between an expanded pipe material and a skelp is 1 :( 1.10-1.30). An expansion pressure balancing device is arranged in the expansion transition area. An expansion angle of the expansion transition area is 30-60 degrees. Annular expansion ratio of the annular expansion and molding area is greater than or equal to 1:2. The mould has a compression ratio of 1 :( 6-12). A straight section of the skelp molding area is 5-12 times as long as the diameter of the skelp. The mould has theadvantages that an online biaxial-oriented modified pressure-bearing pipe material with good strength and tenacity and smooth and flat surface can be produced, and the mould saves material and energyand can implement industrialization.

Owner:浙江驰讯管业有限公司

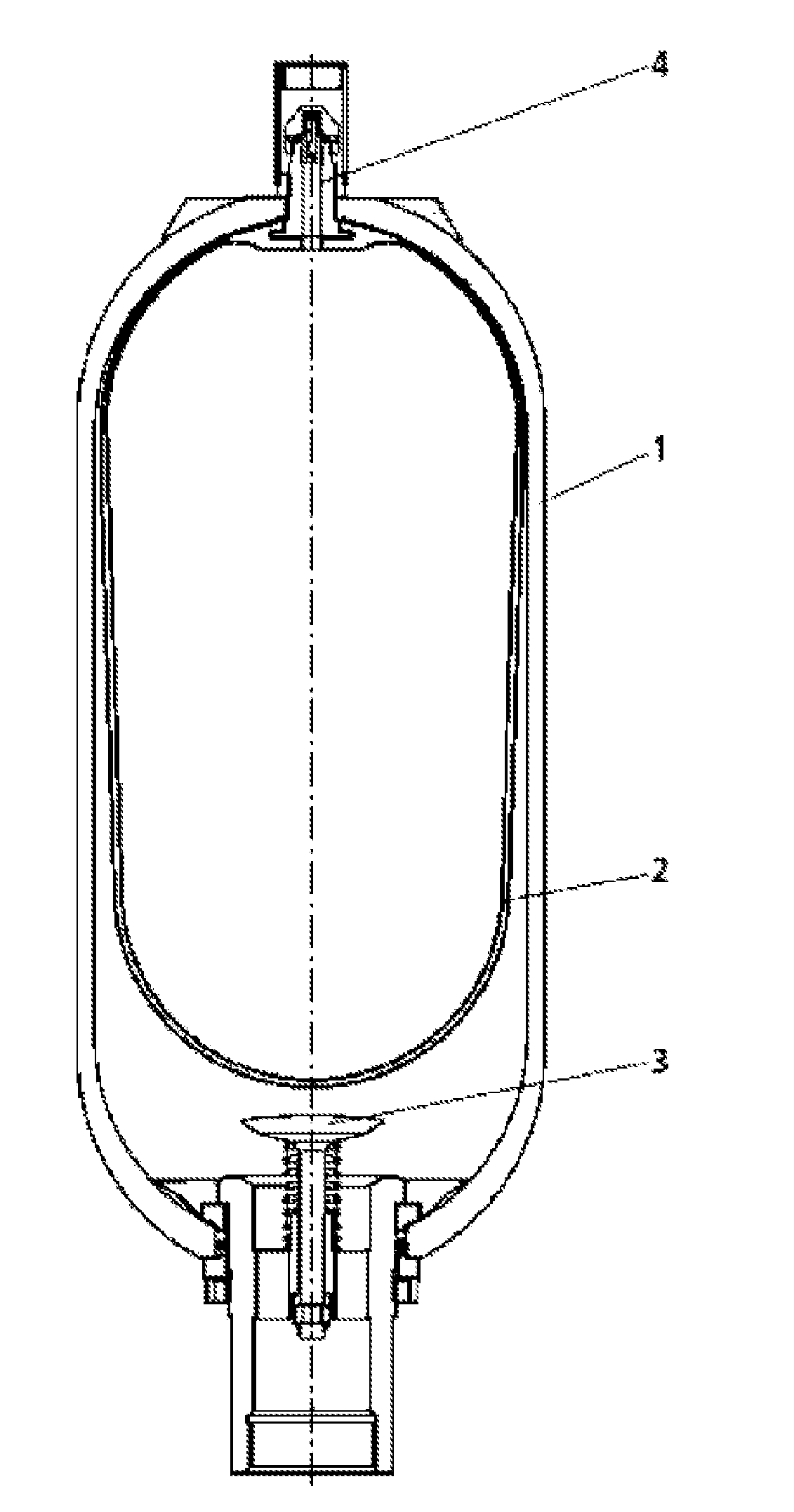

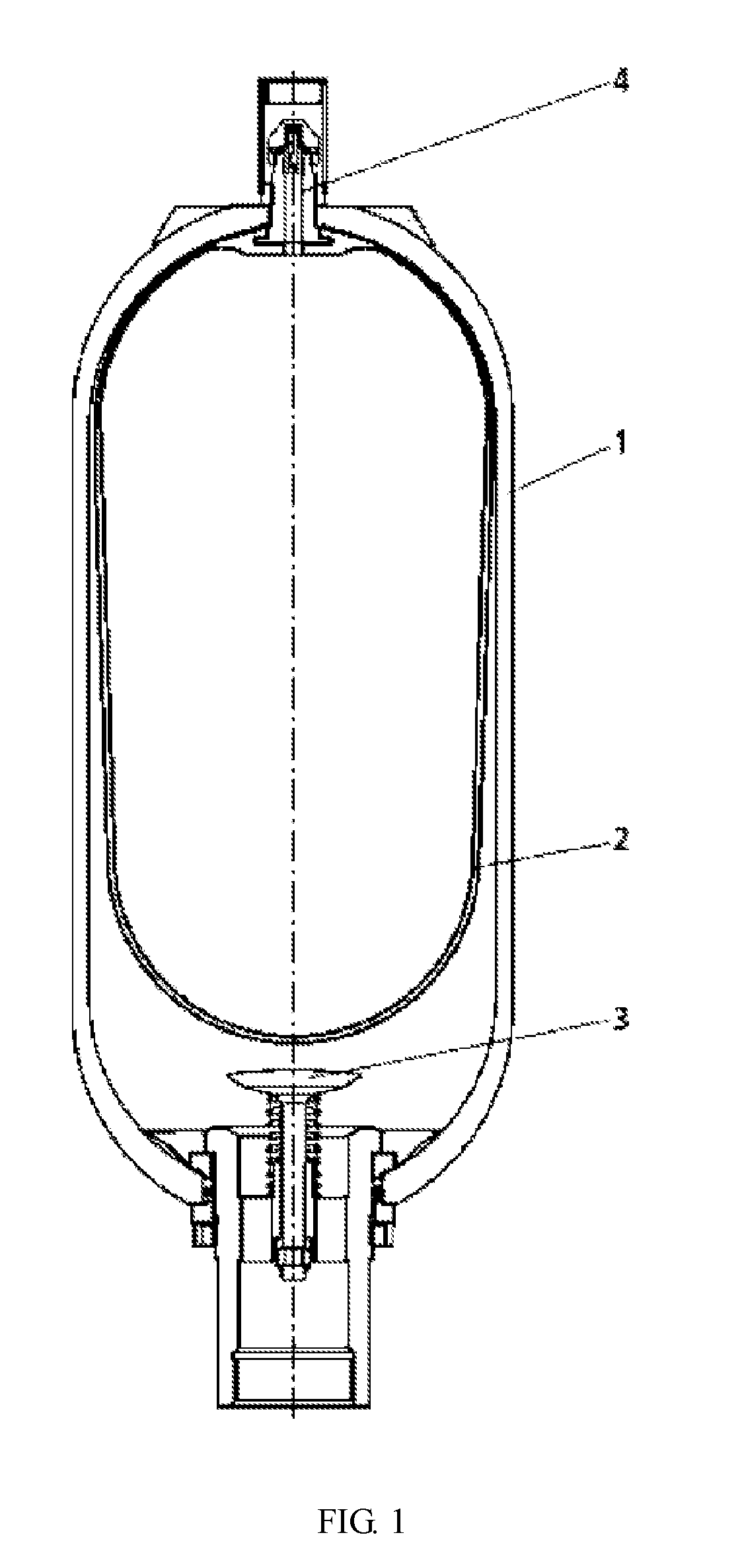

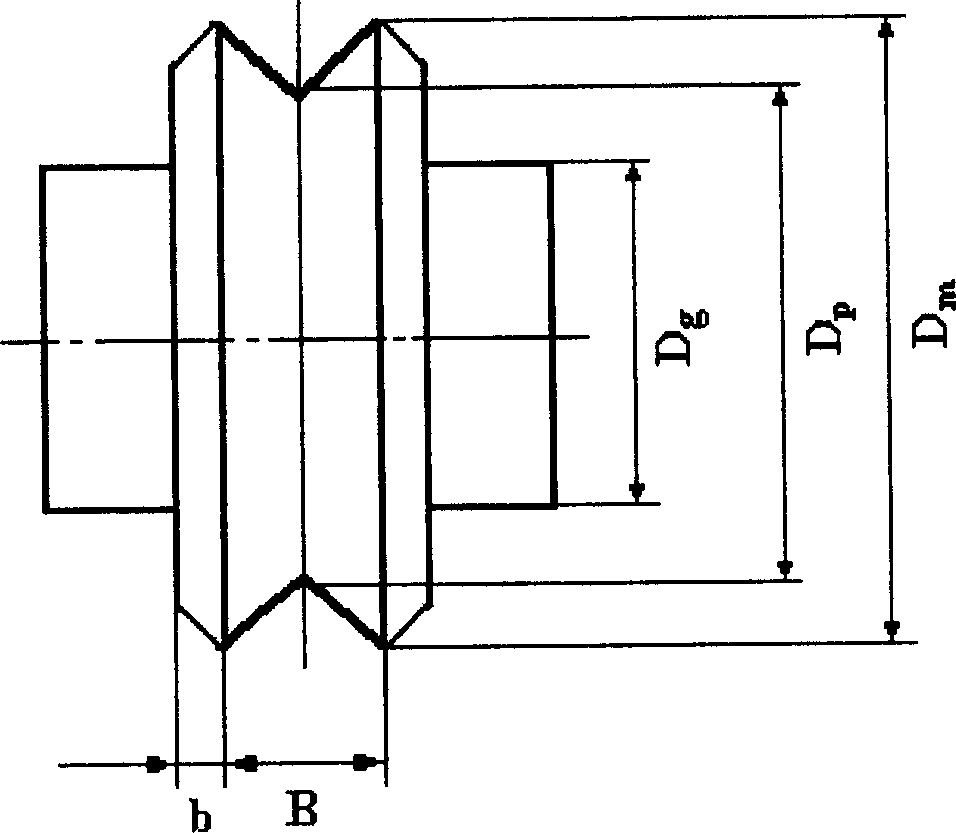

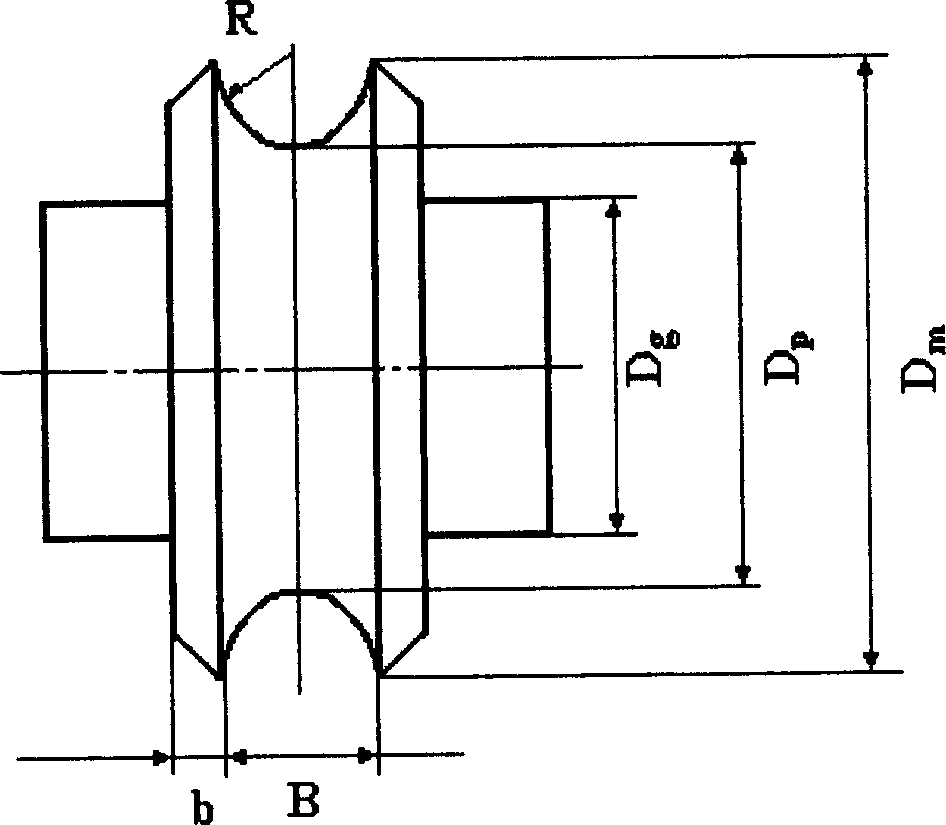

Method for manufacturing integrated hydraulic accumulator bladder

ActiveUS20180290392A1Simple processOvercomes shortcomingActuator accumulatorsHollow articlesVulcanizationRoom temperature

A method for manufacturing a hydraulic accumulator bladder includes the following steps: bonding a rubber sheet to the gas-filled air bladder to form a bladder blank; placing the bladder blank in a vulcanization device for vulcanization to form an initial bladder product; and releasing the gas in the gas-filled air bladder of the initial bladder product, taking the air bladder out, and naturally cooling the initial bladder product to a room temperature to form a finished bladder product. The bladder manufactured by the manufacturing method is integrally formed by one-step vulcanization, and has the advantages of uniform wall thickness, smooth inner and outer surfaces, long fatigue lifetime, a simplified process, high quality and good stability.

Owner:SHIJIAZHUANG SIMKER TECH CO LTD

Hot-rolling perforation-cold-rolling forming method for hollow rock-drill steel

The invention provides a hot-rolled perforation-cold-rolled forming method of hollow drill steel. It is characterized in that: the hot-rolled piercing-cold-rolled forming method is used to produce B and D-type hollow drill steels, and the hot-rolled piercing Φ50 two-roll cross-rolling piercing machine rolls the round solid tube blank of Φ50~Φ65mm in a hot state. Φ50~Φ65mm, hollow capillary tube with wall thickness of 6~17mm, after cooling, it is rolled and formed on a cold rolling mill. The invention starts from the geometric characteristics of the hollow steel and realizes a specific deformation process through tool design. Compared with the existing production method, the main advantages of the present invention are: few working procedures, short flow process, good quality of inner hole, high precision of shape and size.

Owner:UNIV OF SCI & TECH BEIJING +1

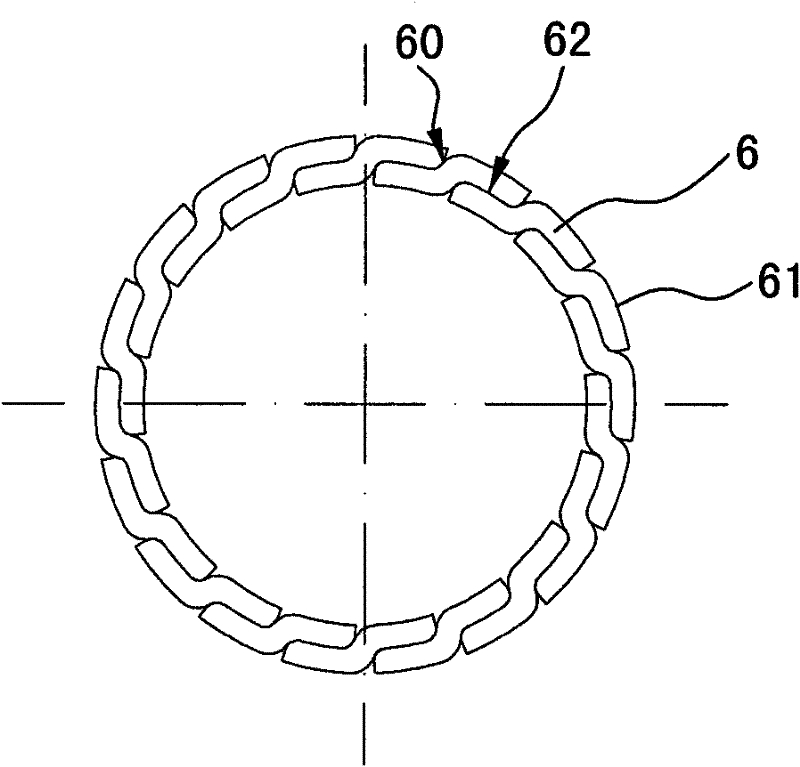

Special-shaped wire sheath for optical fiber unit in special optical cable

InactiveCN102162887AImprove anti-corrosion performanceSmooth inside and outsideFibre mechanical structuresMetallic materialsLap joint

The invention relates to a special-shaped wire sheath for an optical fiber unit in a special optical cable. The special-shaped wire sheath comprises special-shaped wires made of a metal material and a circular sheath formed by arranging the special-shaped wires. The special-shaped wire sheath is characterized in that: the special-shaped wires are metal sheets; and overlapped parts between front metal sheets and rear metal sheets are in lap joint mutually to form a horizontal tubular section and are spirally twisted. Certain parts of all the metal sheets are arranged in an overlapped way, the gaps between the sheets are small, and the lateral pressure resistance is high. Compared with a twisting layer sheath which is formed by arranging circular steel wires (metal single wires), the special-shaped wire sheath has small gaps, a compact structure and a small diameter under the condition of the same effective cross-sectional areas, so that the whole forming optical cable has small diameter and light weight, and the cost of production, transportation, construction and maintenance is saved. Particularly, the special-shaped wires are the sheets, certain parts of the sheets are arranged in a mutually overlapped way, and the sheets have thin walls, so that the special-shaped wire sheath has high pressure and tensile deformation resistance and low impacts of lateral pressure on the optical fiber when the optical fiber unit is bent.

Owner:章君旭 +1

A kind of processing method of magnesium alloy thin-walled tube for degradable absorption stent

The invention belongs to the technical field of biomaterials, and discloses a machining method for a magnesium alloy thin-walled pipe for a degradable and absorbable support. The technological processof the method comprises the steps of smelting, casting, extruding, extruding punching, boring and cleaning of the inner surface and the outer surface, annealing, drawing, repeated conduction of annealing and drawing and obtaining of finished products. In the whole repeated drawing process, the reducing deformation amount of the pipe needs to be controlled during each pass, and the matching relation between the reducing deformation amount and the wall reduction deformation amount is well adjusted at the same time. The pipe obtained through the process is high in precise, the inner surface andthe outer surface are smooth and clean, the mechanical performance is excellent, and the whole process is simple, good in controllability and high in economic benefits.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

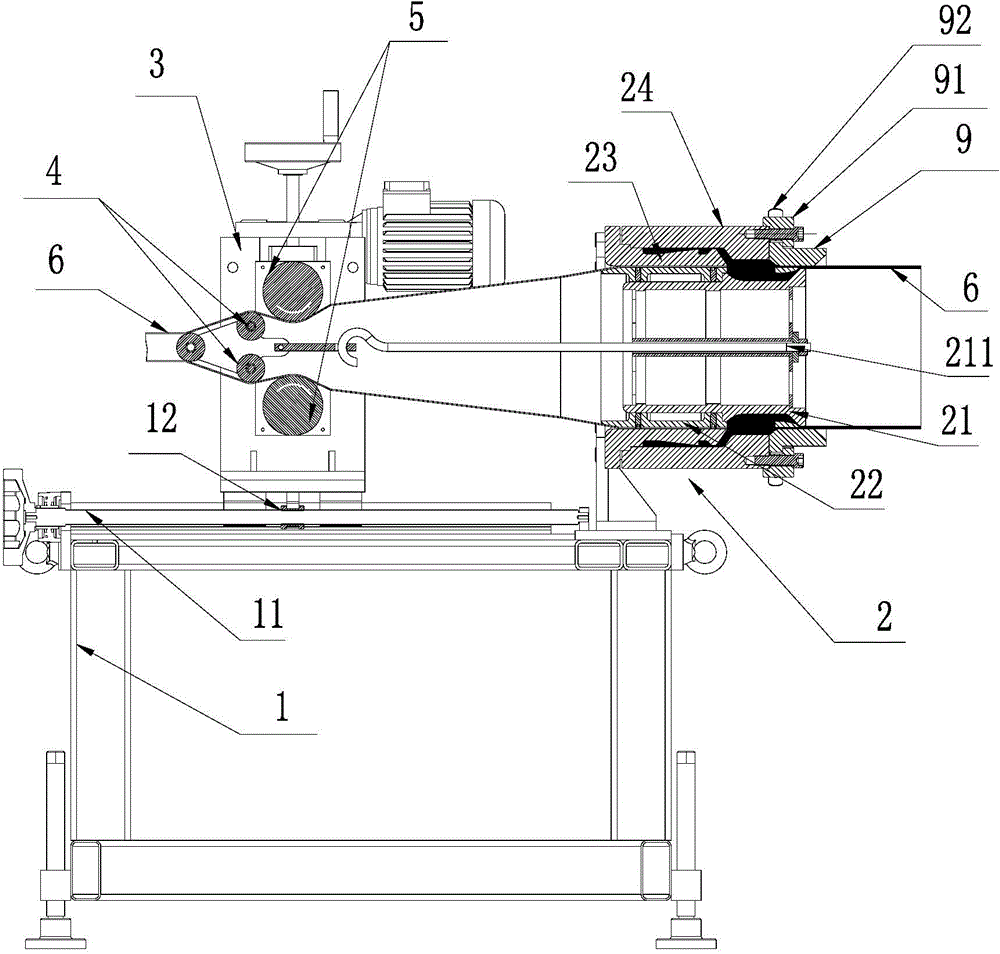

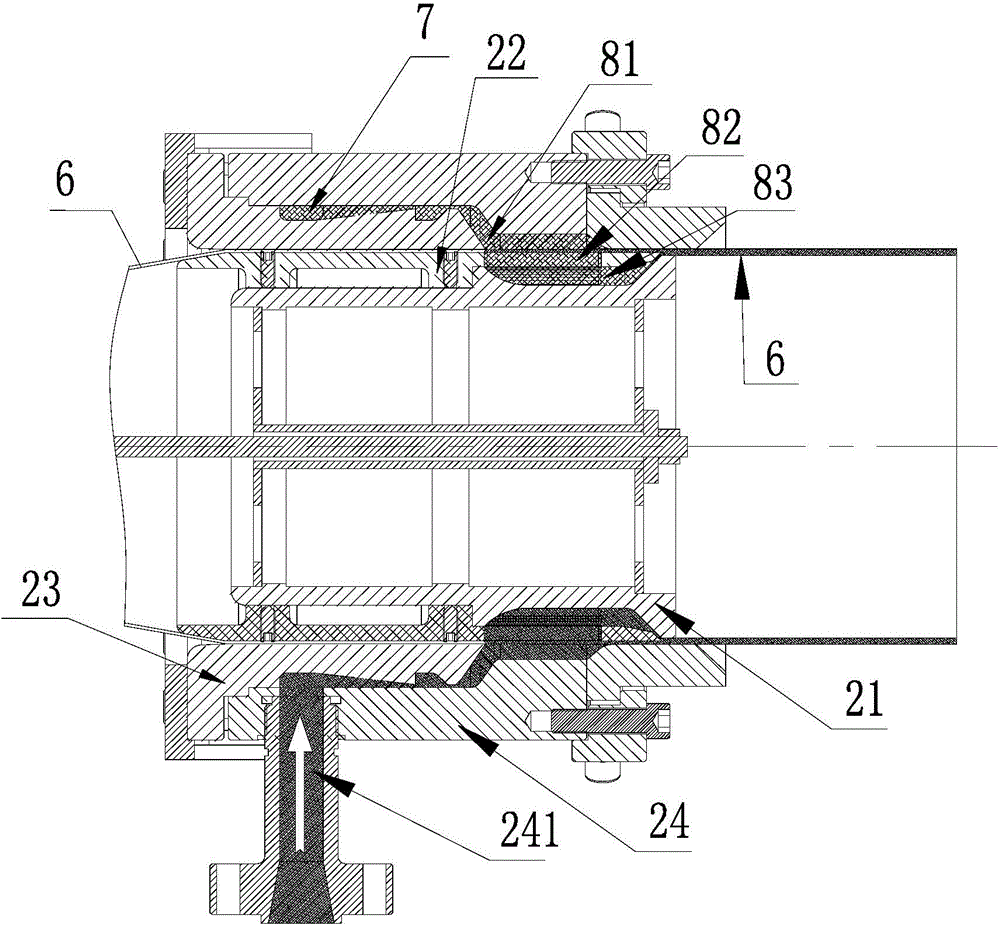

Cladding device used for multilayer composite braided fiber ringlike bands

ActiveCN105172004AContinuous and uniform dense coatingSmooth inner and outer surfacesCoatingsFiberEngineering

The invention discloses a cladding device used for multilayer composite braided fiber ringlike bands. The device comprises a rack, a cladding die, a tensioning and hauling bracket, torpedo-head spreaders and a pair of hauling and conveying rollers, wherein the cladding die is fixed to the rack, the tensioning and hauling bracket faces directly the cladding die and is slidably arranged on the rack; the torpedo-head spreaders are arranged on the tensioning and hauling bracket and separate the multilayer composite braided fiber ringlike bands; hauling and conveying rollers are connected to the tensioning and hauling bracket through shafts and drive the separated multilayer composite braided fiber ringlike bands to penetrate through the cladding die. By means of the device, the multilayer composite braided fiber ringlike bands are evenly coated with polyurethane internally and externally through the die, and a high pressure resistant polyurethane water band pipe which is smooth and flat in internal surface and external surface is produced out.

Owner:GPM MACHINERY SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com